Sub-grid adjustable anaerobic-anoxic-aerobic biochemical reactor

An aerobic biochemical and reactor technology, which is applied in the field of wastewater treatment, can solve the problems of difficult adjustment of residence time and treatment load, single arrangement of biochemical reaction sections, and restrictions on development and application, etc., and achieves stable and efficient treatment effects, wide application, Flexible length of pool type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

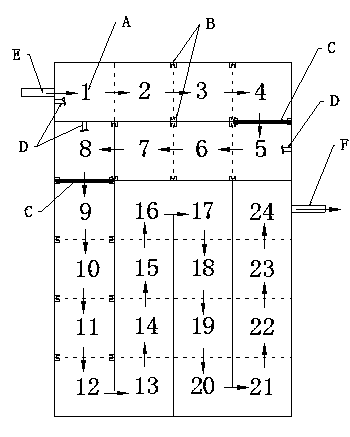

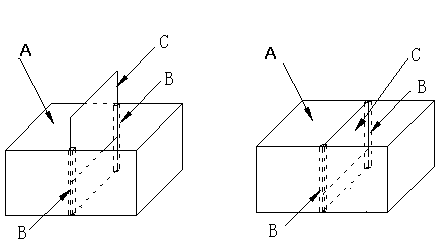

[0034] Such as Figure 1 to Figure 2 As shown, a grid-adjustable anaerobic-anoxic-aerobic biochemical reactor, the reactor is in the corridor type, including 24 grid pools (A), 24 grid pools (A) It is divided into anaerobic section, anoxic section and aerobic section, and there is a card slot (B) between each two subdivided pools from the first compartment (A) to the twelfth subdivided pool (A), The slot (B) can be inserted into the partition (C) to realize the segmentation of the anaerobic section, the anoxic section and the aerobic section. The lower part of the partition (C) is provided with a water outlet; the lower part of the reactor is provided There is an underwater propeller (D), the first compartment pool (A) is connected to the water inlet pipe E, and the 24th compartment pool (A) is connected to the water outlet pipe F.

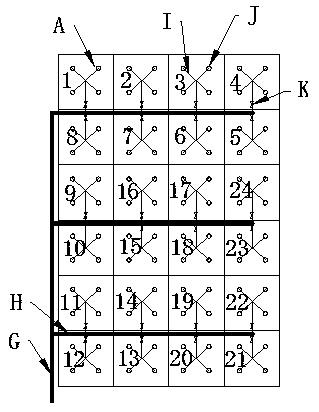

[0035] Such as image 3 As shown, the lower part of the reactor is provided with an aeration device, and the aeration device includes an aerati...

Embodiment 2

[0039] A grid-adjustable anaerobic-anoxic-aerobic biochemical reactor, the reactor is corridor-shaped, including 24 grid pools (A), and the 24 grid pools (A) are allocated as anaerobic Oxygen section, anoxic section and aerobic section, there is a card slot (B) between each of the first to 12th compartment pools, and the card slots (B) can be inserted into the separator (C) Realize the segmentation of anaerobic section, anoxic section and aerobic section, the lower part of the partition (C) is provided with a water orifice; the lower part of the reactor is provided with an underwater propeller (D), The first compartment (A) is connected to the water inlet pipe E, and the 24th compartment (A) is connected to the outlet pipe F.

[0040] Such as image 3 As shown, the lower part of the reactor is provided with an aeration device, and the aeration device includes an aeration main pipe (G), an aeration main pipe (H) connected with the aeration main pipe (G), and an aeration main p...

Embodiment 3

[0044] A grid-adjustable anaerobic-anoxic-aerobic biochemical reactor, the reactor is corridor-shaped, including 24 grid pools (A), and the 24 grid pools (A) are allocated as anaerobic Oxygen section, anoxic section and aerobic section, there is a card slot (B) between each of the first to 12th compartment pools, and the card slots (B) can be inserted into the separator (C) Realize the segmentation of anaerobic section, anoxic section and aerobic section, the lower part of the partition (C) is provided with a water orifice; the lower part of the reactor is provided with an underwater propeller (D), The first compartment (A) is connected to the water inlet pipe E, and the 24th compartment (A) is connected to the outlet pipe F.

[0045] Such as image 3 As shown, the lower part of the reactor is provided with an aeration device, and the aeration device includes an aeration main pipe (G), an aeration main pipe (H) connected with the aeration main pipe (G), and an aeration main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com