Drilling device and method for metal doors and windows

A metal door and window and drilling device technology, which is applied in the field of door and window processing, can solve the problems of unfavorable cost control of production enterprises, reduced production efficiency, and high manual labor intensity, and achieve the effect of drilling operations at fixed positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

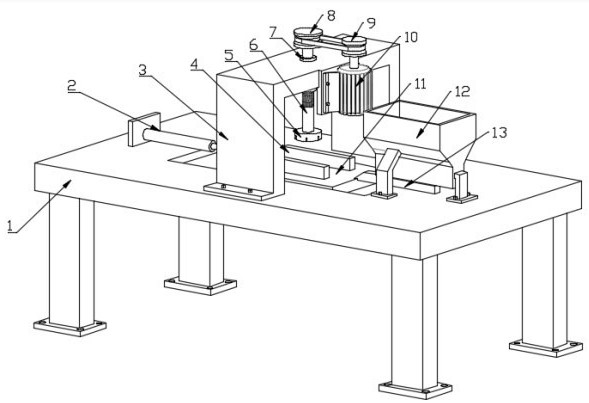

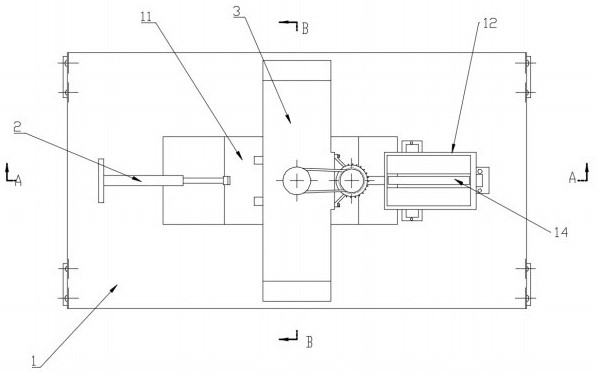

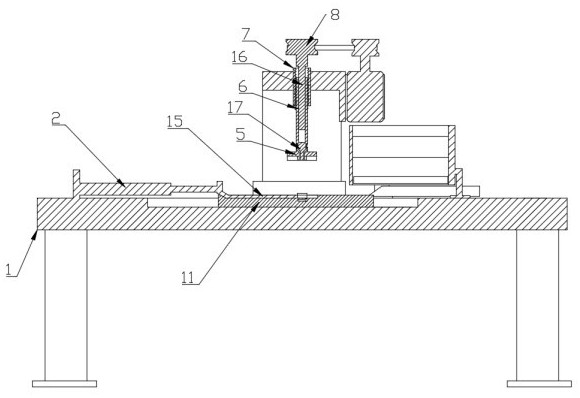

refer to Figure 1~Figure 4 , in this embodiment, a drilling device for metal doors and windows is proposed, which is used to drill holes for metal door and window lattice rods, and the drilling device for metal doors and windows includes:

The workbench 1 may be a rectangular plate-like structure, and a placement station and a processing station are arranged on the workbench 1 . Workbench 1 is used for support and installation. The bottom of the workbench 1 can be provided with support legs, the bottom of the support legs is fixedly provided with a backing plate, and the backing plate is provided with through holes through which bolts can pass through the workbench 1 to fix the workbench 1 on the ground or an assembly line. Of course, the bottom of the support leg can also be provided with a rotating wheel, a universal wheel, or a combination of the two, and the rotating wheel and / or the universal wheel are provided with a clamping plate for braking, so as to facilitate the m...

Embodiment 2

refer to Image 6 , in this embodiment, a drilling method for metal doors and windows is proposed, comprising the following steps:

S1 , the push-pull member pushes the sliding table 11 into the placement station, and the window lattice rod 14 falls on the sliding table 11 .

[0034] S2. The push-pull member pulls the sliding table 11 to move toward the processing station, and the transmission structure 15 drives the clamping rod 4 to move closer, and the clamping rod 4 moves closer to clamp the window mullion rod 14 .

[0035] S3. Determine the pressure F of the clamping rod 4 1 is greater than a preset F 1标 , if yes, execute S4.

[0036] S4, the distance sensor detects that the distance from the end of the window lattice rod 14 is L 0 .

[0037] S5, according to a preset punching position L i Control the push-pull member to move the sliding table 11, and the moving distance is L 0 +L i .

[0038] S6. The rotating driving member drives the polygonal rod 16 to drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com