Riveting machine for refrigerator side plate

The technology of a riveting machine and a riveting mechanism is applied in the field of riveting machines for refrigerator side panels, which can solve the problems of inability to meet the processing requirements of workpieces of different sizes, inability to realize one-time riveting riveting tasks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

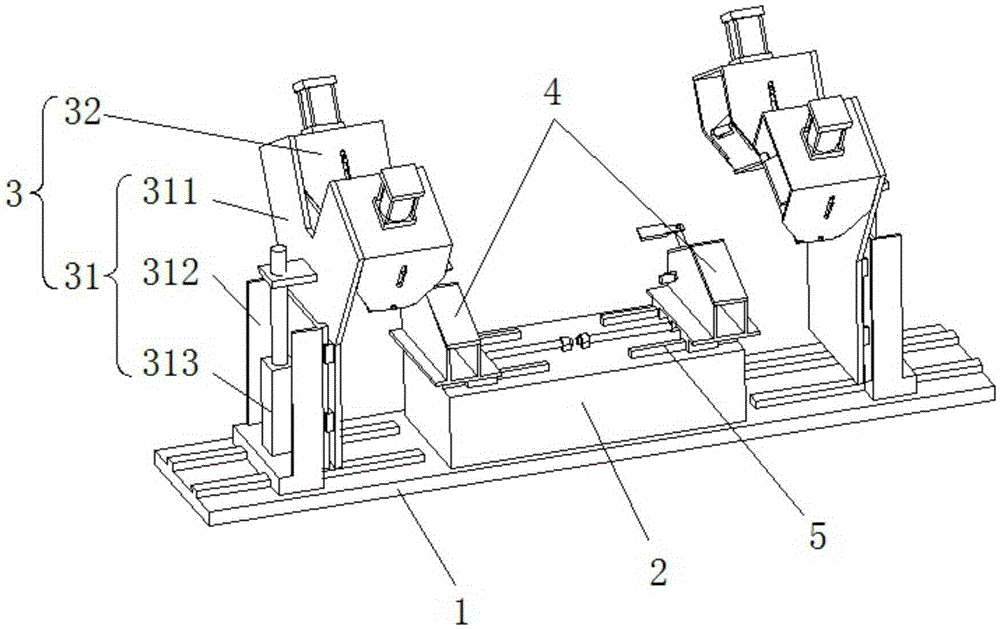

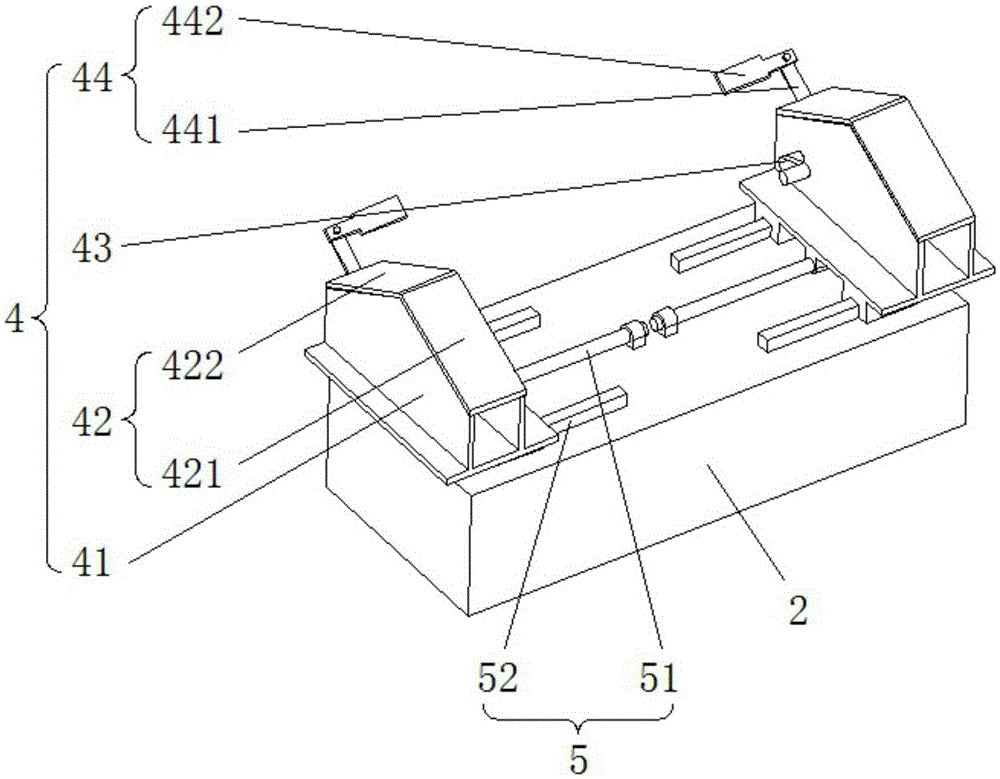

[0027] See Figure 1 to Figure 5 , the present invention includes a frame 1, a workbench 2 and a riveting mechanism 3; the workbench 2 is fixedly arranged on the frame 1; There is a positioning frame 4 for placing workpieces; the riveting mechanism 3 includes a lifting device 31 and a riveting device 32;

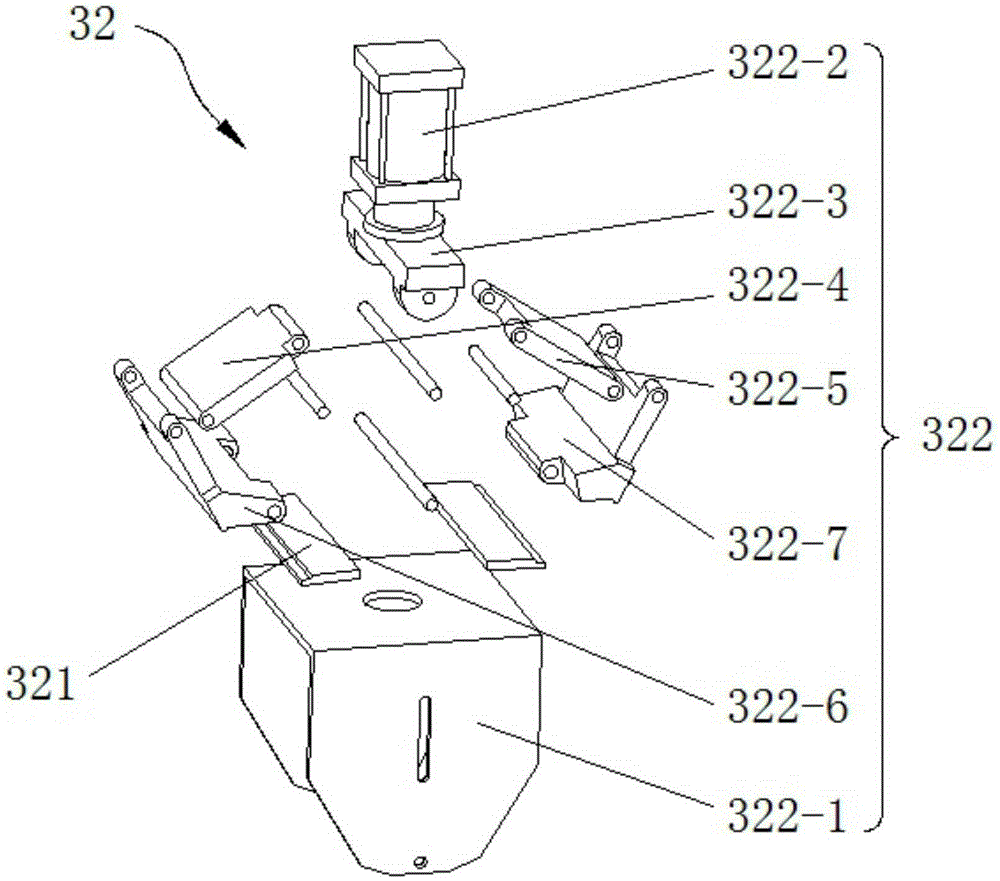

[0028] The lifting device 31 includes a lifting plate 311, a base 312 and a lifting cylinder 313; the lifting cylinder 313 is fixedly arranged on the base 312; the lifting plate 311 is dynamically arranged on the base 312; the lifting cylinder 313 The telescopic rod is fixedly connected with the lifting plate 311; the riveting device 32 is fixedly arranged on the lifting plate 311;

[0029] The riveting device 32 includes a riveting jig 321 and a closing driving assembly 322 for driving the riveting jig 321 to close; the riveting jig 321 is fixedly arranged on the closing driving assembly 322 .

[0030] The closing drive assembly 322 includes a bracket 322-1, a riveting cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com