Patents

Literature

39results about How to "Realize the punching operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

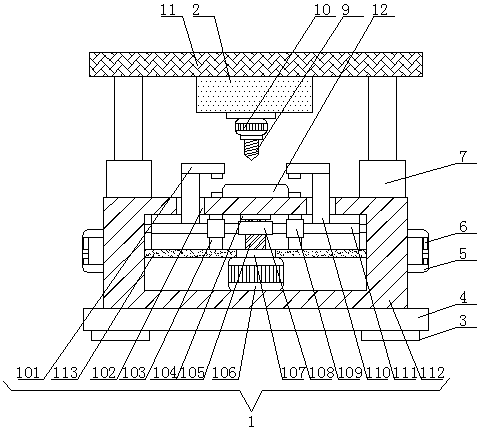

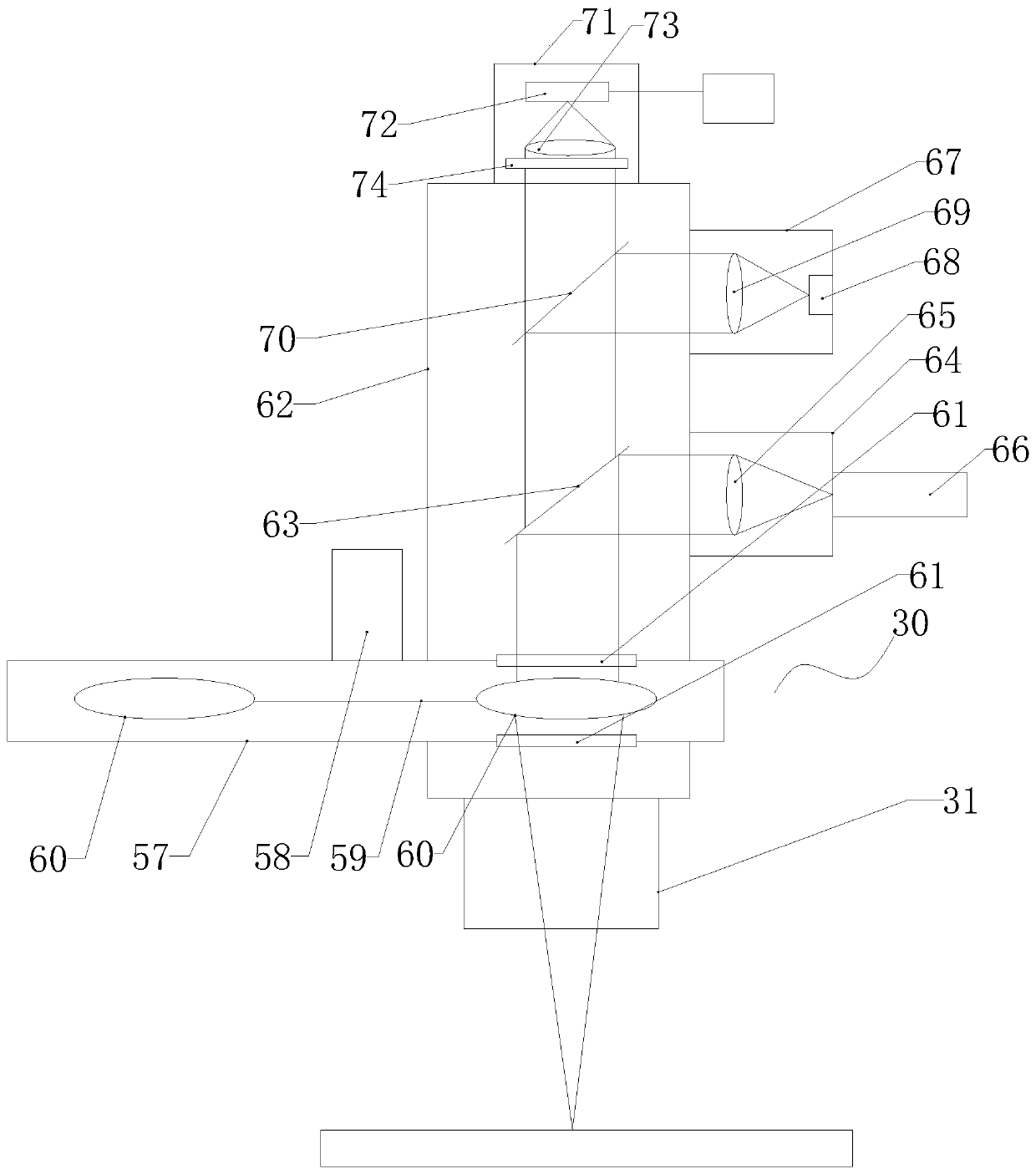

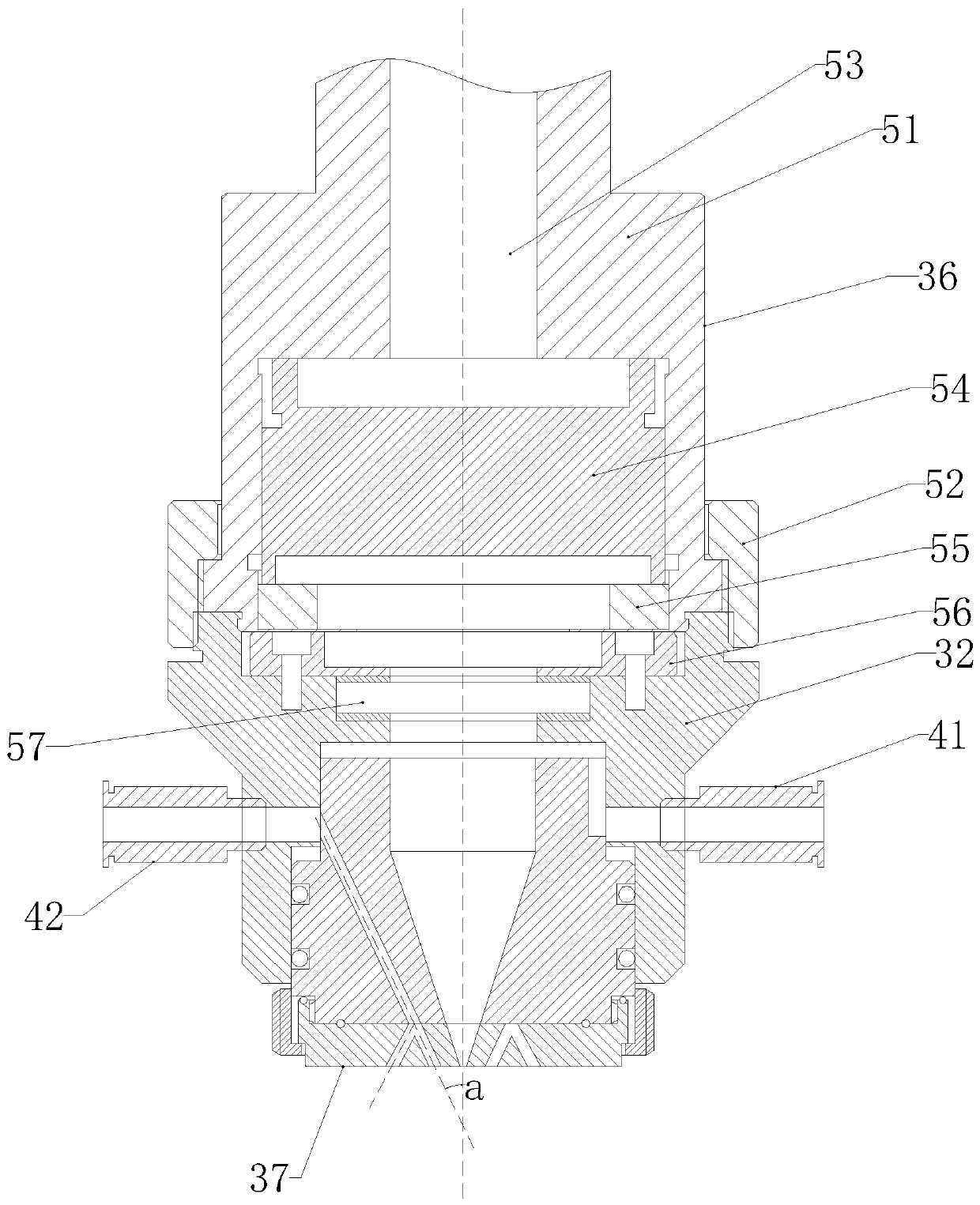

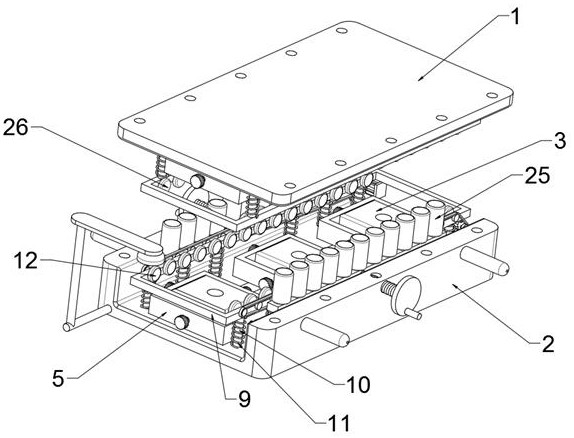

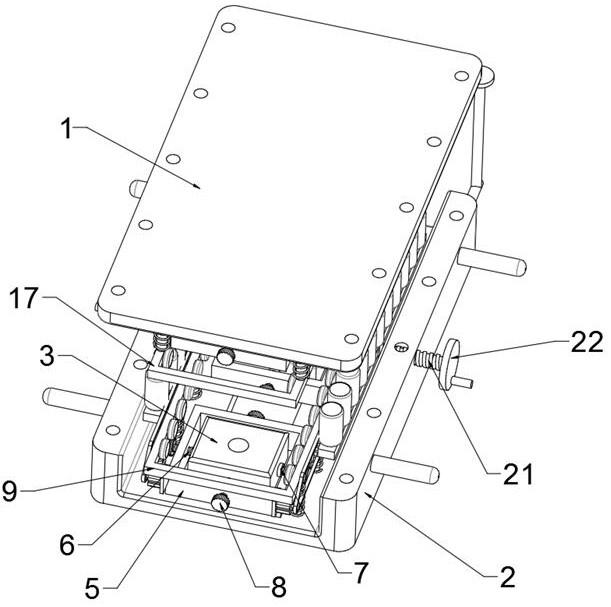

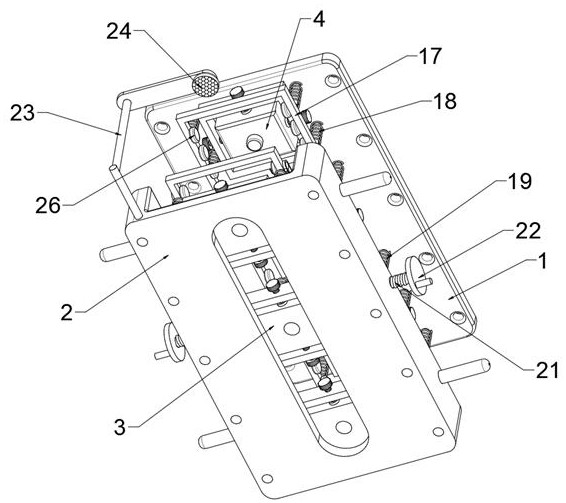

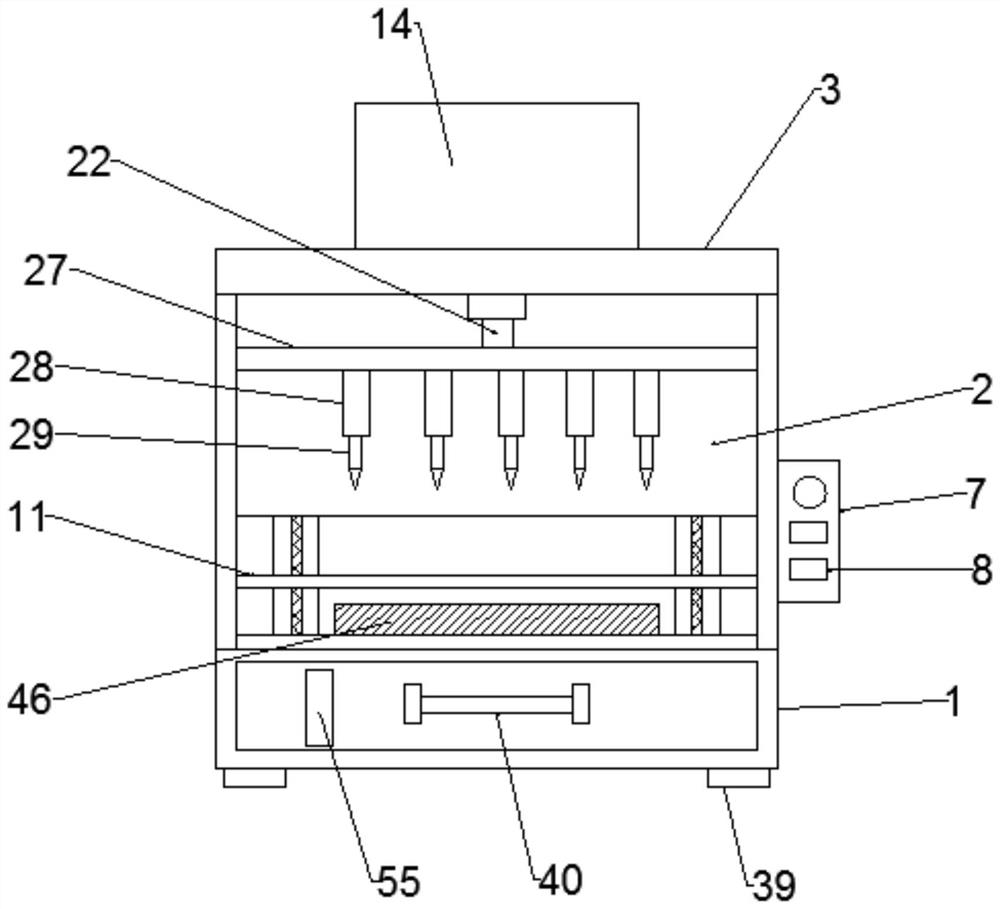

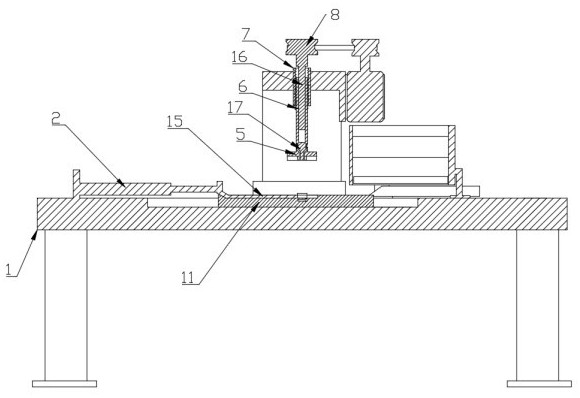

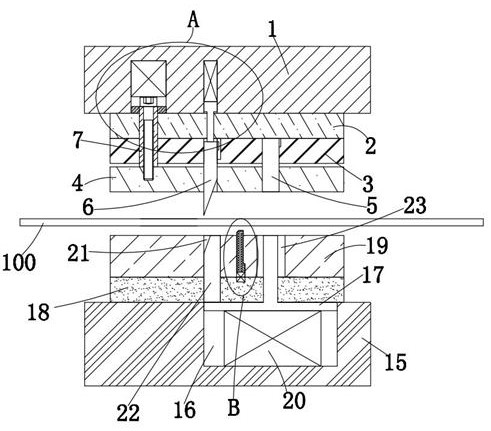

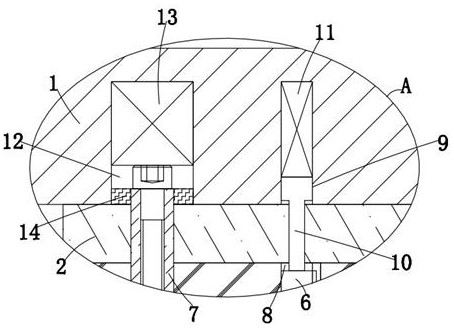

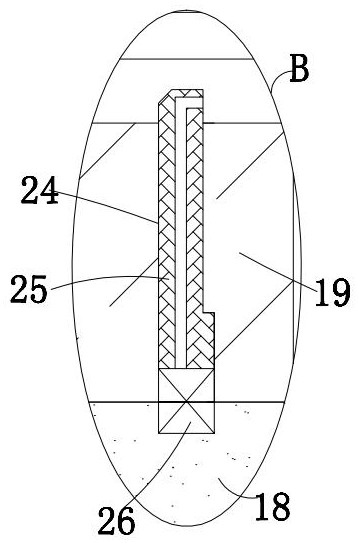

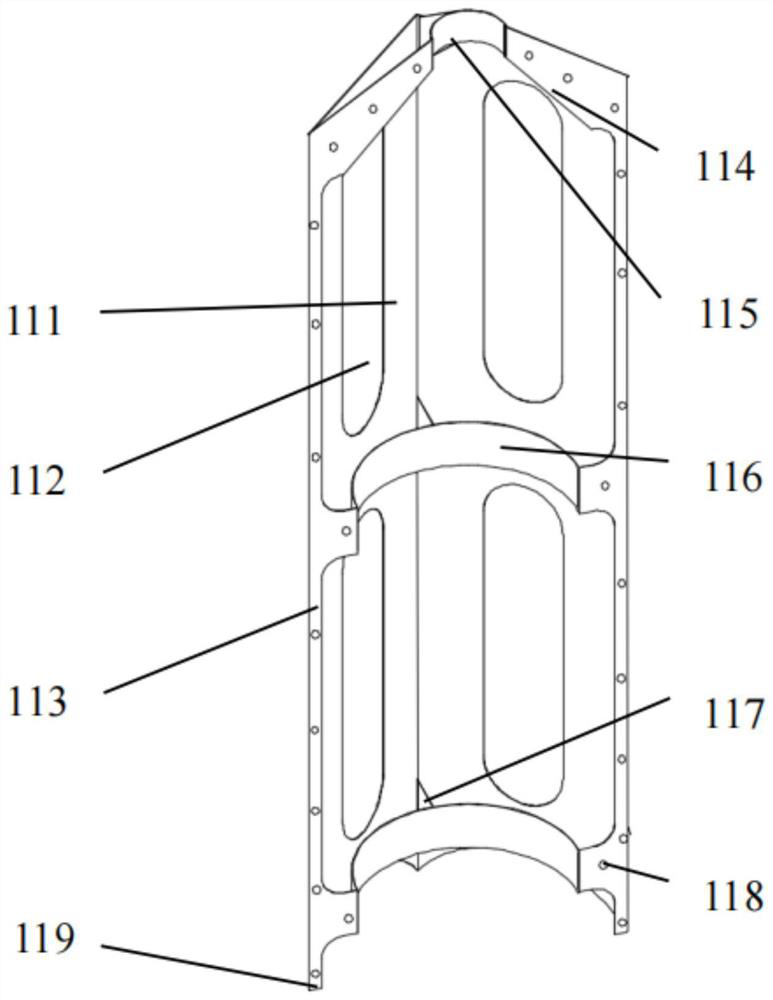

Machining tool for metal sealing gasket

ActiveCN114054591ASolve the waste of manpowerRealize the punching operationShaping toolsPerforating toolsMachine toolMachining

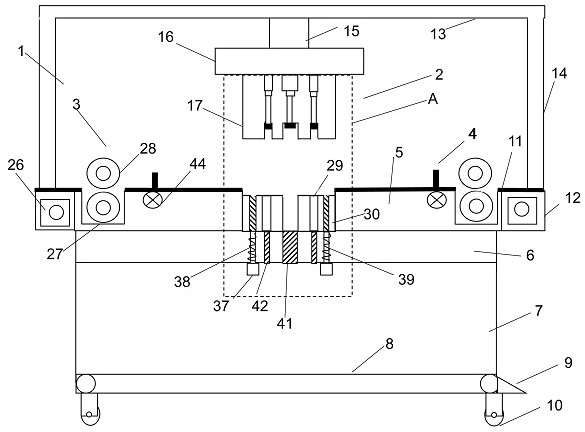

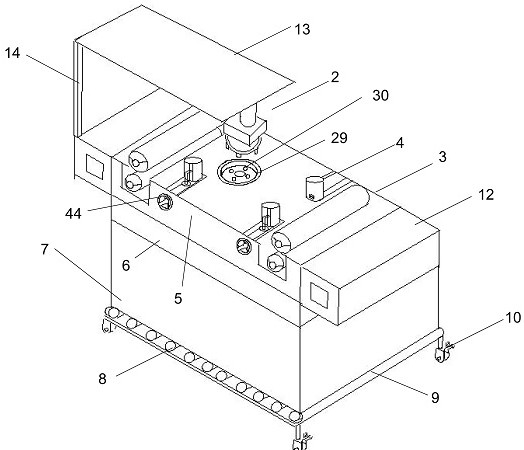

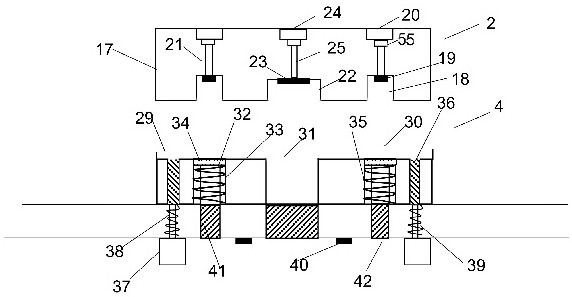

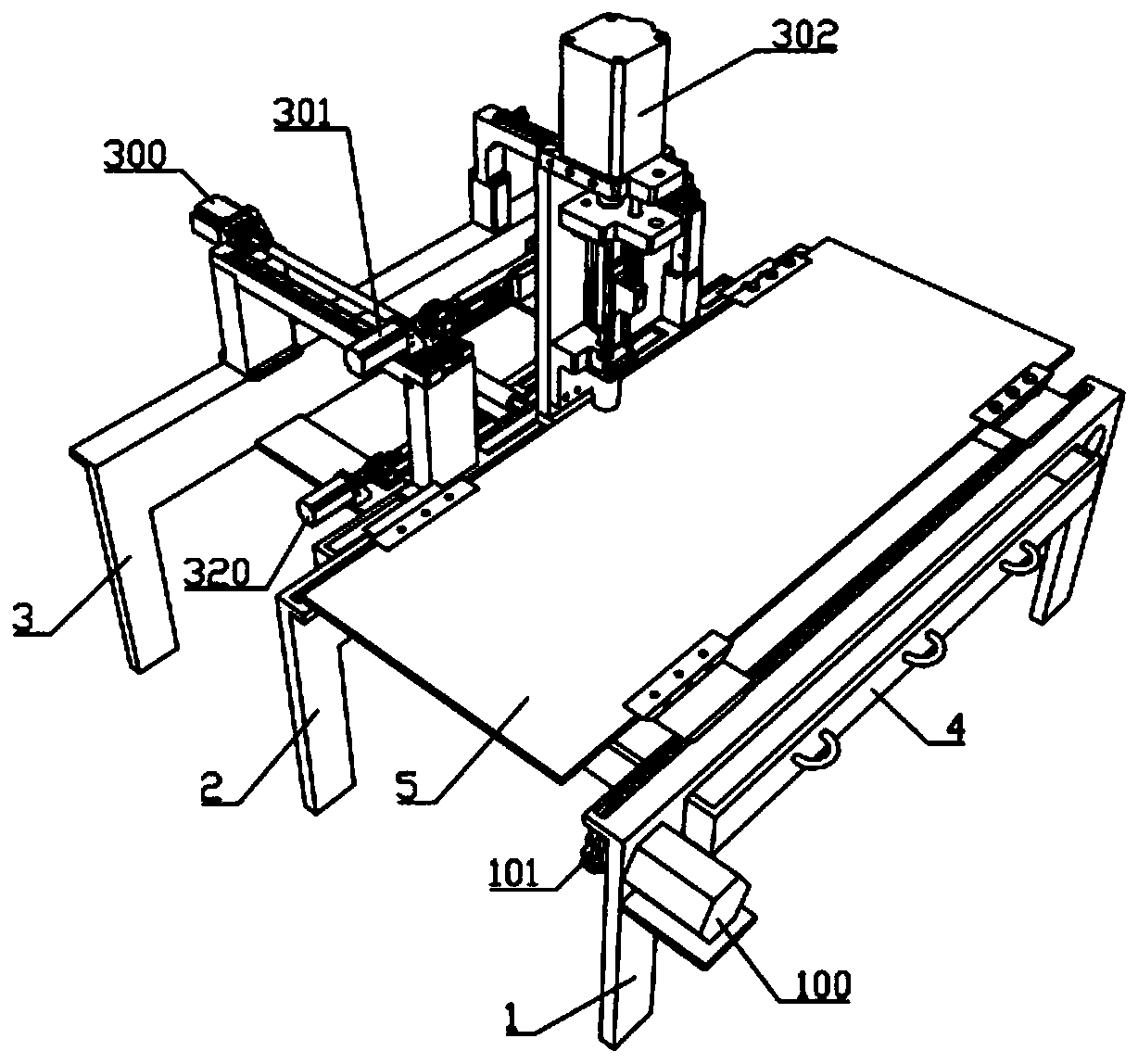

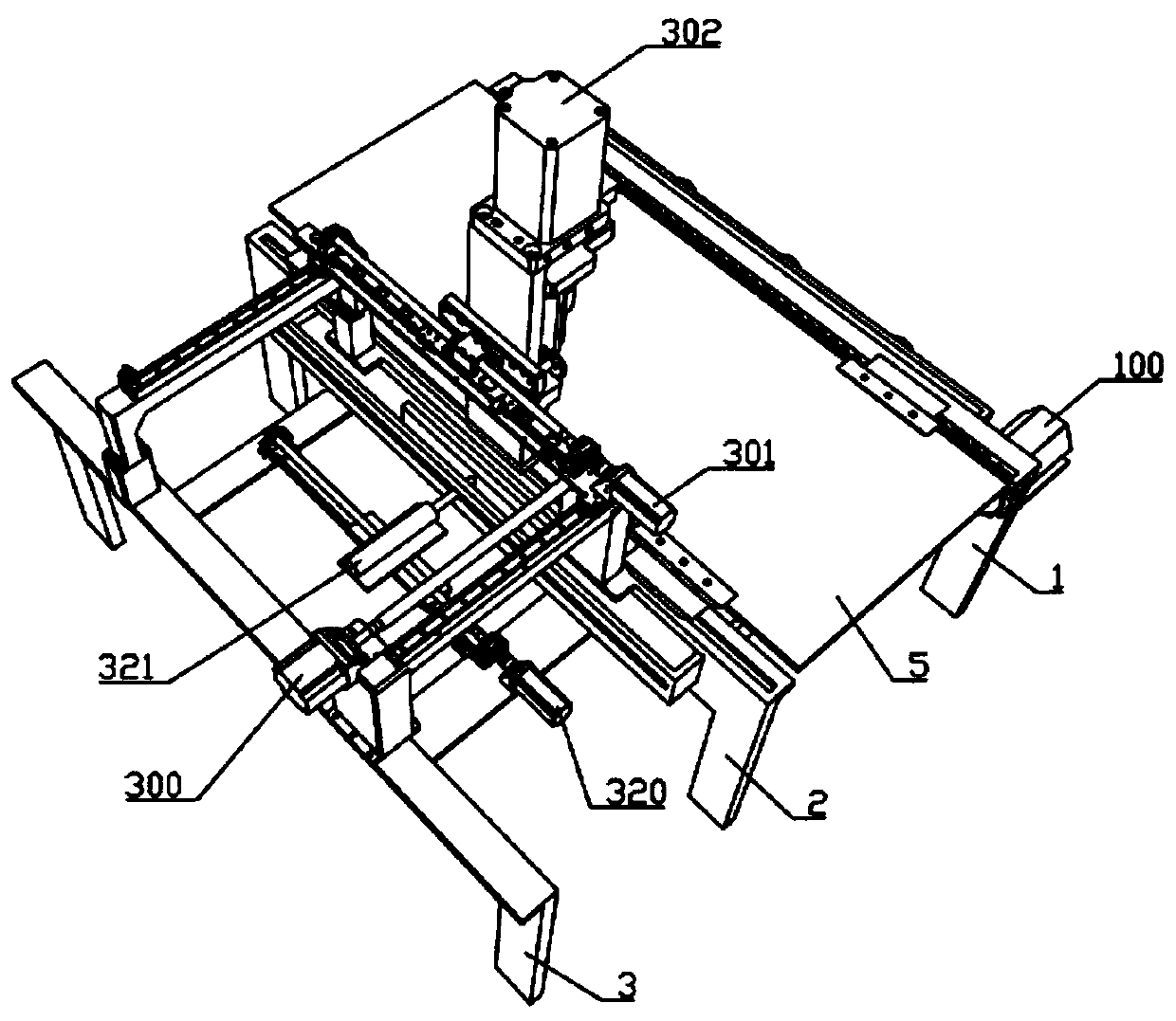

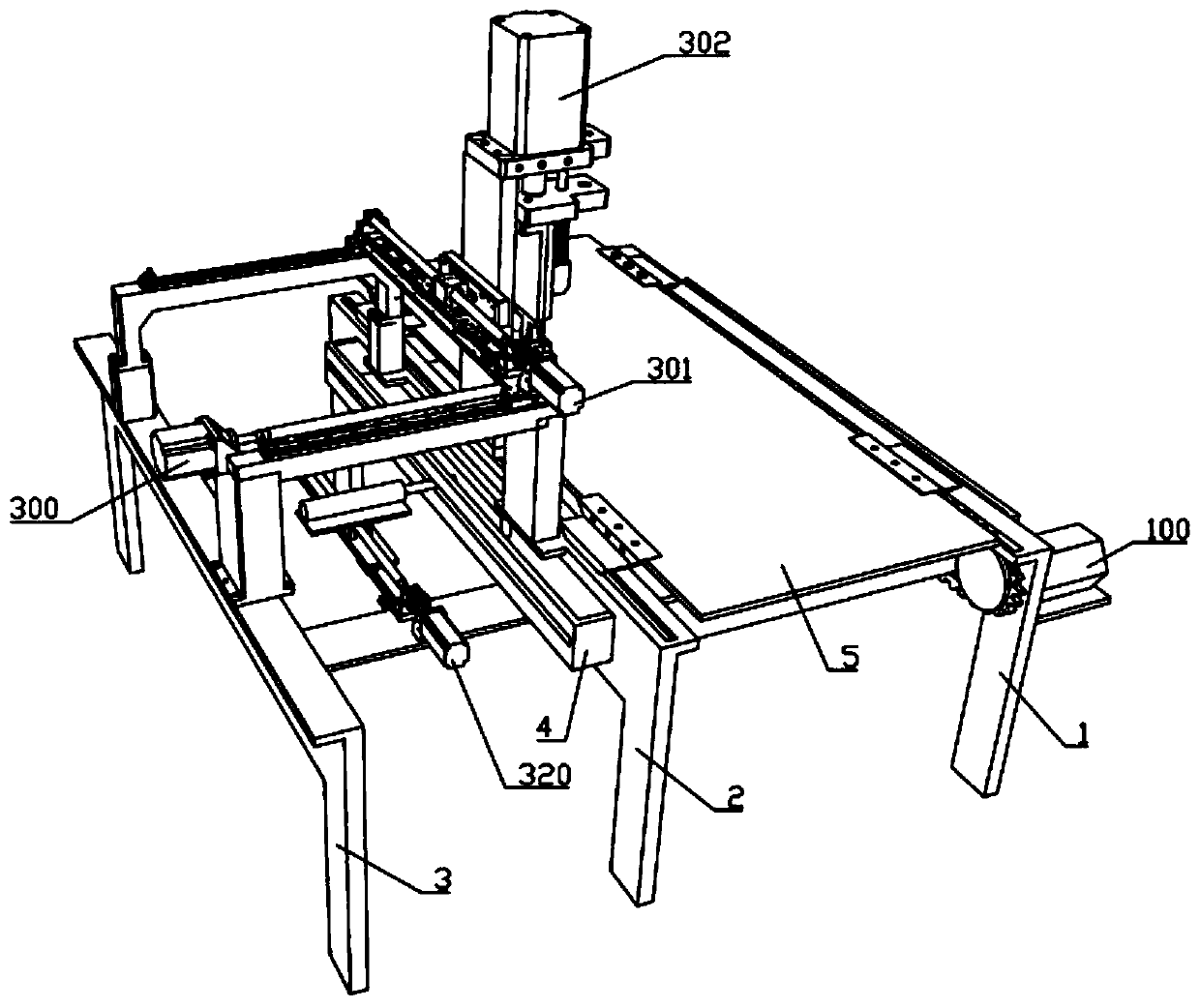

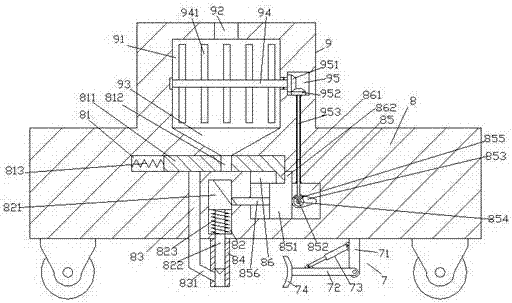

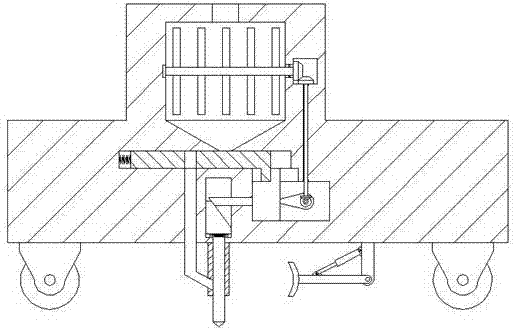

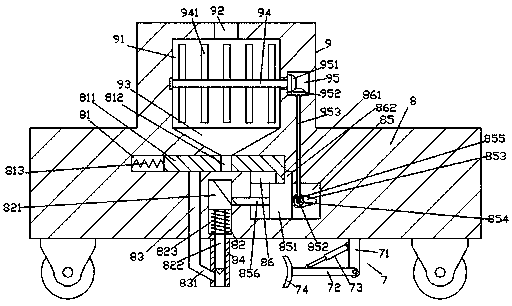

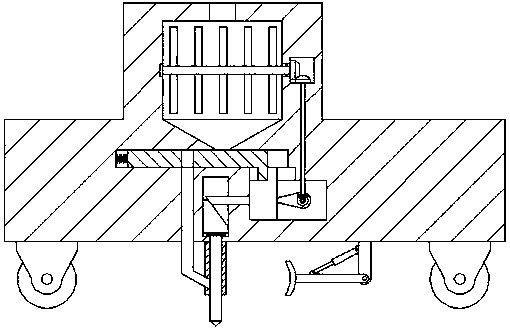

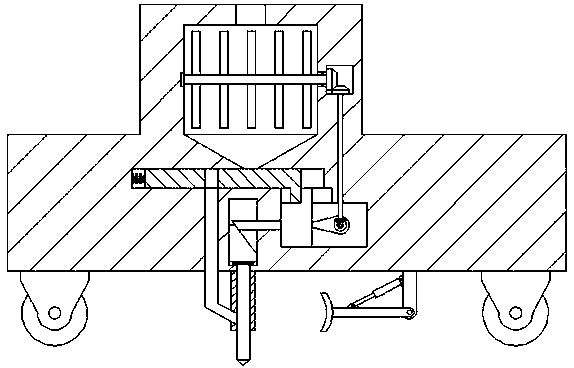

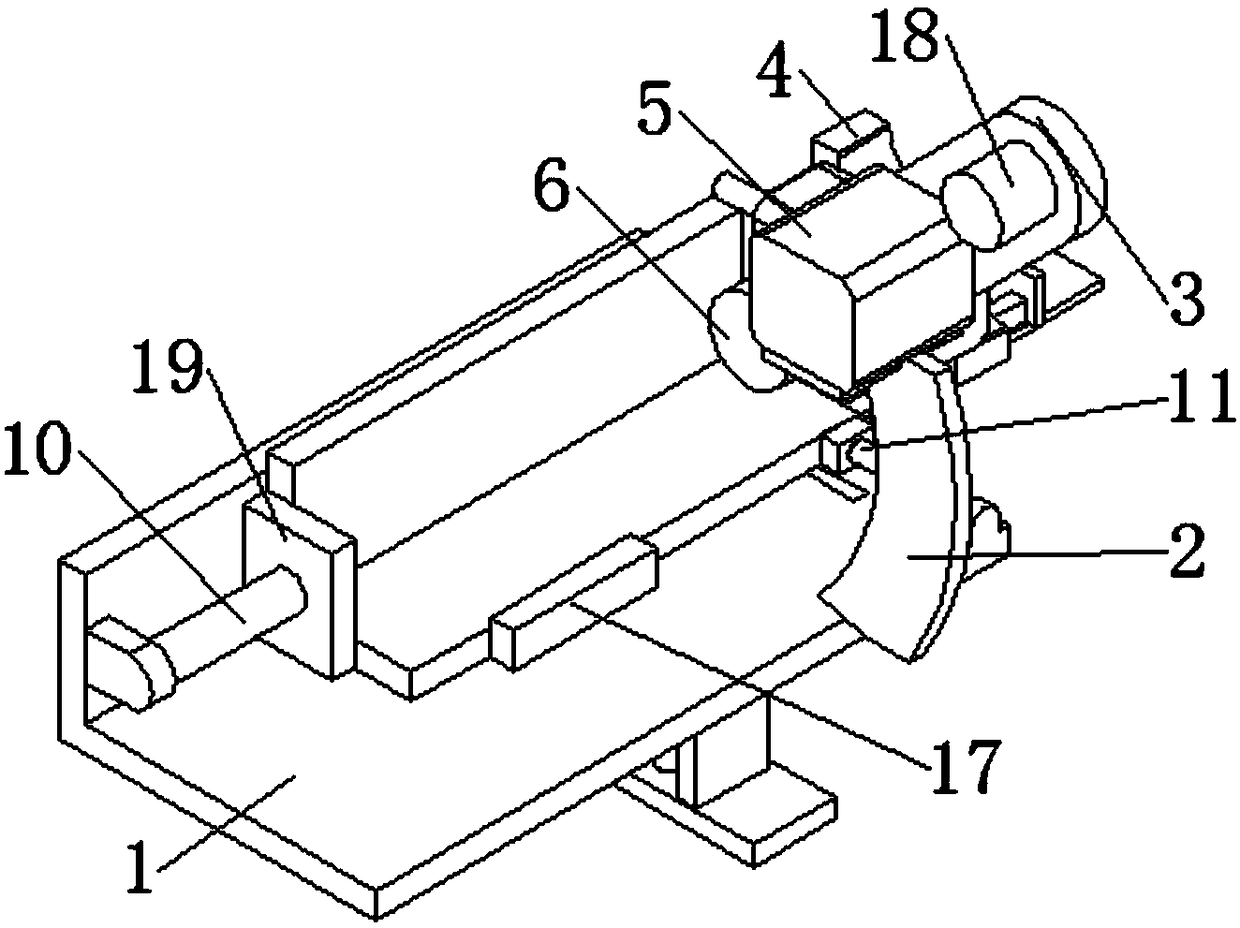

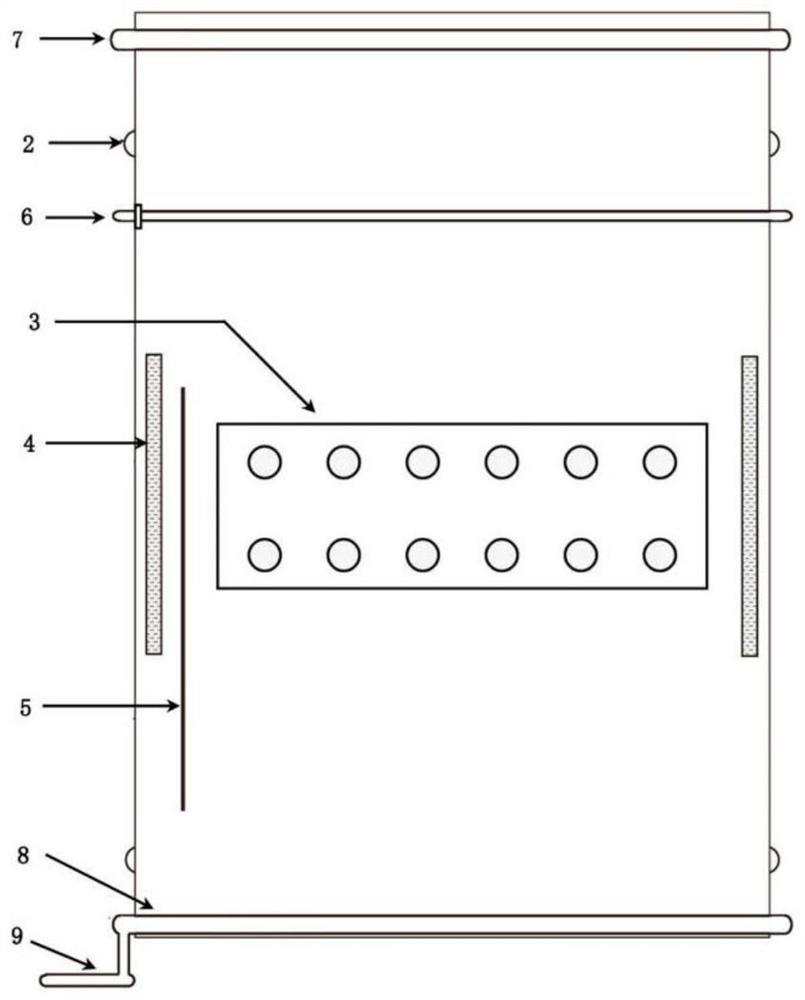

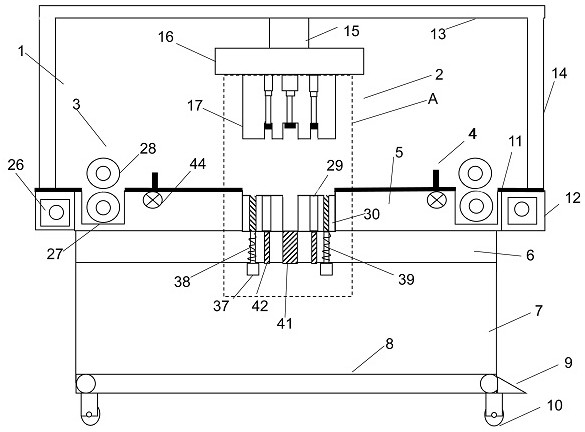

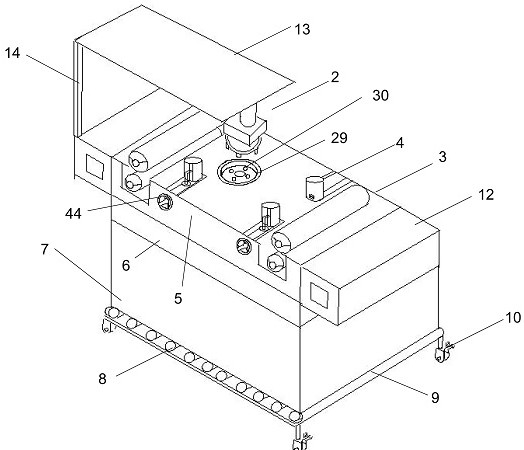

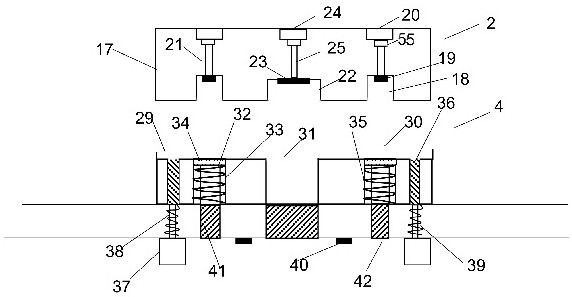

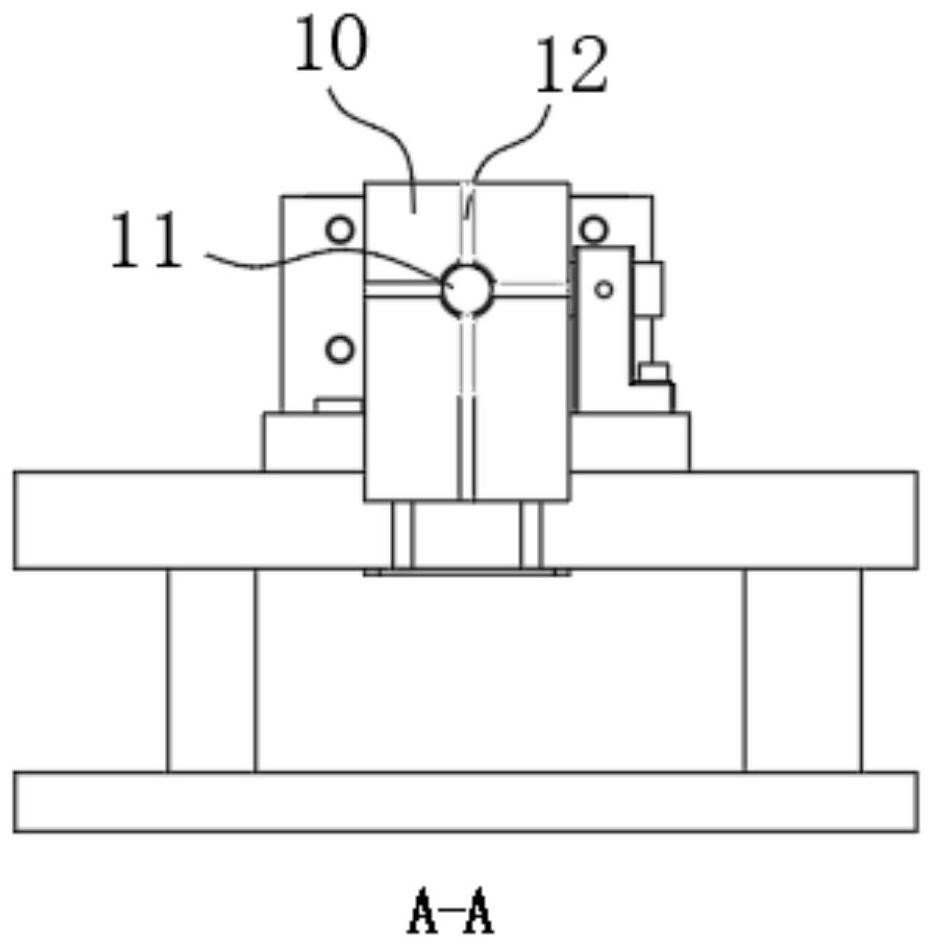

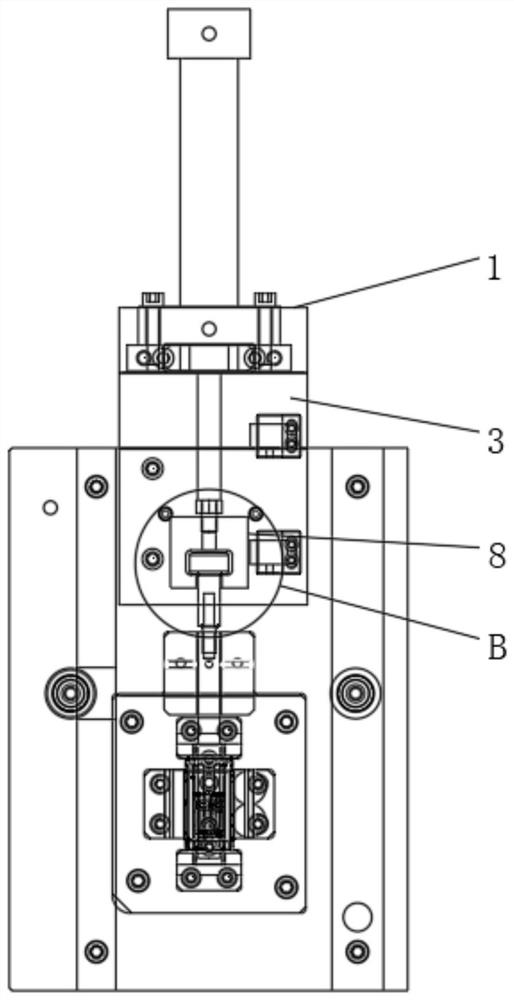

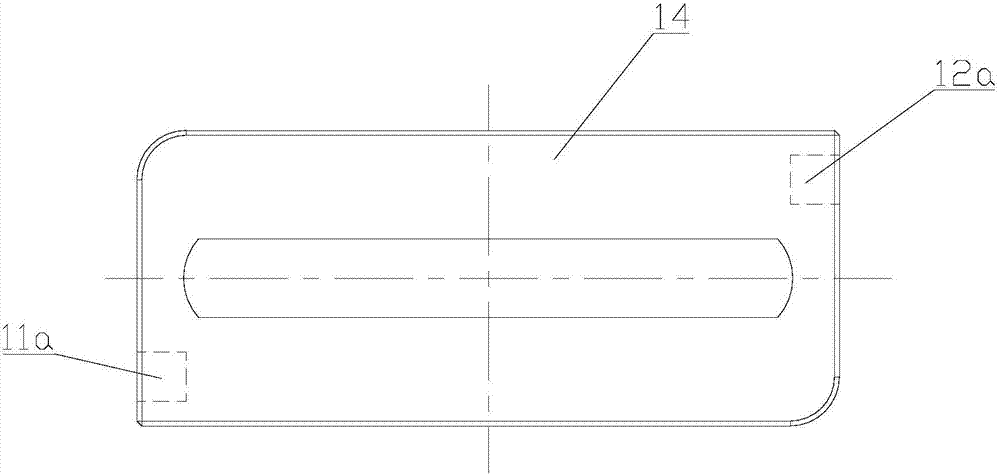

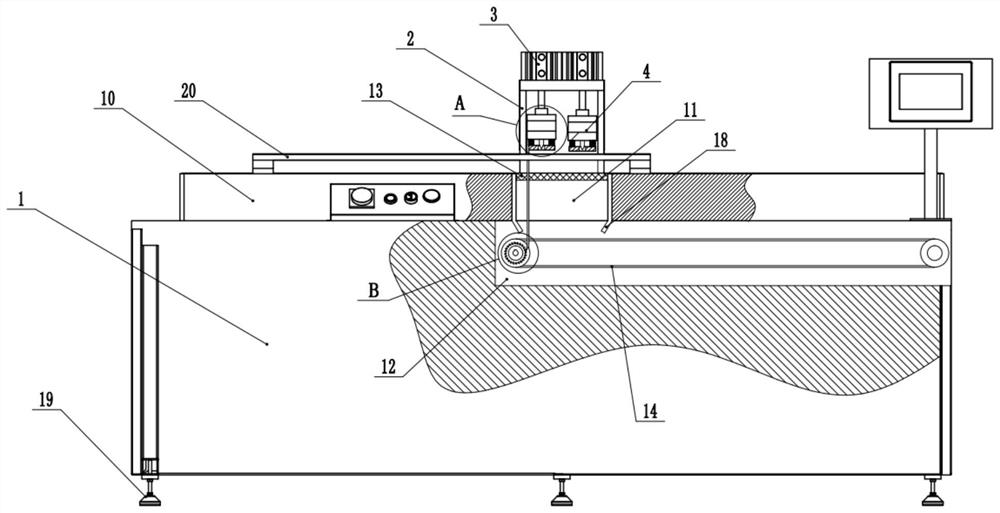

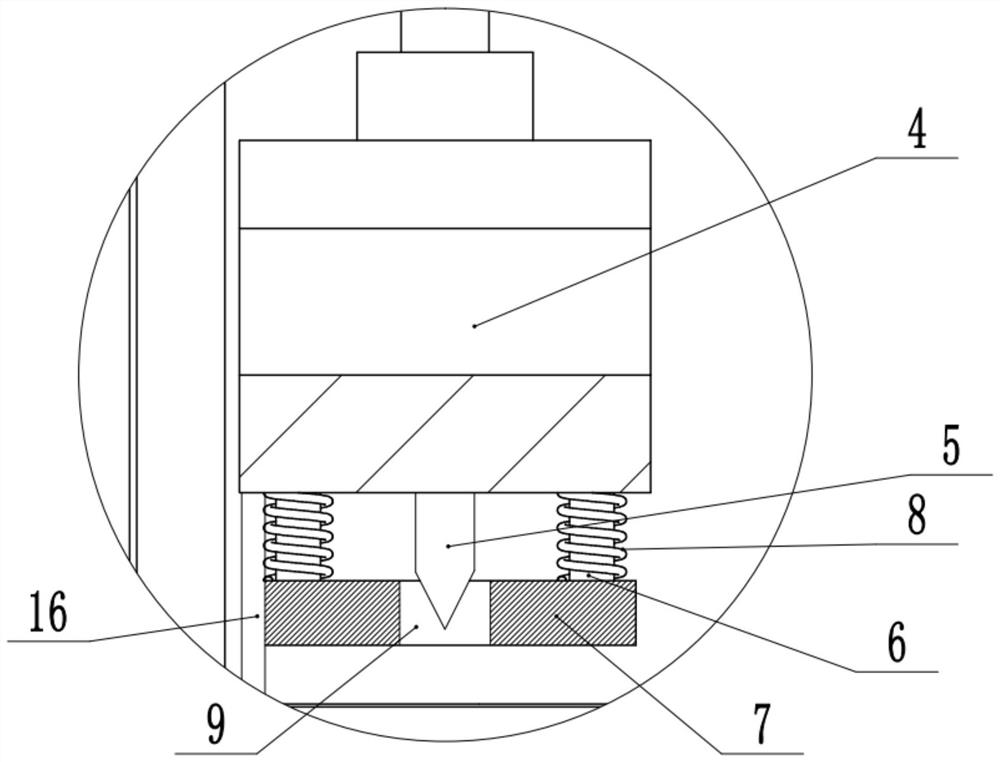

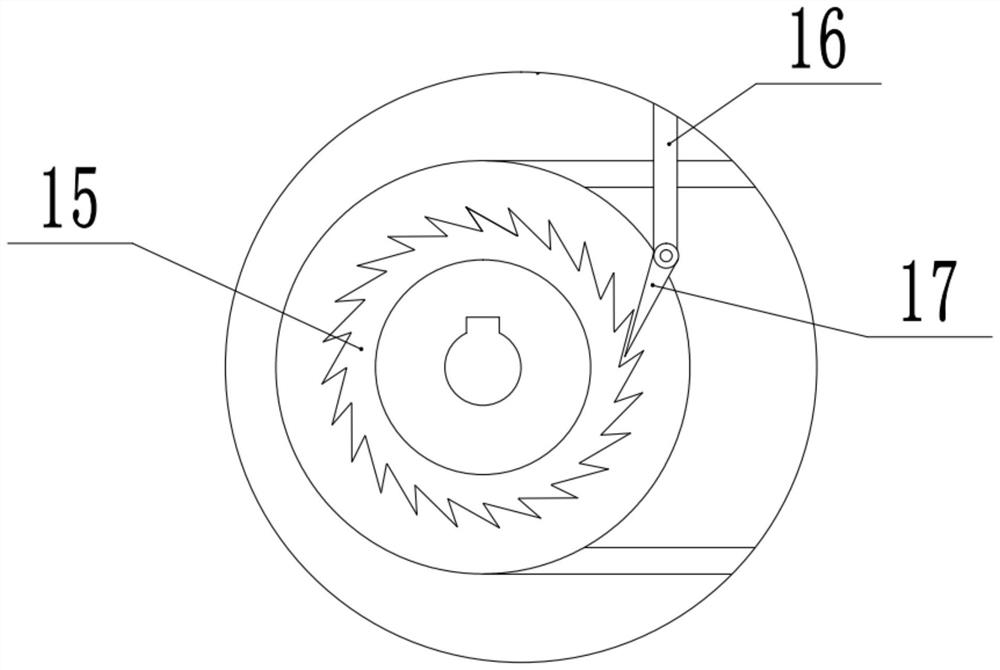

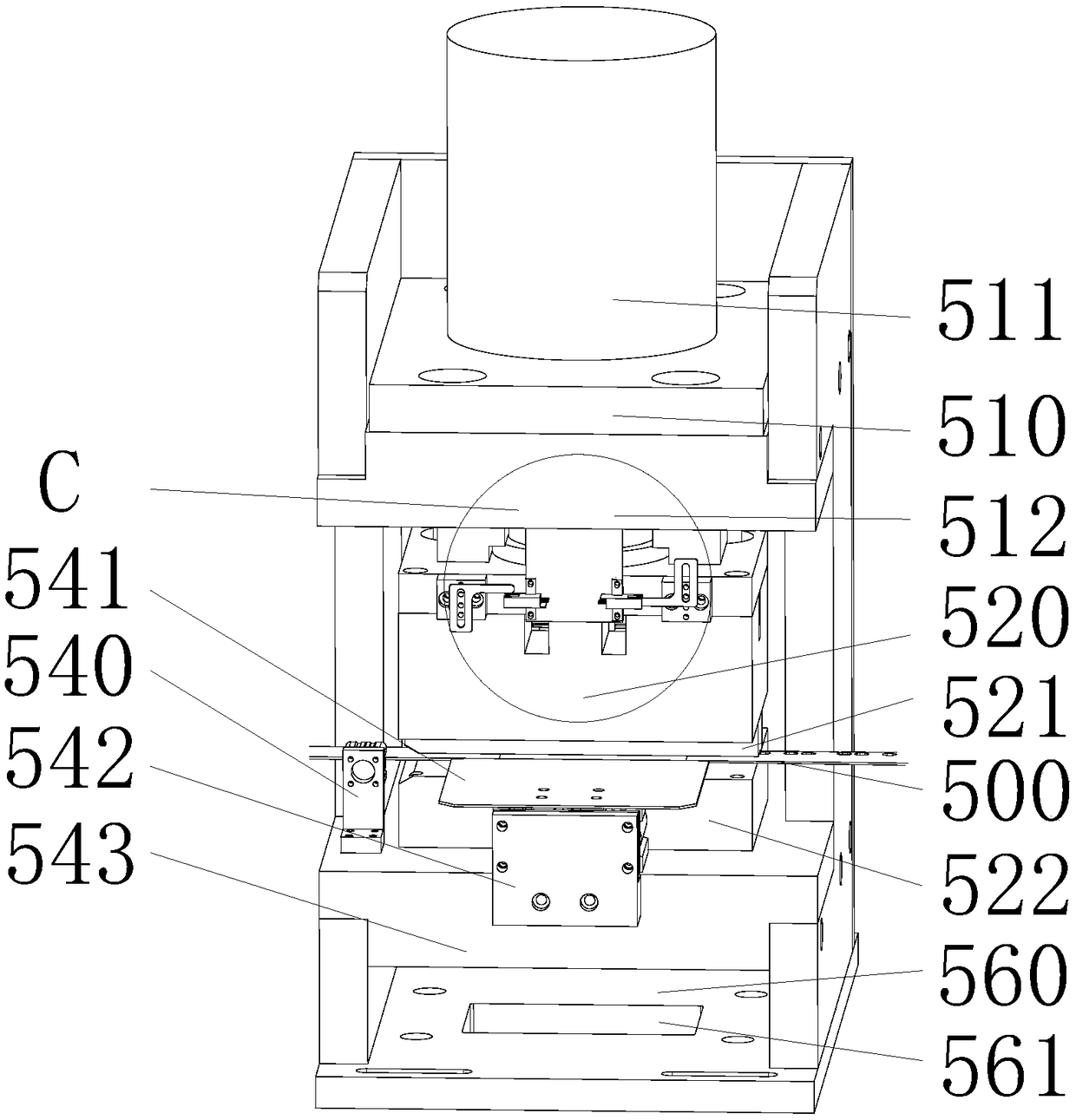

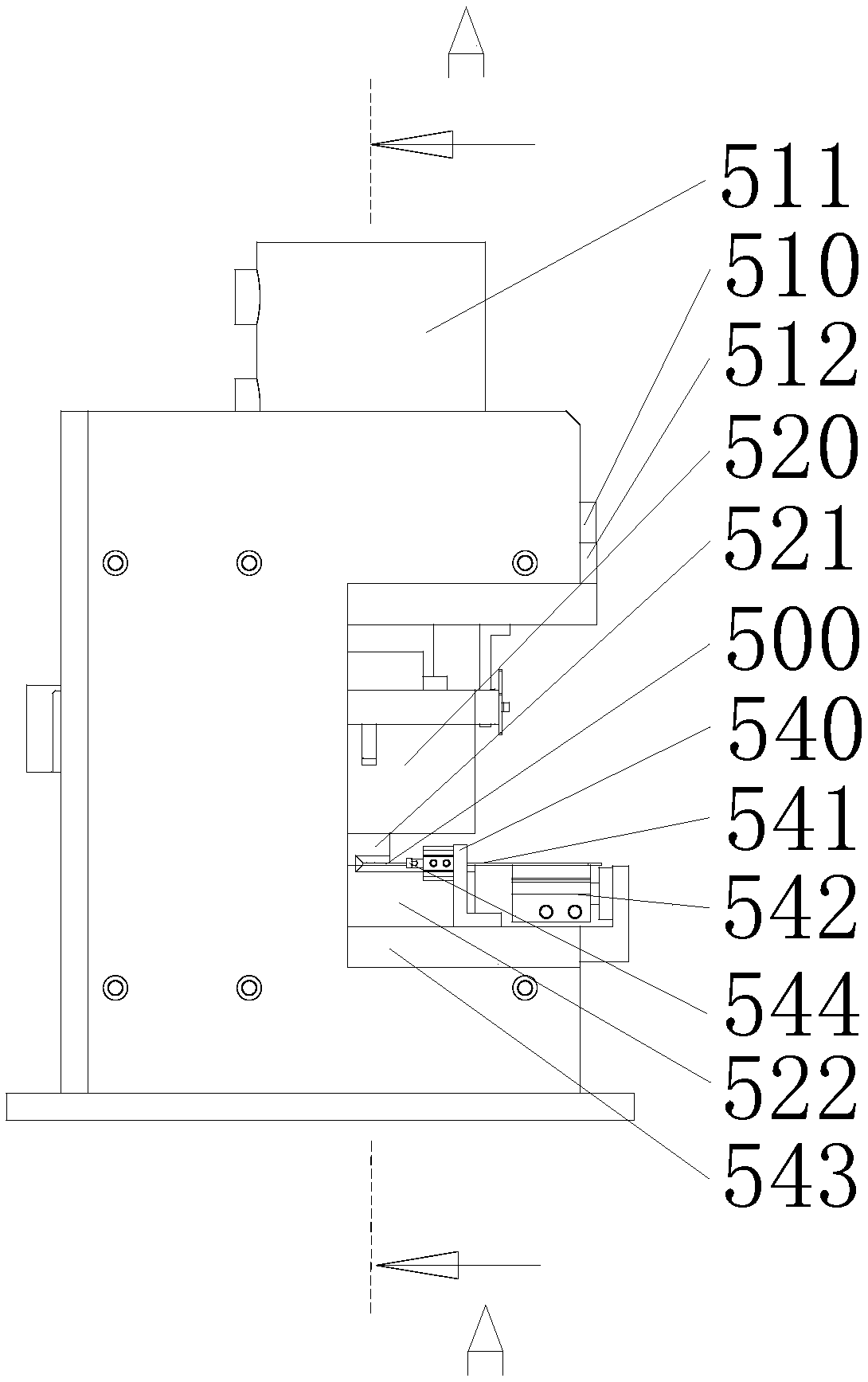

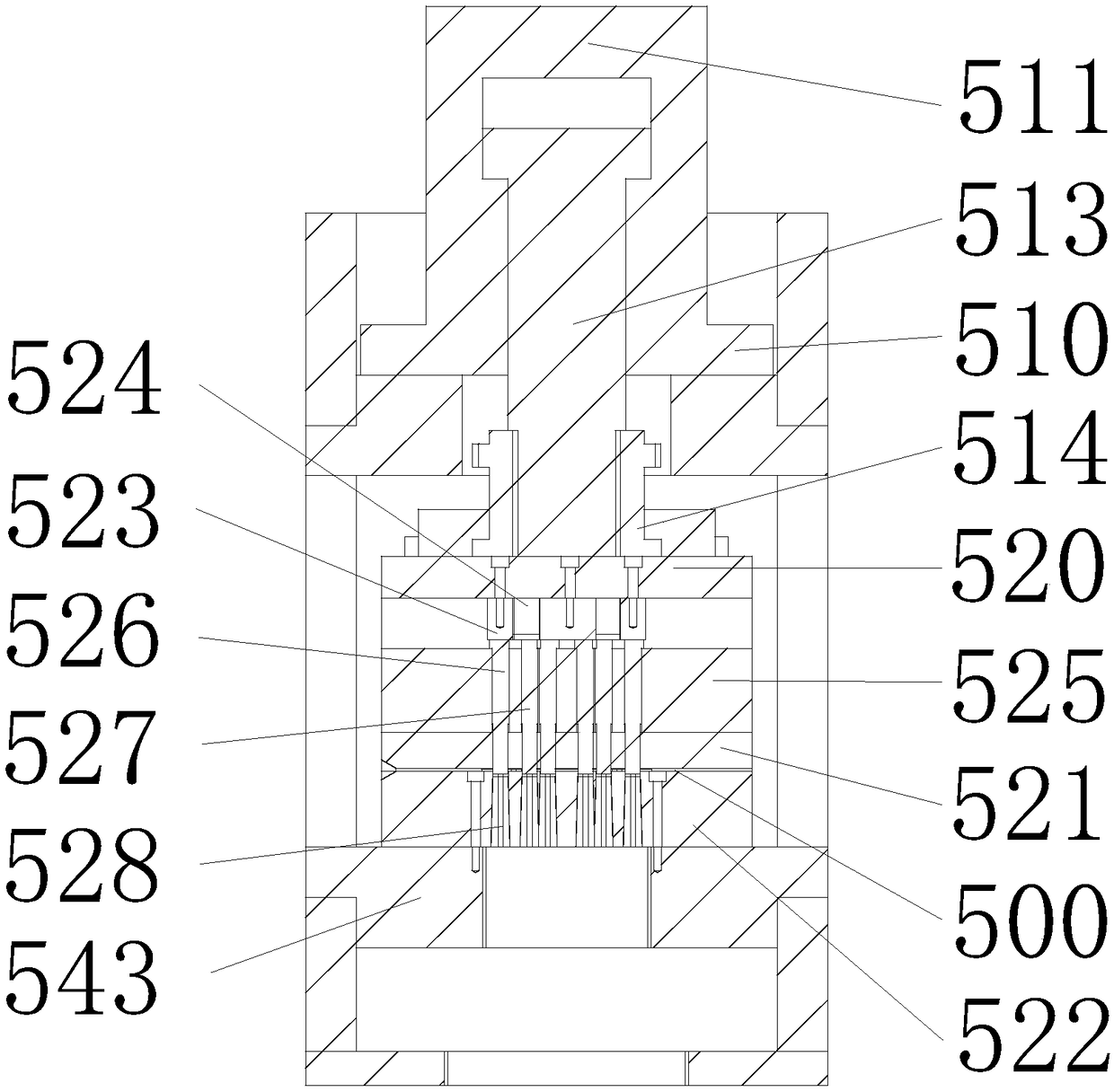

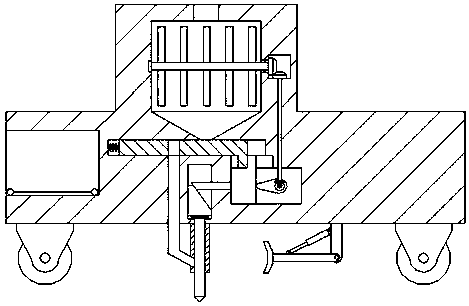

The invention discloses a machining tool for a metal sealing gasket. The machining tool comprises a stamping cavity, a die cavity, a bearing box and a workbench and further comprises a stamping mechanism, a feeding mechanism and a clamping mechanism, wherein the stamping cavity is formed in the workbench and composed of a top plate and four brackets located on the workbench, the stamping mechanism is located on the top plate, the bottom surface of the workbench is connected with the die cavity, control boxes are arranged on the left side and the right side of the die cavity, a die groove is formed in the die cavity, the upper portion of the die groove is not covered by the workbench, the feeding mechanism and the clamping mechanism are further arranged on the workbench and in the die cavity, the bearing box is arranged below the die cavity, the bearing box communicates with a waste box, a conveying belt is arranged in the waste box, a discharging port is formed in the joint of the conveying belt and the waste box, and universal wheels are connected to the bottom surface of the waste box. According to the invention, automatic feeding of metal plates, stamping machining of sealing gaskets and automatic ejection and taking can be achieved, waste materials are automatically discharged, manpower is saved, and the machining efficiency is improved.

Owner:烟台长鑫密封产品有限公司

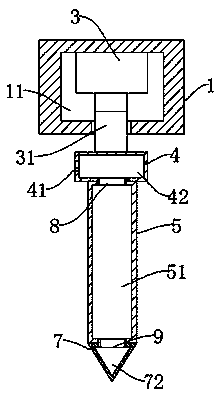

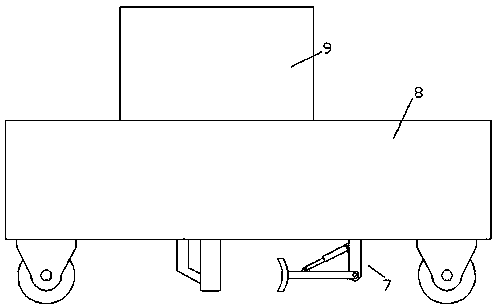

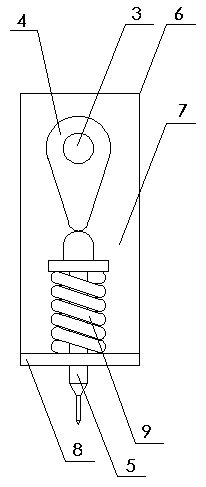

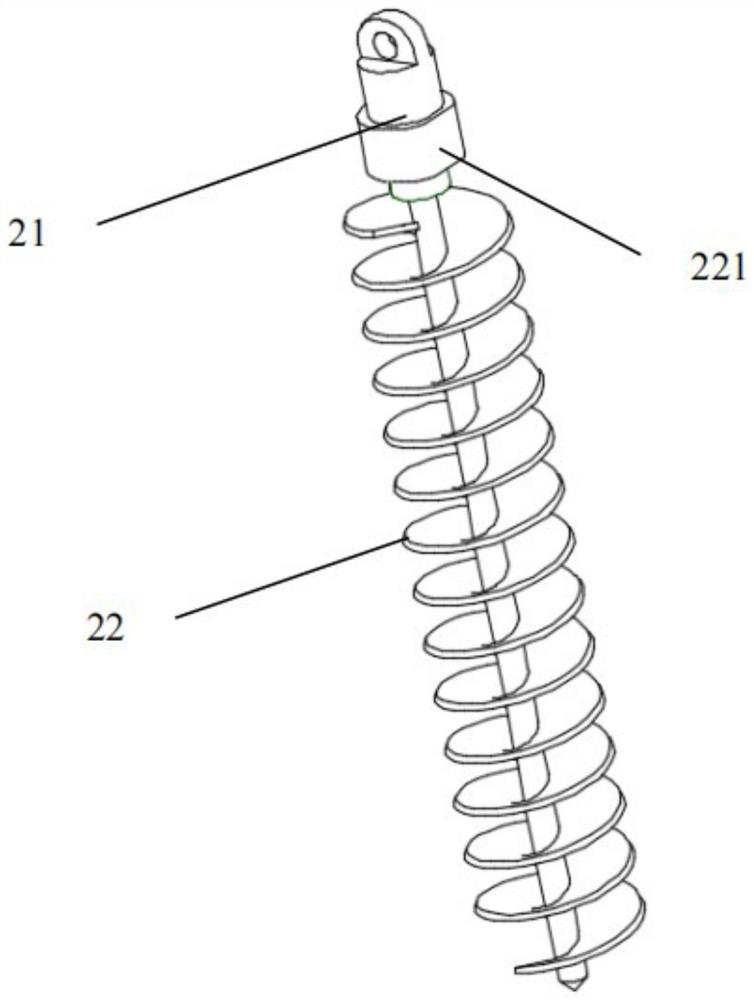

Rapid punching device for wild nursery stock planting

InactiveCN110999597AWon't breakGuaranteed to grow verticallyPlantingFurrow making/coveringElectric machineryStructural engineering

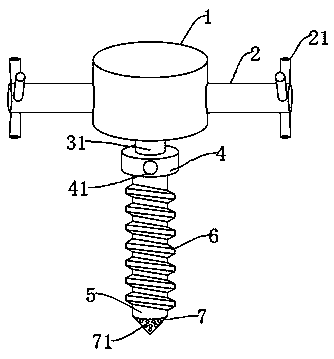

The invention discloses a rapid punching device for wild nursery stock planting. The rapid punching device comprises a short column, wherein a handle is respectively connected with and arranged at themiddle positions of the side walls of two ends of the short column in a threaded manner; a hand wheel is fixedly arranged at the other end of each handle; a cavity is arranged in the short column; amotor is fixedly arranged at the middle position of the top surface of the interior of the cavity; the output shaft of the motor is fixedly connected with a rotating shaft; the other end of the rotating shaft penetrates through the cavity and is fixedly welded with the center position of the top surface of a connecting disc; the center position of the bottom surface of the connecting disc is fixedly connected with the rotating shaft; a threaded block is fixedly arranged at the upper part of the outer wall of the rotating shaft; meanwhile, a drill bit is fixedly arranged at the bottom end of the rotating shaft. When the rapid punching device provided by the invention is used in punching work, soil tissues at four walls of a pit can be well protected from being damaged; through the threadedblock, the spiral rough surfaces of four walls of the pit facilitate adhesion of the root system of a newly-planted nursery stock; vertical growth of the nursery stock can be well guaranteed; and thesurvival rate of the nursery stock is greatly increased.

Owner:安徽绿泉生态农业股份有限公司

Single-station automatic punching equipment for automobile precision accessory machining

InactiveCN108972068AIncrease frictionImprove stabilityLarge fixed membersPositioning apparatusPunchingEngineering

The invention discloses single-station automatic punching equipment for automobile precision accessory machining, and relates to the technical field of automobile manufacturing. The single-station automatic punching equipment comprises a lifting mechanism with the bottom face fixedly connected with a fixing base. A workpiece body is placed at the middle portion of the upper surface of the liftingmechanism. Two symmetric first electric push rods are fixedly connected to the upper surface of the lifting mechanism. A fixing plate is arranged above the lifting mechanism. The telescopic end of each first electric push rod is fixedly connected with the bottom face of the fixing plate. The bottom face of the fixing plate is fixedly connected with a horizontal movement mechanism with the bottom face provided with a movable plate. The single-station automatic punching equipment for automobile precision accessory machining can integrally achieve automatic accessory punching work, the situationthat during work, a worker fixes an accessory by one hand, the other hand operates punching equipment, and accordingly the accessory punching work can be achieved is avoided, the labor output of the worker is reduced, and the work efficiency is improved.

Owner:樊祥

Numerical control door plate punching waste treatment device and using method thereof

InactiveCN111036761AAchieve teleportationRealize the punching operationMetal-working feeding devicesPositioning devicesWaste treatmentStructural engineering

The invention belongs to the technical field of door production and manufacturing and relates to a numerical control door plate punching waste treatment device. The device comprises a front side frame, a middle frame, a rear side frame, a material receiving box, a punching mechanism and a material pushing mechanism; the front side frame, the middle frame and the rear side frame are all inverted-U-shaped; the top of the front side frame is vertically folded backwards to form a front platform; a long-strip-shaped through hole is horizontally formed in the top face of the front platform from leftto right; the top of the middle frame is vertically folded forwards to form a middle platform; a long-strip-shaped sliding groove with the length equal to that of the long-strip-shaped through hole is horizontally formed in the top face of the middle platform from left to right; the left ends and the right ends of the front side frame, the middle frame and the rear side frame are aligned; a frontinserting opening is horizontally formed in the middle of the front wall of the front side frame from left to right; and a rear inserting opening the same as the front inserting opening is horizontally formed in the middle of the rear wall of the middle frame. The invention further relates to a using method of the device. With the device and the using method thereof adopted, the lock hole of a door plate can be punched and formed at a time; a positioning effect is good; the collection and treatment of waste materials can be facilitated; and efficiency is high.

Owner:重庆函木科技有限公司

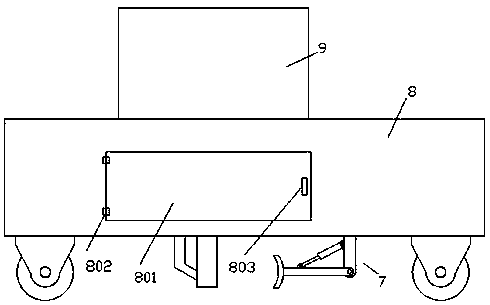

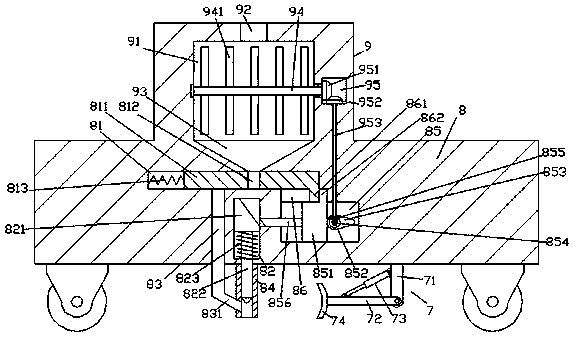

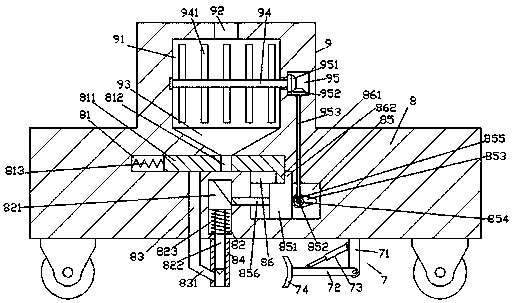

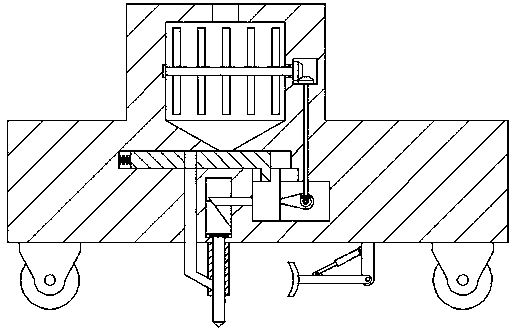

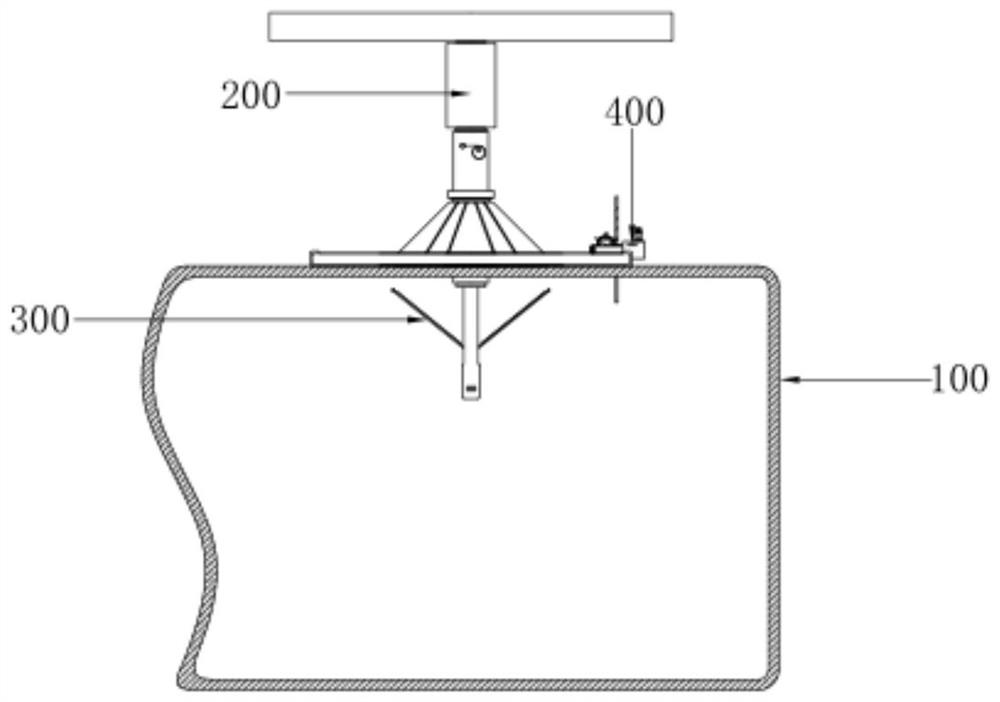

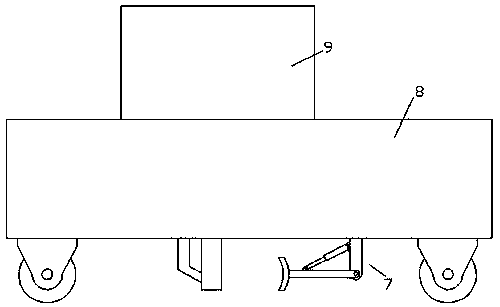

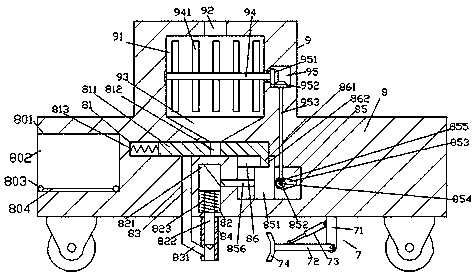

Deep soil fertilizing device

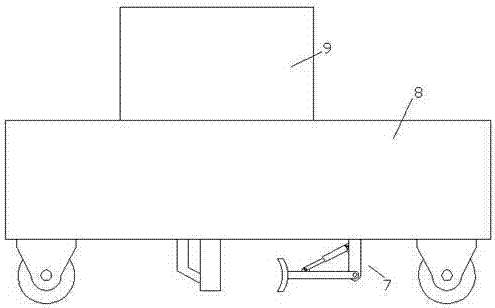

ActiveCN107258184AImprove work efficiencyQuality improvementPlantingFertiliser distributersEngineeringPulley

The invention discloses a deep soil fertilizing device, comprising a moving cart and a storage box arranged at the top of the moving cart; a storage chamber is arranged in the storage box, the bottom of the storage chamber is communicated with a funnel chamber that extends down into the moving cart, a transmission chamber is arranged in the storage box to the right of the storage chamber, a first bevel pulley is arranged in the transmission chamber, a stirring shaft extended to the left is fixed to the left end of the first bevel pulley, a left extension of the stirring shaft penetrates the inner wall of the storage box between the transmission chamber and the storage chamber and is in rotational fit connection with the same, the tail end of the left extension of the stirring shaft is extended into the storage chamber and is in rotational fit connection with the left inner wall of the storage chamber, the bottom of the funnel chamber is communicated with a first slide slot that extended side to side, a lifting slide chamber is arranged in the moving cart below the first slide slot, and a feeding pipe extended vertically is arranged in the moving cart to the left of the lifting slide chamber. The deep soil fertilizing device is simple in structure and convenient to operate, can prevent blockage due to fertilizer accumulating, and can provide increased utilization rate of fertilizer.

Owner:GUANGZHOU YAOKAI LANDSCAPE DESIGN CO LTD

Anti-clogging deep soil fertilizer application apparatus

InactiveCN107690881AImprove work efficiencyQuality improvementPlantingFertiliser distributersMobile vehicleEngineering

The invention discloses an anti-clogging deep soil fertilization device, which comprises a mobile vehicle body and a material storage box arranged on the top of the mobile vehicle body. Extending and extending into the funnel chamber of the moving car body, the storage box on the right side of the storage chamber is provided with a transmission chamber, and a first cone wheel is provided in the transmission chamber, and the left end of the first cone wheel is fixed with a shaft extending to the left. The stirring shaft is set, the extension section on the left side of the stirring shaft runs through the inner wall of the storage box between the transmission chamber and the storage chamber and is connected in rotation and fit, the left extension end of the stirring shaft extends into the storage chamber and is connected to the left side of the storage chamber The inner wall is rotated and connected, and the bottom of the funnel cavity is connected with the first sliding groove extending to the left and right sides. The mobile car body below the first sliding groove is provided with a lifting sliding cavity, and the moving car body on the left side of the lifting sliding cavity A feeding pipe extending up and down is provided; the invention has simple structure, convenient operation, can prevent fertilizer accumulation from causing blockage, and improves the utilization rate of fertilizer.

Owner:方倩

Deep soil quantitative fertilizer application apparatus

InactiveCN107690882AImprove work efficiencyQuality improvementPlantingFertiliser distributersMobile vehicleEngineering

The invention discloses a quantitative fertilization device for deep soil, which comprises a mobile vehicle body and a material storage box arranged on the top of the mobile vehicle body. A material storage cavity is arranged in the material storage box, and a downwardly extending and Extending into the funnel chamber of the moving car body, the storage box on the right side of the storage chamber is provided with a transmission chamber, and the first cone wheel is arranged in the transmission chamber, and the left end of the first cone wheel is fixed with a shaft extending to the left. Stirring shaft, the extension section on the left side of the stirring shaft runs through the inner wall of the storage box between the transmission chamber and the storage chamber and is connected with rotation. The left extension end of the stirring shaft extends into the storage chamber and rotates with the left inner wall of the storage chamber Cooperate with the connection, the bottom of the funnel cavity is connected with the first sliding groove extending to the left and right sides, the mobile car body below the first sliding groove is provided with a lifting sliding chamber, and the mobile car body on the left side of the lifting sliding chamber is provided with The feeding pipe is extended up and down; the invention has a simple structure and is convenient to operate, can prevent the fertilizer accumulation from causing blockage, and improves the utilization rate of the fertilizer.

Owner:方倩

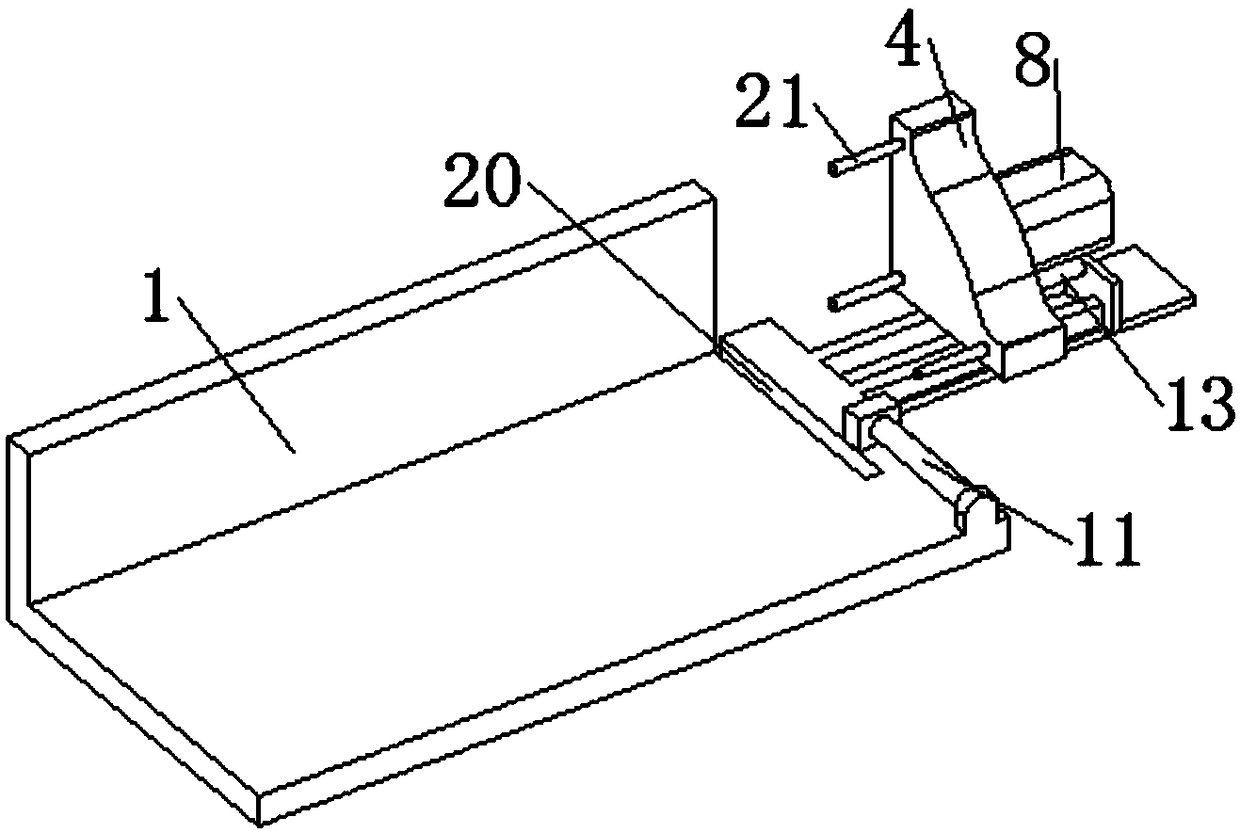

Auxiliary device for door and window corner drilling and grooving

InactiveCN109262276AReduce processing difficultyReduce processing timeOther manufacturing equipments/toolsEngineeringMachining time

The invention discloses an auxiliary device for door and window corner drilling and grooving. The auxiliary device comprises a worktable, wherein the worktable is a right-angle plate, one end of the worktable is provided with a main motor mounting rack, a motor I is fixedly installed above the main motor mounting rack, the end of an output shaft of the motor I is fixedly provided with a rotary plate, one end of the rotary plate is provided with a through hole, the end of the rotary plate is fixedly provided with a motor II, an output shaft of the motor II penetrates through a through hole of the rotary plate, the axes of the motor I and the motor II are parallel, and the end of the output shaft of the motor II is fixedly provided with a motor mounting base. The auxiliary device for door and window corner drilling and grooving integrates drilling, grooving and cutting, achieves integral machining of multiple working processes, decreases the clamping times, shortens the machining time and improves the machining precision.

Owner:安徽名特玻璃有限公司

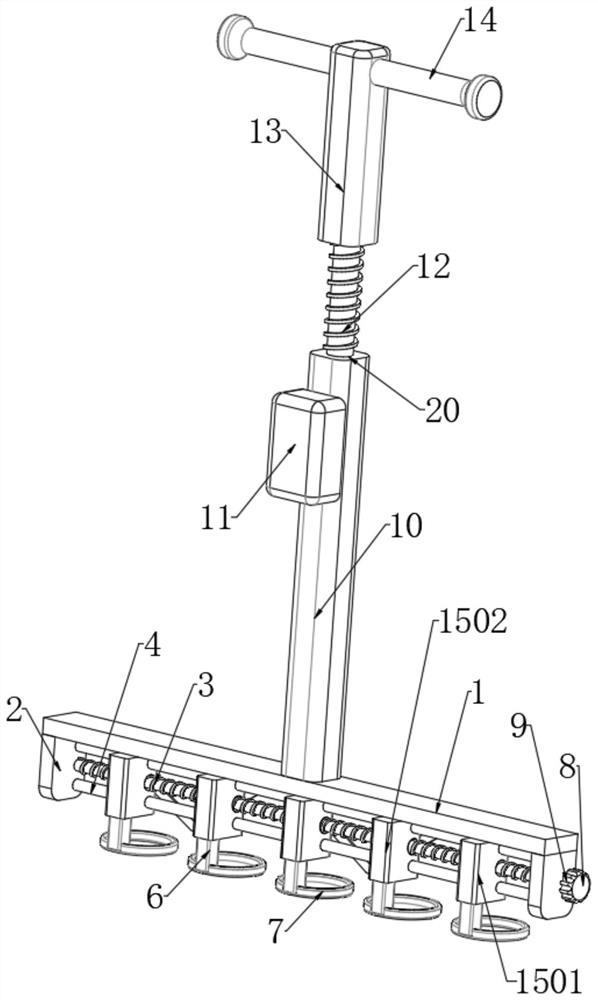

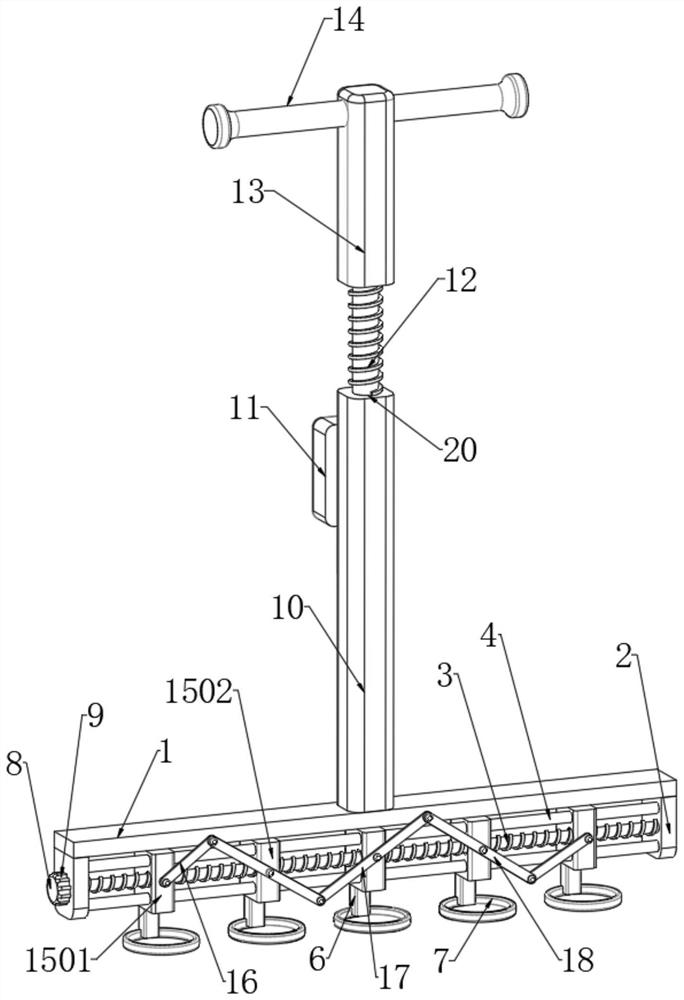

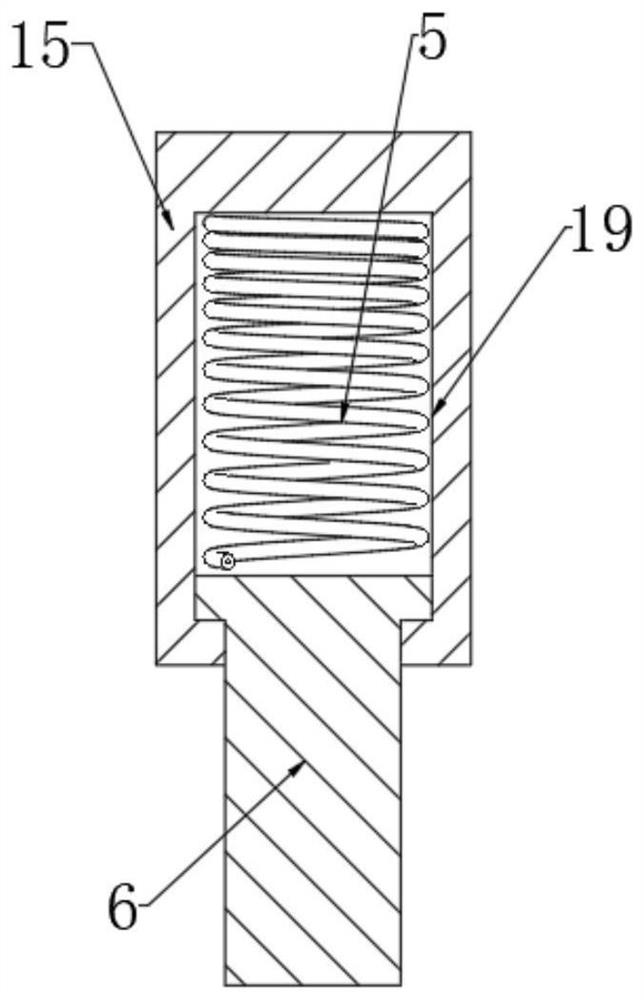

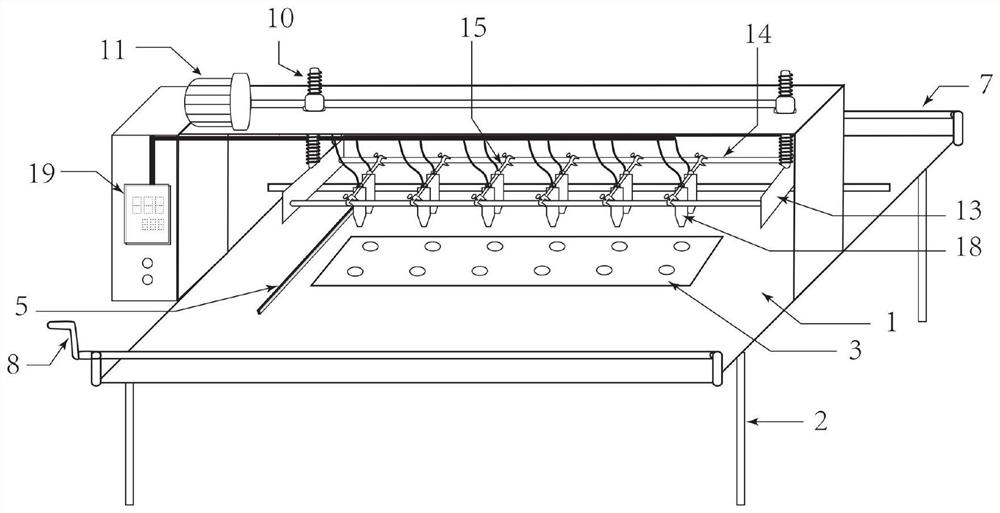

Grass-preventing cloth punching device adapting to seedling growth requirements

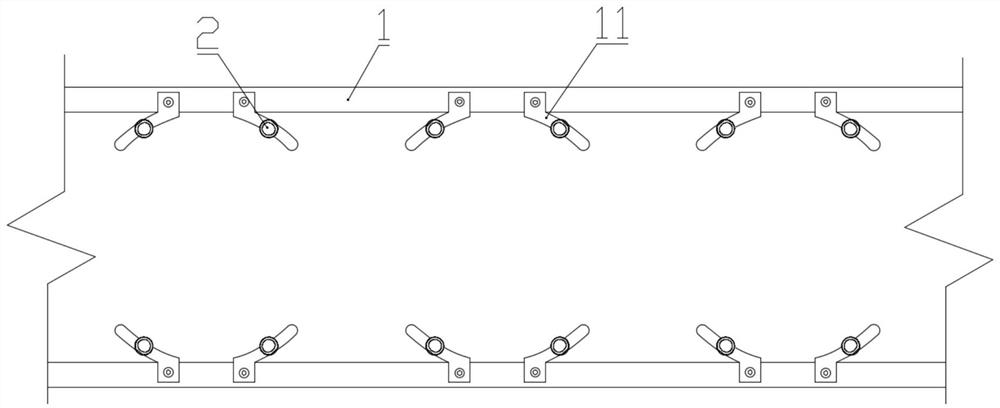

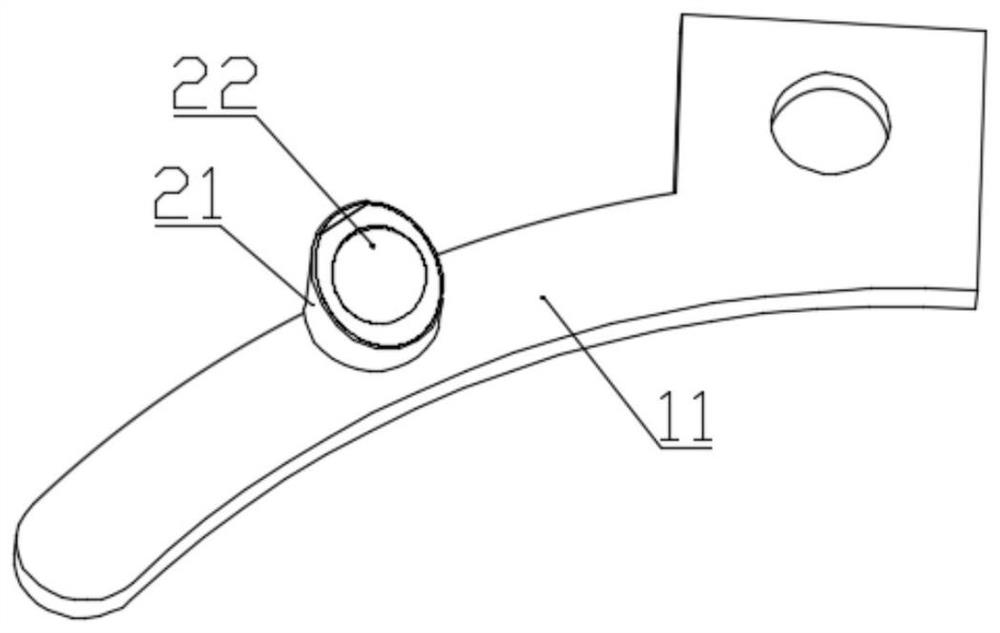

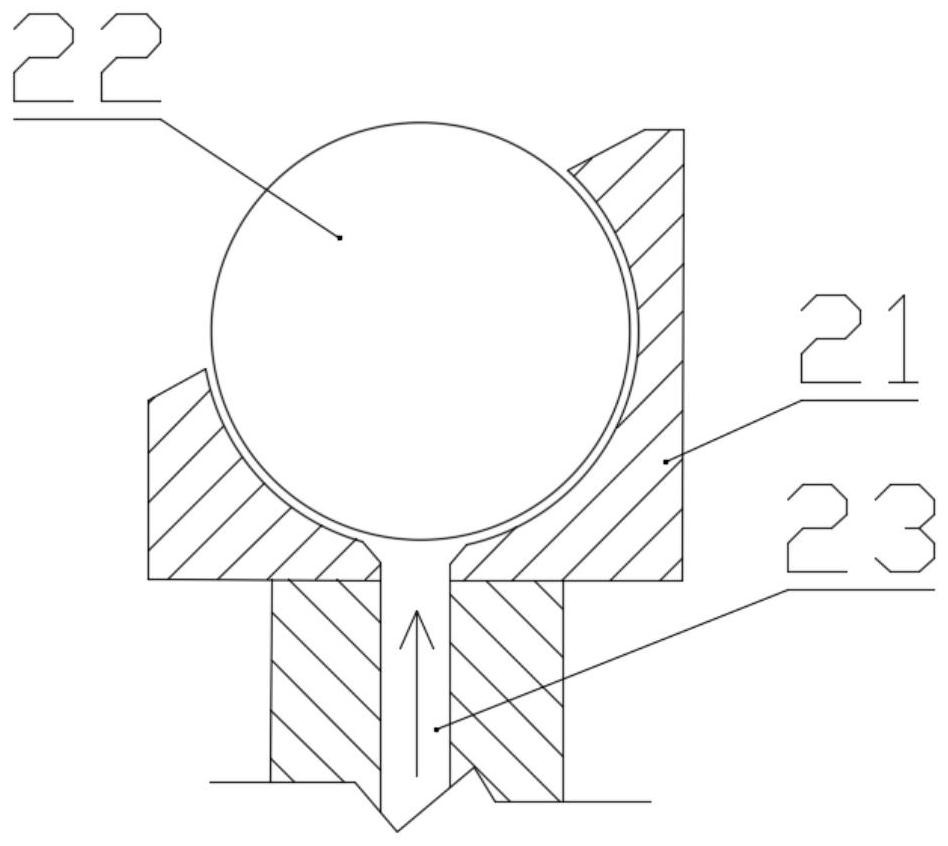

InactiveCN112385460ARealize equidistant adjustmentEasy to usePlant protective coveringsAgricultural engineeringStructural engineering

The invention discloses a grass-preventing cloth punching device adapting to seedling growth requirements. The grass-preventing cloth punching device comprises a supporting plate and a power source, two symmetrically-arranged fixing blocks are fixedly connected to the lower side wall of the supporting plate, two symmetrically-arranged guide rods are fixedly connected to the opposite side walls ofthe two fixing blocks, and the side walls of the guide rods are sleeved with sliding block sets; and each sliding block set comprises two symmetrically-arranged first sliding blocks and a plurality ofsecond sliding blocks arranged in an array manner, lead screws are inserted into the side walls of the sliding block sets, the two ends of the lead screws are rotationally connected with the side walls of the fixing blocks, and one end of each lead screw penetrates through the side wall of the corresponding fixing block and is fixedly connected with a rotary knob. According to the grass-preventing cloth punching device adapting to the seedling growth requirements, the punching distance can be adjusted at equal intervals according to the seedling growth requirements, use is more convenient, applicability is higher, meanwhile, the grass-preventing cloth punching device can adapt to uneven soil ground, and the punching effect is better.

Owner:江西威骏科技股份有限公司

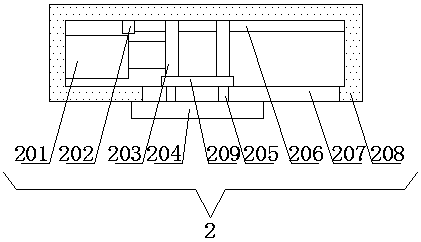

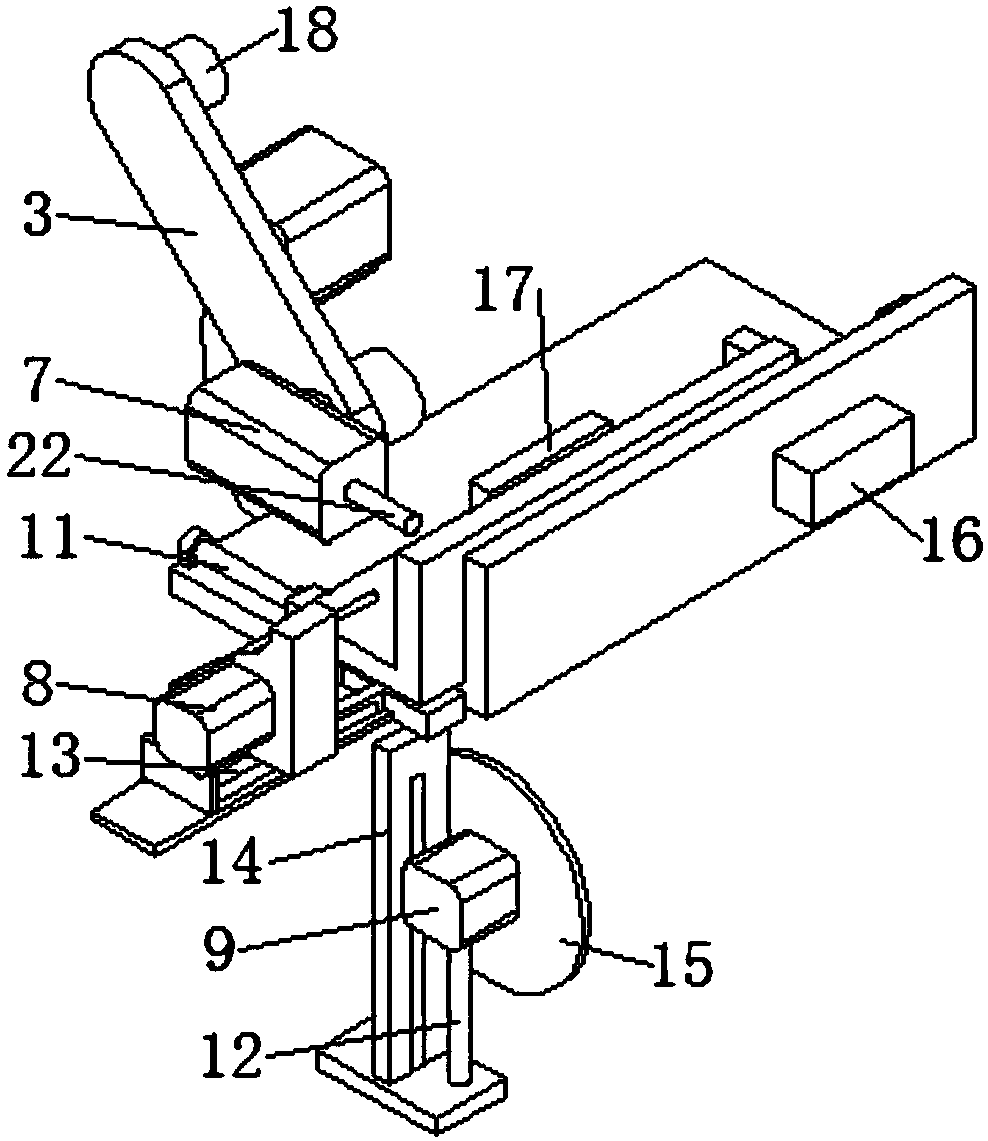

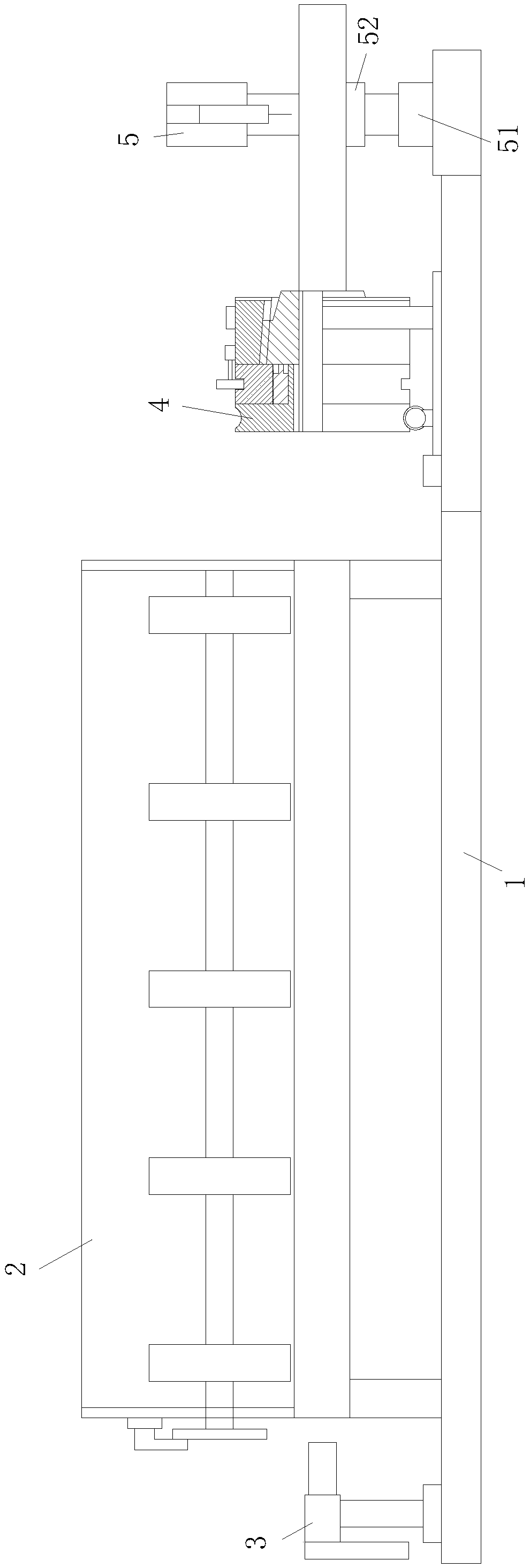

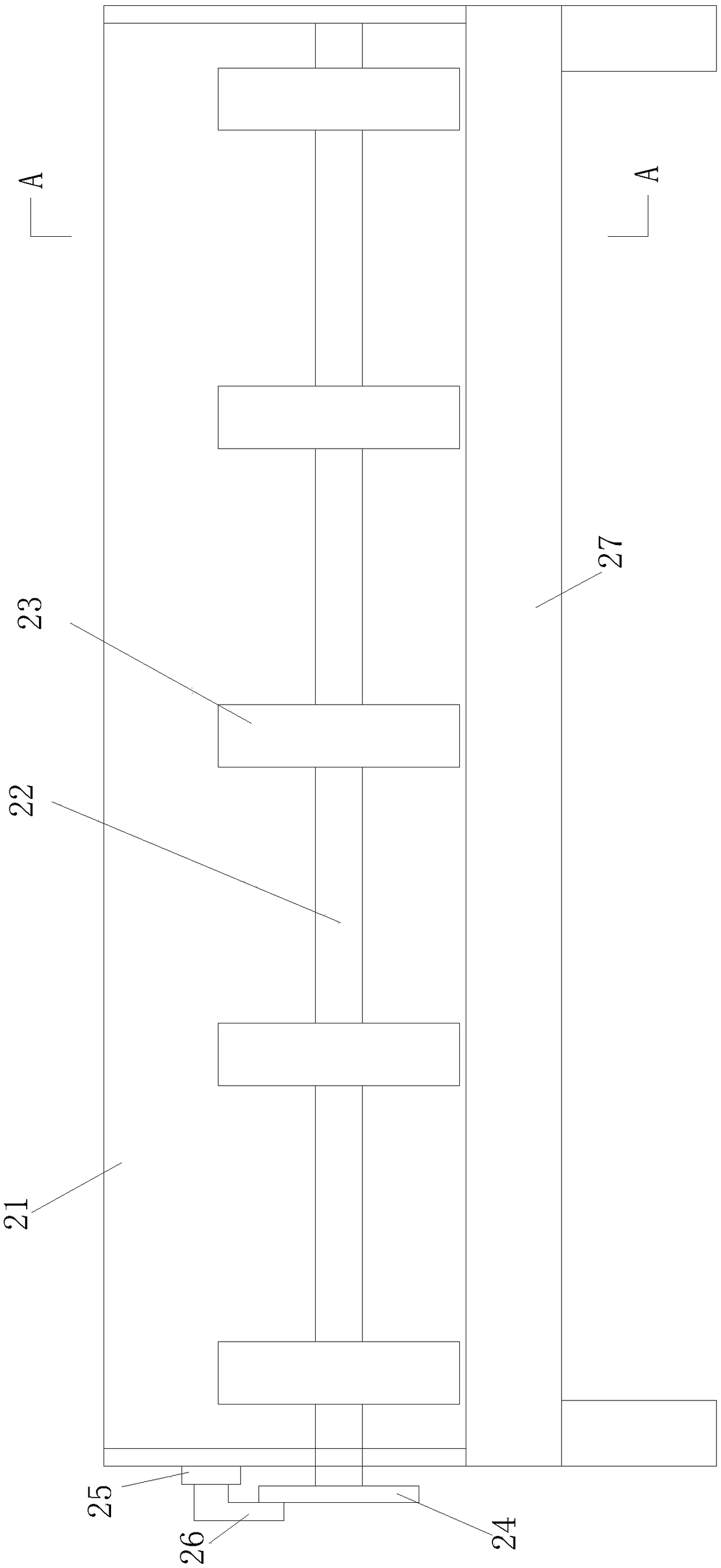

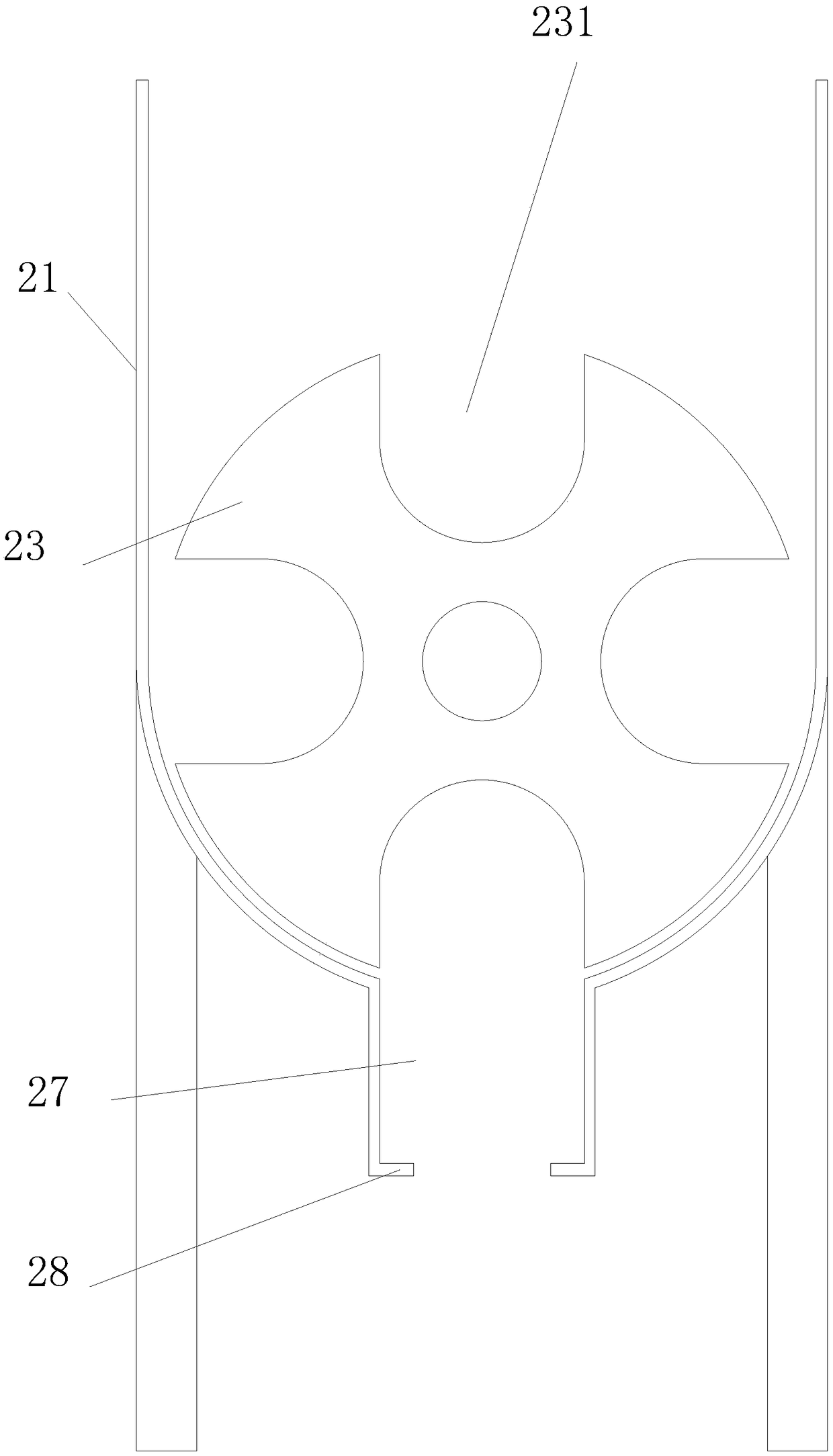

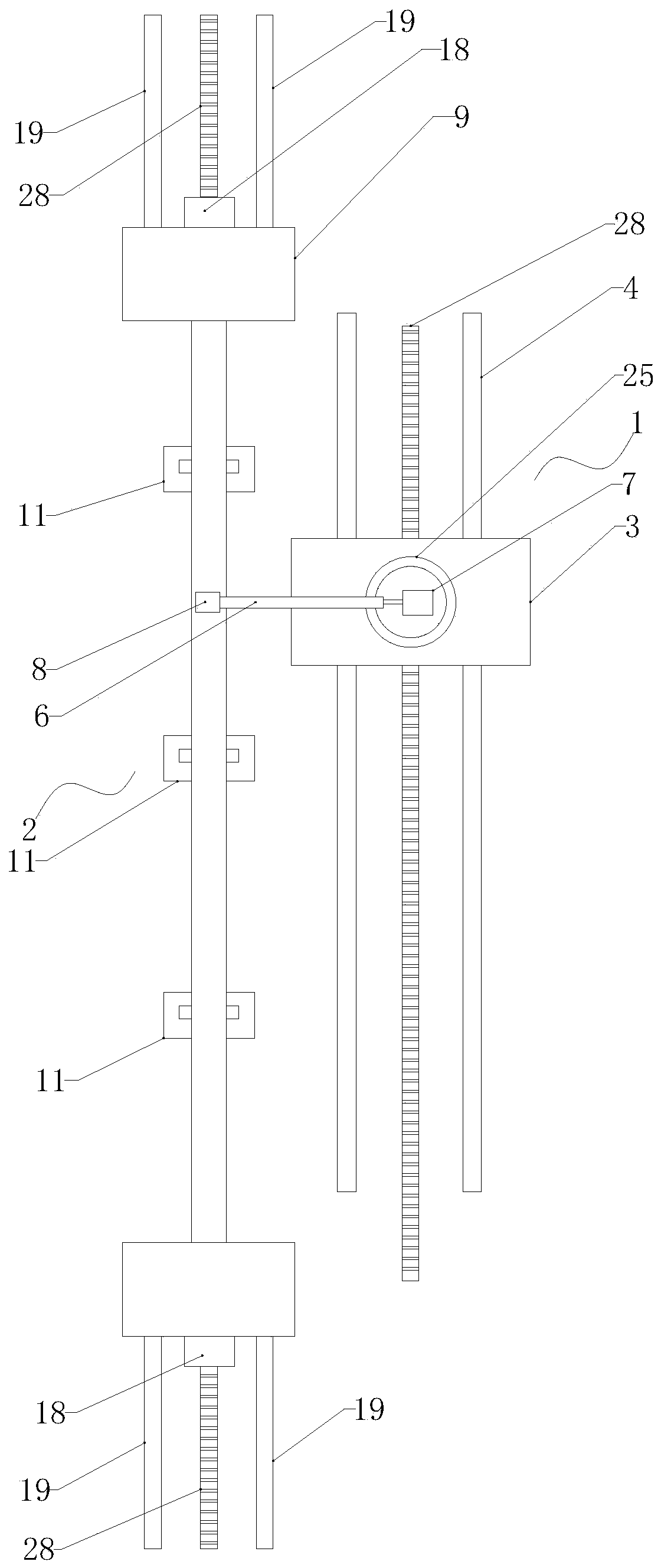

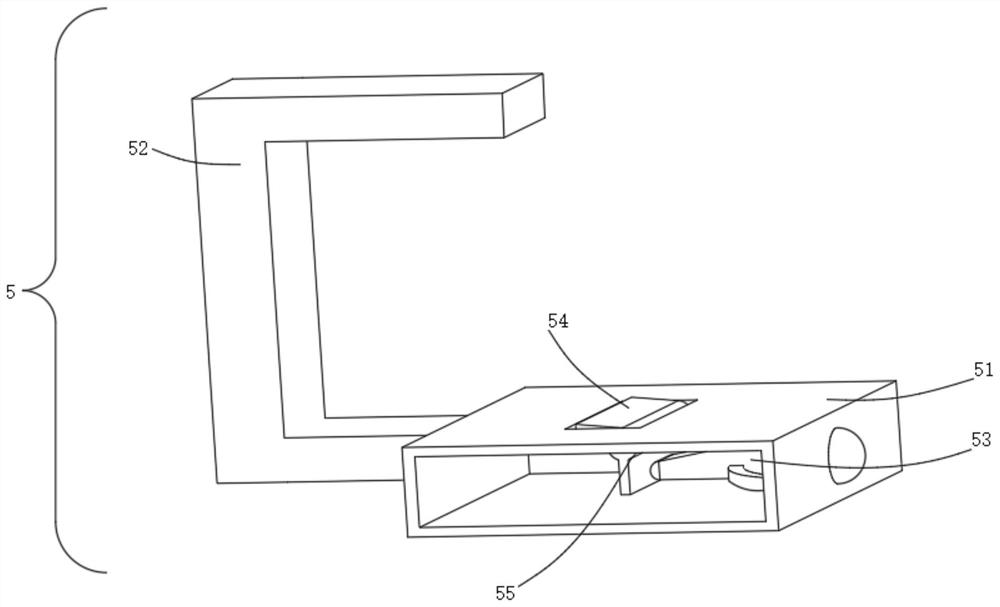

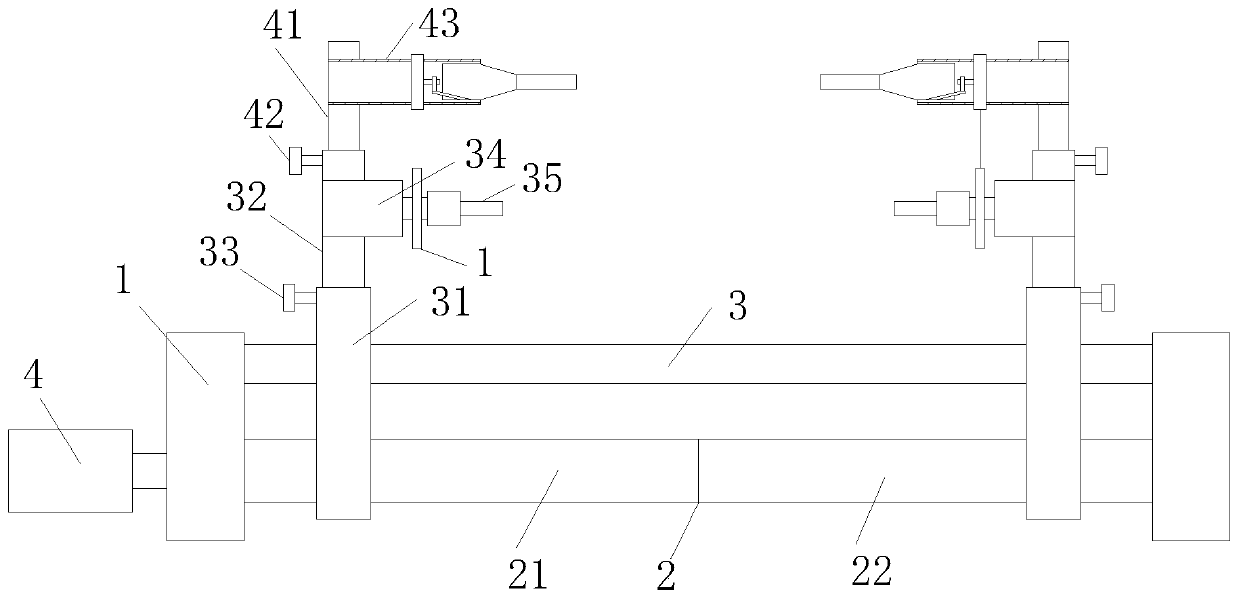

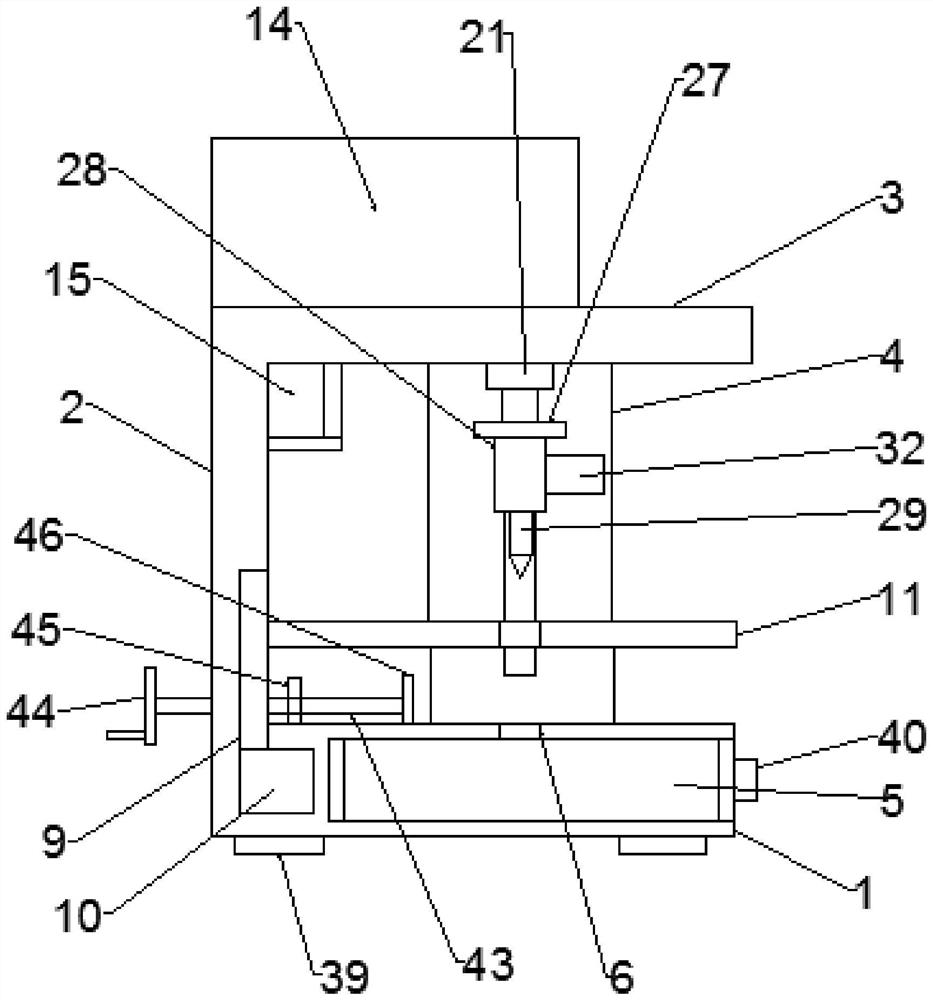

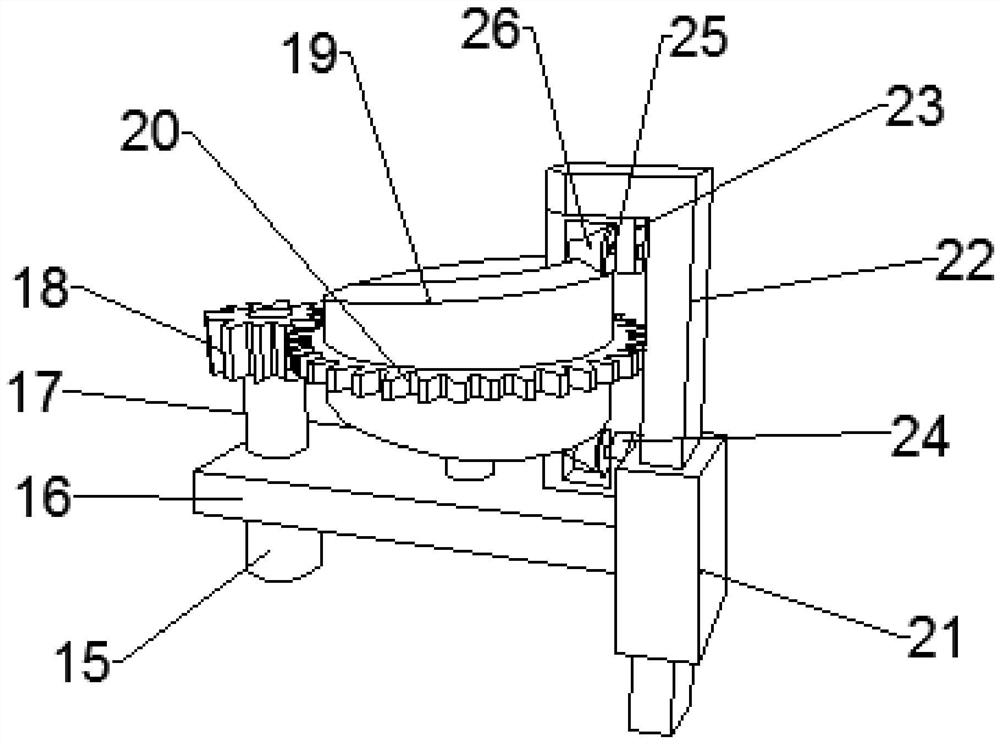

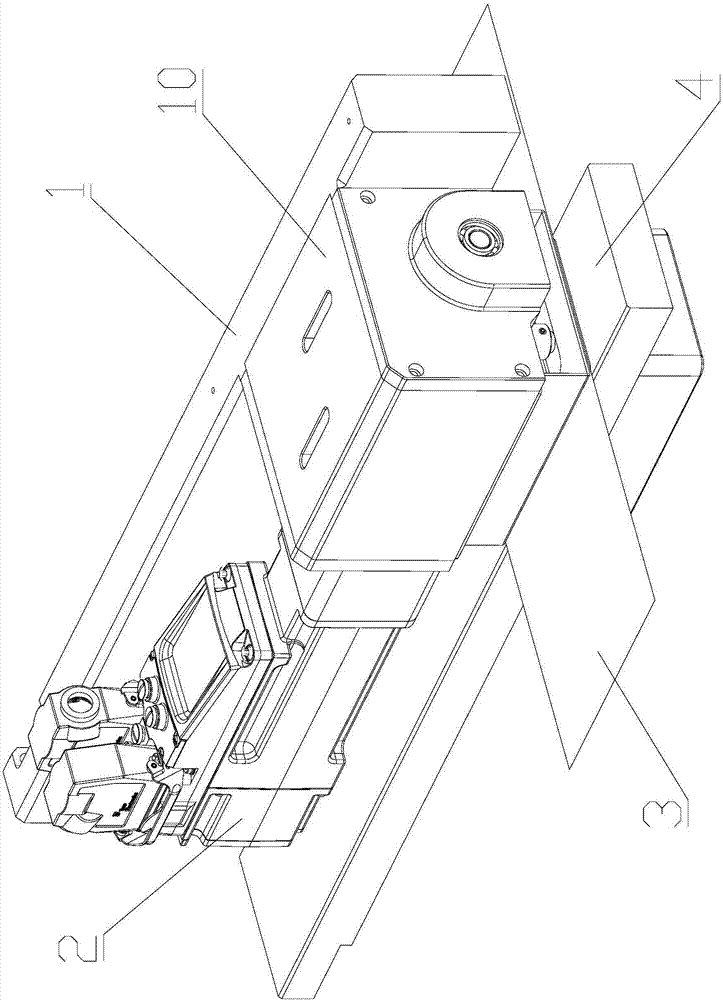

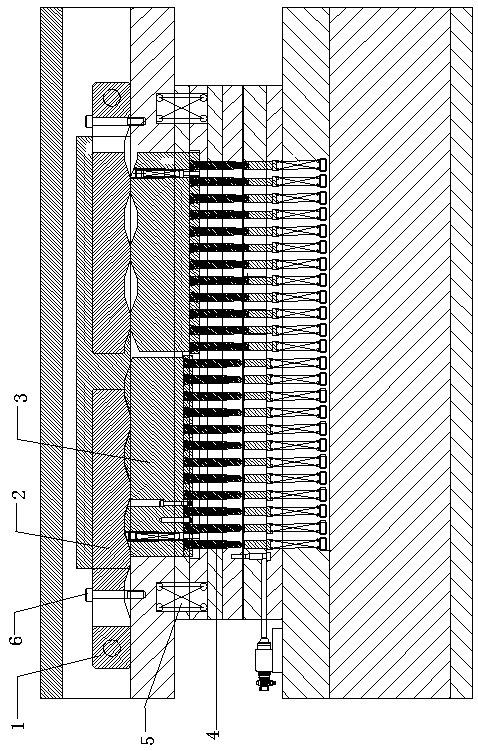

Automatic punching device for pipe rack of double-wheel electric vehicle

InactiveCN109201864ARealize the punching operationPrevent rotationPerforating toolsPunchingElectric vehicle

The invention discloses an automatic punching device for the pipe rack of a double-wheel electric vehicle. The automatic punching device comprises a base; a material discharging assembly is mounted onthe base; a material feeding assembly is installed below the material discharging assembly; the material feeding assembly is mounted on the base through a sliding connection mode; the material feeding assembly and the material discharging assembly are matched with each other; a clamping rotary assembly is mounted to one side of the material discharging assembly; the clamping rotary assembly is mounted on the base through a sliding connection mode; and one side of the clamping rotary assembly, which is far away from the material discharging assembly, is provided with a punching assembly. Withthe automatic punching device for the pipe rack of the double-wheel electric vehicle of the invention adopted, the automatic feeding and automatic rotary punching of the pipe rack are realized; the labor intensity of workers is decreased; production efficiency can be improved; the multi-angle punching operation of the pipe rack is realized; punching precision is ensured; and with worm-gear transmission realized, the pipe rack can be prevented from rotating during punching, and therefore, the stability of punching work is ensured.

Owner:临泉县赛莱斯农用车有限公司

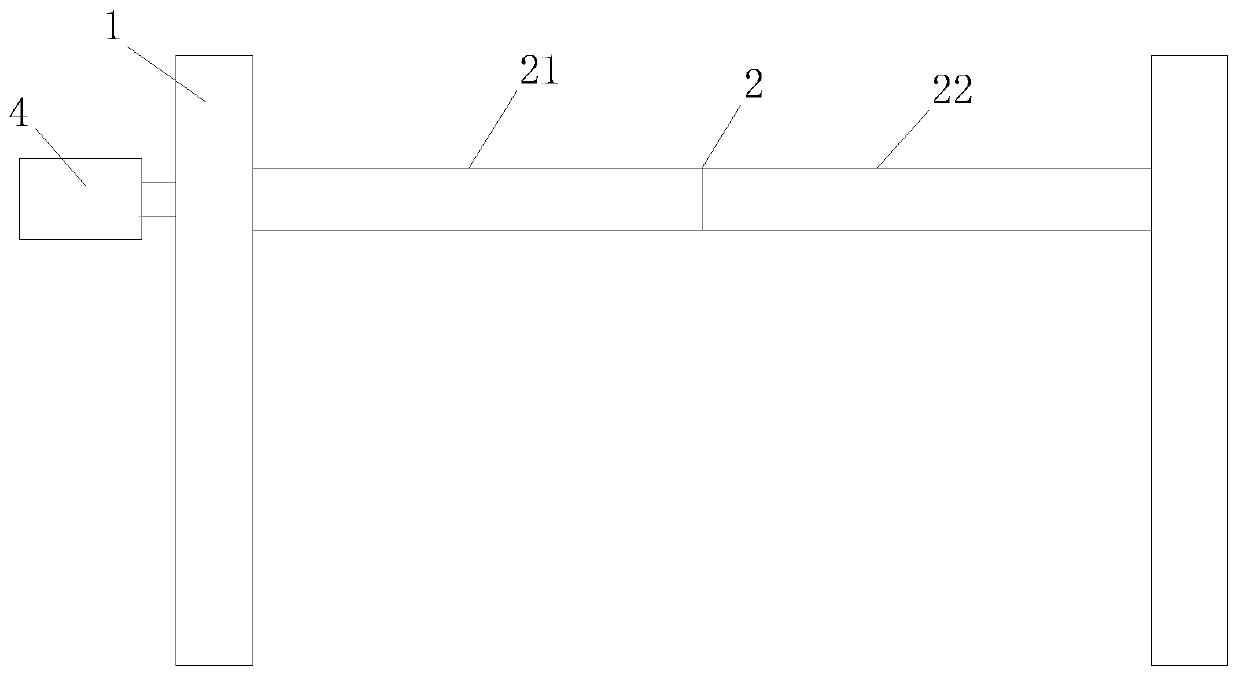

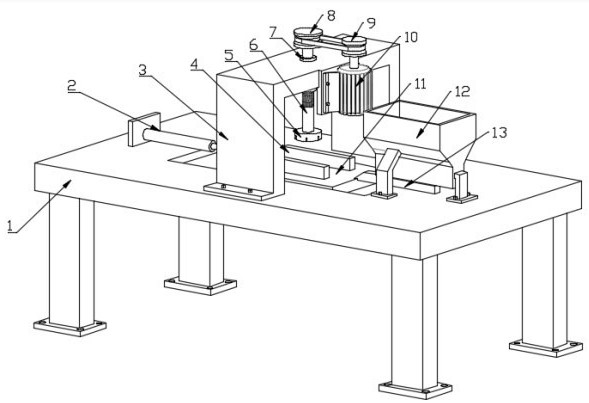

Working station for square pipe cutting

PendingCN110328455ARealize the cutting operationRealize the punching operationLaser beam welding apparatusEngineeringDrive motor

The invention relates to a working station for square pipe cutting. The working station for square pipe cutting comprises a cutting assembly and a laser cutting workpiece clamping assembly, wherein the cutting assembly comprises an installation table, an installation table drive mechanism, a connection arm arranged on the surface of the installation table, a connection arm drive mechanism, and a laser cutting device arranged on the end part of the connection arm, and the laser cutting workpiece clamping assembly comprises two movable tables, a movable table drive mechanism and a plurality of workpiece clamping devices; each workpiece clamping device comprises a base, a supporting plate arranged above the base, a supporting plate lifting device arranged on the surface of the base and provided with an output shaft which is connected with the supporting plate, and clamping plates arranged at the left side and the right side of the surface of the supporting plate; and an opening is formedin one side of each movable table, an overturning disc is arranged on the inner side surface of each movable table, a location groove adaptive to a square pipe is formed in the inner side surface of each overturning disc; and an overturning disc drive motor driving the corresponding overturning disc to rotate is further arranged on each movable table. The working station for square pipe cutting islow in environment pollution, and high in automation degree and working efficiency.

Owner:江苏国电新能源装备有限公司

A deep soil fertilization device

ActiveCN107258184BImprove work efficiencyQuality improvementPlantingFertiliser distributersEngineeringPulley

Owner:GUANGZHOU YAOKAI LANDSCAPE DESIGN CO LTD

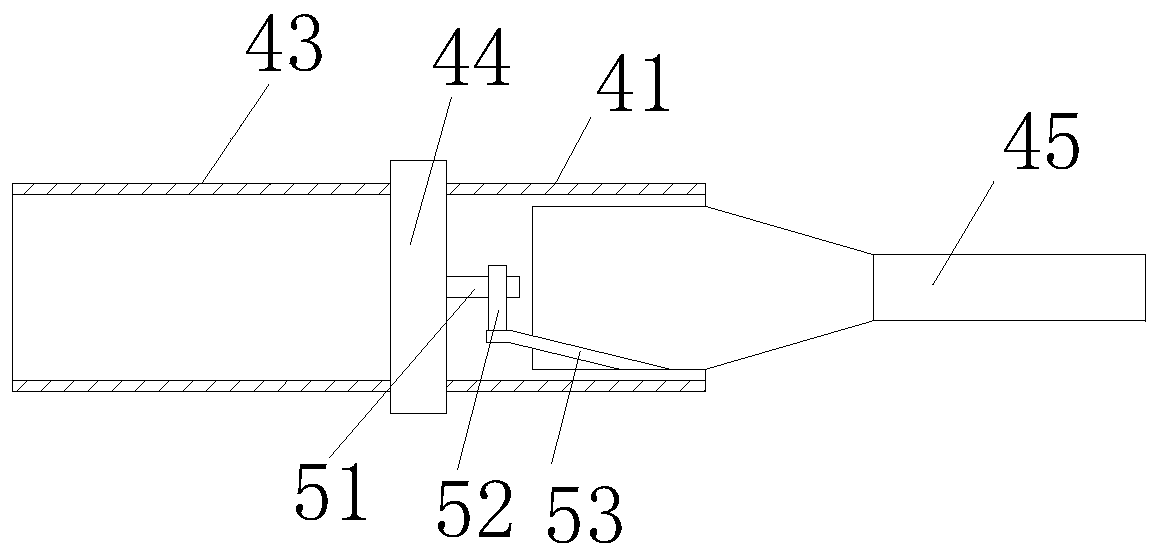

Heating and punching device for gardening ground cloth

PendingCN111645142ARealize the punching operationInhibit growthMetal working apparatusTemperature controlAgricultural science

The invention discloses a heating and punching device for gardening ground cloth. The heating and punching device comprises a workbench, a lifting device, a punching head support, an electric heatingiron mold, an intelligent temperature control system, a feeding roller mechanism and a receiving roller mechanism. Compared with the prior art, the heating and punching device has the advantages thatpunching operation of the gardening ground cloth can be realized, the size and the spacing of holes can be adjusted according to the growth requirements of different crops, the growth of weeds can beeffectively prevented by planting gardening crops in the holes of the breathable and durable gardening ground cloth, the pollution of herbicides to the environment is reduced, and the time and the cost are saved.

Owner:上海正禾农业科技有限公司 +1

Punching die for wood board

InactiveCN114536497ARealize the punching operationAvoid cloggingBark-zones/chip/dust/waste removalWood punching outPunchingStructural engineering

The invention discloses a punching die for a wood board, and relates to the technical field of punching dies. The punching die for the wood board comprises a supporting base, a die base is fixed to the upper surface of the supporting base, an ejection device facilitating ejection of waste is arranged in the die base, a transverse supporting plate is fixed to the side wall of the supporting base, and a punching machine is fixedly embedded in the transverse supporting plate. A cleaning linkage device is arranged at the middle end of the bottom of the transverse supporting plate, and a fixed extrusion device is fixed to the bottom of the transverse supporting plate. According to the punching die for the wooden board, the wooden board is placed on the die base, then the punching block is controlled to move downwards through a punching machine, punching operation on the wooden board is achieved through cooperation with the punching groove, then waste is ejected out of the punching groove through the ejection device, the effect of conveniently taking out the waste is achieved, and therefore the waste is prevented from blocking the punching groove, and the punching efficiency is improved. And therefore, the convenience of secondary punching is improved.

Owner:向旭

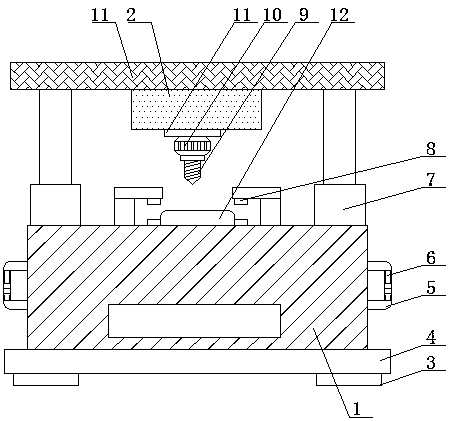

Automobile aluminum part machining die

ActiveCN112122448AImprove work efficiencyGood punching effectShaping toolsPerforating toolsStructural engineeringManufacturing engineering

The invention relates to the technical field of automobile aluminum part machining, and particularly relates to an automobile aluminum part machining die. The automobile aluminum part machining die comprises an upper die mounting base and a lower die mounting base, wherein a strip-shaped open groove is formed in the upper end face of the lower die mounting base; a plurality of lower punching diesare evenly arranged in the strip-shaped open groove and fixedly connected with the lower die mounting base through first fixing assemblies; a plurality of upper punching dies are evenly arranged on the lower end face of the upper die mounting base and correspond to the lower punching dies in position; the upper punching dies are fixedly connected with the upper die mounting base through second fixing assemblies; a conveying assembly is arranged in the strip-shaped open groove; and two limiting assemblies are symmetrically arranged in the lower die mounting base. According to the automobile aluminum part machining die, continuous conveying and punching operation can be conducted, punching and conveying actions do not interfere with each other, meanwhile, the automobile aluminum part machining die can adapt to automobile strip-shaped aluminum parts of different dimensions, and the punching effect is guaranteed through the hot punching technology during punching.

Owner:湖南湖大三佳车辆技术装备有限公司

Drilling device for tree drip infusion

InactiveCN111557180ARealize the punching operationSuitable for drilling operationsHorticulture methodsInfusion techniqueElectric machinery

The invention discloses a drilling device for tree drip infusion, and relates to the technical field of plant infusion. The drilling device comprises two stand columns, a screw rod, a sliding rail, afirst motor and two groups of drilling parts which are symmetrically arranged, wherein the screw rod is rotatably connected between the two stand columns; the screw rod has a first threaded section and a second threaded section; the thread screwing directions of the first thread section and the second thread section are opposite; the sliding rail is fixedly connected between the two stand columns;the first motor is in power connection with the screw rod; and each drilling part comprises a first support, a second support, a first fastener, a second motor and a drill bit, wherein the first support is in threaded connection with the screw rod and is in sliding connection with the sliding rail, the second support is movably arranged in the first support in a sleeving mode, the first fasteneris in threaded connection with the first support, the second motor is arranged on the second support, and the drill bit is in power connection with the second motor. By virtue of the drilling device,two holes can be automatically drilled at the same time, and compared with the prior art, the working efficiency is improved.

Owner:安徽匠桥财务咨询服务有限公司

Punching device suitable for polyester filament fabric and application method thereof

InactiveCN110625684AReduce manufacturing costSimple structureMetal working apparatusPolyesterDrive motor

The invention discloses a punching device suitable for a polyester filament fabric, and relates to the technical field of textile processing. The punching device comprises a workbench, a feeding mechanism and a punching mechanism, wherein the feeding mechanism comprises a feeding wheel rotationally arranged on the workbench and a driving device for driving the feeding wheel to rotate; the drivingdevice comprises a driving motor; the punching mechanism comprises a rotating shaft rotationally arranged above the workbench, a cam coaxially and fixedly arranged on the rotating shaft and a drill bit driven by the cam and reciprocating in the vertical direction; the feeding wheel is in transmission connection with the rotating shaft through a transmission belt. The invention further provides anapplication method of the punching device suitable for the polyester filament fabric. The driving motor can provide power for feeding and punching at the same time, so that the production cost is reduced, the structure of the punching device is simpler, and maintenance and overhaul are easy.

Owner:JIANGSU JINDA TEXTILE IND

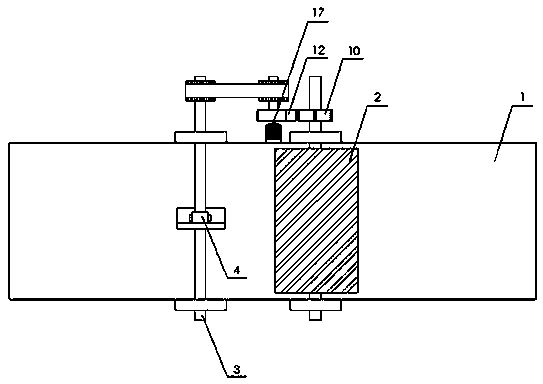

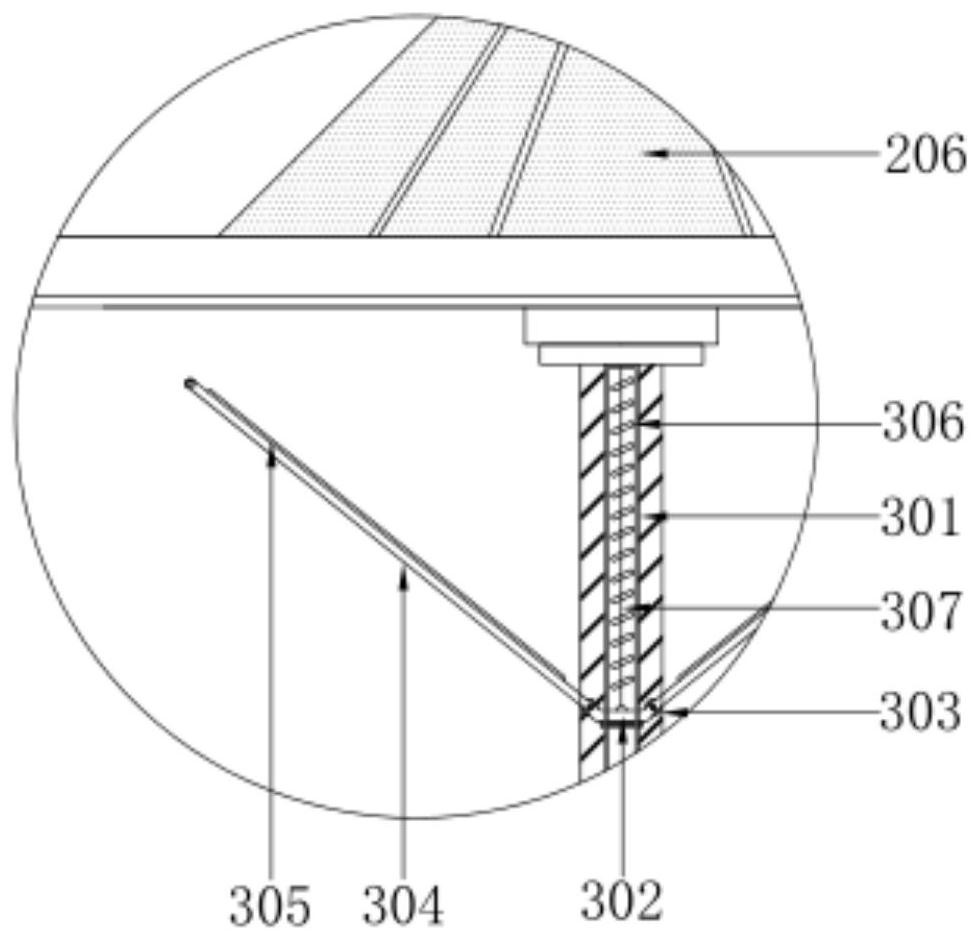

Inner cavity inclined hole punching anti-cracking machining equipment for water meter machining

The invention discloses inner cavity inclined hole punching anti-cracking machining equipment for water meter machining in the technical field of water meter machining, and the inner cavity inclined hole punching anti-cracking machining equipment comprises a water meter body, an upper hot pressing assembly comprising a stamping rod with a bottom end fixedly connected with a guide column, a lower hot-pressing punching assembly comprising a fixed shaft fixedly inserted into the inner cavity of a punching rod, and a ring cutting assembly arranged on the periphery of the joint of the upper hot-pressing assembly and the lower hot-pressing punching assembly. Through the punching rod and a through hole advancely arranged in the to-be-punched part of the water meter body, insertion is achieved, so that a rotating rod rotates outwards until an electric heating pipe on the rotating rod abuts against the inner wall of the water meter body, the plastic body of the to-be-punched part of the water meter body is softened through heat transfer, and an induction signal is triggered; and a movable base block is driven to drive an arc-shaped cutter to perform ring cutting operation along the periphery of the heating part on the water meter body, so that the problem of product scrapping caused by cracking of the punching part of the easily-broken water meter body is avoided, the punching operation is quickly and efficiently realized, and the processing efficiency is improved.

Owner:王许仙

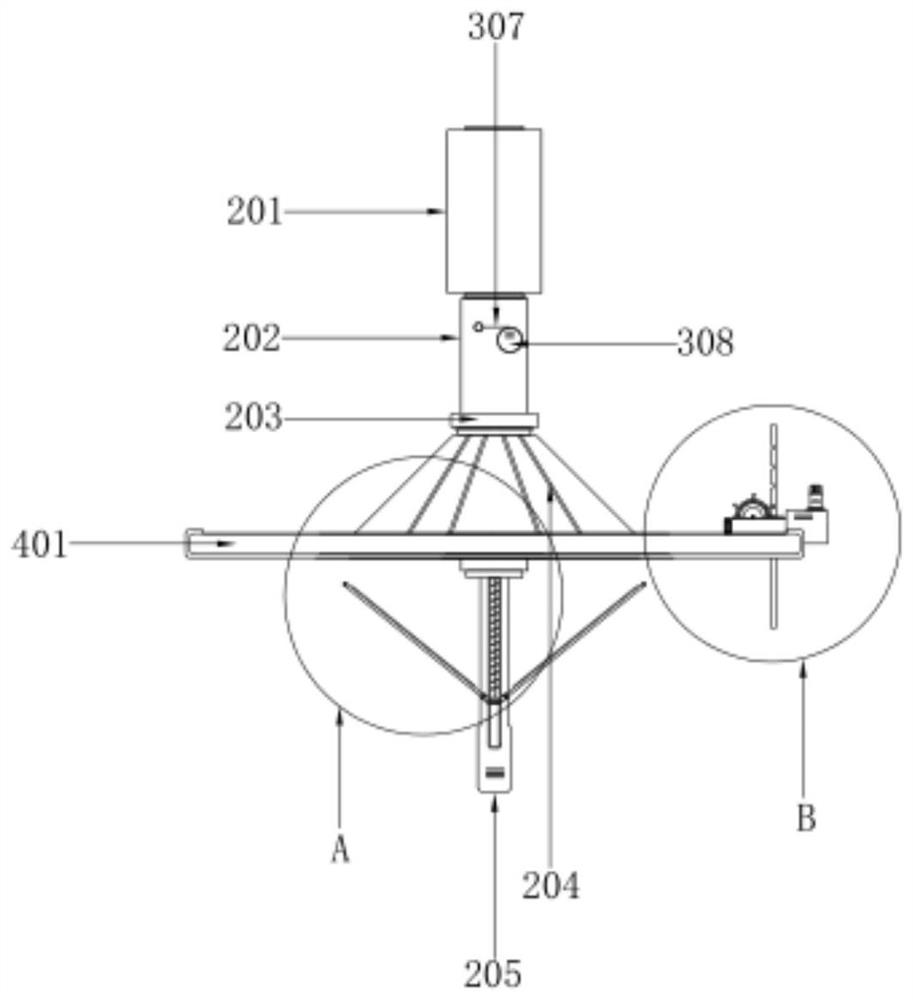

A processing tool for metal sealing gasket

ActiveCN114054591BSolve the waste of manpowerRealize the punching operationShaping toolsPerforating toolsProcess engineeringConveyor belt

The invention discloses a processing tool for a metal sealing gasket, which comprises a stamping cavity, a mold cavity, a receiving box, a workbench, and a stamping mechanism, a feeding mechanism and a clamping mechanism. The cavity is composed of a top plate and four brackets on the workbench. The stamping mechanism is located on the top plate. The bottom surface of the workbench is connected to the mold cavity. Control boxes are arranged on the left and right sides of the mold cavity, and mold grooves are arranged in the mold cavity. And the upper part of the mold groove is not covered by a workbench, and a feeding mechanism and a clamping mechanism are also provided on the workbench and in the mold cavity, and a receiving box is located below the mold cavity, and the receiving box is connected to a waste box, and the waste box is provided with a A conveyor belt, an outlet is provided at the interface between the conveyor belt and the waste box, and universal wheels are connected to the bottom surface of the waste box. The invention can realize automatic feeding of metal plates, stamping processing of sealing gaskets, automatic ejection and retrieving of materials, and automatic discharge of waste materials, which saves manpower and improves processing efficiency at the same time.

Owner:烟台长鑫密封产品有限公司

Perforating device for binding financial materials

InactiveCN112757384AEasy to punchEvenly punchedMetal working apparatusStructural engineeringControl switch

The invention discloses a perforating device for binding financial materials. The perforating device comprises a supporting seat, a supporting plate is arranged at one end of the supporting seat, the supporting plate and the supporting seat are fixedly connected through welding, a top plate is arranged at the upper end of the supporting plate, a control box is arranged in the middle of one side of one side plate, and a plurality of control switch keys are arranged on the control box; an adjusting device is arranged in a containing groove, a rolling device matched with an inclined wheel is arranged at the side, located in a fixed box body, of a lifting rod, a clamping device connected with a clamping hole in a matched manner is arranged in the middle of one side of a mounting sleeve, and the clamping device comprises a fixed frame located at one side of the mounting sleeve; and a pulling block is arranged at the end, away from the mounting sleeve, of the fixed frame, and a spring is arranged at the position, located between a fixed ring and one end of the inner wall of the mounting sleeve, of a clamping pin. The perforating device has the beneficial effects that punching operation on the financial materials is achieved, uniform and tidy perforating on the financial materials is also achieved, dislocation is avoided, the structure is simple, and operation is convenient.

Owner:重庆丹含科技有限公司

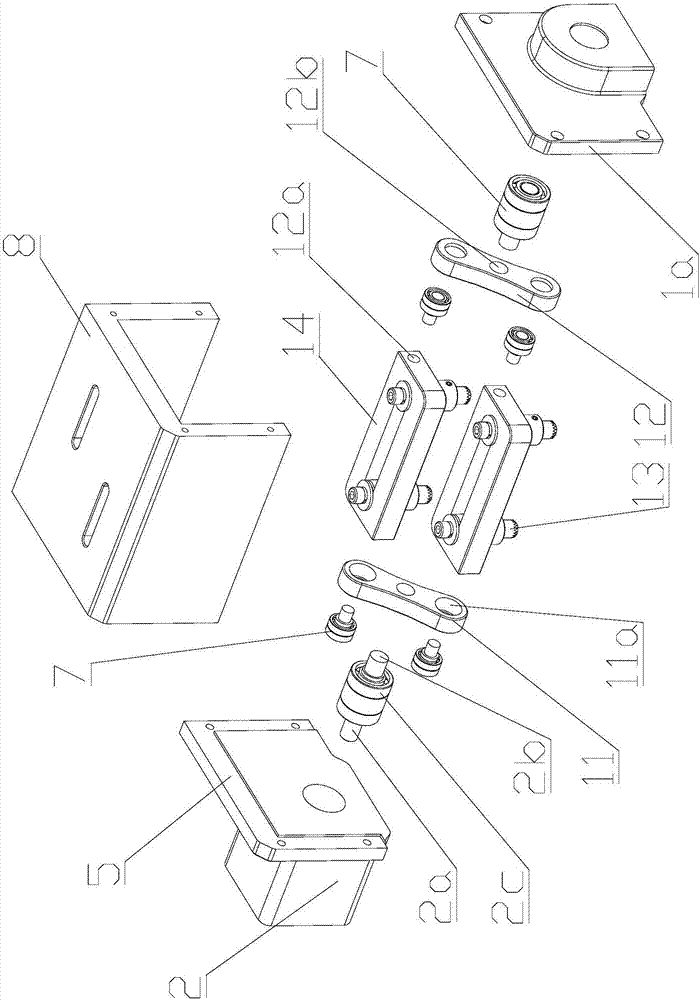

Die structure capable of automatically centering and laterally stamping inner hole of casting

PendingCN113351740ARealize the punching operationAdjustable structure positionPerforating toolsMetal working apparatusPunchingStructural engineering

The invention relates to a die structure capable of automatically centering and laterally stamping an inner hole of a casting, which comprises an oil cylinder and an oil cylinder joint; the end part of the oil cylinder is fixedly connected with an oil cylinder flange through a screw, and the end part of the oil cylinder flange is provided with an oil cylinder fixing seat; a rear-position sensor fixing seat and a front-position sensor fixing seat are fixed to one side wall of the upper end of the oil cylinder fixing seat; a rear-position sensor is arranged at the upper end of the rear-position sensor fixing seat; and a front-position sensor is installed at the upper end of the front-position sensor fixing seat. The die structure capable of automatically centering and laterally stamping the inner hole of the casting provided by the invention has the beneficial effects that through movement of a punch fixing block and a punching punch, the structure positions of the punching punch and a punching part at the front end of the punching punch can be adjusted, an arc-shaped notch is arranged at the middle of the upper end wall of a floating joint, a movable spring plunger is clamped into the arc-shaped notch arranged at the middle of the upper end wall of the floating joint, and freedom degree limiting operation is conducted on the floating joint.

Owner:灏昕汽车零部件制造无锡有限公司

A continuous punching mechanism

ActiveCN105729566BSimple structureRealize the punching operationMetal working apparatusPunchingReciprocating motion

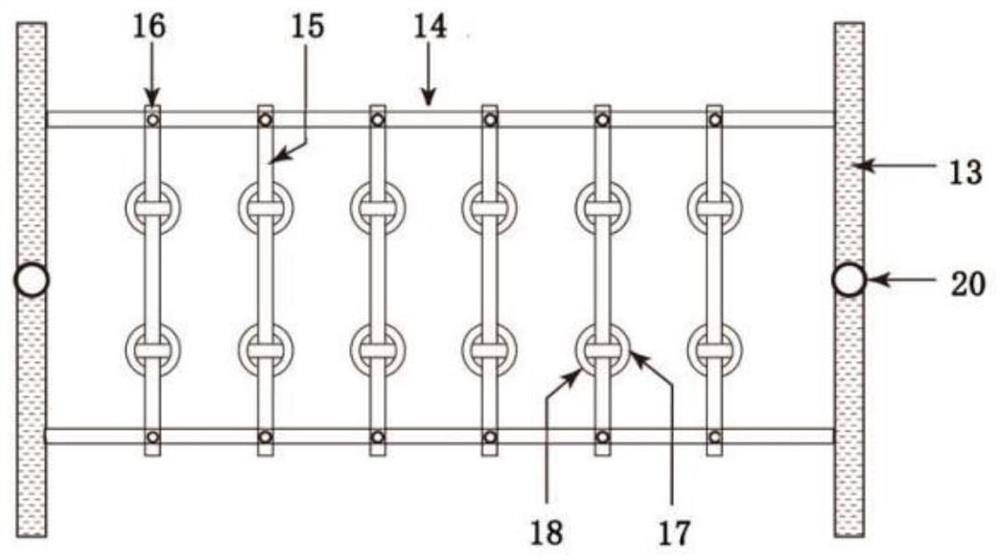

The invention relates to a continuous punching mechanism which comprises a rack, a driving device, inner connecting rods, outer connecting rods, punches and punch mounting seat plates. A power output shaft of the driving device is connected with one end of each inner connecting rod and drives the inner connecting rods to rotate; the other ends of the inner connecting rods are hinged to the inner side faces of the corresponding punch mounting seat plates. One end of each outer connecting rod is hinged to the rack, and the other end of each outer connecting rod is hinged to the outer side face of the corresponding punch mounting seat plate. The driving device drives the punch mounting seat plates to rotate up and down circularly through the inner connecting rods. The continuous punching mechanism is simple in structure, the punches continuously rotate in the same direction, a packaging bag film synchronously and horizontally moves, and punching is achieved in the moving process of the punches and the packaging bag film; the punching action is continuous without intermittence, so that production efficiency is improved; meanwhile, due to the fact that the reciprocating moving mode is not adopted as the moving mode of the punching mechanism any more, vibration and noise of overall equipment are effectively lowered, and higher-speed punching is possible.

Owner:LANGRUI PACKAGING TECH CANGZHOU CO LTD

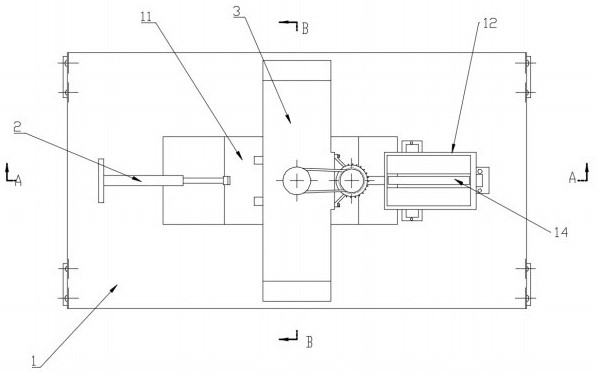

Continuous die for production of condenser side plate

The invention provides a continuous die for the production of a condenser side plate. A quick changing mechanism is arranged between an upper die body and a lower die body, and the quick changing mechanism includes a quick changing handle, a quick changing drawing strip, a quick changing punch pad plate and a quick changing punch. The quick change punch pad plate is installed at the bottom of theupper die body through a reset part, and quick change protrusions are uniformly and upwards arranged on the upper surface of the quick changing punch pad plate. The quick changing handle is installedon the upper die body in a matched mode. The quick changing drawing strip and the quick changing handle are installed in a matched mode, the position of the quick changing drawing strip corresponds tothe quick changing punch pad plate, and quick changing grooves matched with the quick changing protrusions are uniformly and inwards formed in the bottom surface of the quick changing drawing strip.The quick changing punch is installed on the quick changing punch pad plate in a matched mode. The continuous die for the production of the condenser side plate is novel in structure, adjustment and replacement of the quick changing punch are achieved quickly and effectively, the punching operation of condenser side plates of different models under the same set of die is achieved, and the continuous die for the production of the condenser side plate can be used for the production of different models and multiple similar products; and the research and development costs can be greatly reduced, machine equipment is saved, and the production cost is reduced.

Owner:滁州市艾德模具设备有限公司

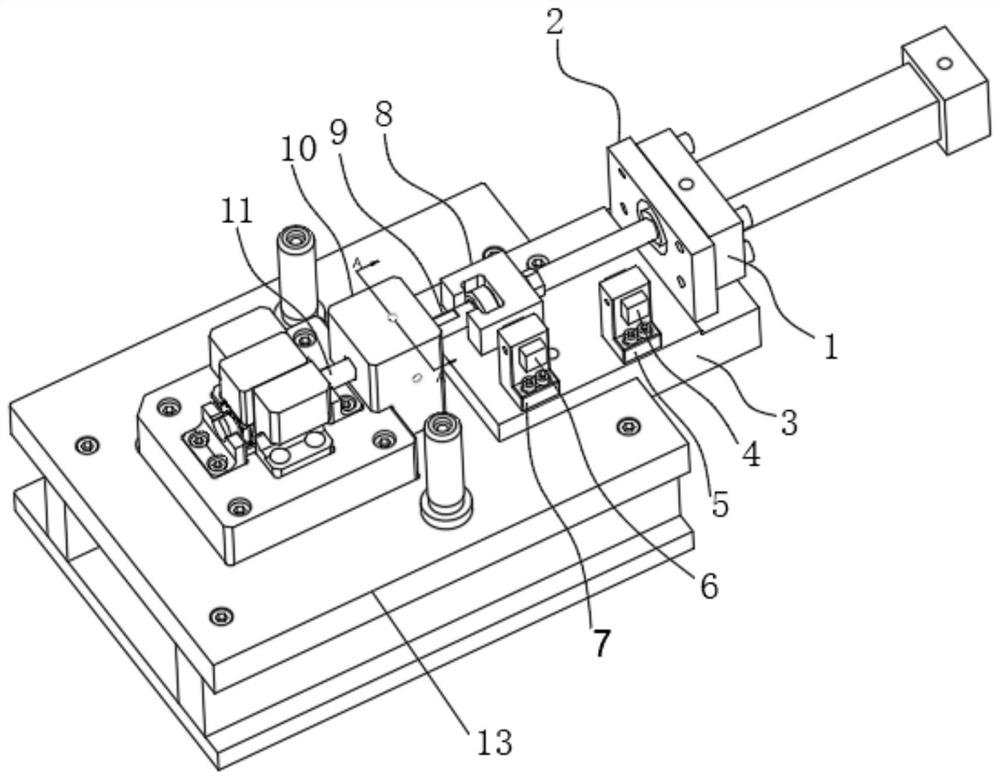

Drilling device and method for metal doors and windows

ActiveCN114570980ARealize linkage operationRealize the punching operationAutomatic control devicesMeasurement/indication equipmentsDistance sensorsWorkbench

The invention relates to the technical field of door and window machining, and discloses a drilling device and method for metal doors and windows, and the drilling device for the metal doors and windows comprises a sliding table which is slidably arranged on the upper surface of a workbench. The push-pull piece is installed on the workbench. The two clamping rods are oppositely located on the sliding table in a sliding mode. And the drilling pressing piece is mounted on the workbench. The first pressure sensor is used for sensing the pressure of the lifting rod. The second pressure sensor is used for sensing the clamping force of the clamping rod. The distance sensor is used for sensing the end distance of the window lattice rod. The controller is used for controlling the push-pull piece to push the sliding table to enter the placing station, and the window lattice rod falls on the sliding table; the push-pull piece pulls the sliding table to move towards the machining station, the clamping rods are driven by the transmission structure to be close to each other, and the clamping rods are close to clamp the window lattice rod; and quantitative drilling and moving are carried out. Window lattice rods are clamped and pushed in a linkage mode, and fixed-position punching operation is achieved through pressure and size control.

Owner:徐州科美瑞门窗科技有限公司

Simple delayed stripping mechanism

PendingCN113857330AFacilitates fast punching operationsAvoid jacking into the material beltEjection devicesStructural engineeringMechanical engineering

Owner:苏州正盛科技有限公司

Automatic processing equipment for intercooler

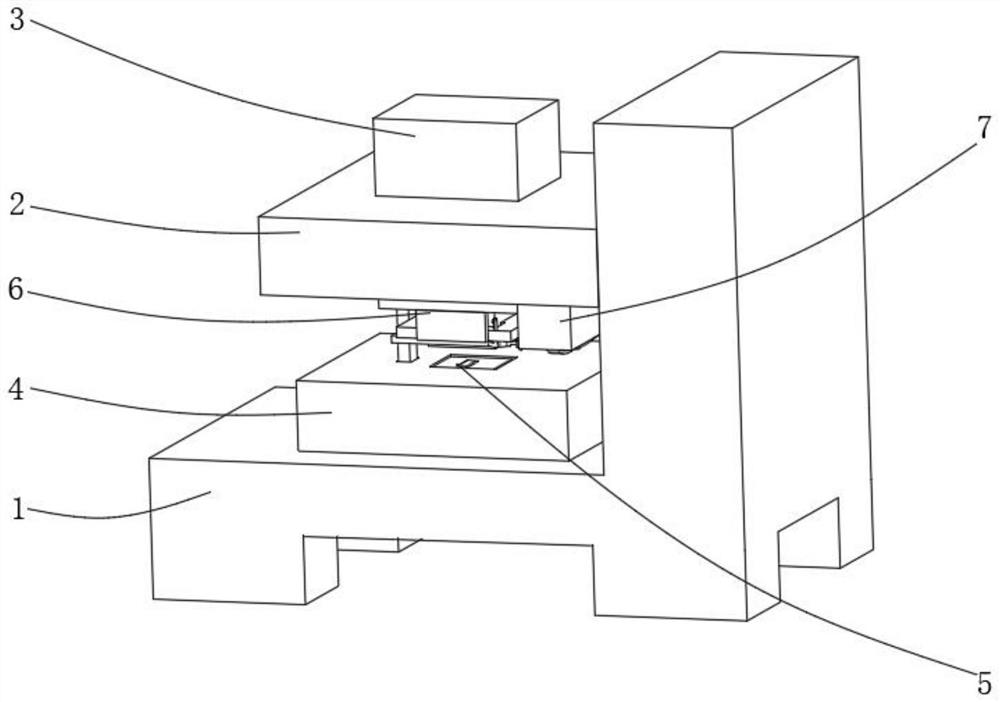

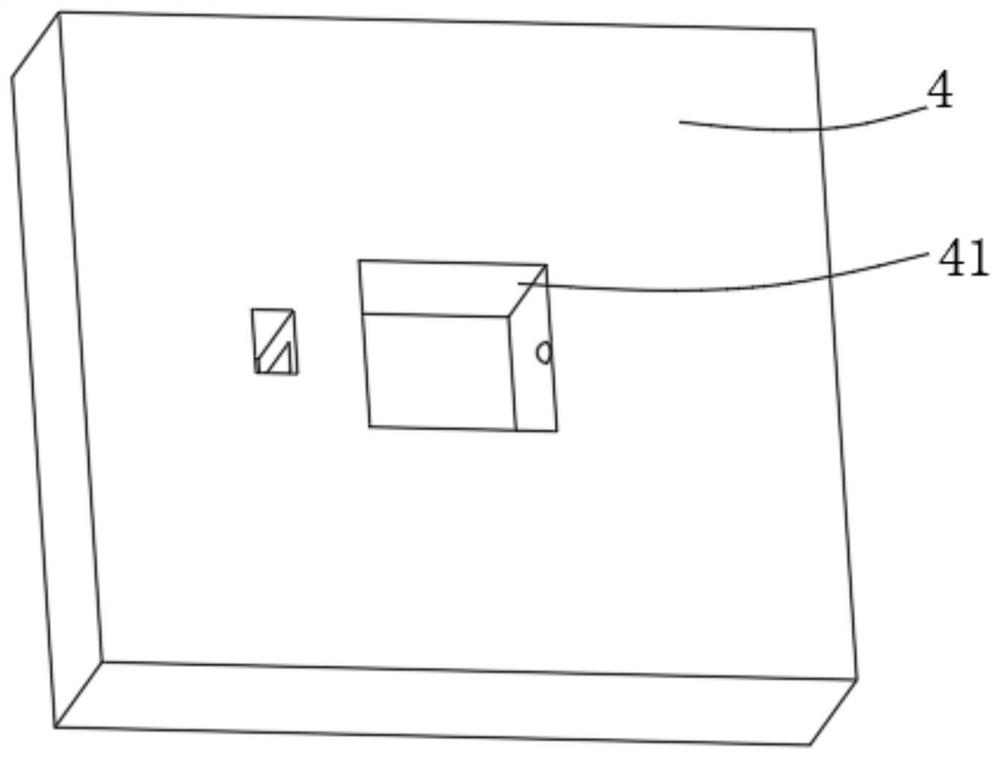

InactiveCN113102795APrevent stackingGuaranteed cleanlinessFeeding apparatusMetal working apparatusRatchetPunching

The invention relates to the technical field of automobile intercooler machining, and particularly discloses automatic processing equipment for an intercooler. The equipment comprises a punching machine, the punching machine comprises a machine body, a punching mechanism is arranged at the top of the machine body, a collecting groove is formed in the position, under the punching mechanism, of the machine body, a cavity is formed in the machine body, and the cavity communicates with the collecting groove. The cavity communicates with the outside, a conveying belt is arranged in the cavity, and a rotating shaft of the conveying belt is coaxially and fixedly connected with a ratchet wheel. A connecting rod is fixed to the free end of the punching mechanism, and ratchets matched with the ratchet wheel are arranged at the bottom end of the connecting rod. In the process that the connecting rod moves to the bottommost end from the initial position, the ratchets can make contact with the ratchet wheel. The invention aims to provide the automatic processing equipment for the intercooler so as to solve the technical problem that chippings generated by punching in the intercooler are inconvenient to clean.

Owner:CHONGQING WANSI METAL SPECIAL TYPE FORMING

Selective punching device

InactiveCN108906975ARealize the punching operationImprove drilling accuracyMetal working apparatusPunchingComputer module

The invention discloses a selective punching device comprising a selective punch module and a driving module for powering the selective punch module. The selective punch module includes punches and anadjusting plate, the punches move up and down and abut to punch a steel belt, the number of the punches is a lot, the adjusting plate can move in a front-rear direction and adjust the stamping intensity of at least one punch, the upper side of each punch is provided with a cavity, the adjusting plate can move in the horizontal direction and fills the cavity, the up-and-down depth of the cavity isgreater than the movement distance of the punch, and the driving module includes a driving source capable of providing power and a moving end outputting power outwards to make punched holes move up and down. The selective punching device can selectively punch holes and is high in precision, compact in structure and wide in application range.

Owner:苏州市翔耀精密自动化设备有限公司

Deep soil fertilization apparatus

InactiveCN107690883AImprove work efficiencyImprove yield and qualityPlantingFertiliser distributersFertilizerGastric tube feeding

The invention discloses a deep soil fertilization device, which comprises a mobile vehicle body and a material storage box arranged on the top of the mobile vehicle body. into the funnel chamber of the moving car body, the storage box on the right side of the storage chamber is provided with a transmission chamber, the transmission chamber is provided with a first cone wheel, and the left end of the first cone wheel is fixed with a stirring shaft extending to the left. Shaft, the extension section on the left side of the stirring shaft runs through the inner wall of the storage box between the transmission chamber and the storage chamber and is connected by rotation. Connection, the bottom of the funnel cavity is connected with the first sliding groove extending to the left and right sides, the mobile car body below the first sliding groove is provided with a lifting sliding chamber, and the mobile car body on the left side of the lifting sliding chamber is provided with an upper and lower sliding groove. The feeding pipe is extended; the invention has simple structure and convenient operation, can prevent fertilizer accumulation from causing blockage, and improves the utilization rate of fertilizer.

Owner:方倩

Manufacturing process of glass pot cover

InactiveCN112720870ARealize automatic guidanceRealize the punching operationEdge grinding machinesLiquid surface applicatorsGlass fiberPunching

The invention discloses a manufacturing process of a glass pot cover. The manufacturing process sequentially comprises a flattening and punching procedure, an edge polishing procedure and an edge covering strip extruding procedure. Automatic guide and fixation of the glass fiber reinforced plastic pot cover, automatic machining of a center hole, edge grinding and edge covering strip extrusion can be sequentially achieved. A supporting ball assembly and a punching assembly can achieve automatic guide and punching operation of the product; a rotation driving assembly and a rotation supporting assembly can drive the product to rotate, then edge grinding operation is conducted through an edge grinding assembly, and automatic gluing can be achieved through a gluing assembly; and an edge covering assembly can extrude and fix a specific edge covering strip to the edge of the glass pot cover. The automation degree is high, the technical problem that in the prior art, glass fiber reinforced plastic pot cover machining excessively depends on manpower is solved, and the machining efficiency is high.

Owner:镇江杰欣厨具有限公司

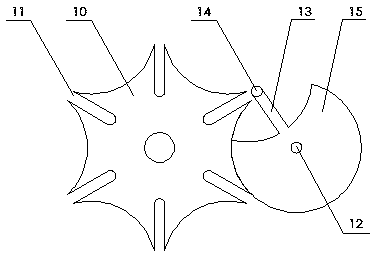

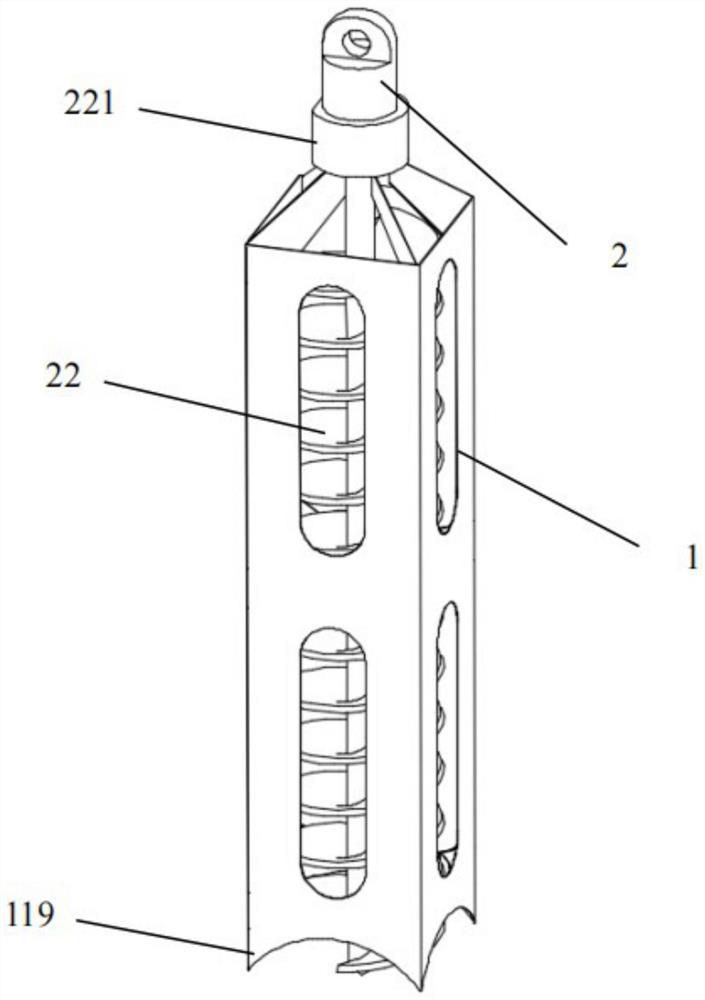

Polygonal punching tool

PendingCN113530456AImprove work efficiencyRealize the punching operationDrill bitsDrilling machines and methodsPunchingTriacontagon

The invention discloses a polygonal punching tool. The polygonal punching tool comprises a drill bit assembly and a cutting assembly. The drill bit assembly comprises a driving element and a spiral drill bit; the spiral drill bit is fixedly connected to the output end of the driving element; the cutting assembly comprises cutting side plates, the multiple cutting side plates are bent with the radian A to be enclosed and spliced to form a polygon, and the polygon sleeves the drill bit assembly; discharging holes are formed in the cutting side plates; and cutting corners are arranged at the bottom ends of the cutting side plates. Soil around a round hole can be cut in a polygonal mode when the spiral drill bit performs punching, the cut soil is brought out through rotation of the spiral drill bit, and the operation efficiency is improved; and meanwhile, punching operation of various polygonal holes is achieved through the bending frequency change of the cutting tool.

Owner:HUBEI SAN LING SPECIAL PURPOSE VEHICLE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com