Stone bush-hammered surface hammering machine

A lychee noodle and trigger technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of uneven unevenness, low efficiency, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

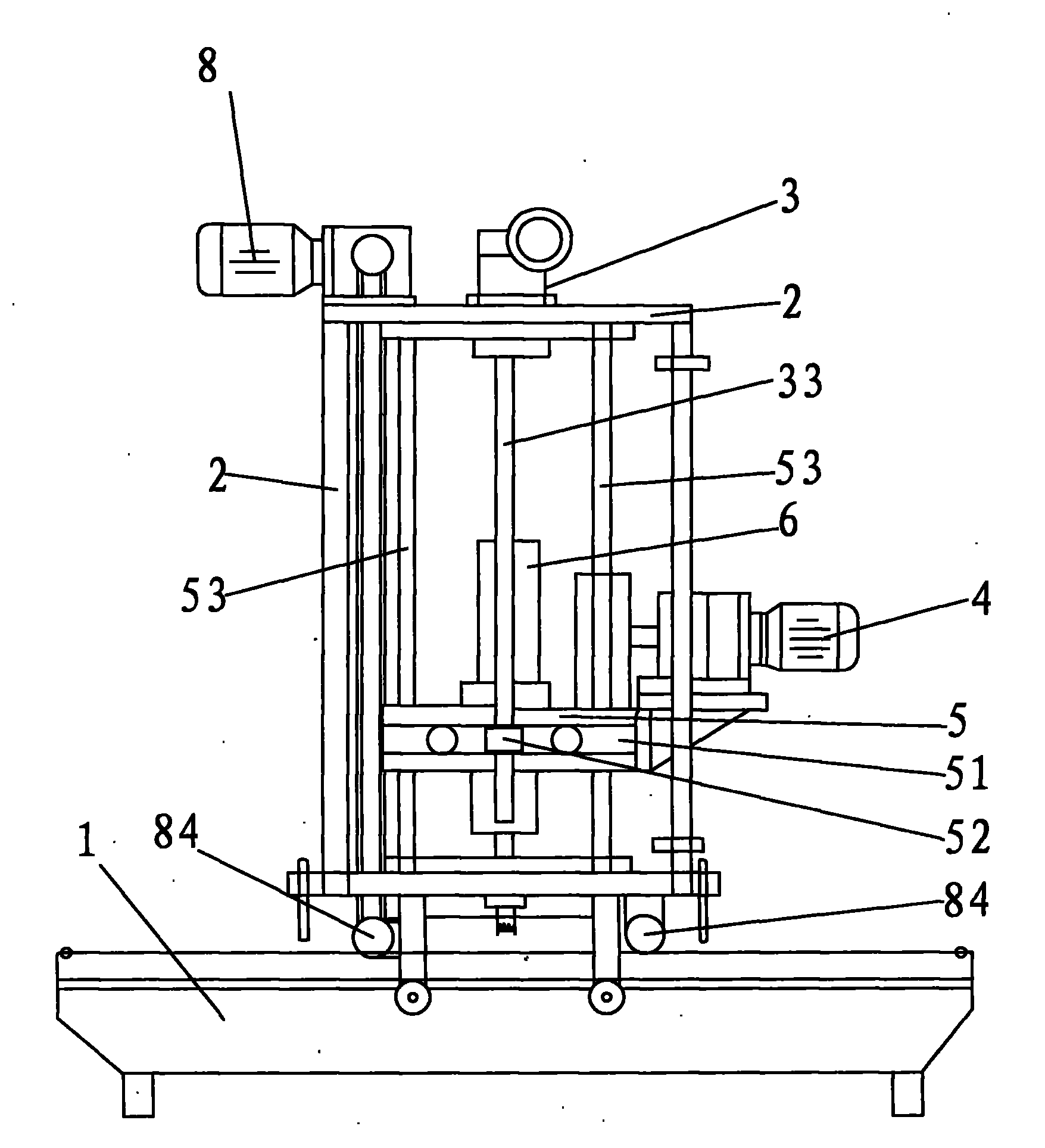

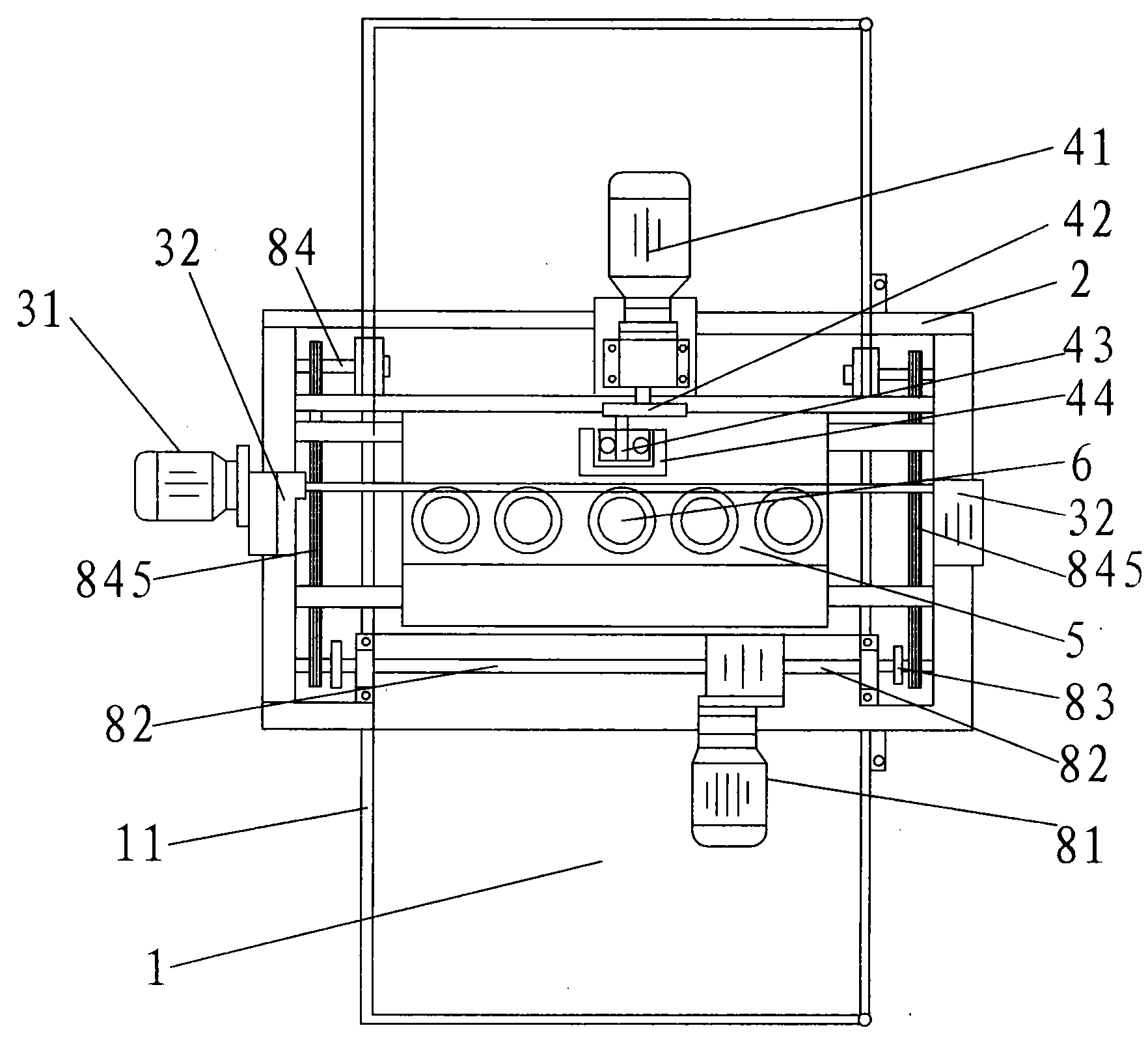

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a stone lychee surface knocking machine includes a workbench 1, a frame 2 arranged on the workbench 1, a lifting assembly 3 arranged on the frame 2, and a left and right swing motor assembly arranged on the frame 2. Become 4, be located at the main board base 5 on the frame, be located at the lychee surface processing device 6 on the main board base 5, be located at the frame forward and backward moving device 8 on the frame 2.

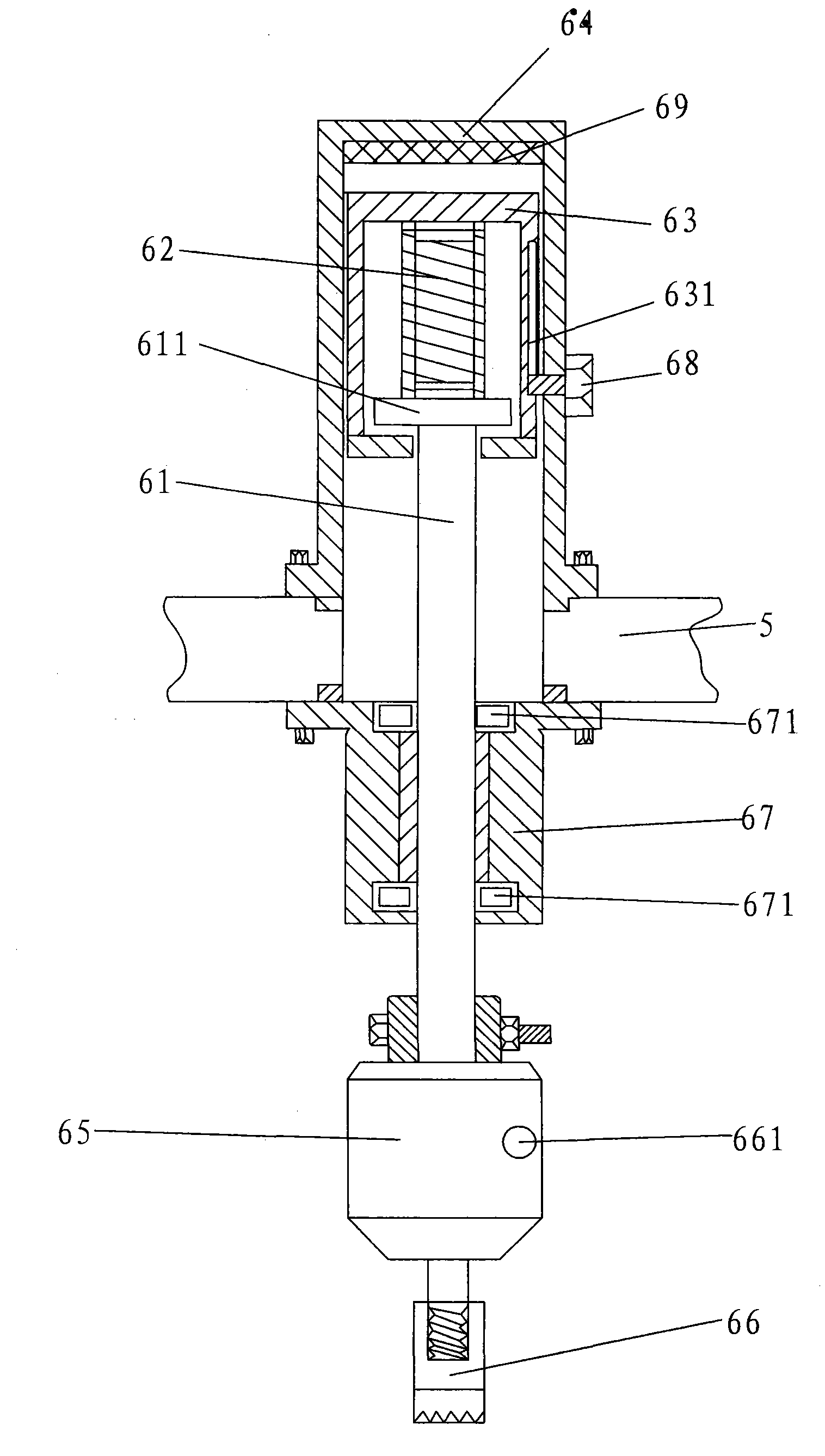

[0015] The lychee noodle processing device 6 includes a main shaft 61, a main shaft pull block 611 fixed on the upper end of the main shaft 61, a spring 62 fixed on the upper end of the main shaft pull block 611, a spring seat 63 sleeved on the spring 62, and a spring seat 63 sleeved on the spring seat 63. The spring seat sliding sleeve 64 on the top, the pneumatic hammer 65 installed at the end of the main shaft 61, the alloy grinding head 66 installed at the lower end of the pne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com