Forming machining method for mariculture net cage pedal antiskid structure

A technology of molding processing and pedals, which is applied in the field of molding and processing of pedal anti-slip structures in marine aquaculture cages, can solve the problems of no pedal anti-slip layer forming processing methods, etc., achieve a wide range of specifications and ensure the effect of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

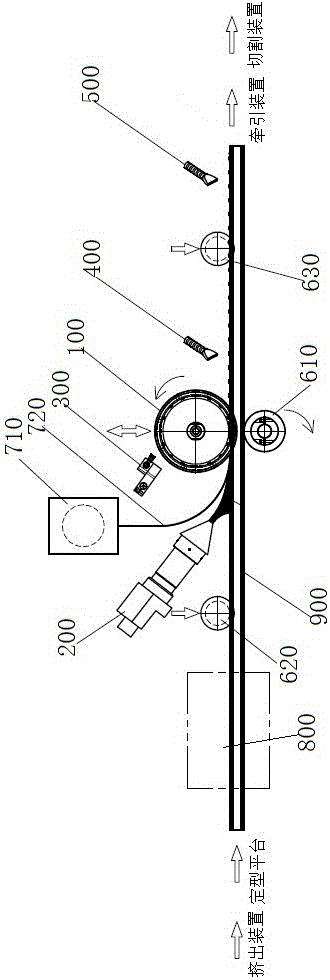

[0038] like figure 1 As shown, a method for forming an anti-skid structure of a marine aquaculture cage pedal is formed by rolling the anti-skid structure on the surface of the profile 900 to form a pedal, which specifically includes the following steps:

[0039] S1: After the extruded profile of the extrusion device is shaped by the shaping platform, it is sent to the cutting device under the traction of the traction device;

[0040] S2: Between the shaping platform and the traction device, the profile coming out of the shaping platform is preheated by the oven 800, and then the hot air blower 200 is used to locally heat one side of the profile 900, and the extrusion die head 710 of the extrusion device extrudes The film medium 720 is pasted on the surface of the profile 900;

[0041] S3: The forming roller device 100 tightly presses the surface of the profile 900 and rolls along with the profile 900. The film medium 720 is combined with the profile 900 after being rolled by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com