Defoaming agent for products having caramel color, and preparation method and application of defoaming agent for products having caramel color

A defoamer, caramel color technology, applied in chemical instruments and methods, foam dispersion/prevention, azo dyes, etc. problem, to achieve the effect of good defoaming effect and small amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

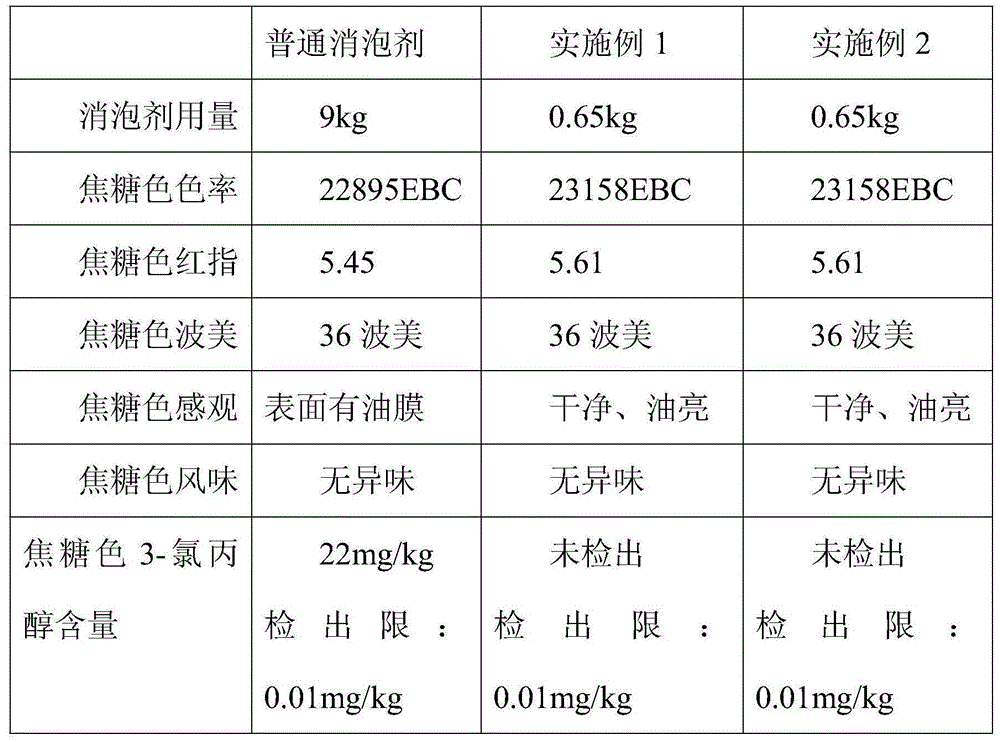

Examples

Embodiment 1

[0025] Take the preparation of 100kg caramel color special defoamer as an example:

[0026] First weigh about 50kg of deionized water and add it to the reactor, and raise the temperature to 80°C; then accurately weigh 9kg of polyoxysilane, 2kg of aluminum stearate, and 2kg of sodium tripolyphosphate into the reactor respectively, and continue Raise the temperature and keep the material temperature at 95°C and stir for 30 minutes; then add 1kg of carboxymethyl cellulose, 1.5kg of disodium EDTA, and 12kg of Tween 60 in sequence, and continue stirring at a constant temperature of 95°C for 60 minutes; make up the remaining deionized water to 100kg, continue stirring for 20 minutes and then cool to room temperature to obtain the required defoamer.

Embodiment 2

[0028] Take the preparation of 100kg caramel color special defoamer as an example:

[0029] First weigh about 50kg of deionized water and add it to the reactor, and raise the temperature to 80°C; then accurately weigh 9kg of polyoxysilane, 2kg of aluminum stearate, and 2kg of sodium tripolyphosphate into the reactor respectively, and continue Raise the temperature and keep the material temperature at 90°C and stir for 30 minutes; then add 1kg of carboxymethylcellulose, 1.5kg of disodium EDTA, and 12kg of Tween 60 in sequence, and continue stirring at a constant temperature of 90°C for 60 minutes; make up the remaining deionized water to 100kg, continue stirring for 20 minutes and then cool to room temperature to obtain the required defoamer.

Embodiment 3

[0031] In the caramel color production process of normal pressure reaction, 0.005% of the defoamer (based on raw material dry basis) is pre-added in the raw materials, and when the material is heated to 90°C, 0.01% of the defoamer (based on raw material) is added again. on a dry basis).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com