Method for measurement of flow-field direction and intensity in crystallizer and flow-field intensity indicator

A strength indication and crystallizer technology, applied in measuring devices, instruments, fluid dynamics tests, etc., can solve the problems that the internal and surface quality of the slab is greatly affected, and there is no effective monitoring method for the flow field in the crystallizer, etc., to achieve The effect of improving internal and external quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention are described in one step:

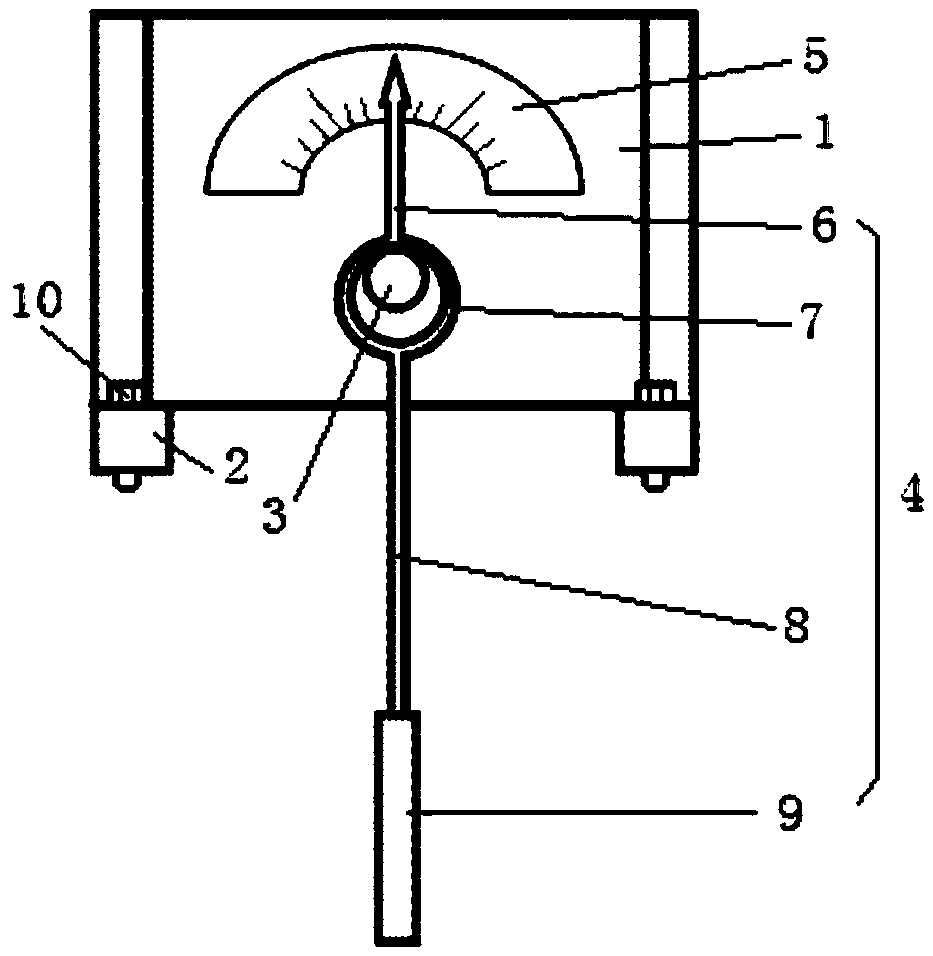

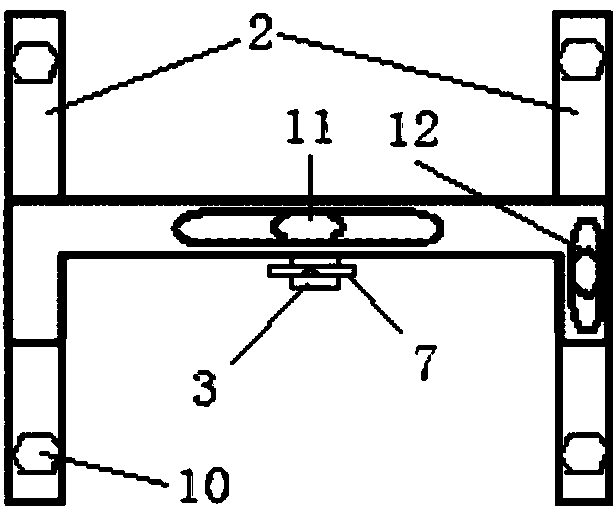

[0021] See figure 1 , figure 2 , is the structural schematic diagram of the embodiment of the flow field intensity indicator of the present invention, including a hanger 1, a horizontal foot 2, a hook 3 and a flow measuring plate 4. The bottom of the hanger 1 is symmetrically provided with a horizontal foot 2, and the hanger 1 A hook 3 and a dial 5 are arranged on the upper, and the flow measuring plate 4 is hung on the hook 3. The flow measuring plate 4 is an integrated structure composed of a pointer 6, a hanging ring 7, a connecting rod 8 and a float 9. A leveling screw 10 is provided at each end of the leveling foot 2 . The hanger 1 is provided with a horizontal horizontal bubble 11 and a vertical horizontal bubble 12 respectively. Before the test, the leveling screw 10 needs to be adjusted so that both the horizontal horizontal bubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com