A coaxial double-head diamond boring machine and fine boring method thereof

A diamond boring machine, coaxial technology, used in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve problems such as reducing production accuracy and efficiency, scratching the inner hole of the cylinder liner, and accumulating errors. , to achieve the effect of improving accuracy, reducing labor intensity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

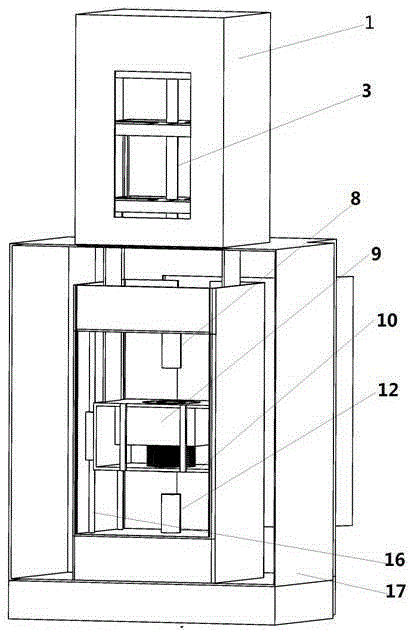

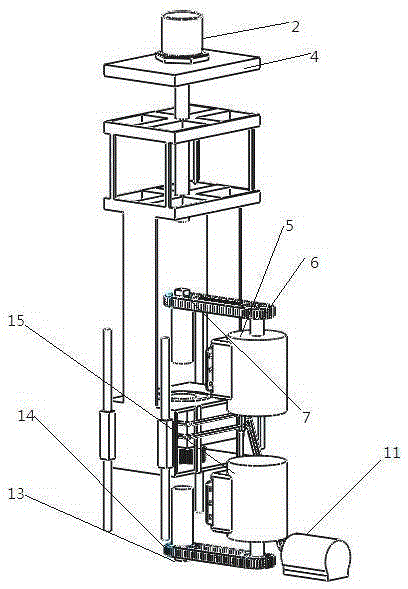

[0016] Such as figure 1 , 2 As shown, the coaxial double-head diamond boring machine includes a support frame 1, a stepping motor 2, a screw 3, a connecting frame 4, an upper AC motor 5, an upper transmission belt 6, an upper encoder 7, an upper spindle 8, a fixture 9, and a workbench 10. Hydraulic device 11, lower spindle 12, lower encoder 13, lower transmission belt 14, lower AC motor 15, guide rail 16, bed body 17; stepper motor 2 is connected to one end of lead screw 3, and the other end of lead screw 3 is connected to the connecting frame 4 connection, the connecting frame 4 is fixed with the workbench 10, the workbench 10 is connected with the guide rail 16, the guide rail 16 is fixed on the bed body 17, the upper AC motor 5 is connected with the upper spindle 8 through the upper transmission belt 6, and the upper encoder 7 is connected with the upper spindle 8 connection, the fixture 9 is connected with the hydraulic device 11, the hydraulic device 11 is fixed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com