A new type of sunflower disc thresher

A sunflower tray and thresher technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of increasing manpower burden, loss of reuse value, inconvenient mixing and separation of flower trays and sunflower seeds, saving manpower, The effect of light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

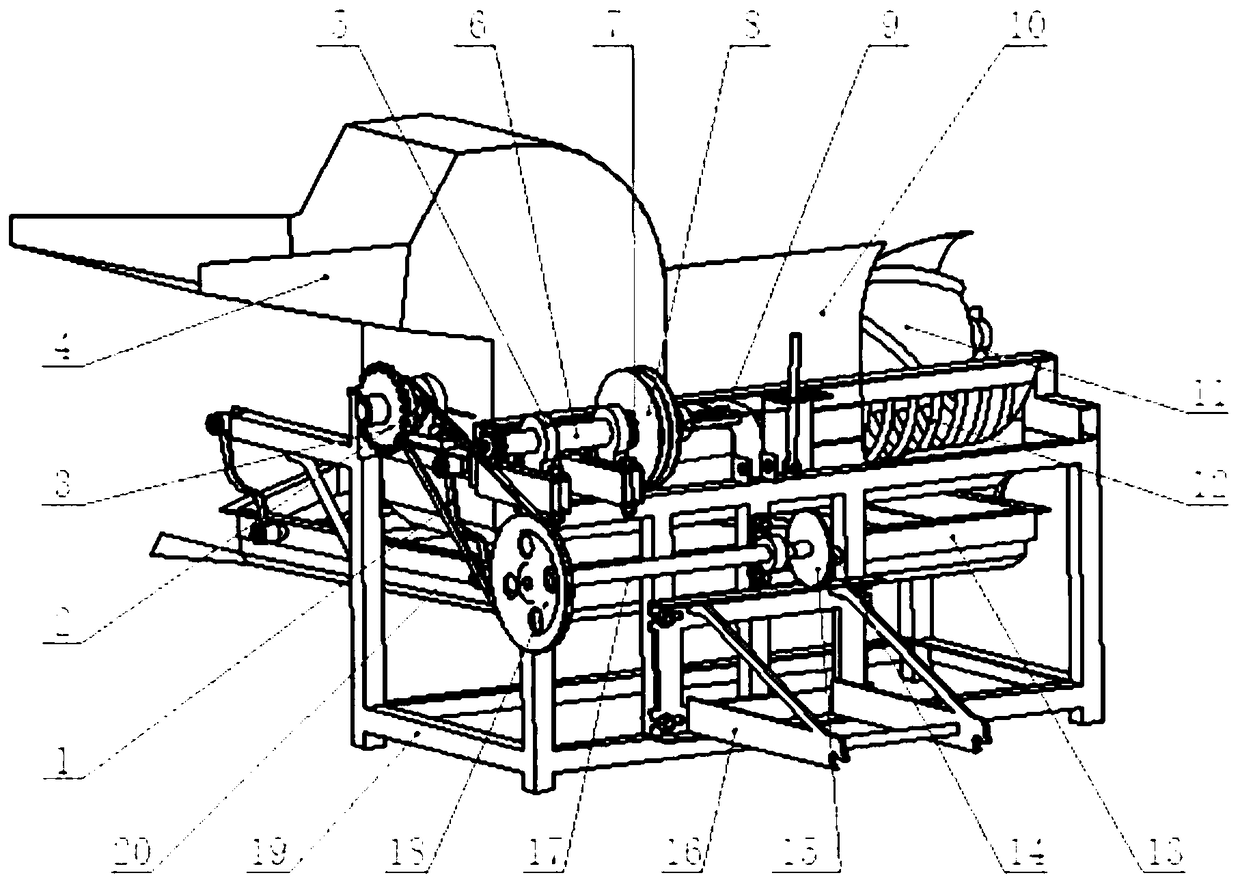

[0037] Such as figure 1 Shown, a kind of novel sunflower dish threshing machine, described threshing device comprises the compound drum that is made of loam cake 10, roller shaft 11 and lower cap 30, and described loam cake 10 upper end is provided with feed inlet 4, and described The surface of the roller shaft 11 is provided with a spiral keyway, the inner walls of the upper cover 10 and the lower cover 30 are provided with grid grooves 12, and the bottom of the lower cover 30 is provided with a leakage hole and a discharge port 33; The roller shaft one 11 passes through both sides of the compound drum, and is provided with a secondary primary pulley 2 at one end thereof, and a pinion 22 and a large sprocket are provided at the tail end of the secondary primary pulley 2;

[0038]Described driving device comprises clutch 9, power pulley 8 and a shaft 6, and described frame 19 is provided with a shaft 6 bearing seat 5, and described bearing seat is provided with a shaft 6, and...

Embodiment 2

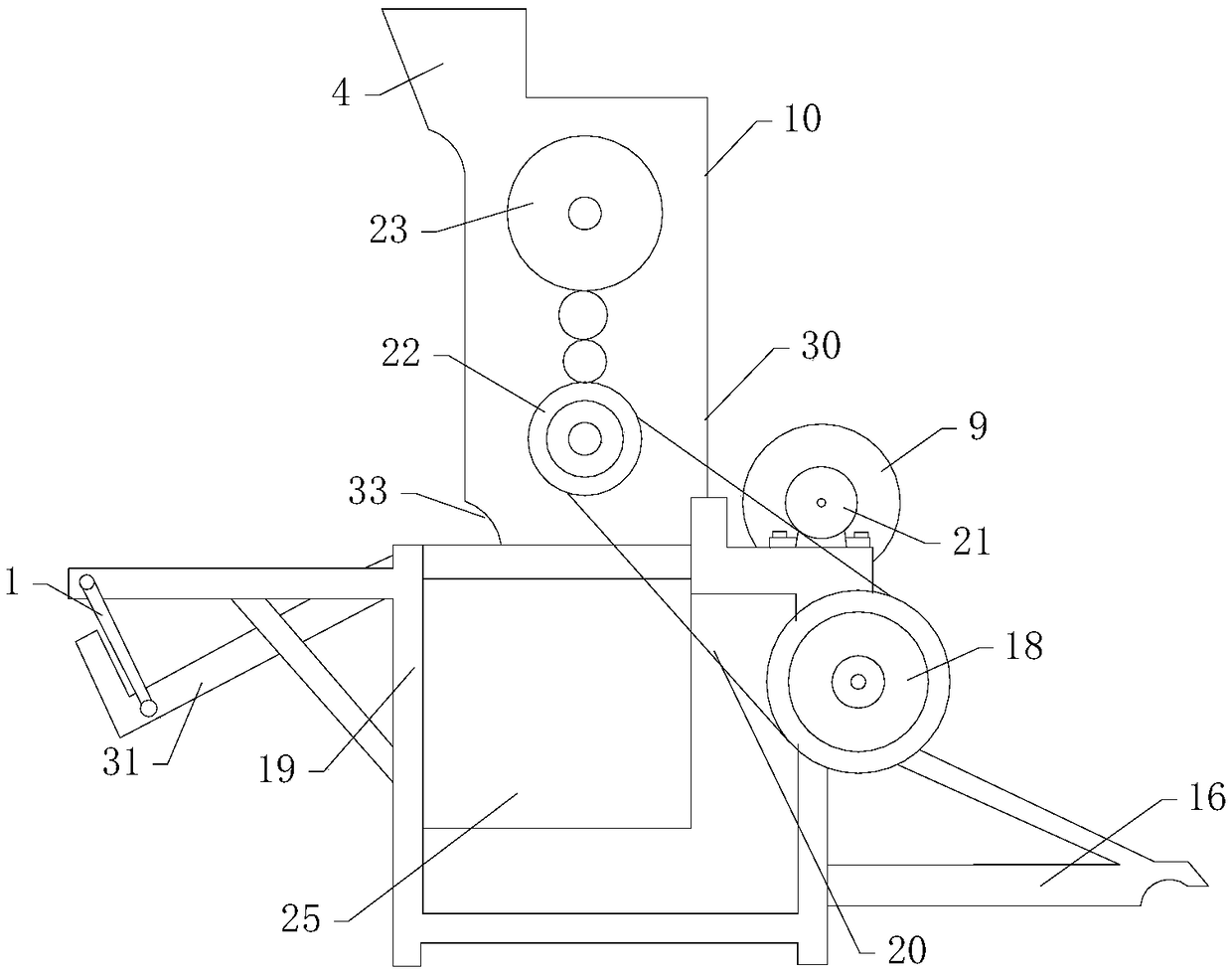

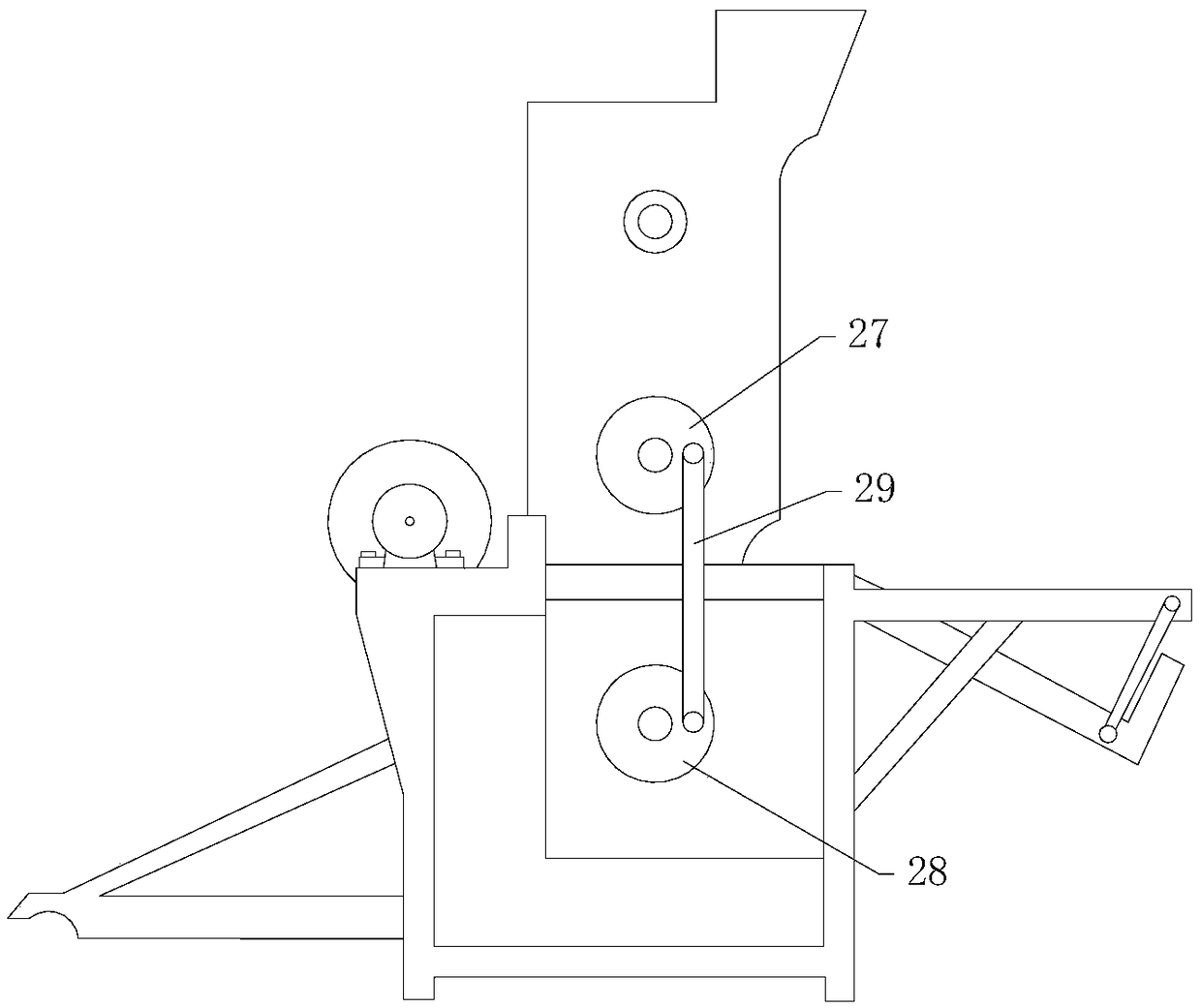

[0044] Such as Figure 2-6 As shown, the threshing device also includes a guide plate 24 and a roller shaft two 32, the roller shaft two 32 is aligned above the roller shaft one 11, and the guide plate 24 is set between the roller shaft one 11 and the roller shaft two 32;

[0045] The upper end of the guide plate 24 is connected with the upper left end of the upper cover 10, and the lower end of the guide plate 24 is in contact with the delivery tube roller, and is connected with the upper left end of the lower cover 30. The upper cover 10, the guide plate 24 and the lower cover 30 are connected from the upper Form a coherent cabin until the next connection;

[0046] Described drive device also comprises to bull gear 23, and one end of described roller shaft 2 32 is provided with bull gear 23, and the position of this bull gear 23 is on the same side as pinion 22, and described bull gear 23 and pinion 22 are meshingly connected , to achieve synchronous reverse rotation, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com