Intersecting line cutting equipment and use method thereof

A technology of intersecting wire cutting and equipment, applied in welding/cutting auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of inability to meet high precision and quality requirements, and inability to meet welding process requirements, and achieve a wide range of applications. ,Easy to operate,Easy to operate the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

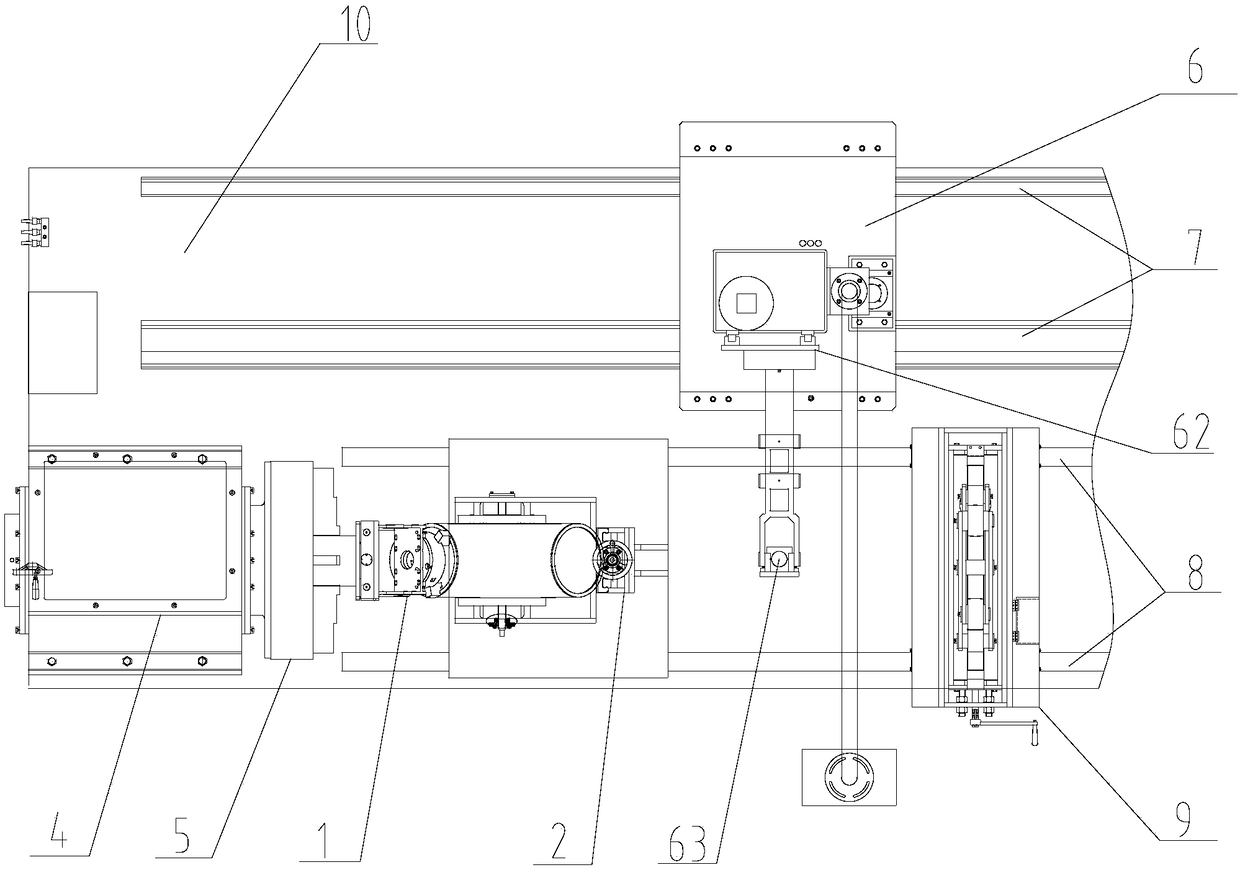

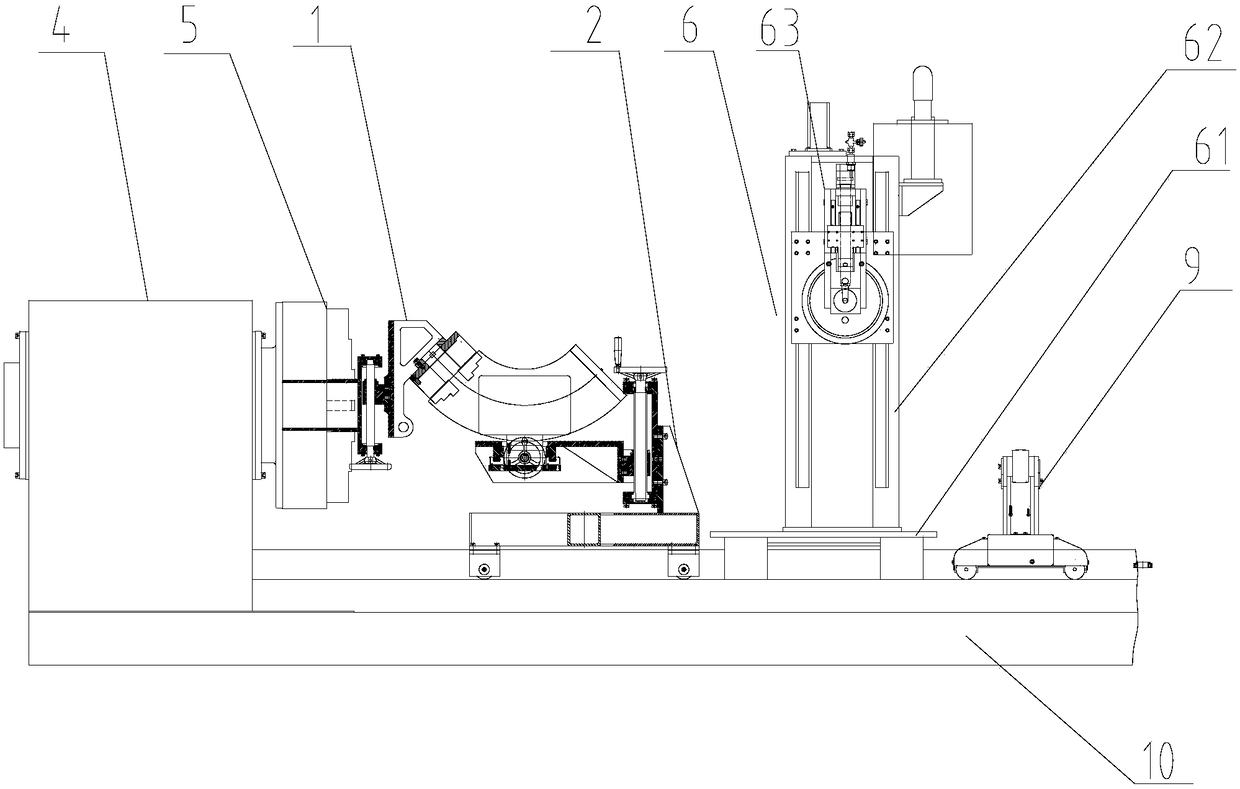

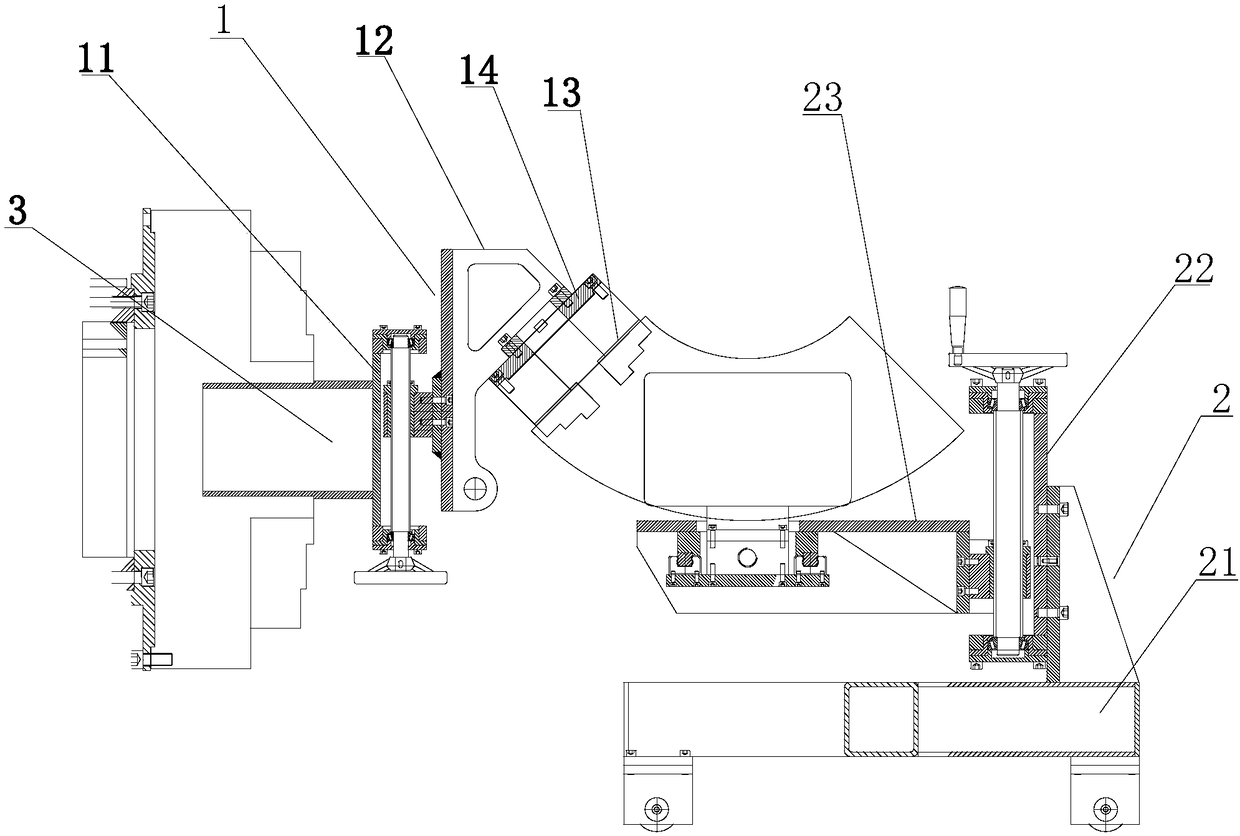

[0039] Such as Figure 1-3 As shown, a kind of intersecting wire cutting equipment includes head box 4, main chuck 5, moving torch group 6, base 10, first guide rail group 7 and second guide rail group 8, first guide rail group 7 and second rail group The guide rail group 8 is arranged on the base 10 in parallel, the second guide rail group 8 is arranged along the central axis of the main chuck 5, and the main chuck 5 is installed on the headstock 5, and the moving cutting torch group 6 includes moving on the first guide rail group 7. Traversing trolley 61, a cutting torch elevating platform 62 is installed on the traversing trolley 61, a tilting mechanism 63 is arranged on the cutting torch lifting platform 62, and a cutting torch is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com