Bamboo fiber yarns and production method thereof

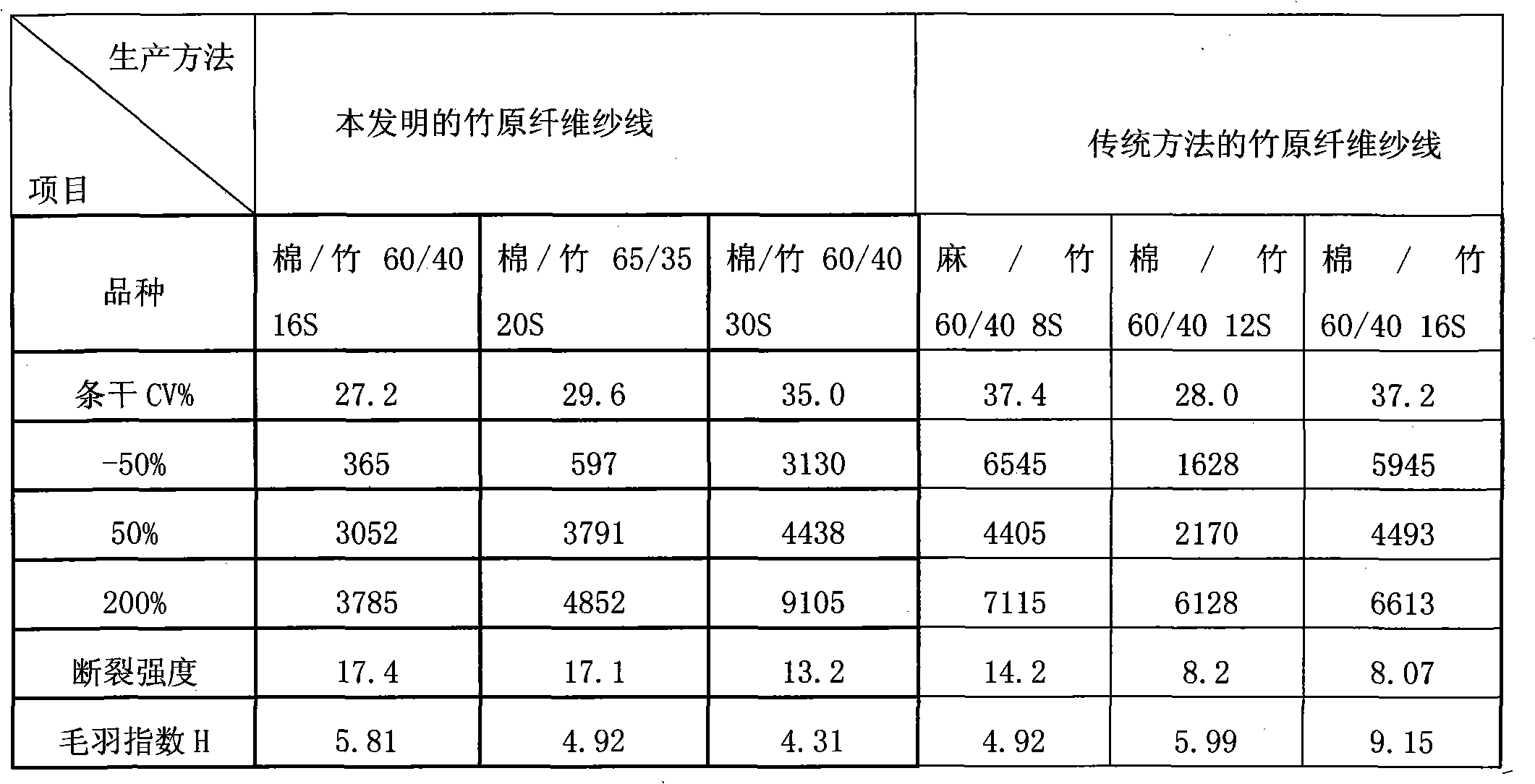

A bamboo raw fiber and production method technology, applied in fiber processing, fiber mixing, yarn and other directions, can solve the problems of difficult draft control, poor length uniformity, poor fiber cohesion, etc., and achieve bright luster and appearance quality The effect of lifting and fine yarn count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: combed cotton / bamboo fiber 80 / 20 30

[0039] 1. Raw material selection: raw bamboo fiber and fine cotton, the ratio is 20 and 80, the total is 100.

[0040] 2. Process flow: (55% bamboo fiber + 45% combed cotton sliver → cleaning → carding → combined) + (cotton → cleaning → carding → sliver winding → combing) → mixed one → mixed two →mixed three→roving→spinning→winding.

[0041] 3. Process parameters:

[0042] 3.1 Design of main process parameters of bamboo fiber + combed cotton

[0043] (1) Blowing: the pretreated bamboo fiber and combed cotton slivers are mixed and arranged according to the ratio of 55% and 45%, the lap weight is 350 g / m, the length is 25 meters, and the comprehensive beater speed is 600 rpm.

[0044] (2) Carding: Quantitative 25g / 5m, cylinder speed 310 rpm, licker-in speed 760 rpm, doffer speed 14 rpm, cover to cylinder gauge: 0.2, 0.175, 0.15, 0.15, 0.175 mm, the distance between cylinder and doffer is 0.075 mm. Spray humidificati...

Embodiment 2

[0054] Embodiment 2: tencel fiber / bamboo fiber (Tencel) 80 / 20 20

[0055] 1. Raw material selection: bamboo fiber and tencel fiber

[0056] 2. Technological process: (60% bamboo fiber + 40% tencel → cleaning → carding → paralleling) + (tencel → cleaning → carding) → mixing one → mixing two → roving → spinning → winding.

[0057] 3. Process parameters:

[0058] 3.1 (60% bamboo fiber + 40% tencel → cleaning → carding → merging) process:

[0059] (1) Cleaning: According to the mixed arrangement of 60% bamboo fiber and 40% tencel, the weight of the lap is 350 g / m, the length is 25 meters, and the comprehensive beater speed is 600 rpm.

[0060] (2) Carding: Quantitative 22.5g / 5m, cylinder speed 310 rpm, licker-in speed 760 rpm, doffer speed 14 rpm, cover to cylinder gauge 0.2, 0.175, 0.15, 0.15 , 0.175 mm, cylinder and doffer distance 0.075 mm. Spray humidification to oil, keep the moisture regain of mixed raw materials at 12-13%.

[0061] (3) Pre-merging: 6 merging, drafting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com