Patents

Literature

38results about How to "Realize linkage operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

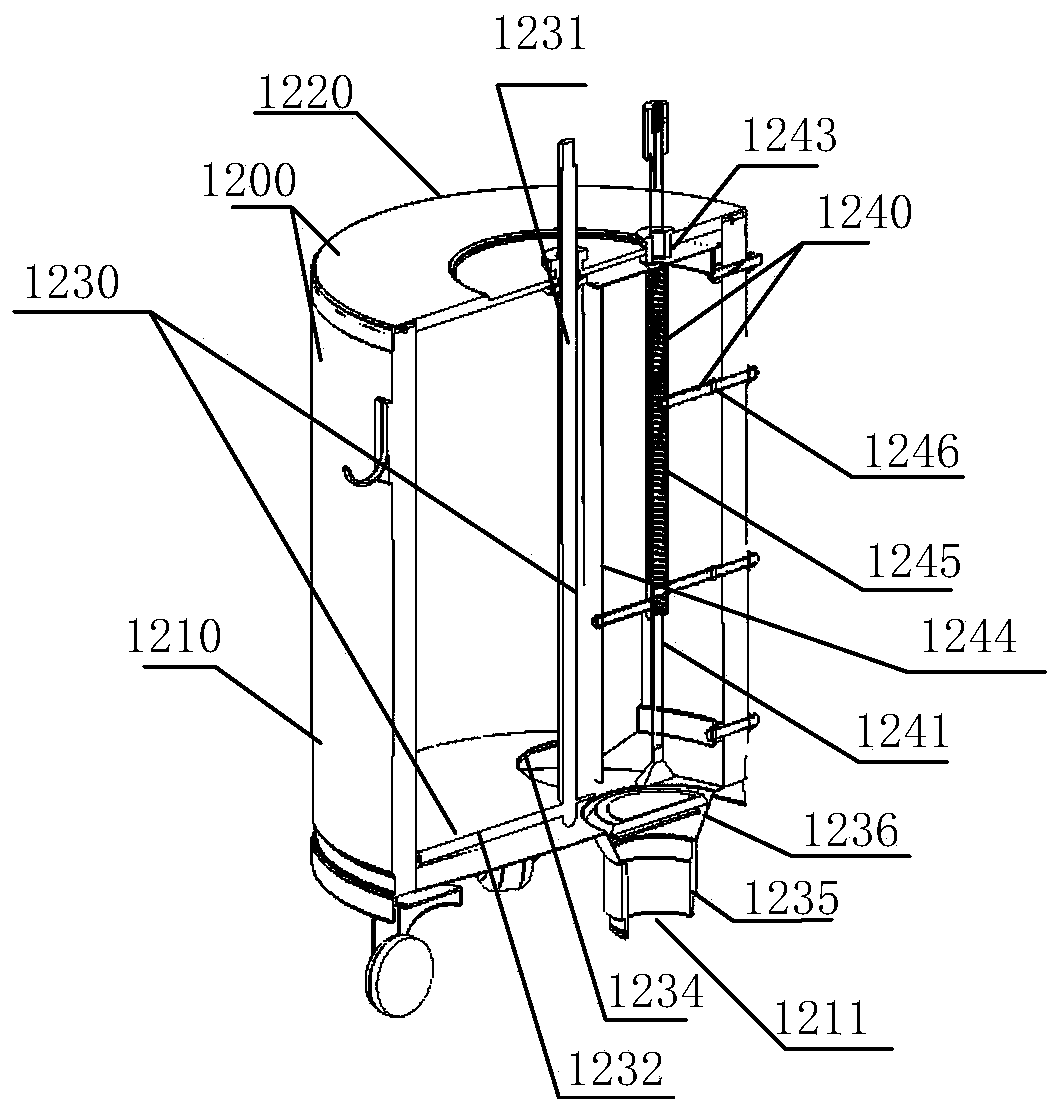

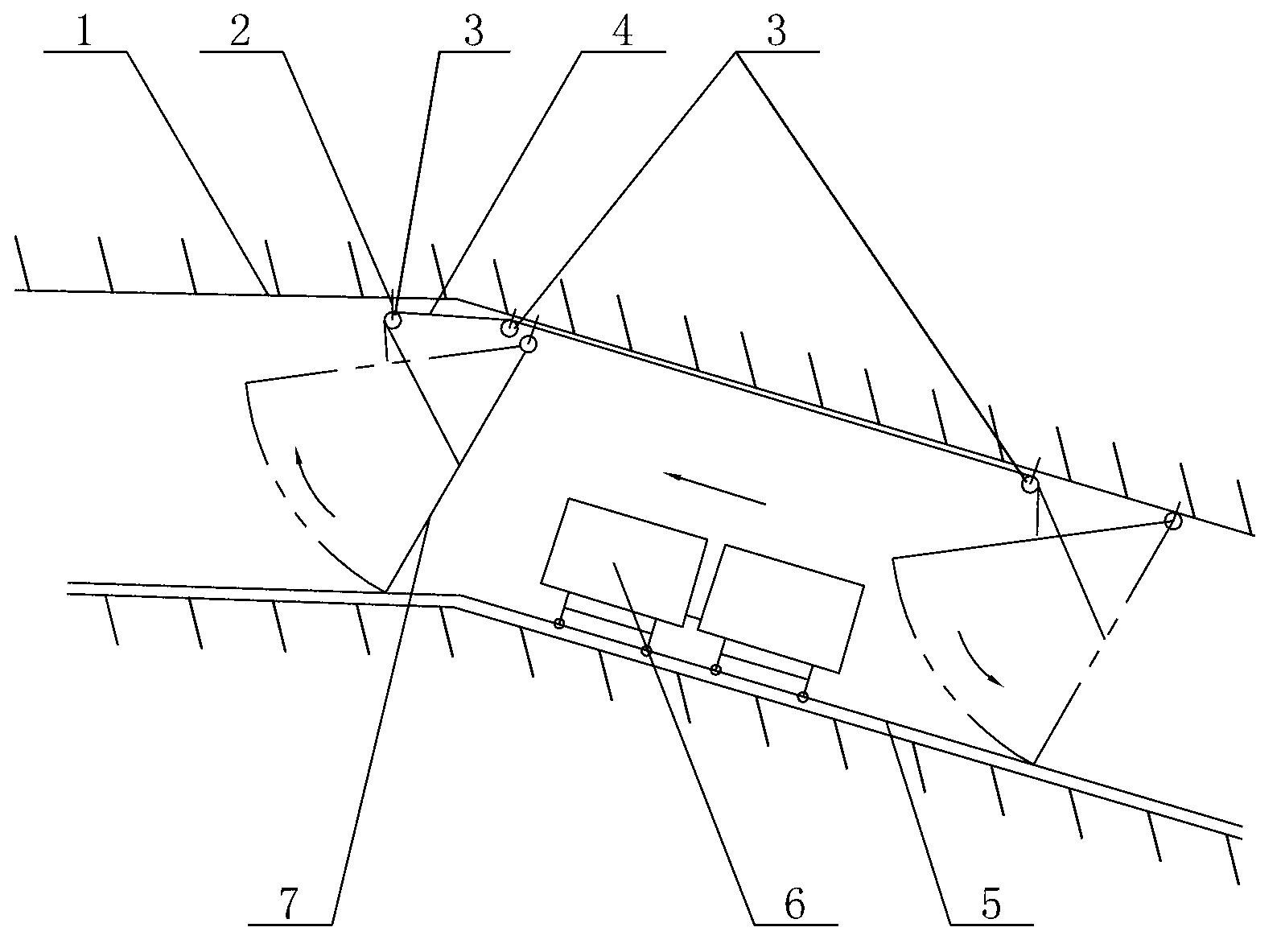

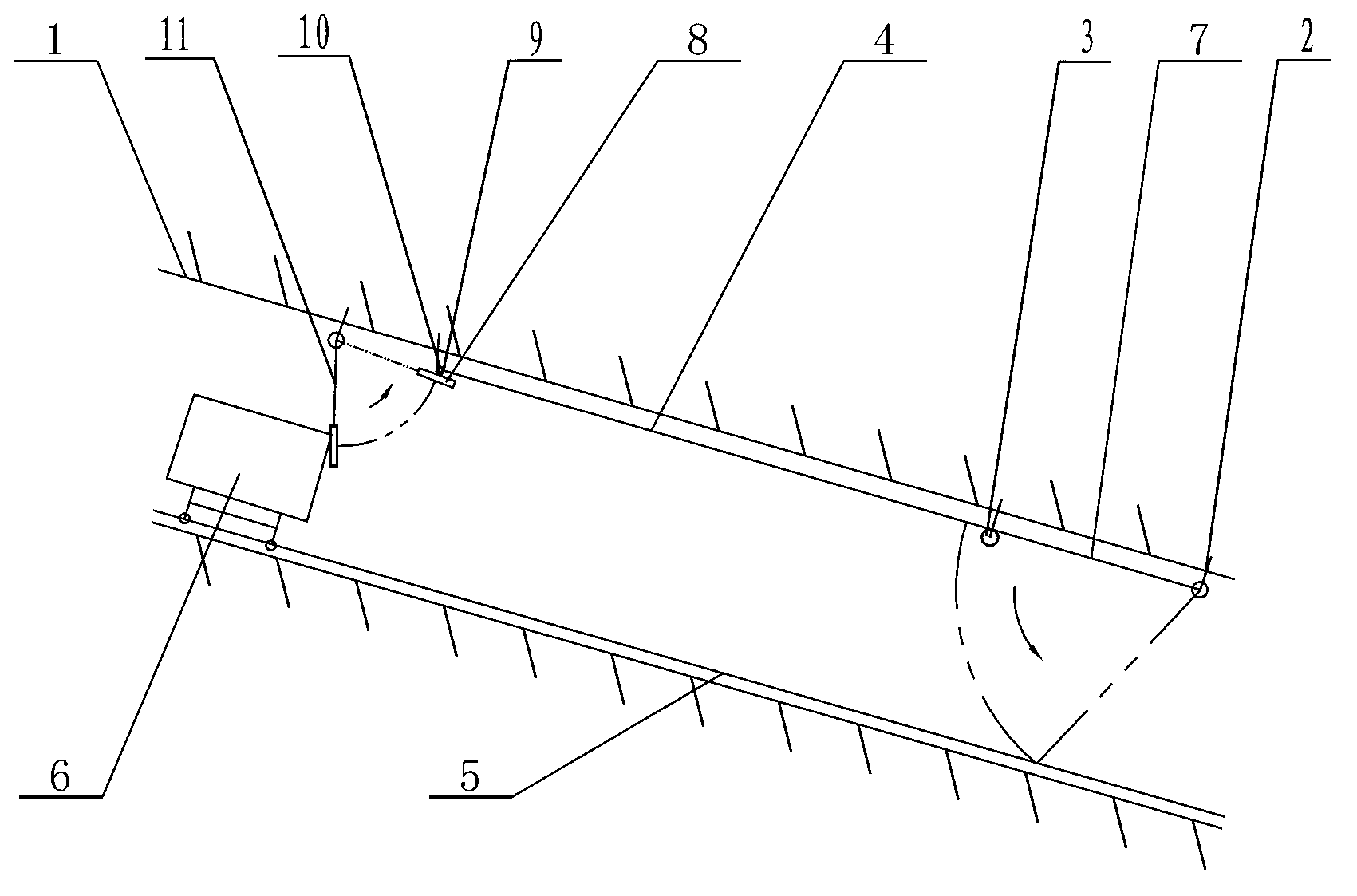

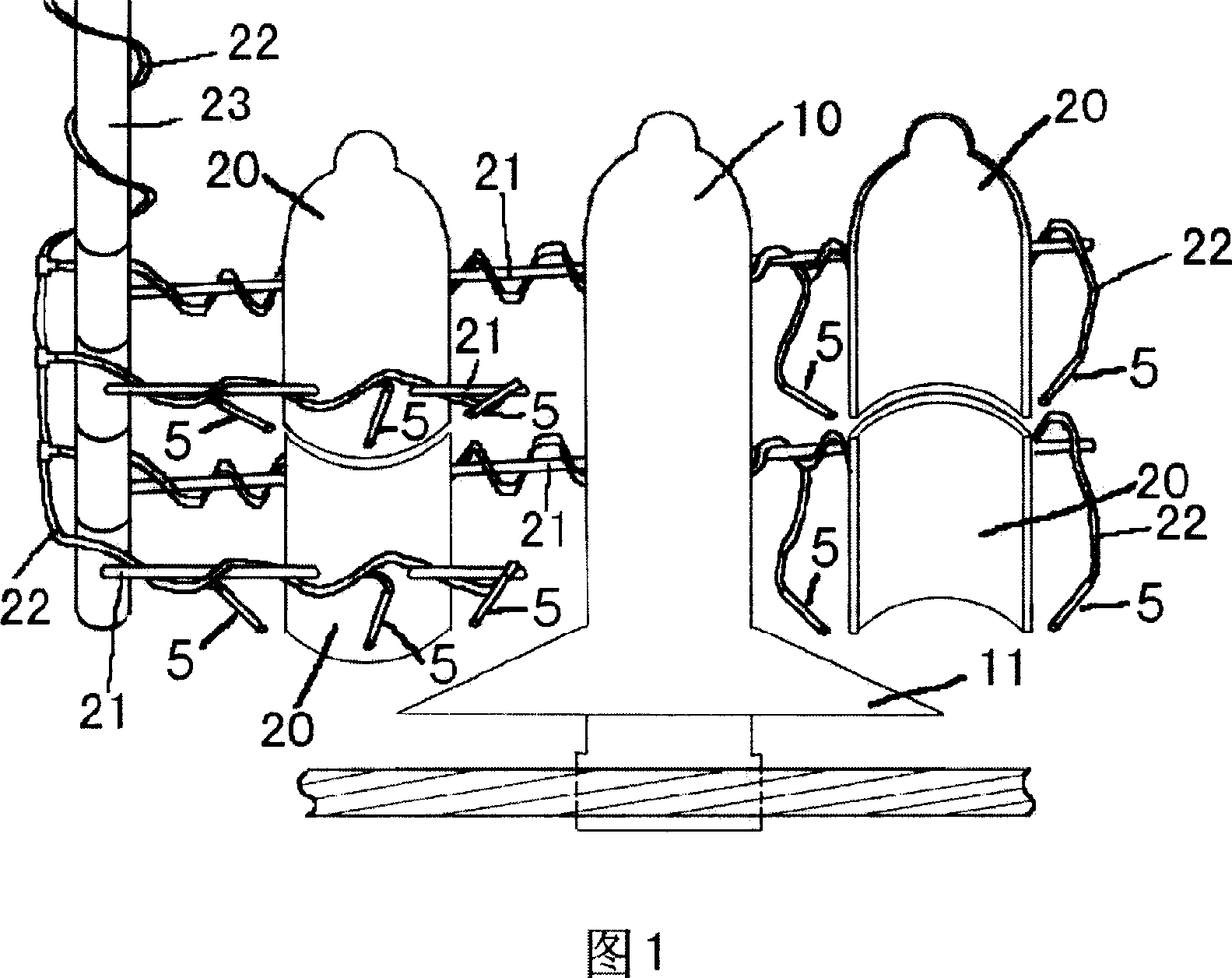

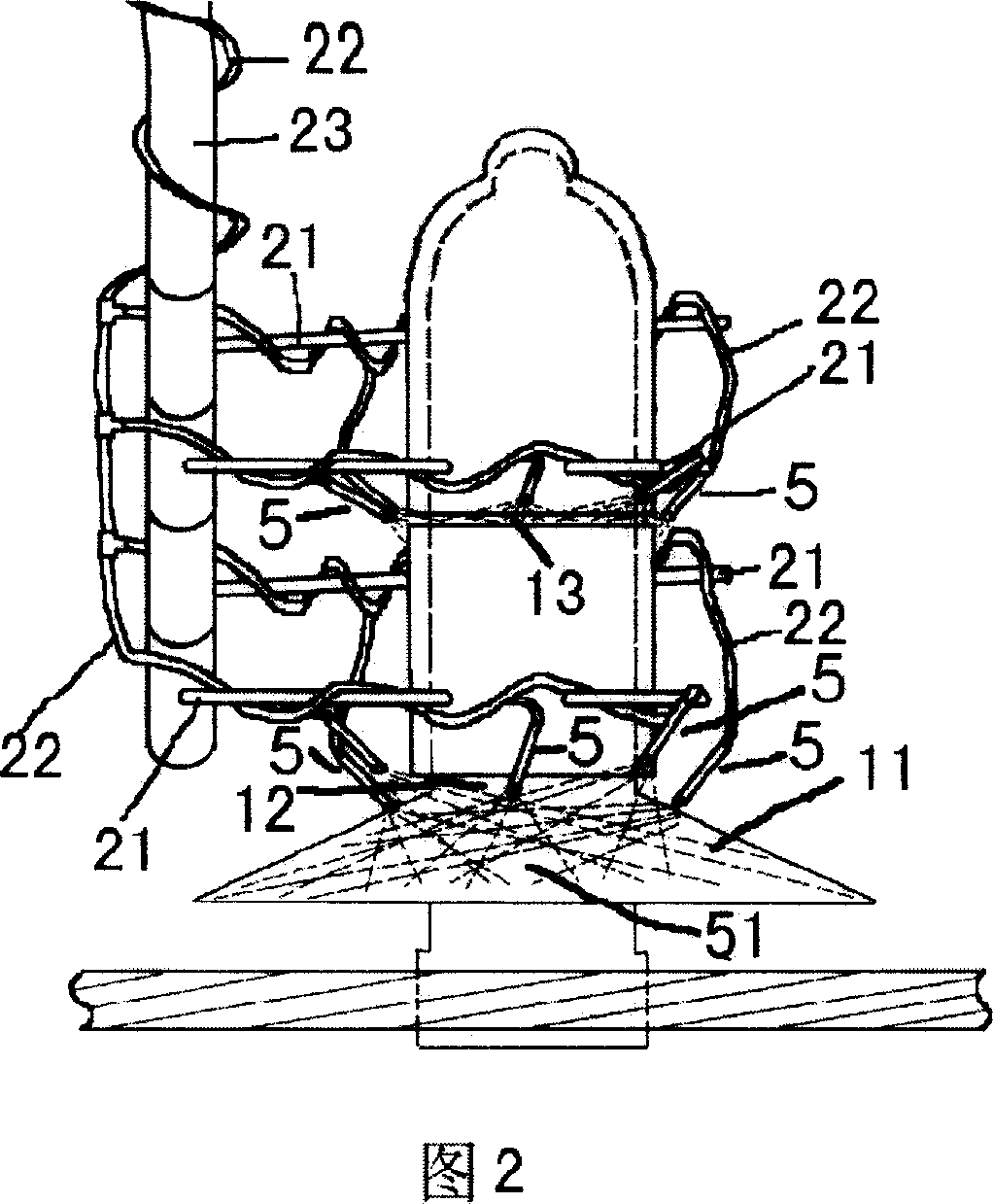

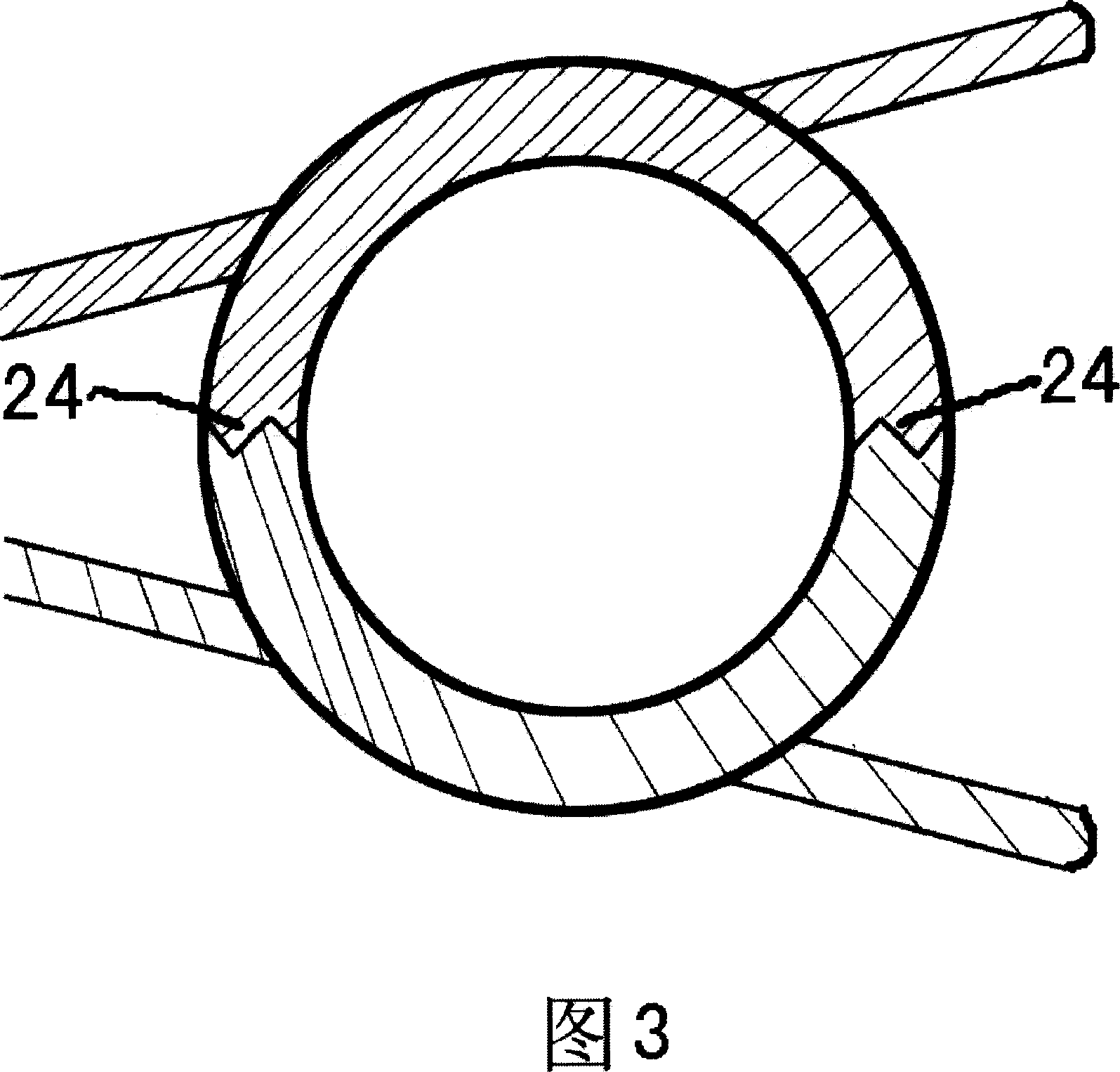

Coal bed hydraulic cutting and sieve tube feeding linked gas extraction apparatus and method

PendingCN109653722AImprove the extraction effectRealize linkage operationDrilling rodsFluid removalHigh pressure waterHigh pressure

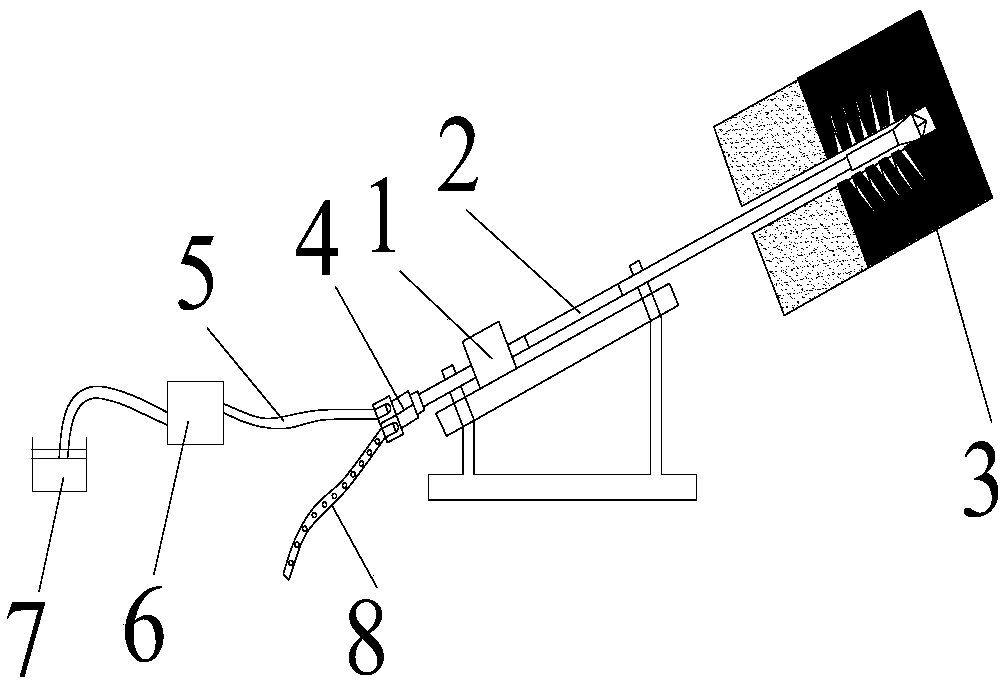

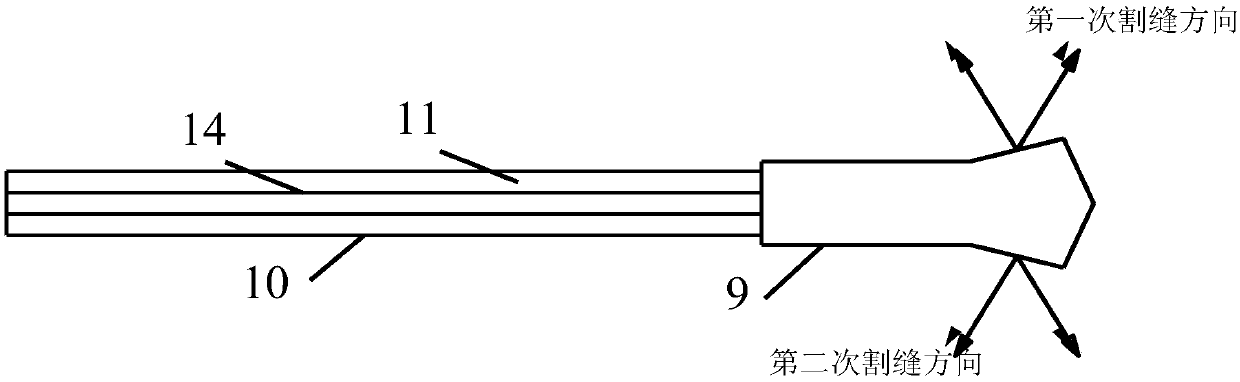

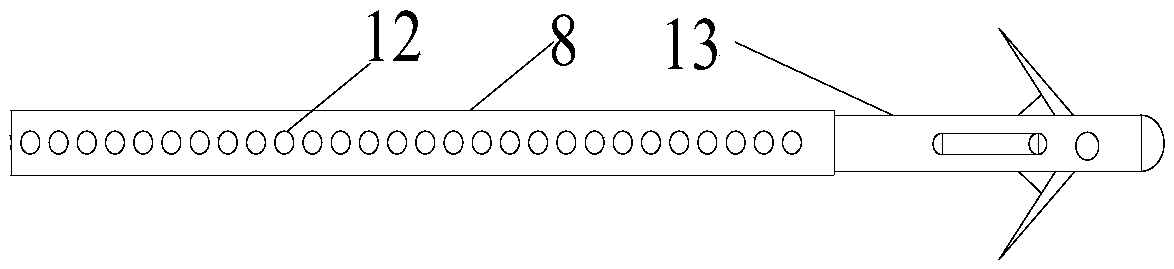

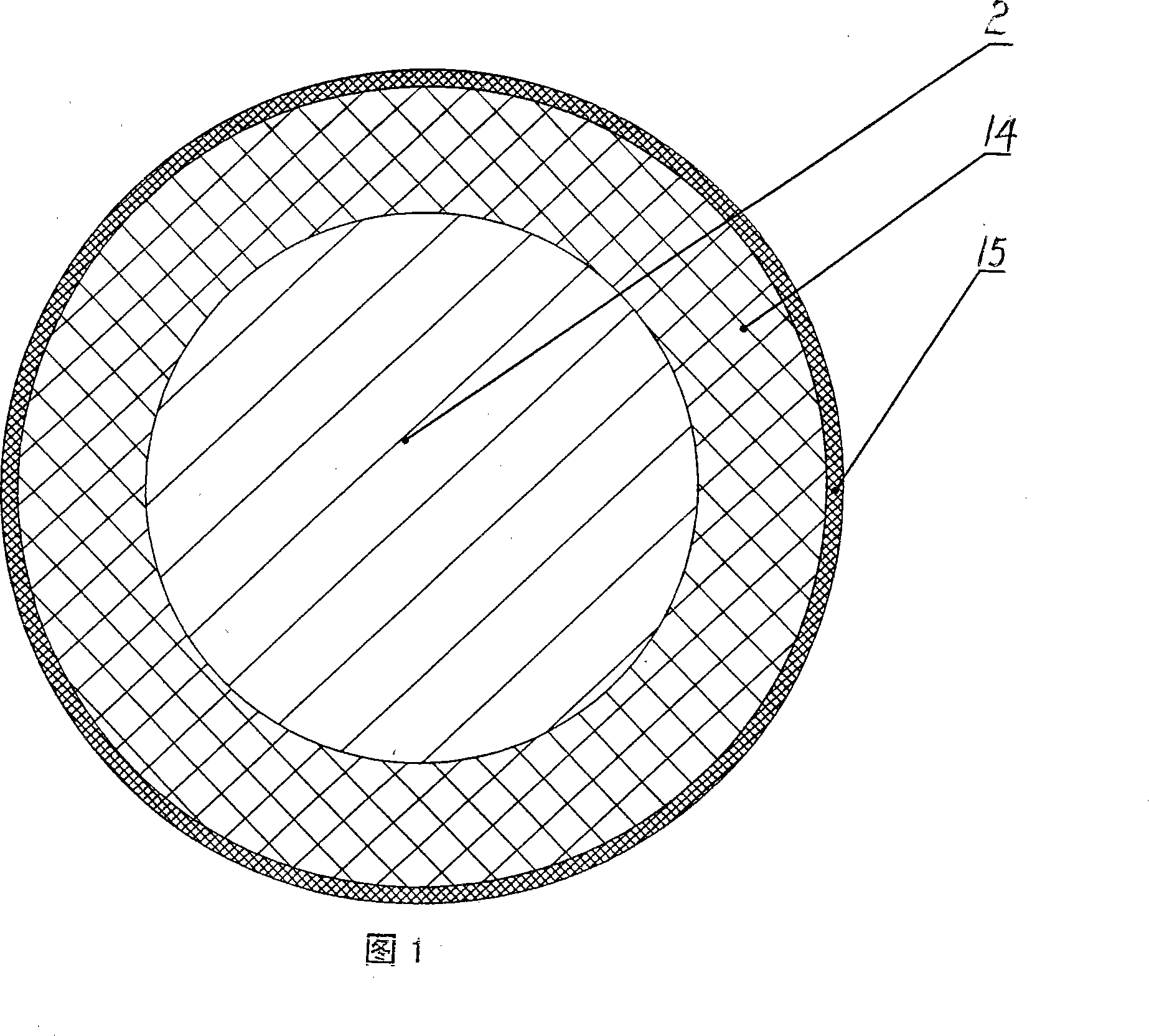

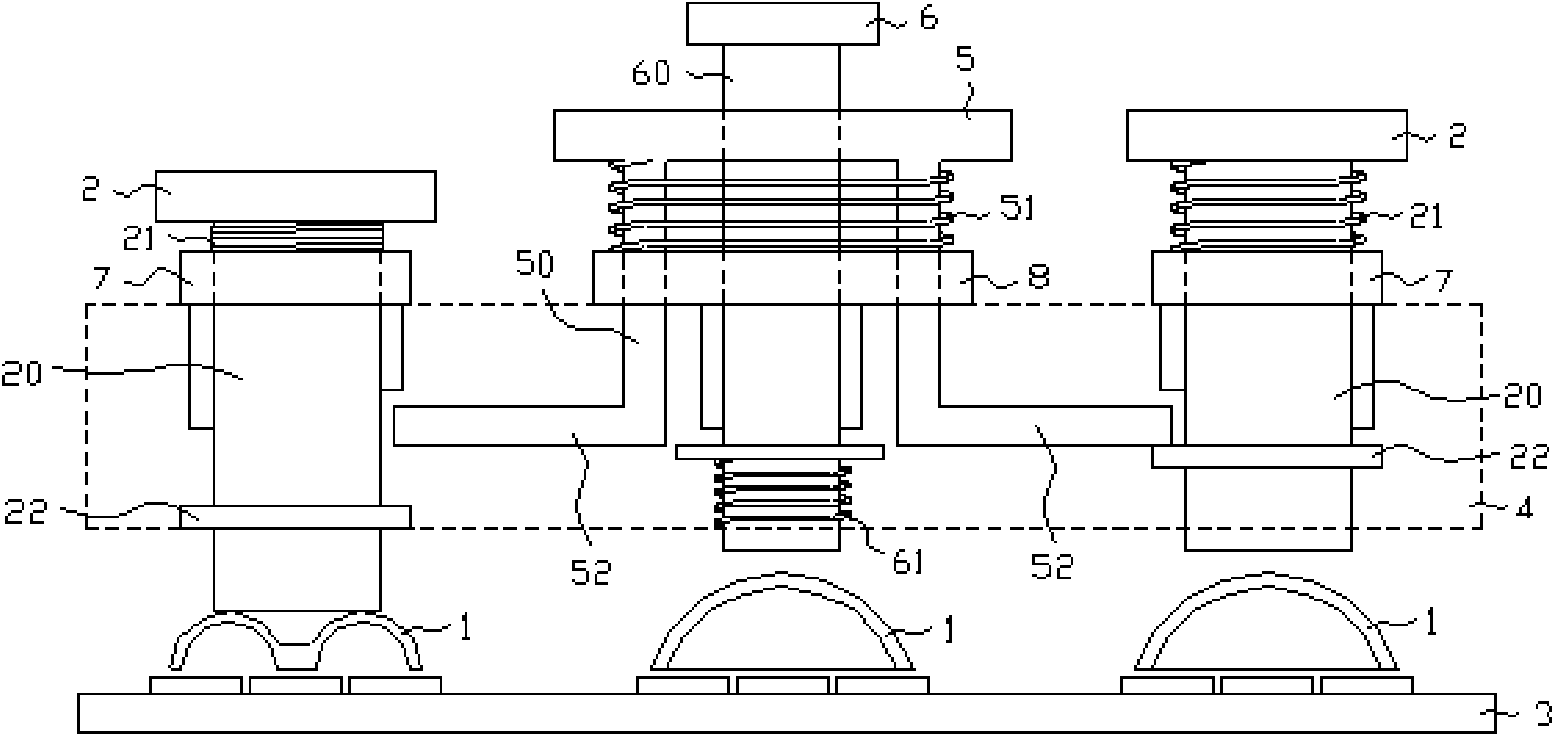

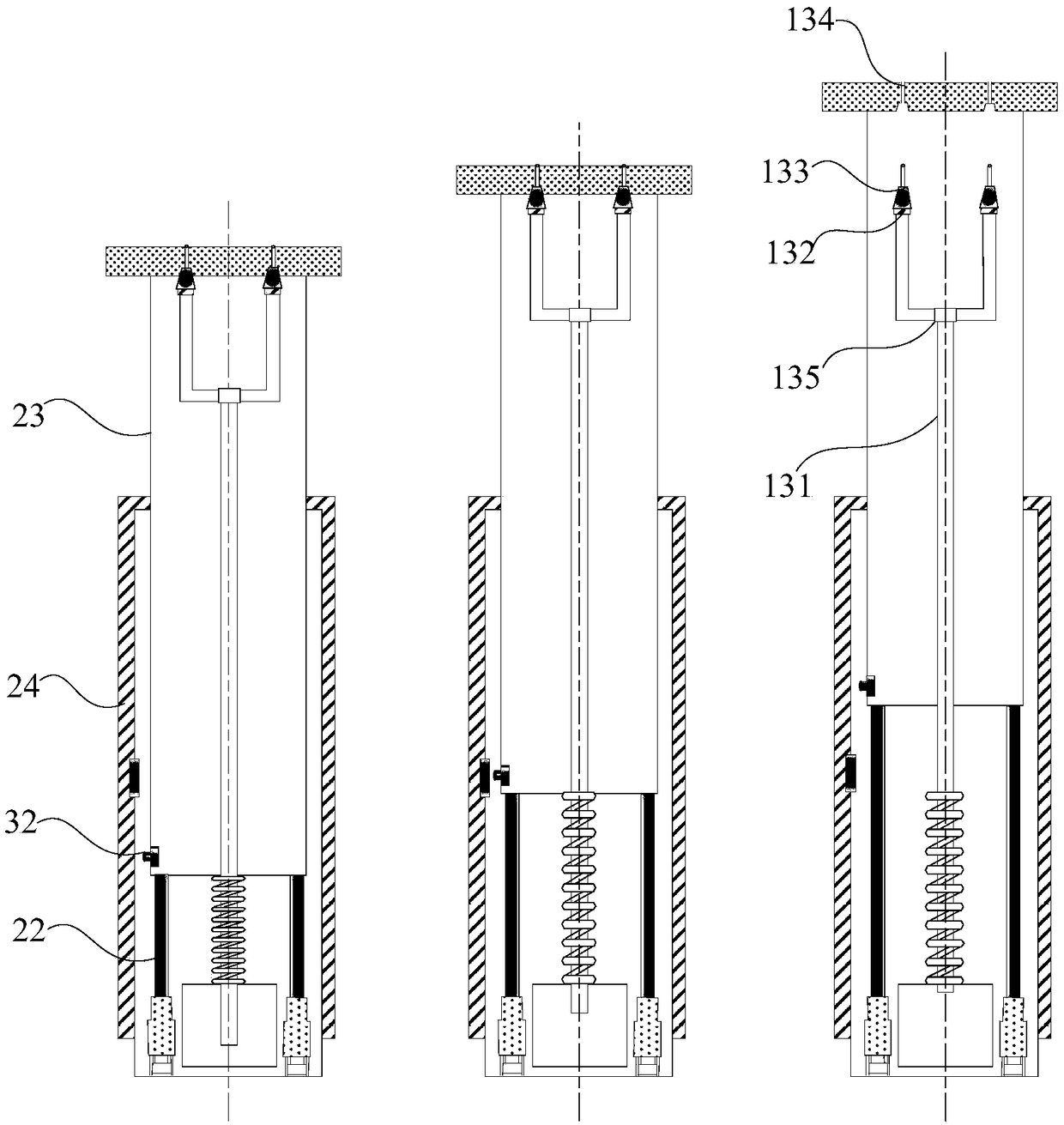

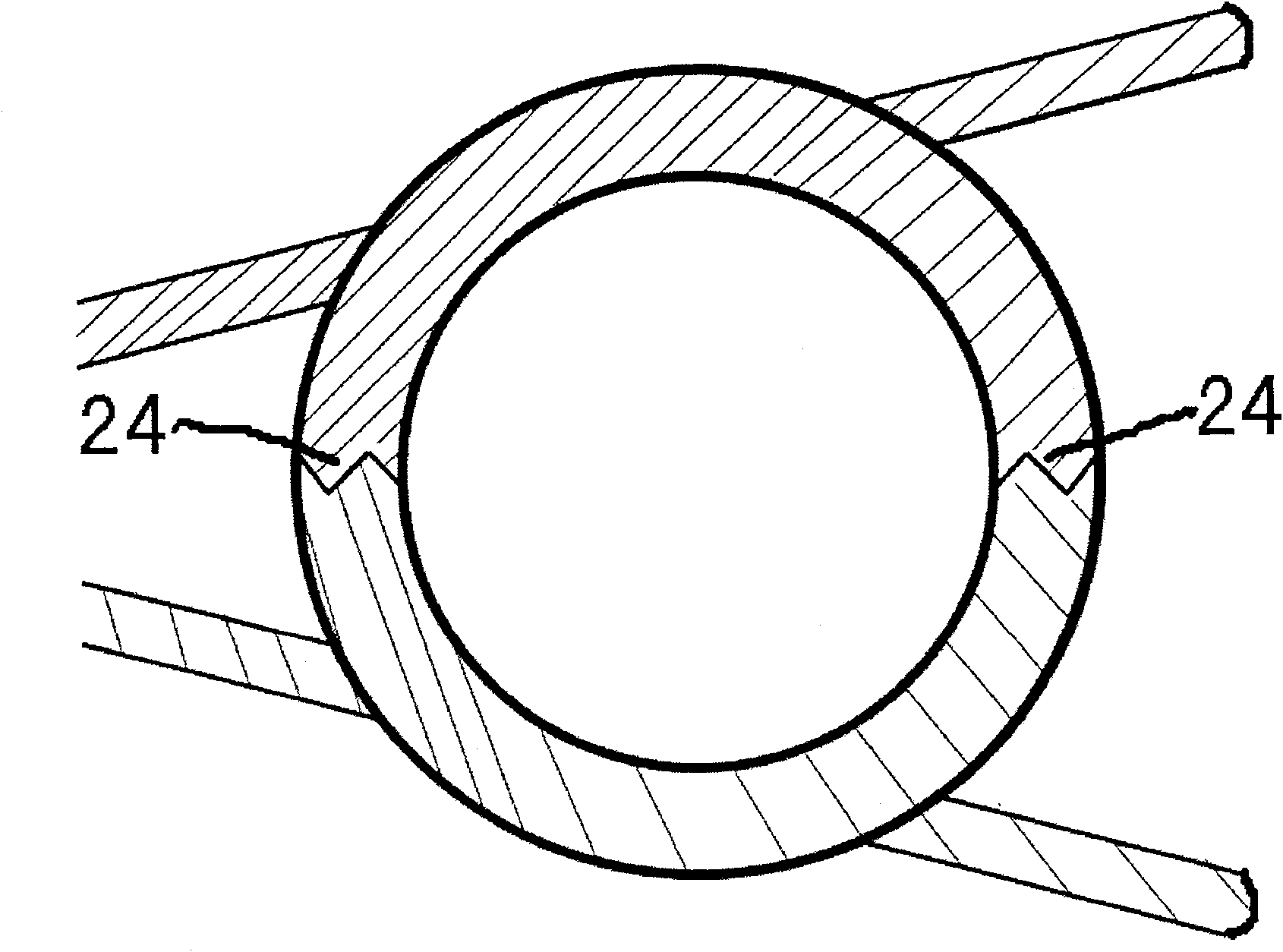

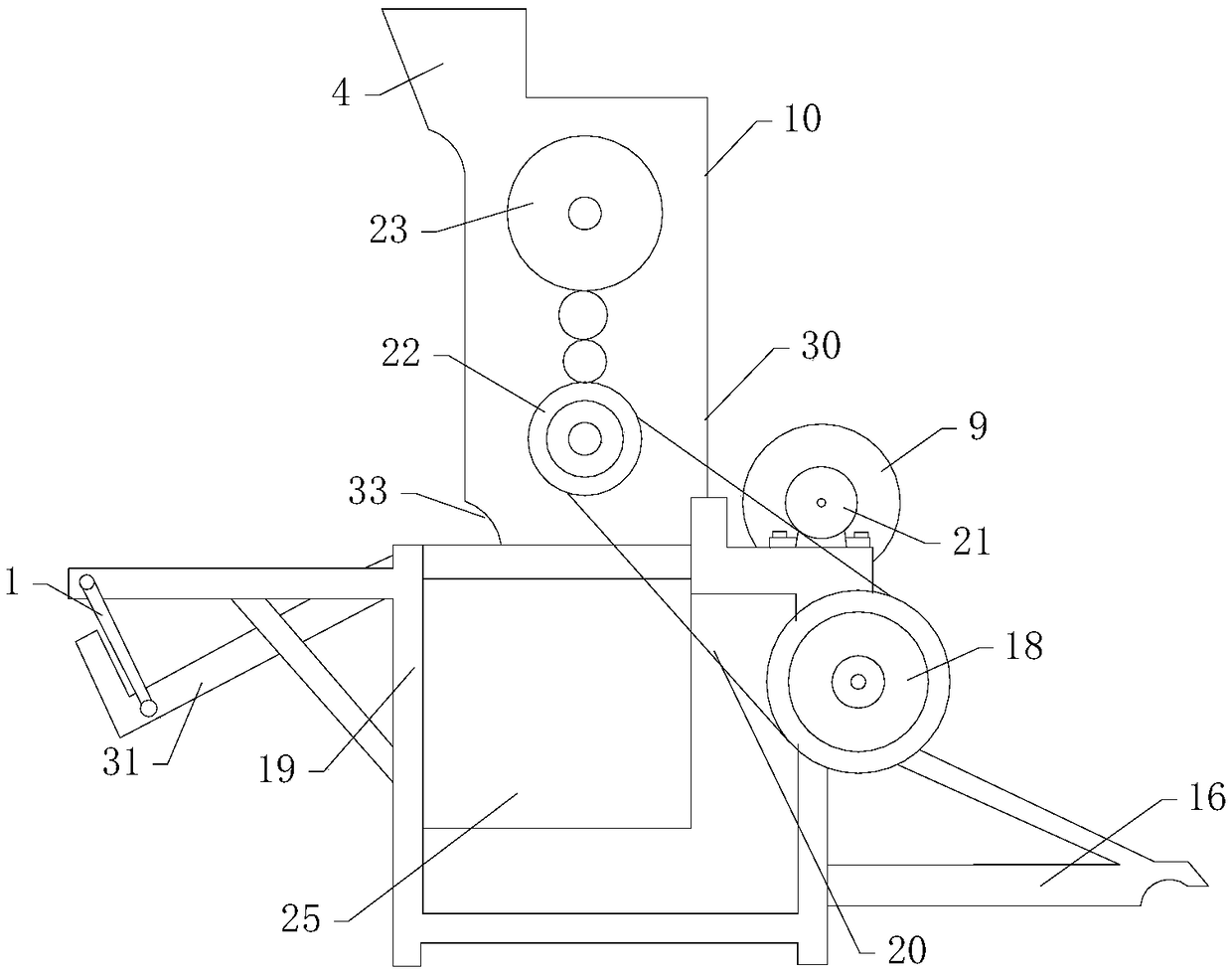

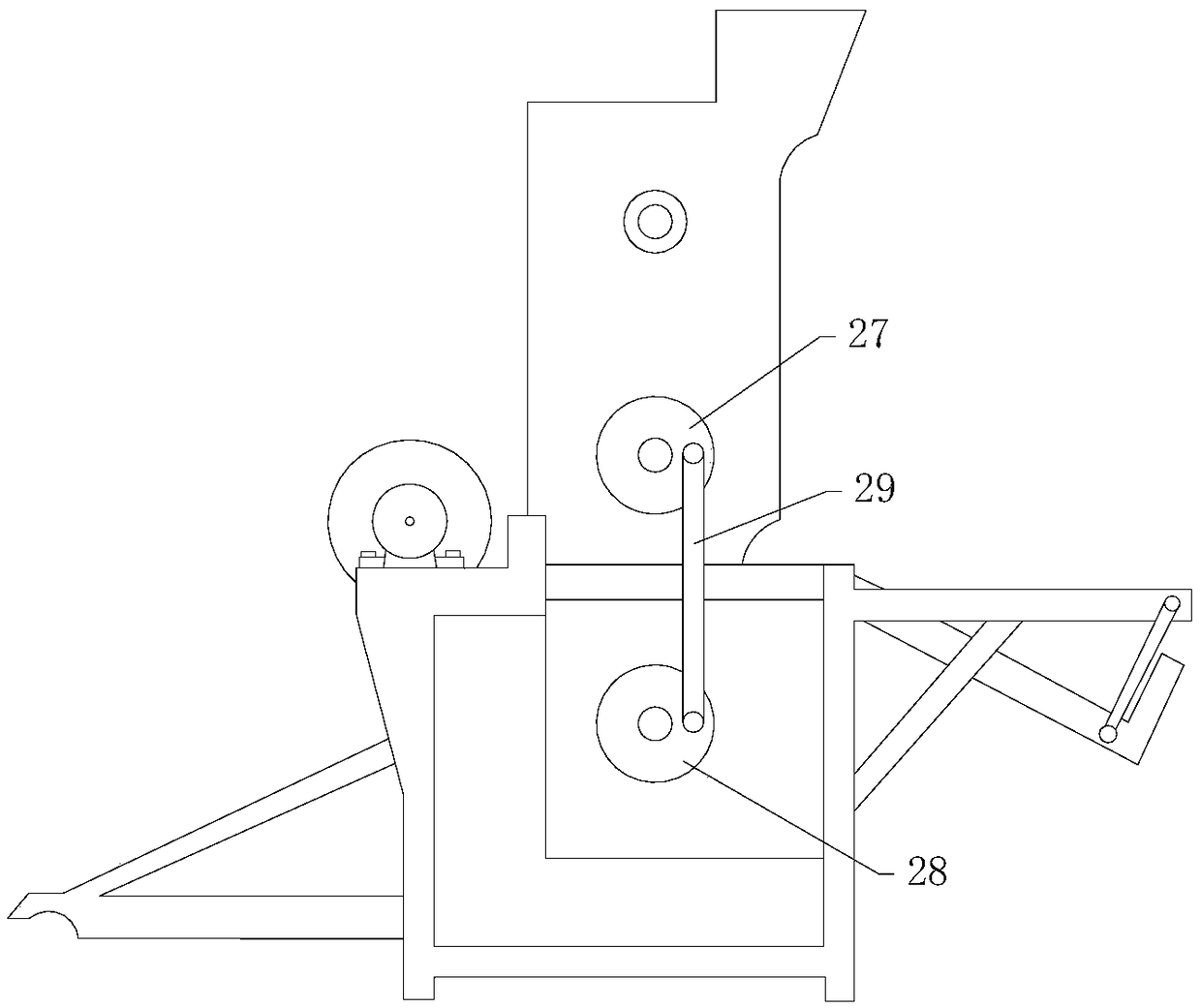

The invention relates to a coal bed hydraulic cutting and sieve tube feeding linked gas extraction apparatus and method, which belongs to the technical field of coal mine safety. The apparatus comprises a drill rod, a high-pressure water flow outer pipe, a special drill bit, a drill rod connecting apparatus, a drill rod tail switching apparatus, a high-pressure water pipe, a flexible sieve tube and a fixing apparatus; the special drill bit is connected with the drill rod, the drill rod is connected with a drilling machine, and the drilling machine is started to drill to a preset depth; the drill rod 10 is a double-layer structure, the inner pipe of the drill rod and an annular space of the drill rod form the high-pressure water flow outer pipe, and the inner pipe and the drill rod are of an embedded structure; the inner pipe of the drill rod is connected with the drill rod connecting apparatus, and the drill rod tail switching apparatus is connected with the flexible sieve tube or thehigh-pressure water pipe; and the flexible sieve tube is connected with the fixing apparatus, so that no movement occurs in the process of withdrawing the drilling and cutting coal. By adopting the coal bed hydraulic cutting and sieve tube feeding linked gas extraction apparatus, a gas flow passage is effectively prevented from being blocked due to the collapse of a borehole; and meanwhile, the secondary hydraulic cutting for the coal body can increase an exposed area of the coal body and improve the gas extraction effect.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A production method for color cable core with color insulation layer

InactiveCN101236808AReduce in quantityRealize linkage operationInsulated cablesConductor/cable markingElectrical conductorInsulation layer

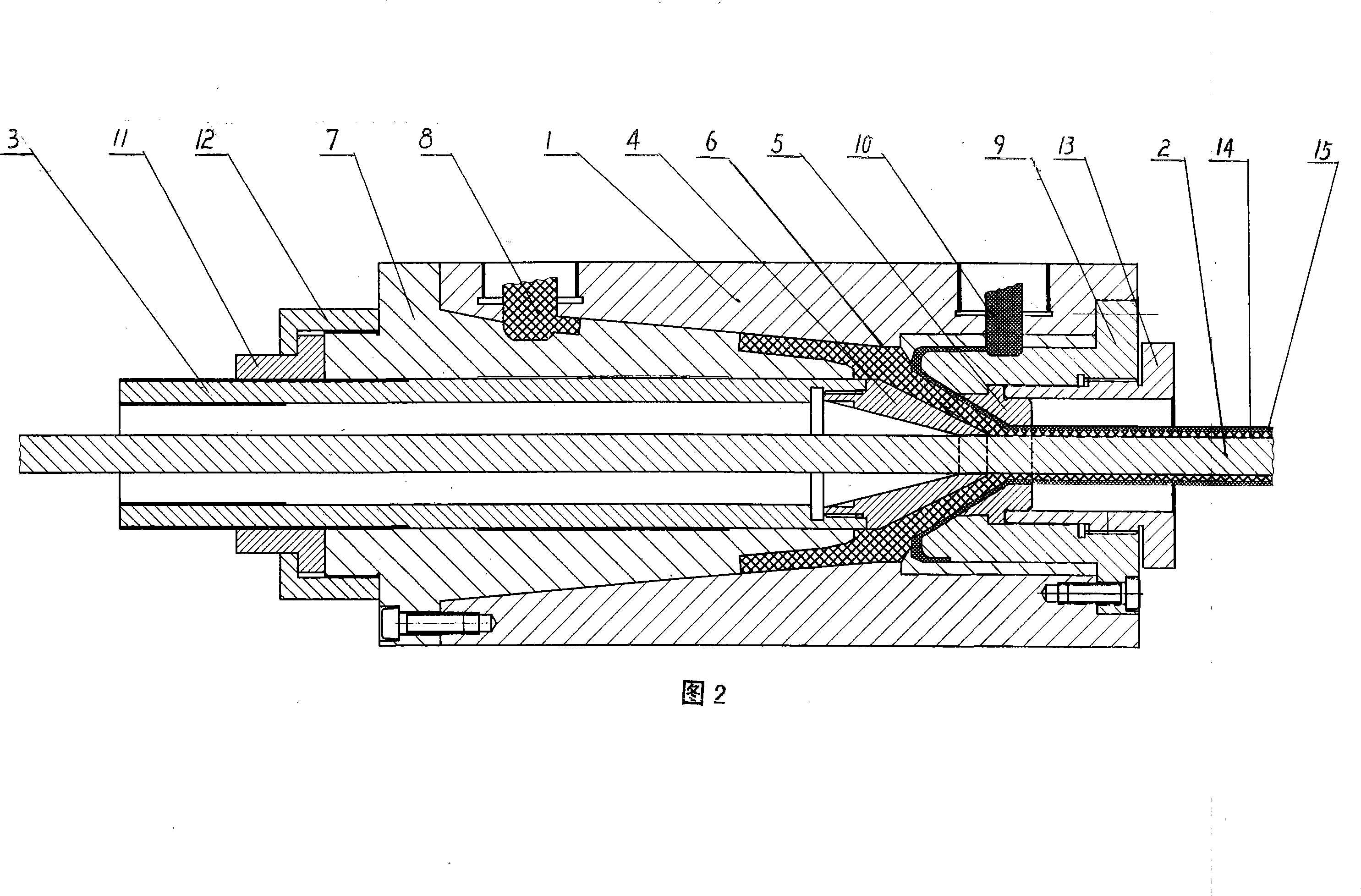

The invention relates to a manufacturing method for a dichroic cable core provided with a colored insulation material layer on the outside, wherein, when the insulation material layer is extruded on a conductor, two plastic extruding machines are used; one is a plastic extruding machine for uncolored insulation materials and the other is a plastic extruding machine for colored insulation materials; the two plastic extruding machines share a double-layer coextrusion handpiece; the uncolored insulation materials are taken as inner layer insulation materials, and the colored insulation materials are taken as outer layer insulation materials; two layers of insulation materials are combined in the same handpiece, and simultaneously extrusion of double-layer insulation materials is completed on a cable conductor. By adoption of the method for color changing of the insulating core, users only need to extrude colored insulation materials in a donkey engine completely, and obviously the means can greatly reduce the number of color changing wastes. By adoption of the method of the invention, the interlocking operation of the two plastic extruding machines is realized and the operating procedure is simplified.

Owner:高荣富

Process for preparing rubber compound of ethylene propylene diene monomer waterproof roll

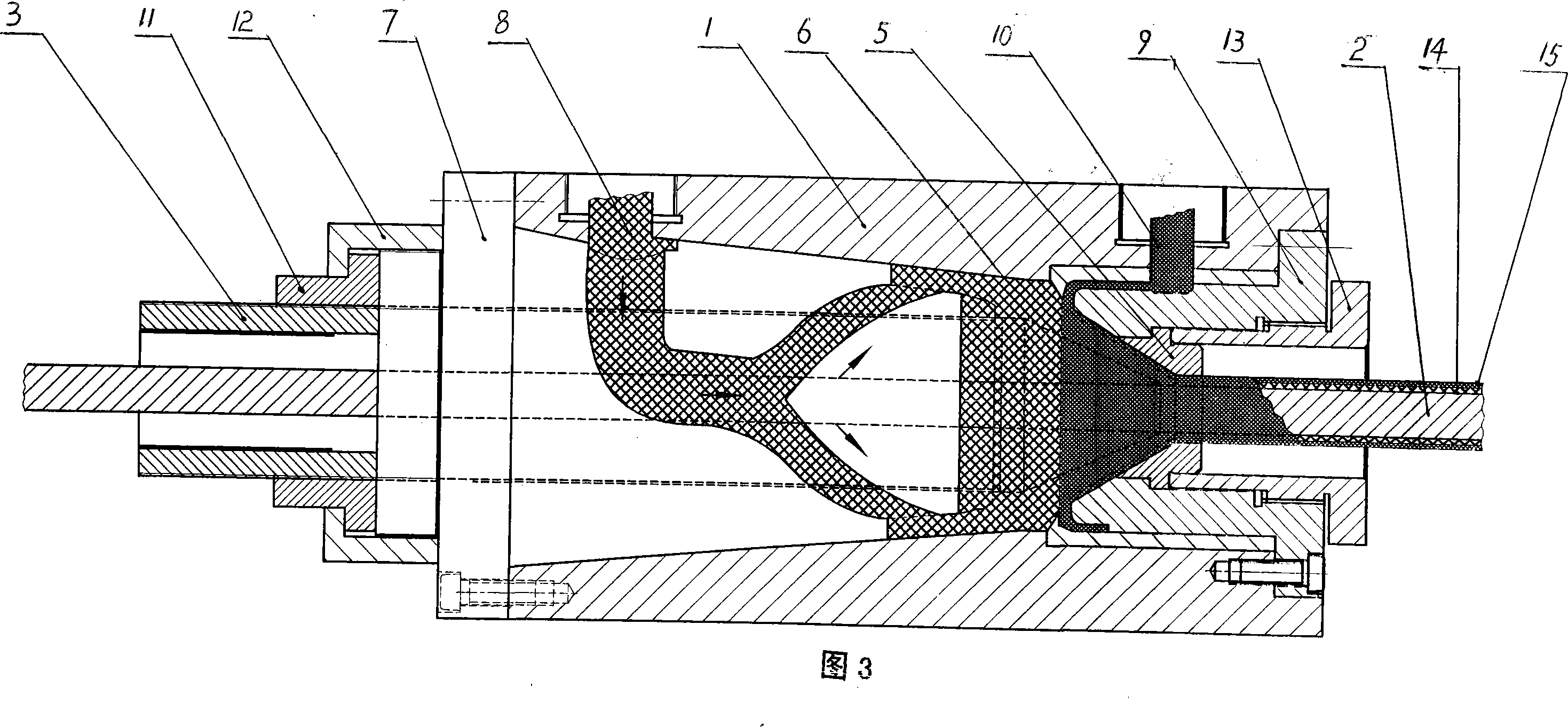

The invention discloses a process for preparing a rubber compound of an ethylene propylene diene monomer waterproof roll. The process comprises the following steps: compounding, filtering rubber, yielding sheets, sulphurating and yielding strips. With the adoption of the manner, in the process for preparing rubber the compound of the ethylene propylene diene monomer waterproof roll, during sulphurating, an open mill is replaced with an internal mixer for sulphurating and compounding. A film cooling machine is used for guaranteeing timely and rapid cooling of the sulphurated rubber compound firstly in the industry, the quality of a prepared product is stable, linkage operation of the internal mixer, a rubber filter, a sheet-outputting machine and the film cooling machine, the energy consumption is reduced, the labor intensity of workers is reduced, the environmental pollution is reduced, and the production efficiency is improved.

Owner:常熟市三恒建材有限责任公司

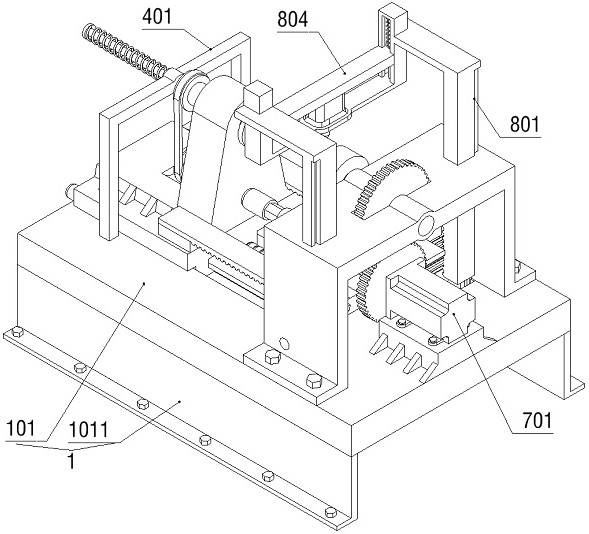

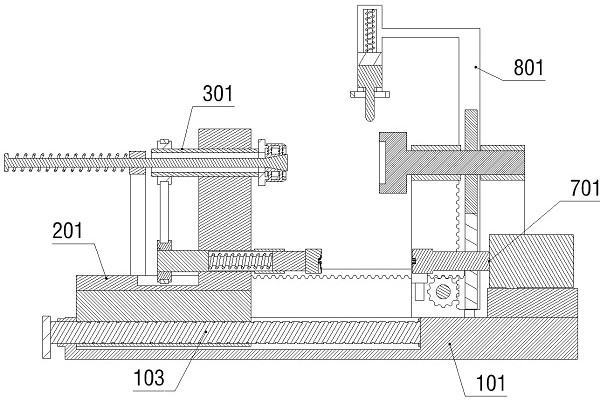

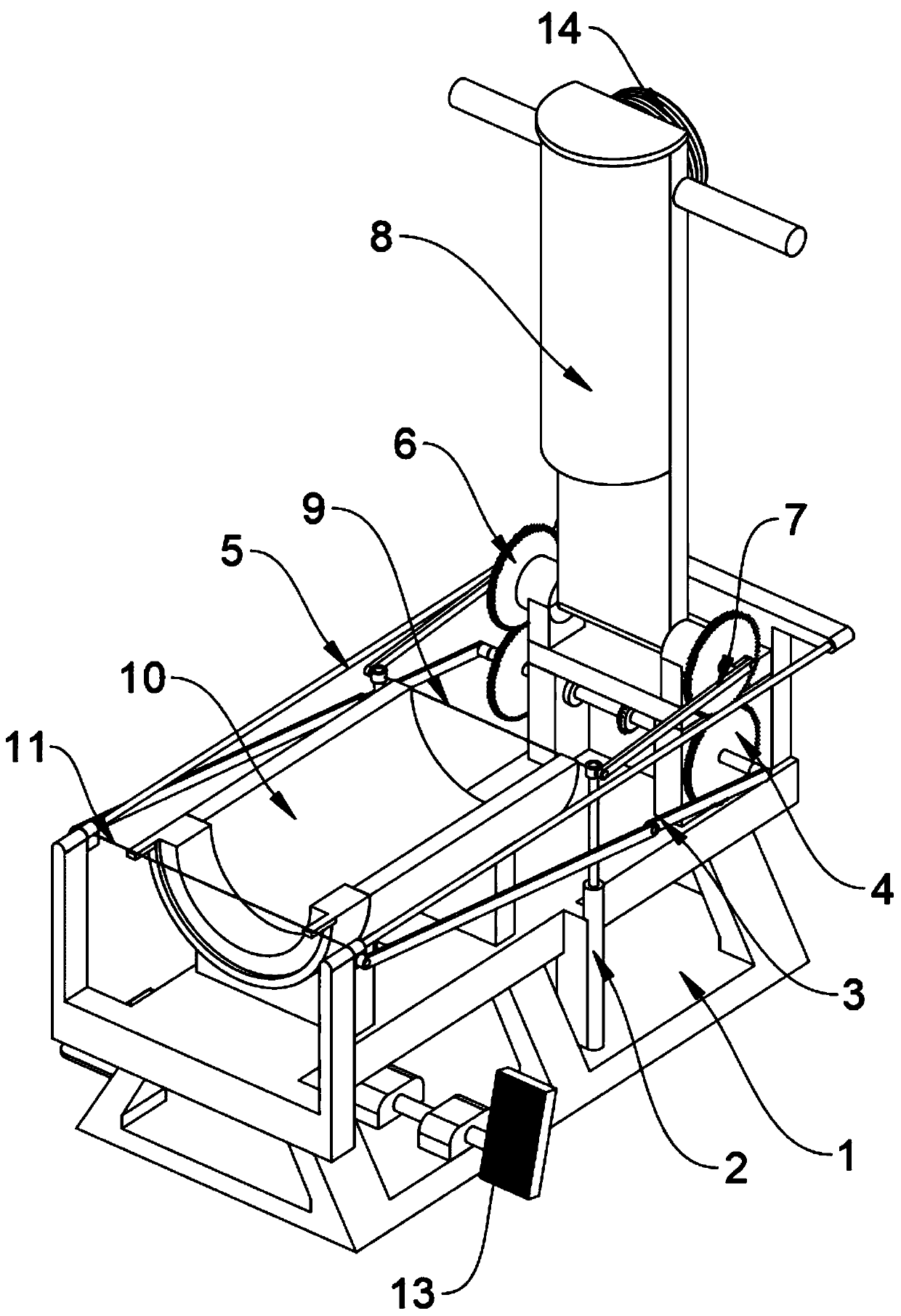

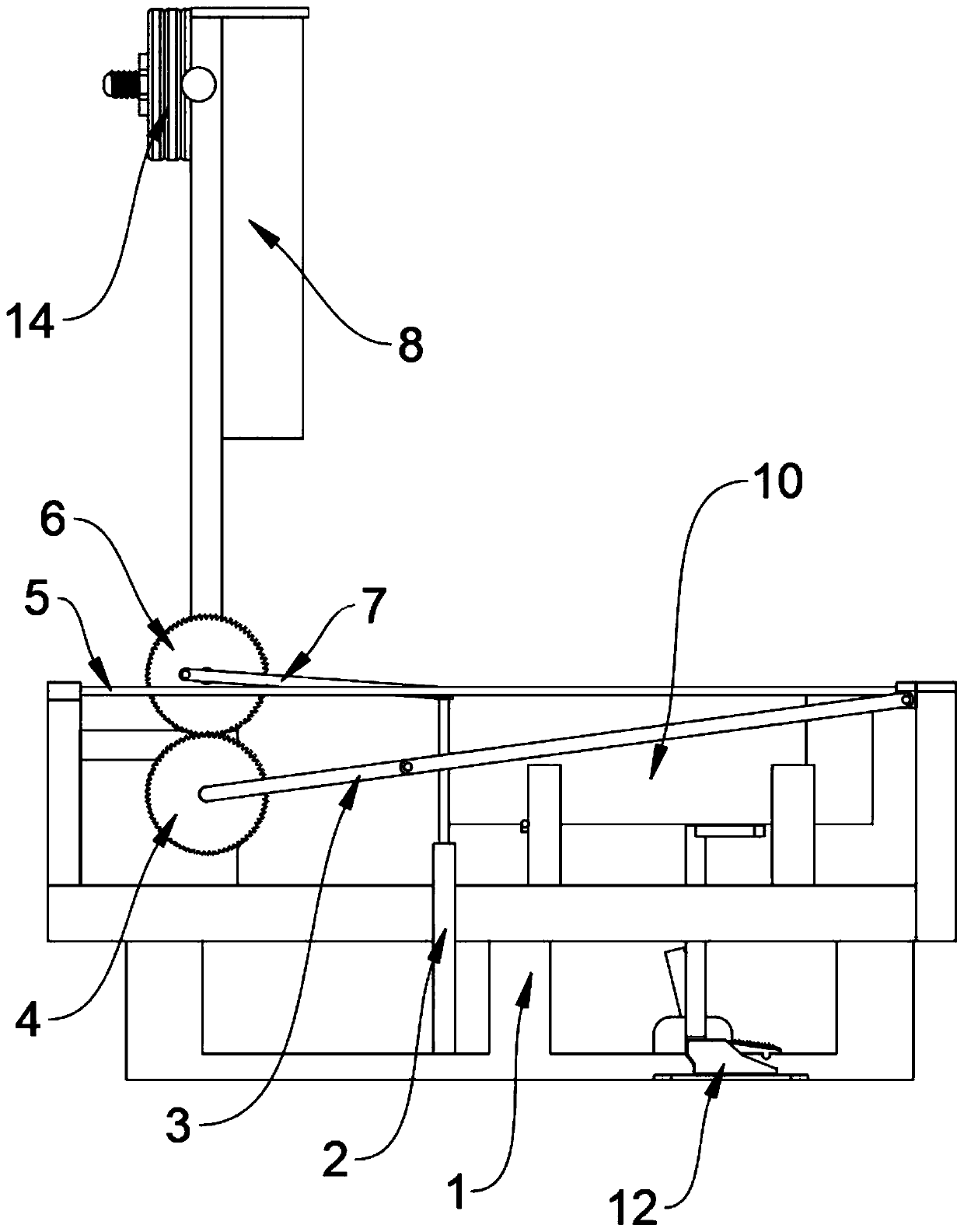

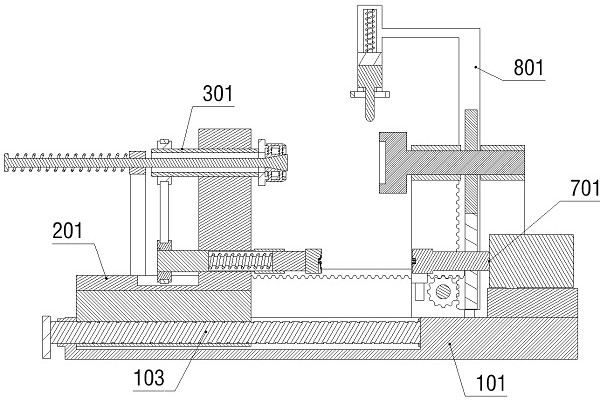

Traction unloading device for construction reinforcement straightening machine

InactiveCN111392110ARealize the collectionConvenient bundling for transportationBundling machine detailsElectric machineryScrew thread

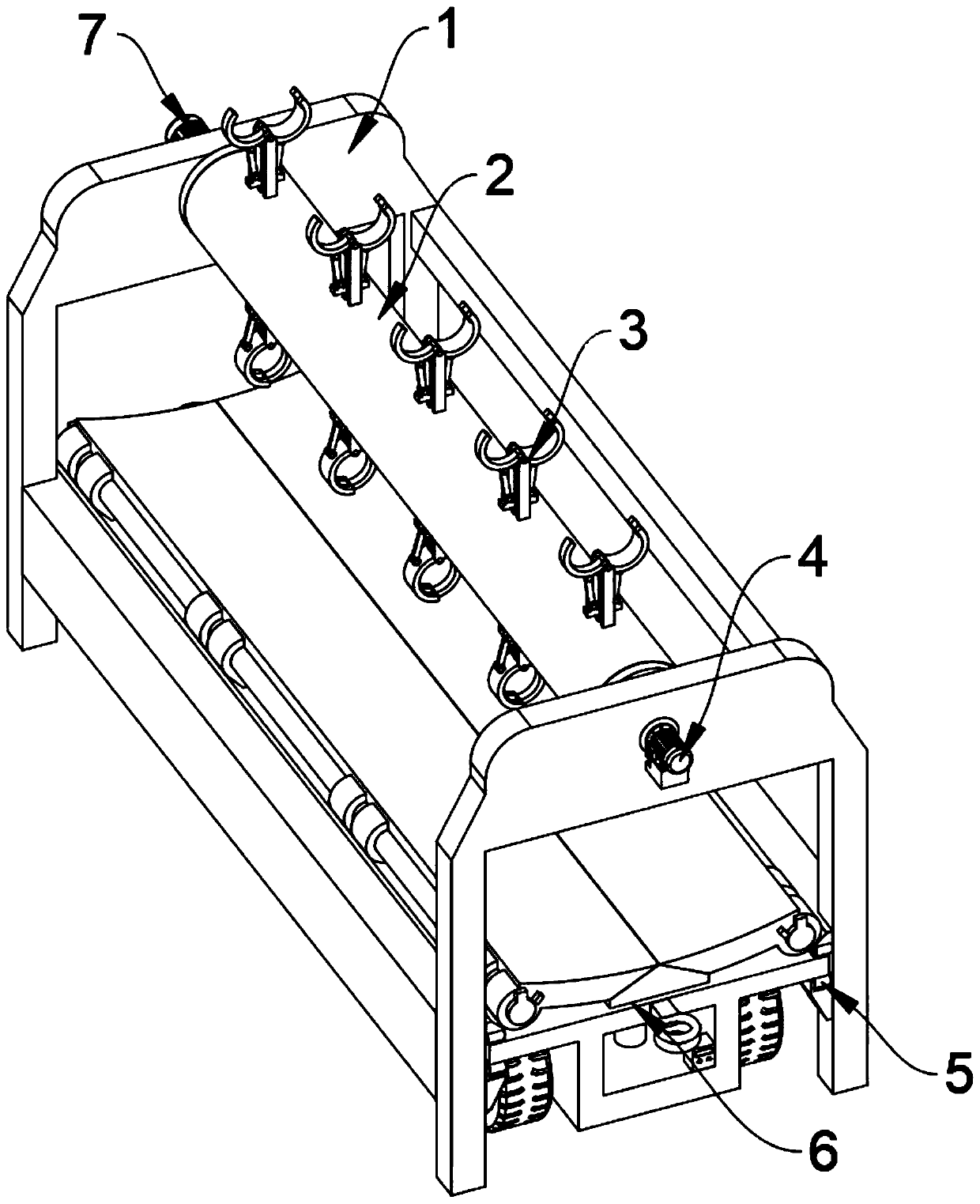

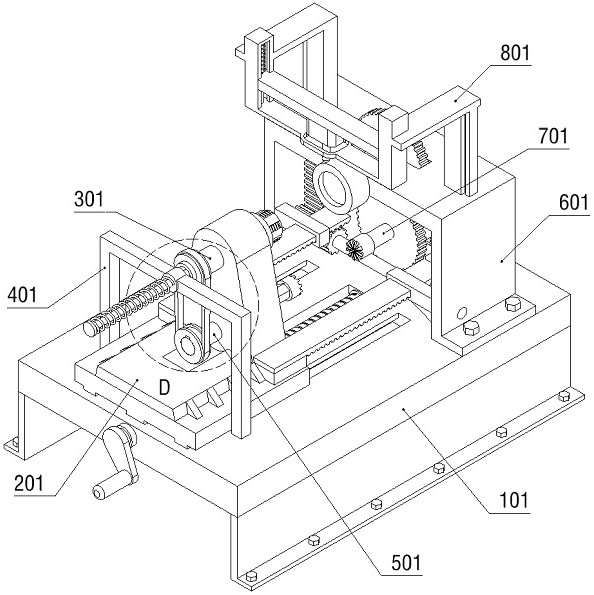

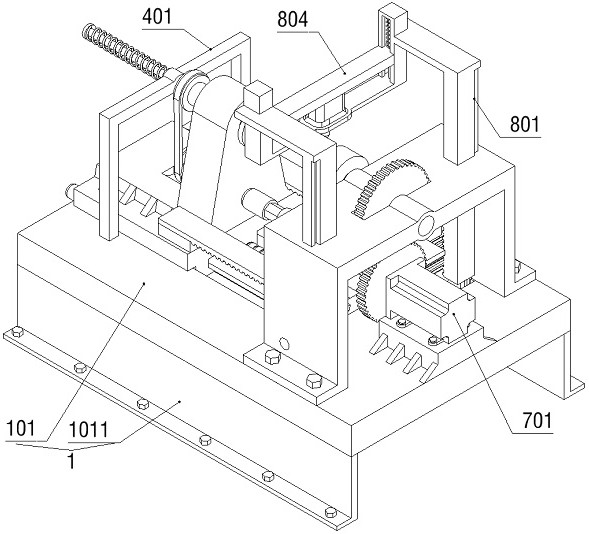

The invention provides a traction unloading device for a construction reinforcement straightening machine. The traction unloading device comprises a fixed mounting bracket and two rows of reinforcement fixing claws; a fixed revolving drum is rotationally mounted on the inner side wall of the top end of the fixed mounting bracket; each row of reinforcement fixing claws comprises five reinforcementfixing claws, and the reinforcement fixing claws are symmetrically mounted on the wall of the fixed revolving drum; and a revolving driving motor is fixed on the side wall of one end of the fixed mounting bracket through bolts. Each reinforcement fixing claw of the traction unloading device for the construction reinforcement straightening machine comprises two arc-shaped claw bodies, claw body control connecting rods, claw body adjusting thread blocks, a claw body supporting frame, a claw body drive bevel gear and a claw body drive screw, the arc-shaped claw bodies are of semi-circular arc-shaped structural design and are matched with each other to be connected to the frame body at the top end of the claw body supporting frame by a shaft, collection for straightened reinforcements is facilitated, and besides, the arc-shaped claw bodies are used for locking, so that bundling and transportation of the reinforcements are convenient for workers.

Owner:天长市天建建筑工程有限责任公司

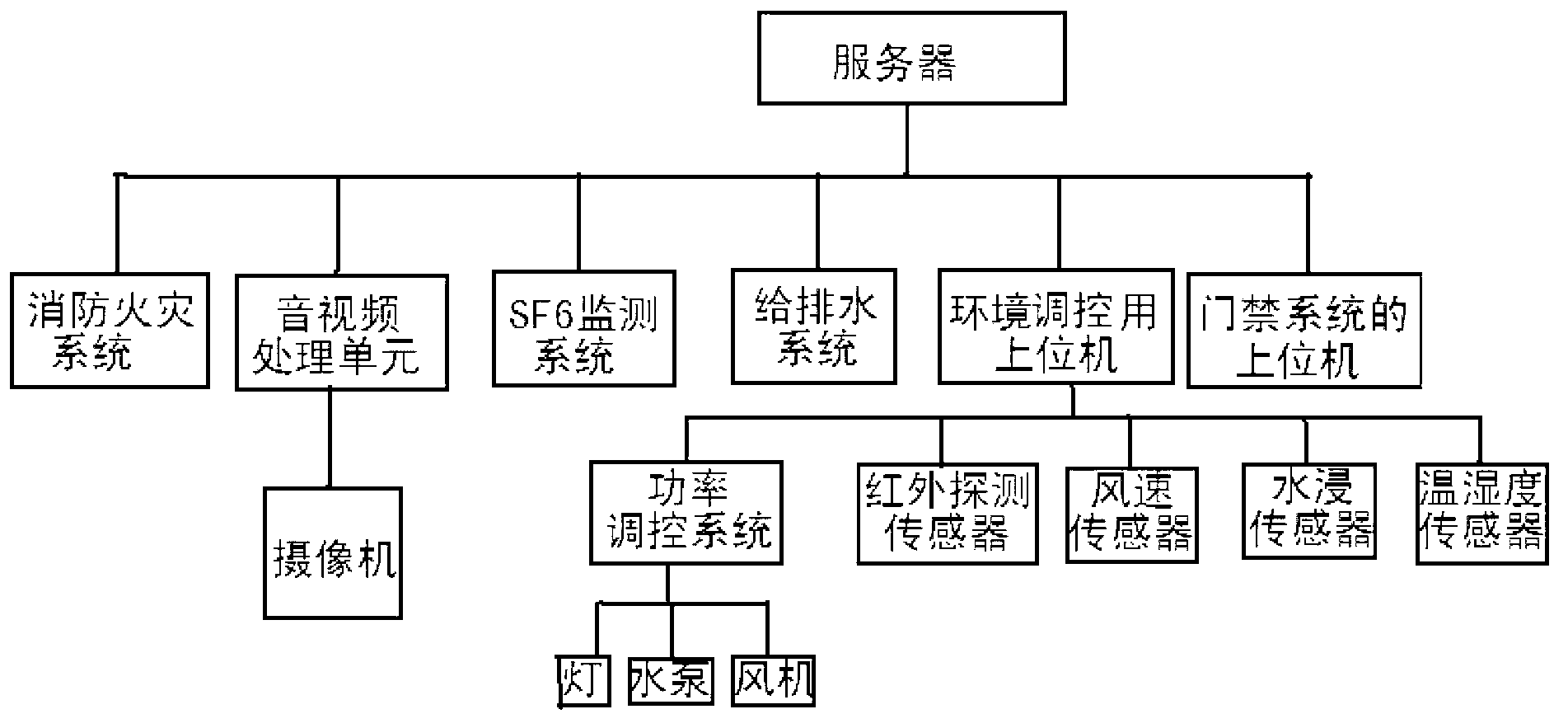

Intelligent substation assist control system

InactiveCN103257634ARealize intelligenceAchieve closureTotal factory controlProgramme total factory controlSmart substationControl system

The invention relates to a technology of substations. An intelligent substation assist control system comprises an environment regulating system which comprises an environment regulating upper computer and a sensor system. The environment regulating upper computer is connected with the sensor system. The environment regulating system further comprises a power regulating system which is connected with the environment regulating upper computer. A lamp, a water pump and a fan are arranged on a control circuit of the power regulating system to regulate the environmental factors of temperature, humidity, dryness and the like of a substation.

Owner:STATE GRID CORP OF CHINA +2

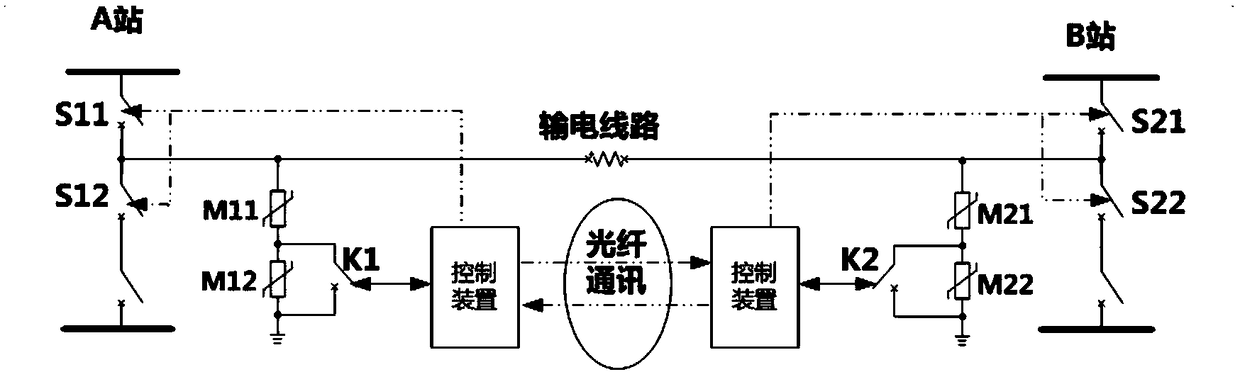

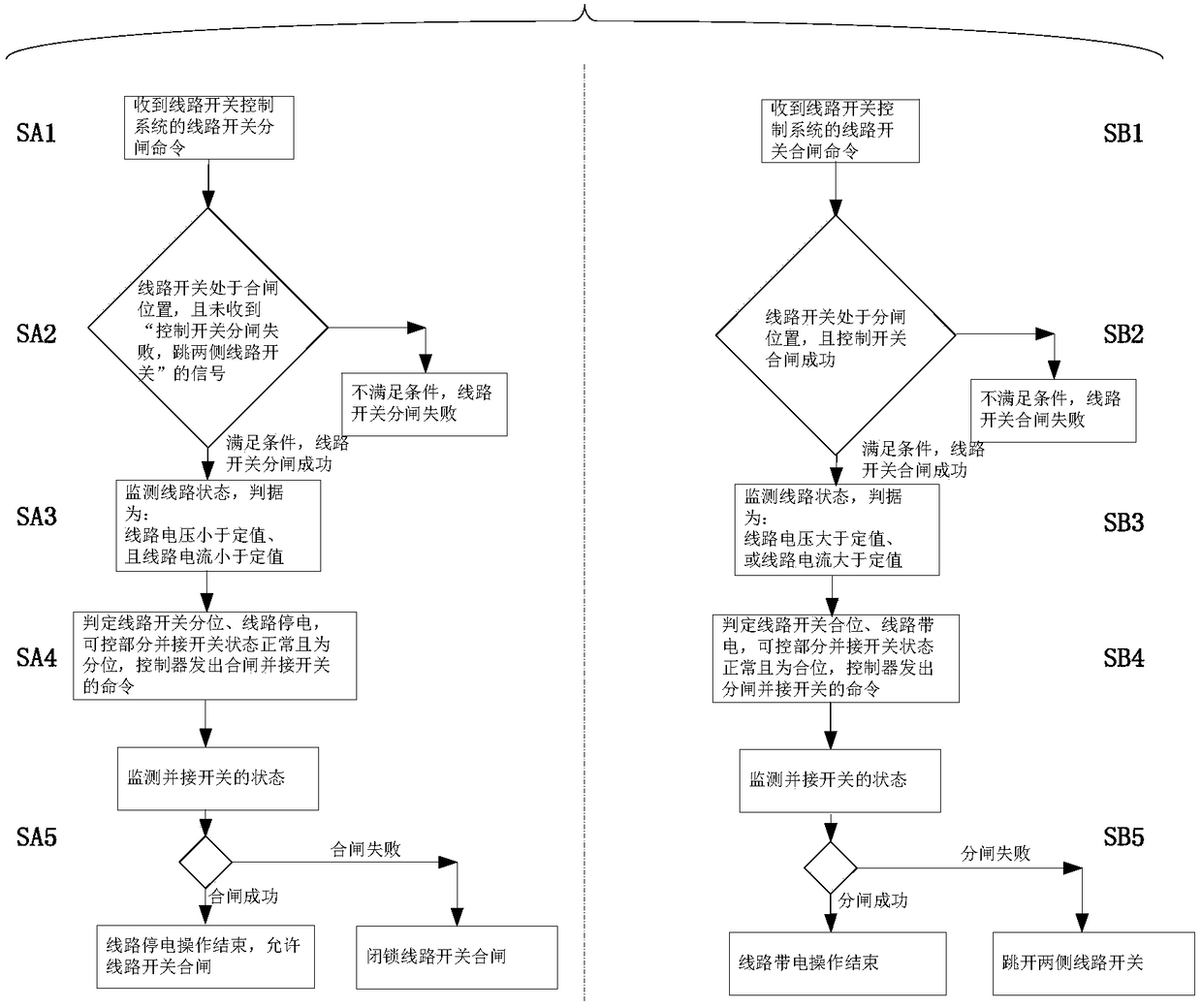

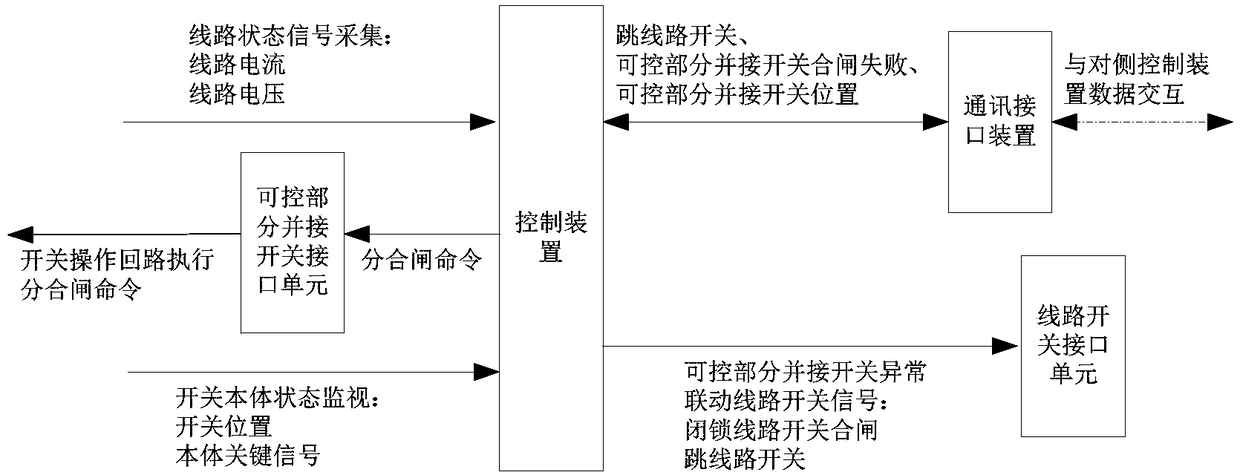

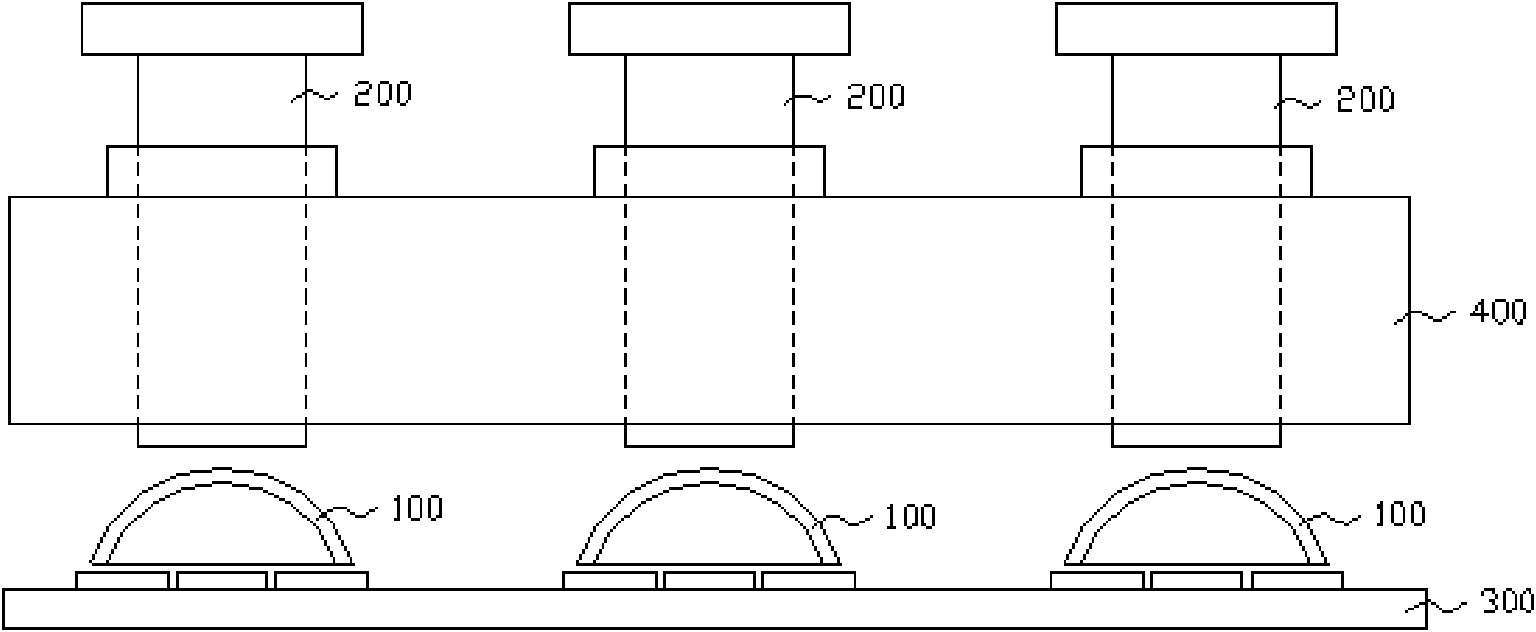

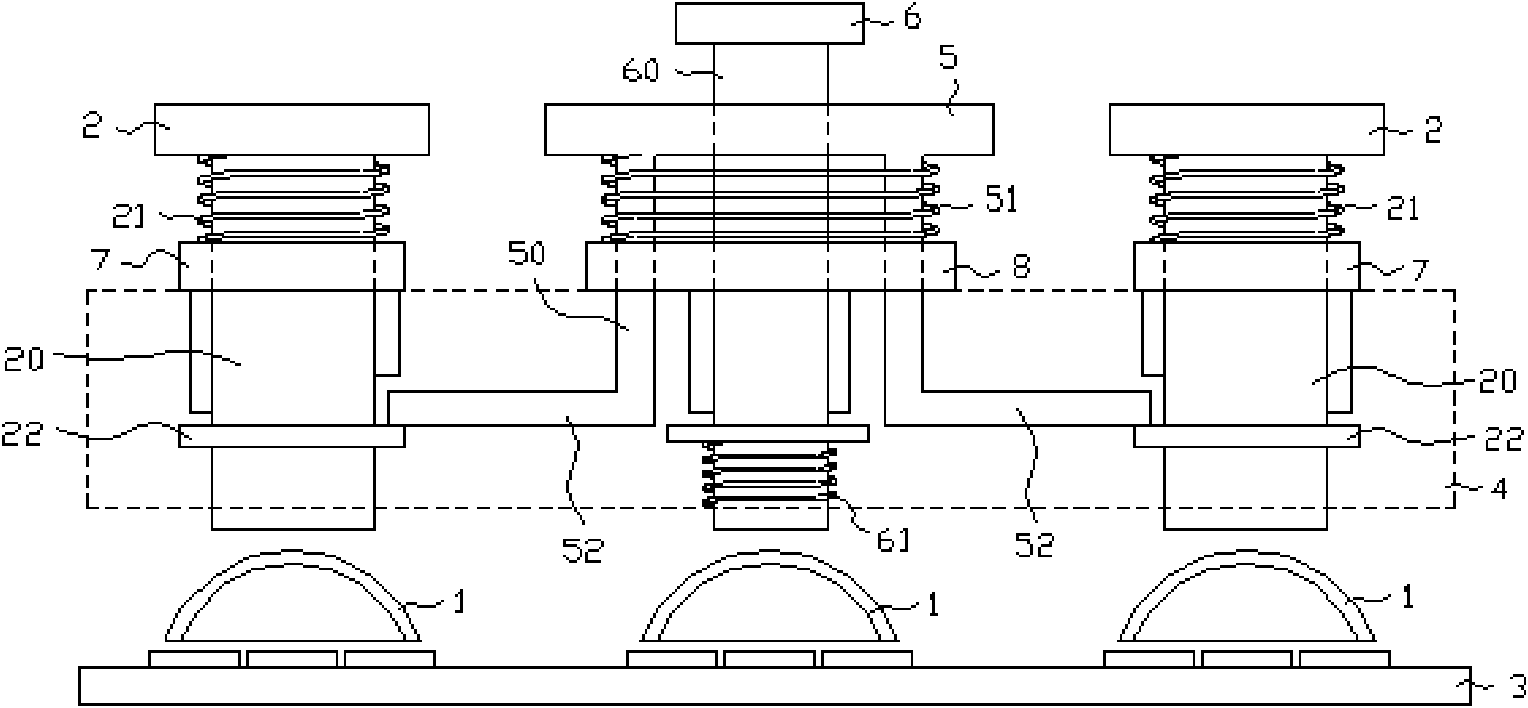

Control method and system of controllable arrester

ActiveCN108448534AClear logicSimple and reliableEmergency protective arrangement detailsInformation technology support systemControl systemEngineering

The invention provides a control method of a controllable arrester. The controllable arrester is composed of a controllable part and a fixed part, wherein the controllable part and the fixed part areconnected in series. The controllable part is switched through a control switch connected with both ends thereof. When the control switch is closed, the controllable part drops out. When the control switch is opened, the controllable part is in. The control method comprises the steps that line electrification detection is carried out; the controllable part is controlled to be connected in parallelwith opening and closing of the control switch according to the detection result, so that in and out of the controllable part automatically cooperate with opening and closing of a line switch; at thesame time, the running state of the control switch connected in parallel with the controllable part is monitored in real time; and when the control switch is abnormal, the line switch is operated inlinkage. The invention further proposes a control system of the controllable arrester. According to the invention, the control system of the controllable part of the controllable arrester and the control system of the line switch can be decoupled; the logic reliability of the controllable part in closing of the lock line switch is improved; and the intervention of operating personnel is reduced.

Owner:NR ELECTRIC CO LTD +2

Linked contact switch structure

Owner:KUNDA COMP TECHKUSN

Riveting device and production line

PendingCN108380762AIncrease riveting speedImprove stabilityMetal-working feeding devicesStripping-off devicesProduction lineEngineering

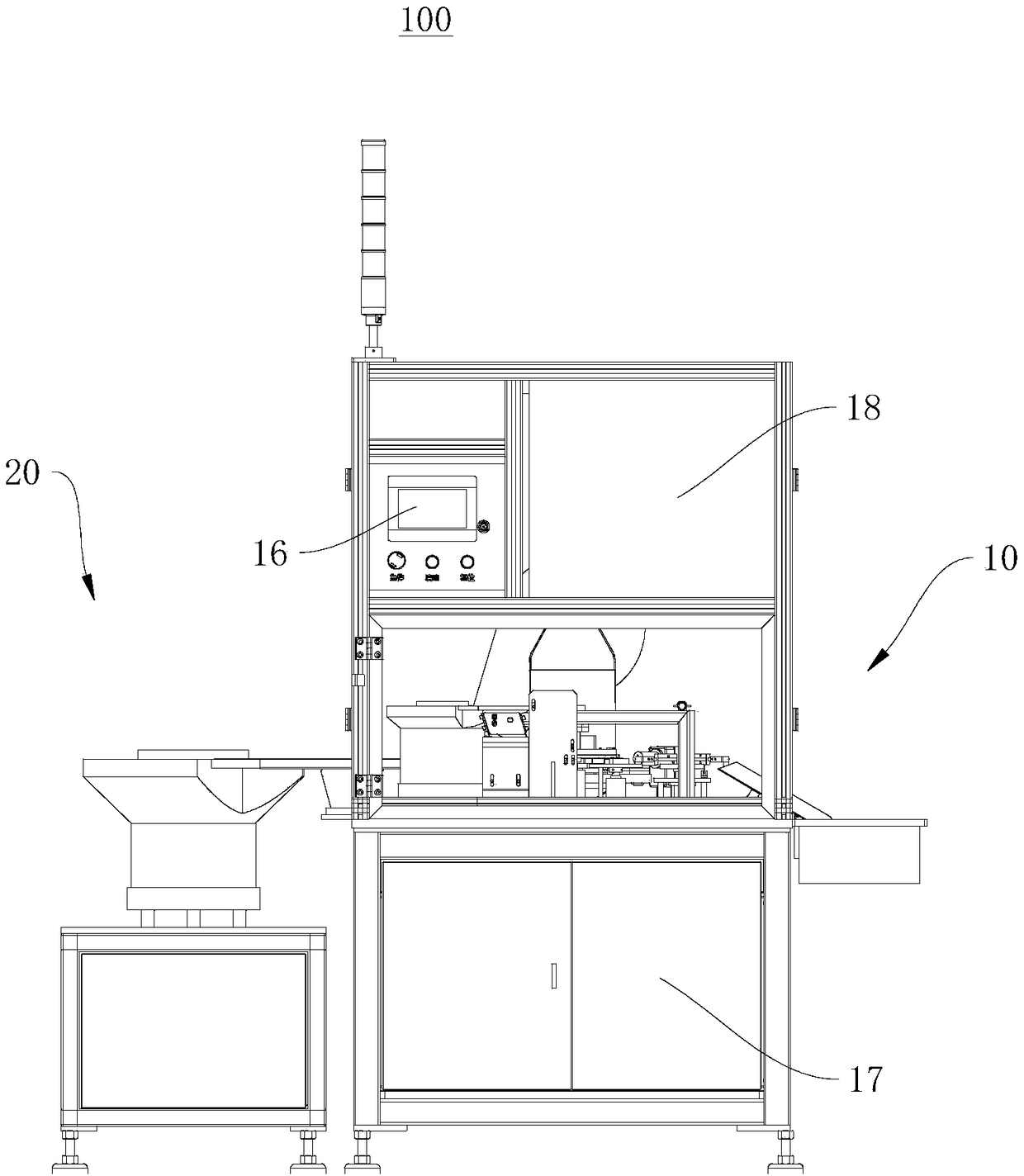

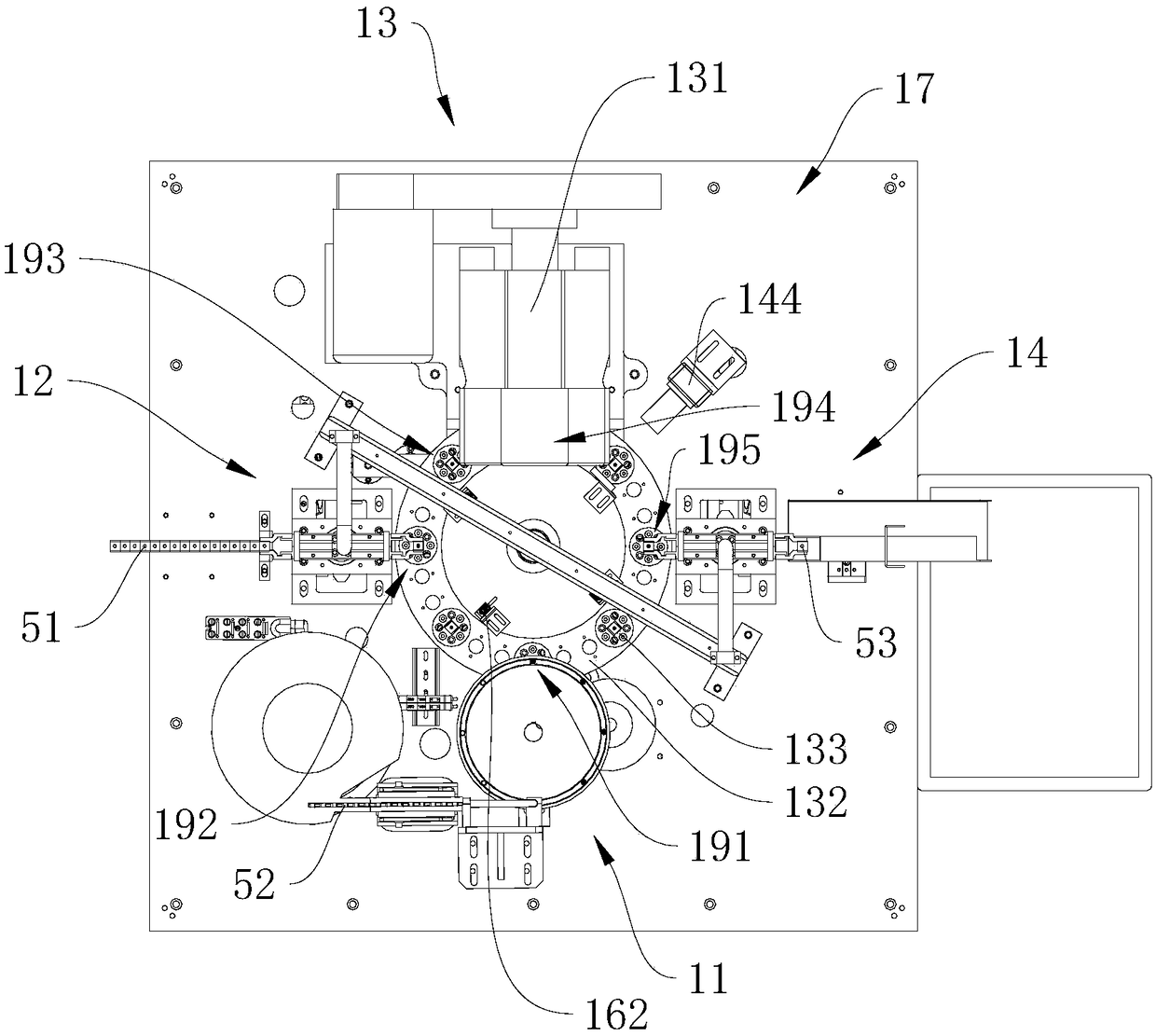

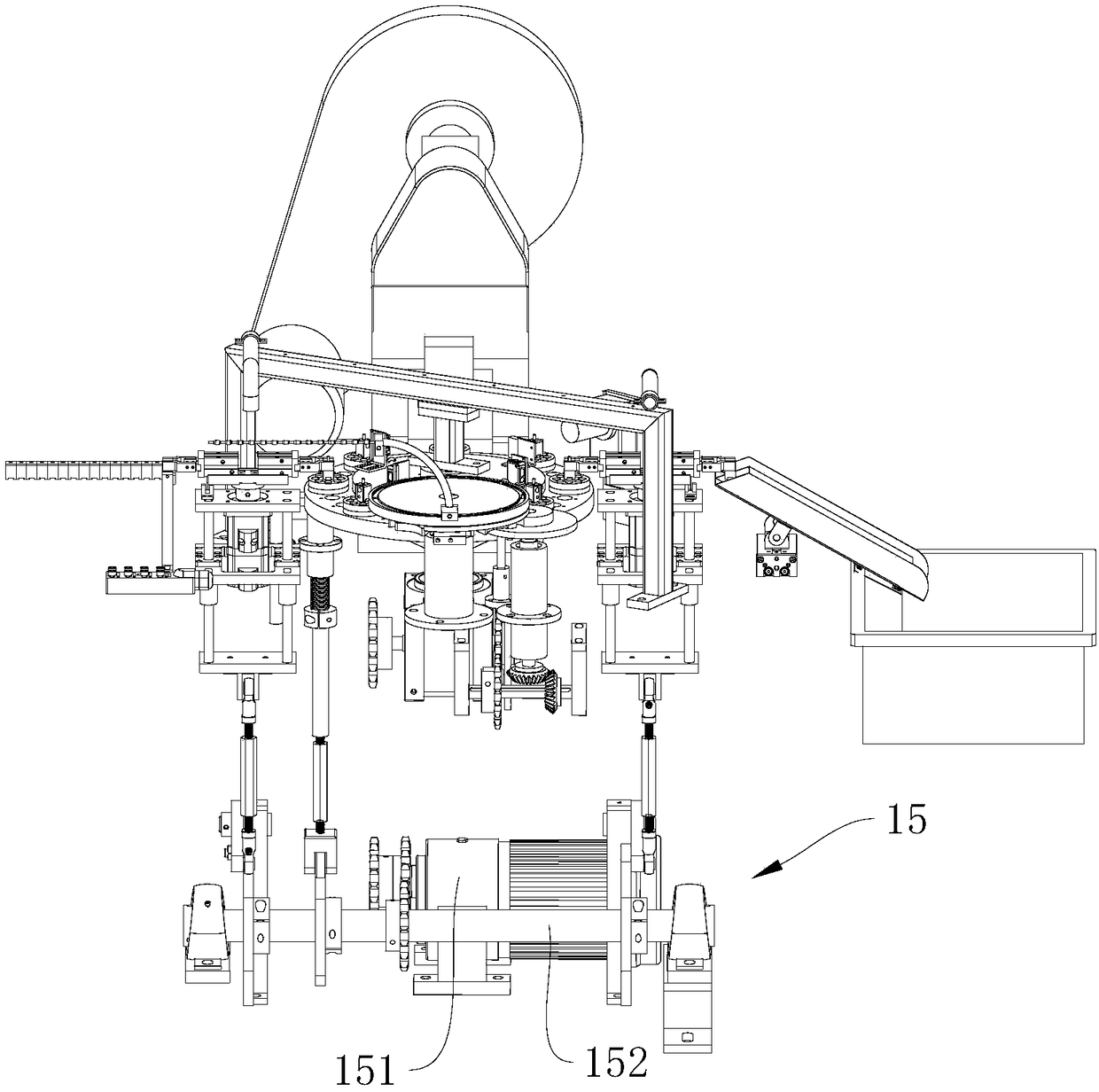

The invention discloses a riveting device and a production line, and relates to the field of automated assembly equipment. The riveting device comprises a first feeding assembly, a second feeding assembly, a riveting assembly, a discharging assembly and a driving assembly; the driving assembly is in transmission connection with the first feeding assembly, the second feeding assembly, a riveting turntable and the discharging assembly separately; the riveting assembly can be driven by the driving assembly to intermittently rotate and drive multiple riveting tools to move so that four of the riveting tools can respectively arrive at a first feeding station, a second feeding station, a riveting station and a discharging station simultaneously; meanwhile, the first feeding assembly places a first structural part to the riveting tools; the second feeding assembly places a second structural part to the riveting tools; a riveting mechanism rivets the first structural part and the second structural part to form a riveting structural part; the discharging assembly clamps the riveting structural part through the riveting tools. The riveting device is high in riveting speed and yield, and solves the problem that the danger degree of manual operation is high.

Owner:XIAMEN YOUXIN INFORMATION TECH CO LTD

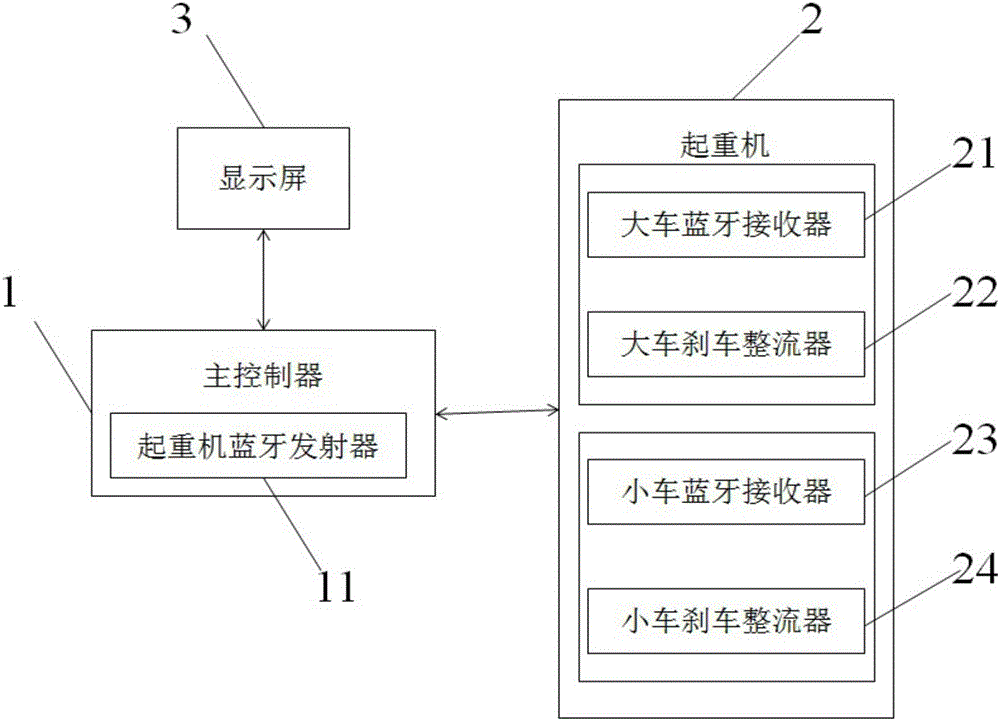

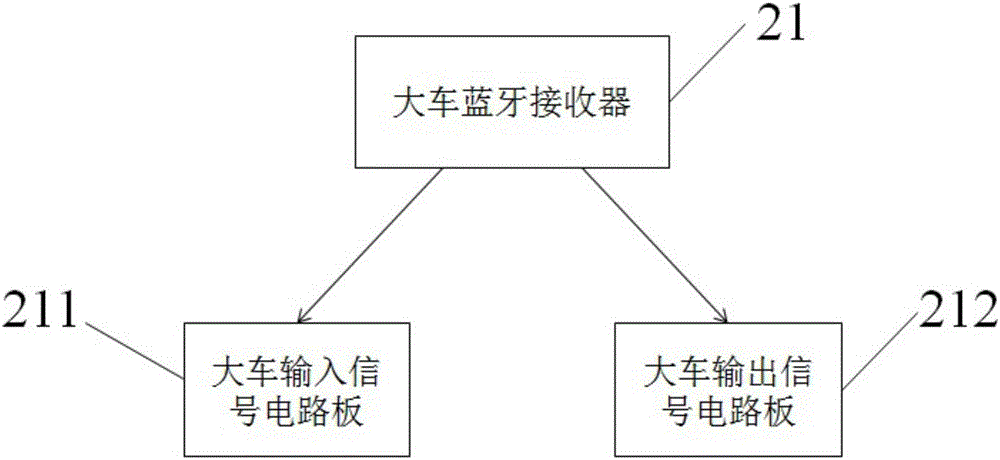

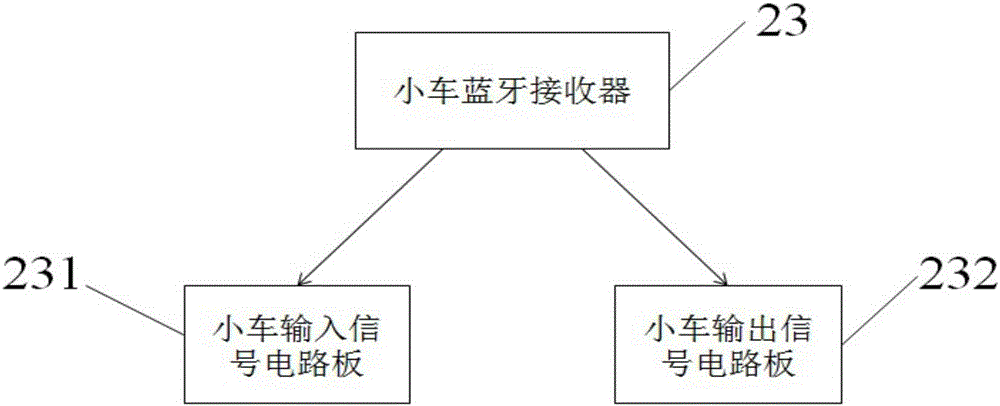

Bluetooth smart control system for cranes

The invention relates to a Bluetooth smart control system for cranes. The Bluetooth smart control system for the cranes comprises a main controller and one or more smart controlled cranes. The main controller is provided with a crane Bluetooth emitter, and each crane comprises a large-vehicle Bluetooth receiver, a large-vehicle brake rectifier, a small-vehicle Bluetooth receiver and a small-vehicle brake rectifier, wherein the large-vehicle Bluetooth receiver comprises a first input signal circuit board and a first output signal circuit board, and the small-vehicle Bluetooth receiver comprises a second input signal circuit board and a second output signal circuit board. Bluetooth smart control is adopted, a high-speed frequency hopping system of the Bluetooth smart control system enables data to be transmitted more reliably without interference of other systems such as Wifi and Zigbee, and transmission is completely bidirectional. Smart operation and safe application performance of the cranes are improved, the smart integration degree of the cranes is high, the adopted technological process is simple, easy to understand and high in practicability, and the manufacturing cost is low.

Owner:SHANGHAI SHT CRANES

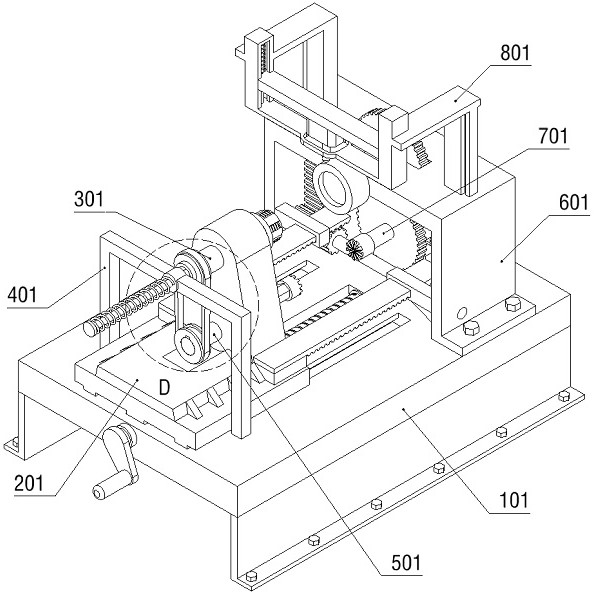

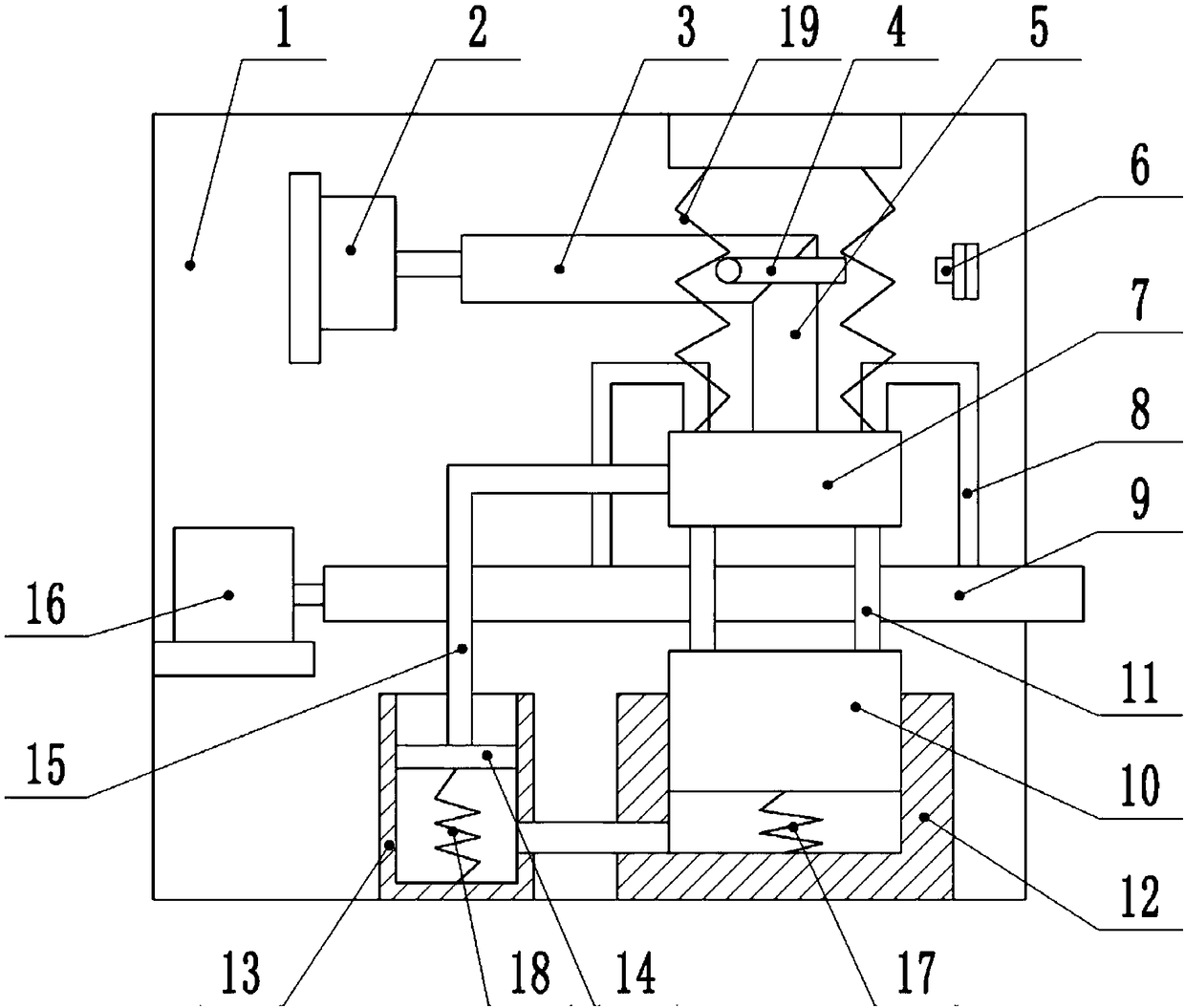

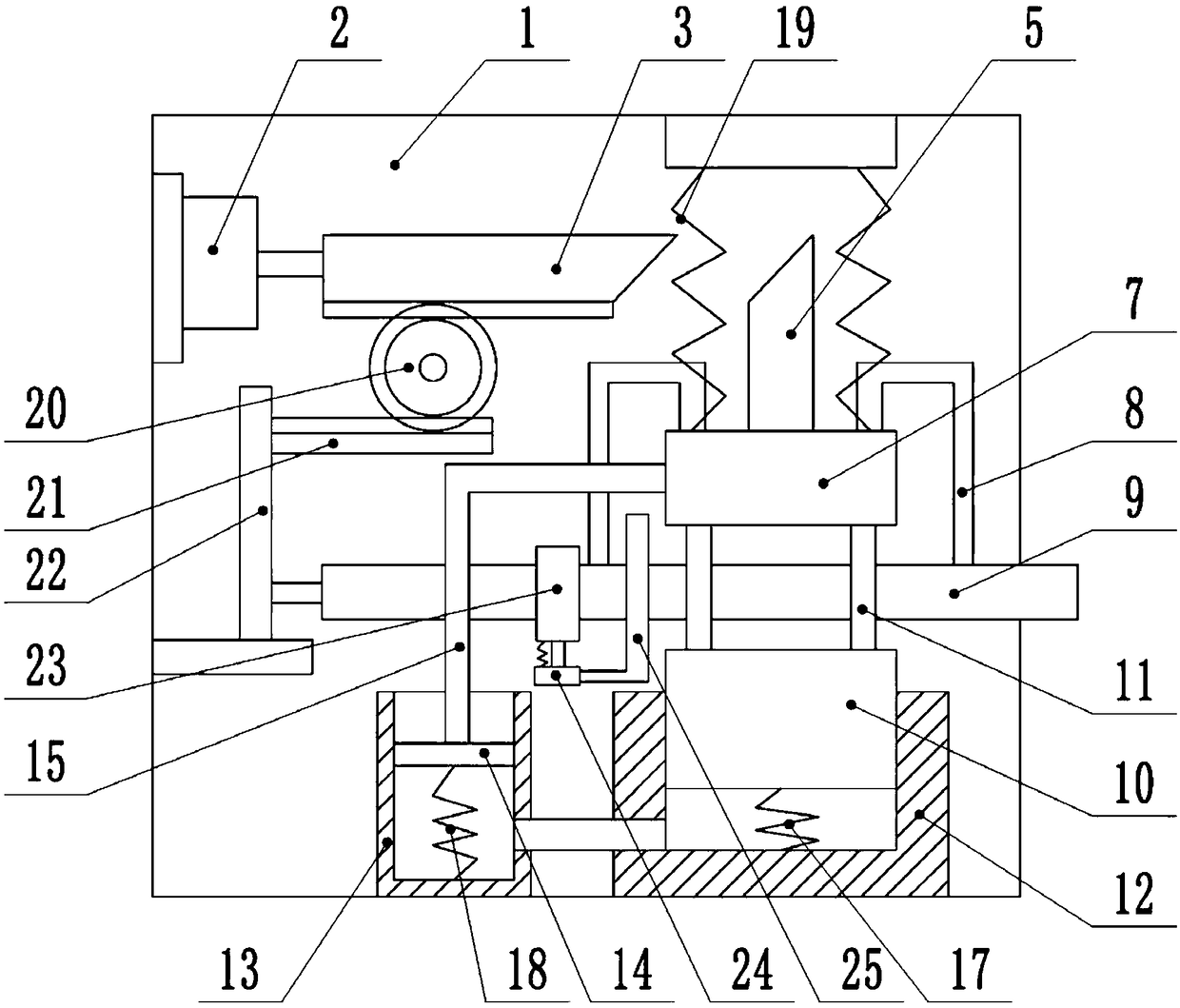

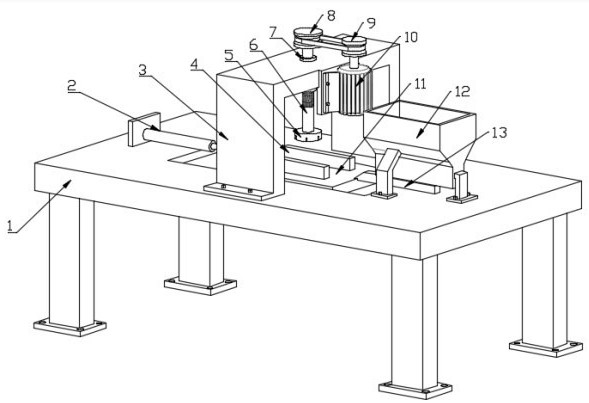

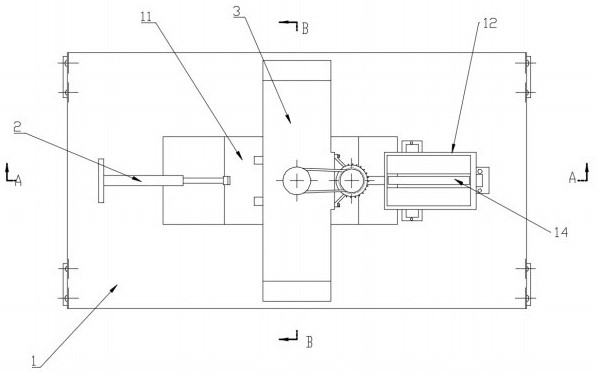

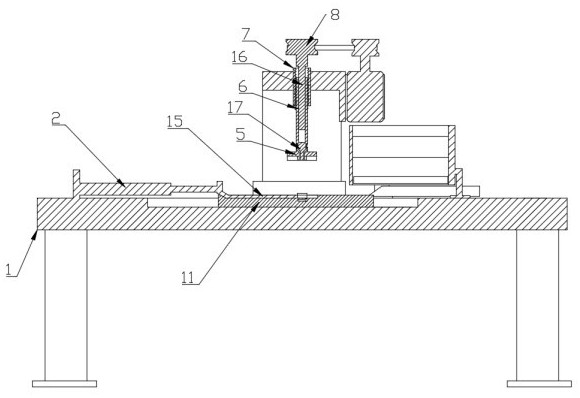

Vibration speed testing device for bearing

ActiveCN113834659AImprove operational efficiencyImprove coaxialityMachine part testingClassical mechanicsBearing vibration

The invention provides a vibration speed testing device for a bearing, and relates to the technical field of bearing testing, and the vibration speed testing device comprises a supporting device which is provided with a linkage propelling part; the linkage propelling part is rotationally connected with a mounting part; a displacement expansion part is fixedly connected to the supporting device; the bottom of the linkage propelling part is rotationally connected with a butt joint driving part; a reverse acceleration device is fixedly connected to the supporting device; the supporting device is fixedly connected with a main shaft driving part; and the reverse acceleration device is connected with a floating detection part in a sliding manner. The vibration speed testing device is simple and efficient in structure, accurate in data and high in bearing coaxiality. The bearing vibration speed testing device solves the problems that an existing bearing vibration speed testing device is low in testing efficiency, influences detection data accuracy, cannot achieve butt joint reverse acceleration testing, cannot achieve floating detection and is poor in attaching performance.

Owner:山东凤鸣新材料有限公司

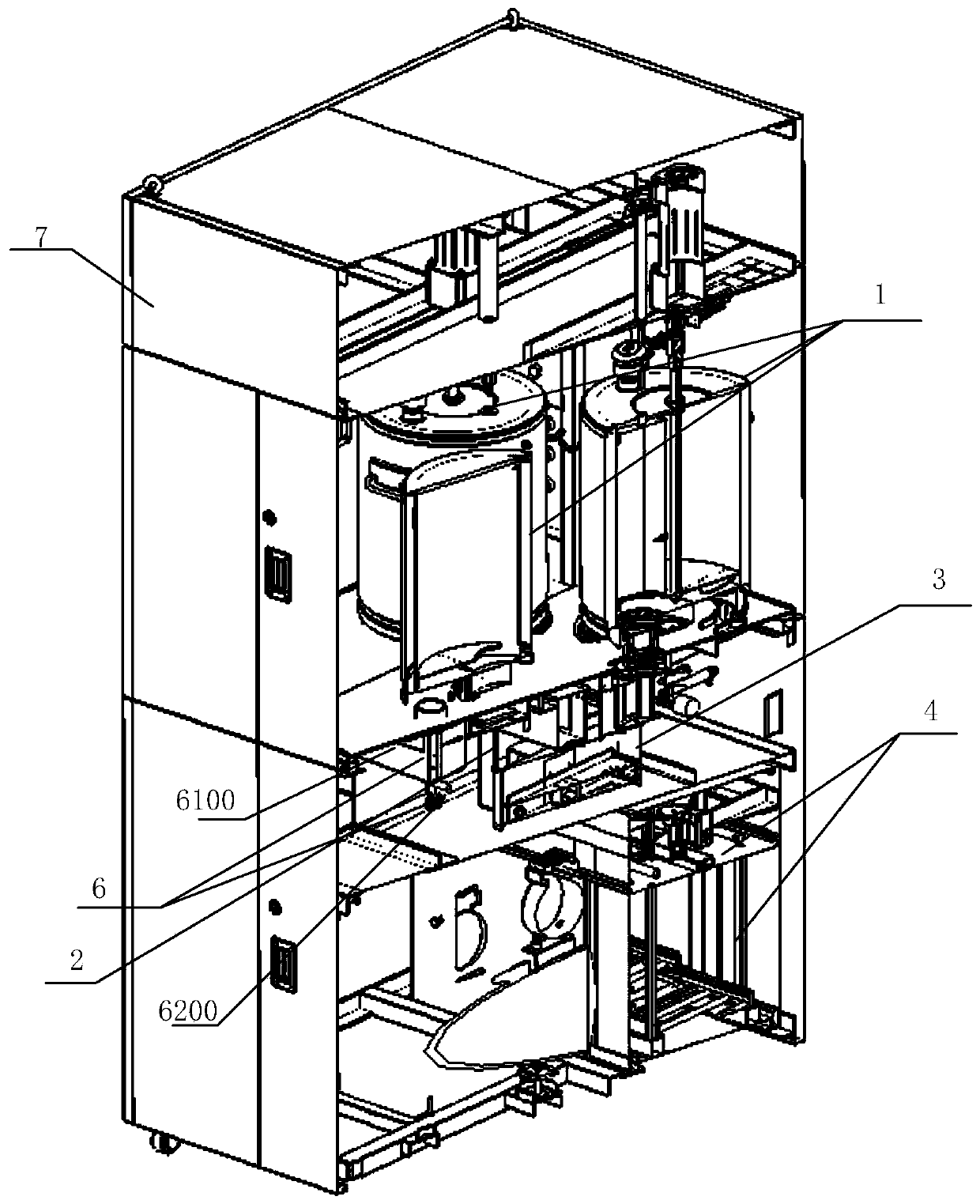

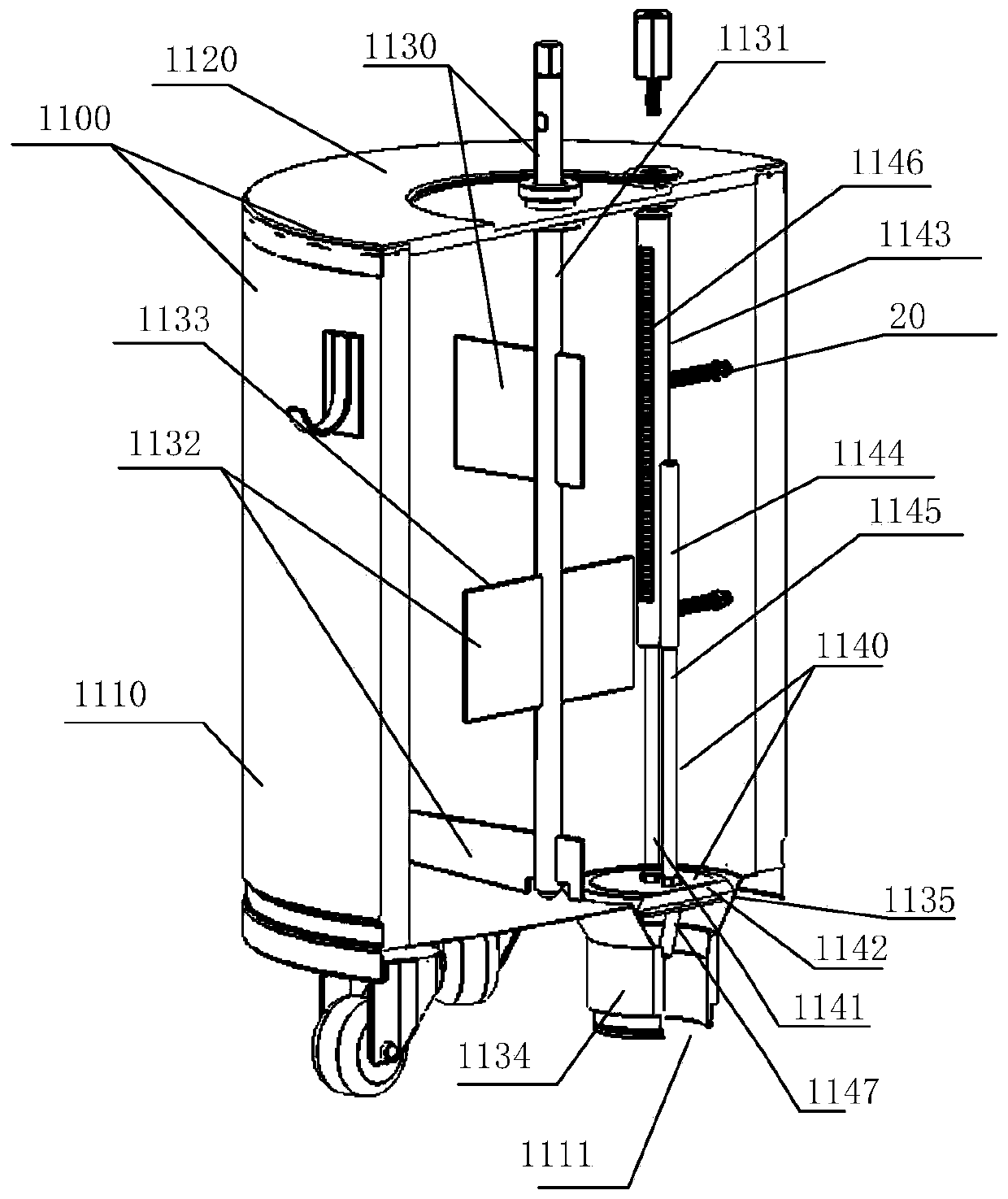

Automatic dish selling machine

PendingCN110613315AAchieve diversificationRealize automatic vendingCoin-freed apparatus detailsCooking vesselsChinese charactersPower output

The invention discloses an automatic dish selling machine which comprises a dish storage barrel set which is used for storing dishes, is shaped like a Chinese character 'pin' and provided with a matched power assembly and comprises a porridge barrel, a cooked dish barrel and a fried dish barrel which are respectively matched with porridge to be sold, cooked dishes to be sold and fried dishes to besold. Each of the porridge barrel, the cooked dish barrel and the fried dish barrel comprises a barrel body, wherein a dish outlet or a rice outlet is formed in the bottom of the barrel body; a coverbody which is matched with the barrel body; a stirring assembly which is arranged in the barrel body, wherein one end of the stirring assembly penetrates through the cover body so as to be in transmission connection with a first power output shaft of the power assembly, and therefore objects contained in the barrel body can fall into the dish outlet or the rice outlet along with rotation; and a plugging assembly, wherein the plugging assembly which penetrates through the cover body and is connected with a second power output shaft of the power assembly so as to switch the working state of thedish outlet or the rice outlet is arranged at the position, corresponding to the dish outlet or the rice outlet, in the barrel body.

Owner:四川奥德瑞斯智能科技发展有限公司

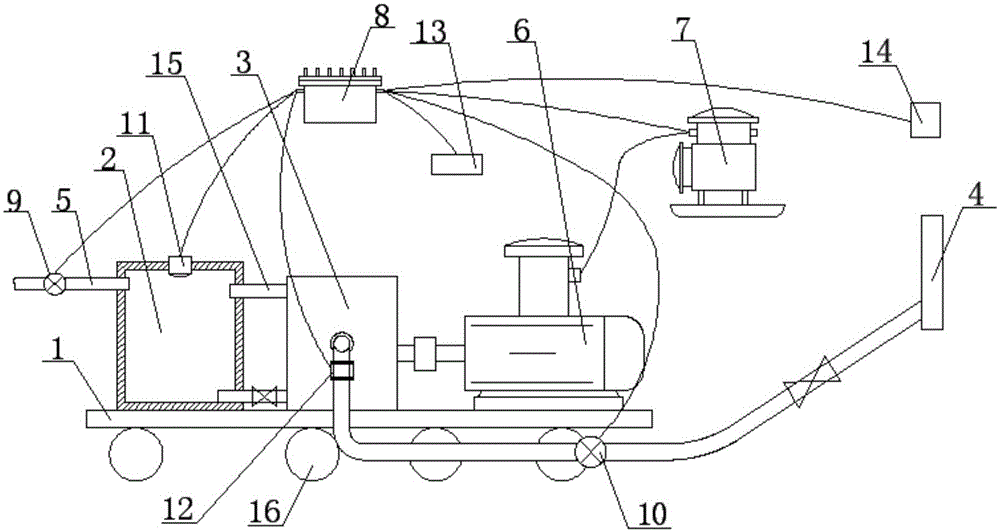

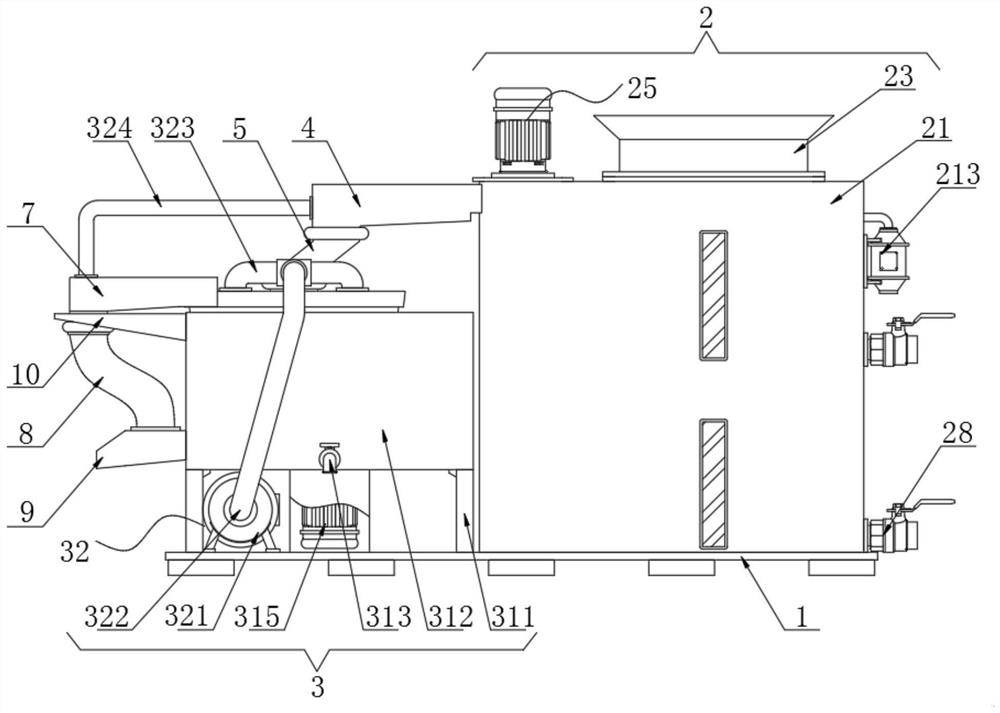

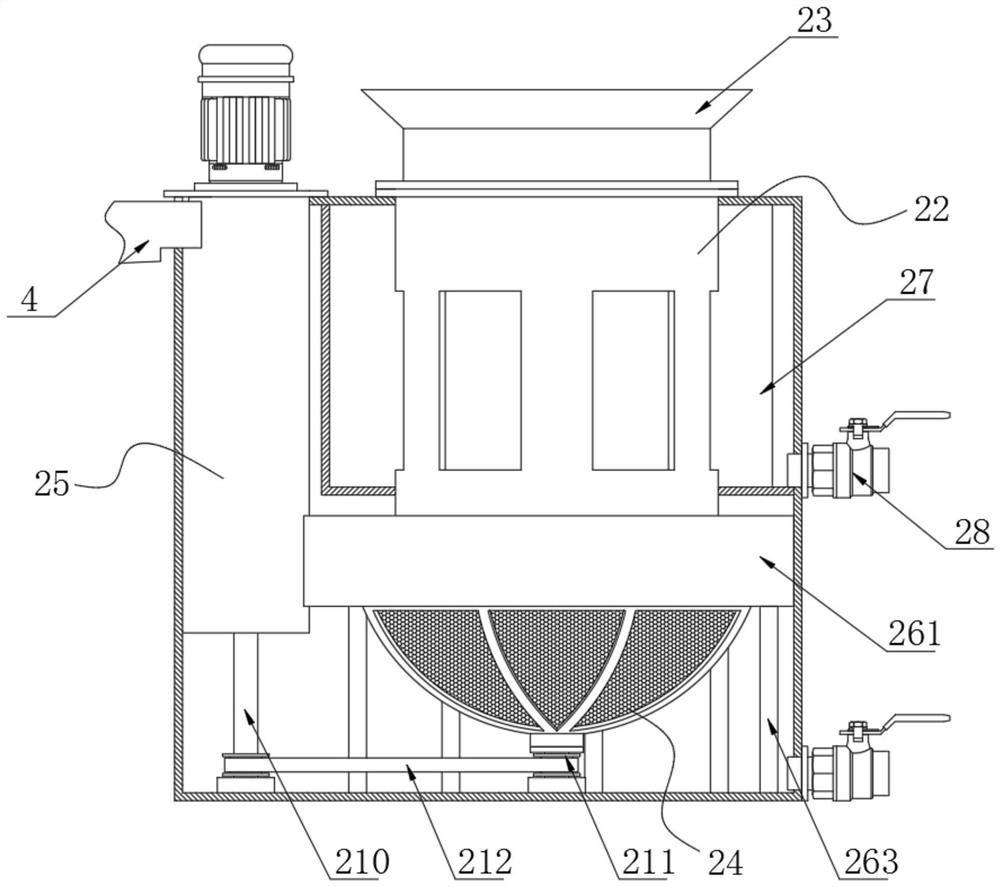

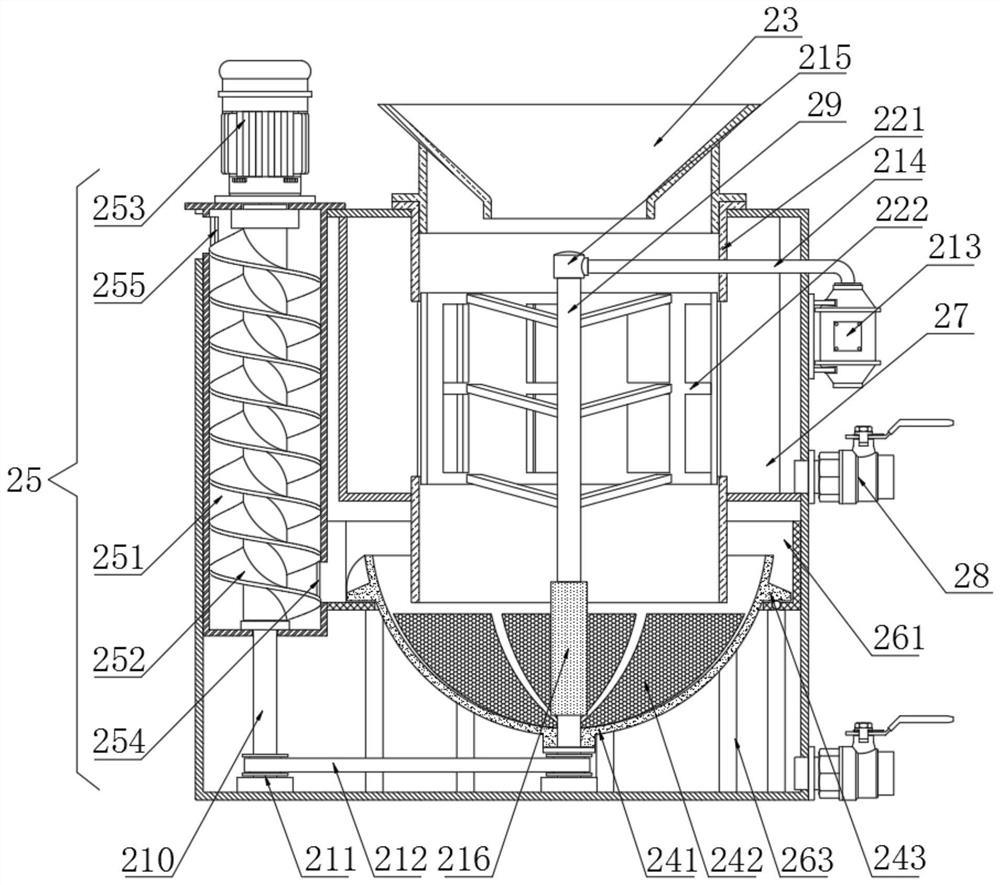

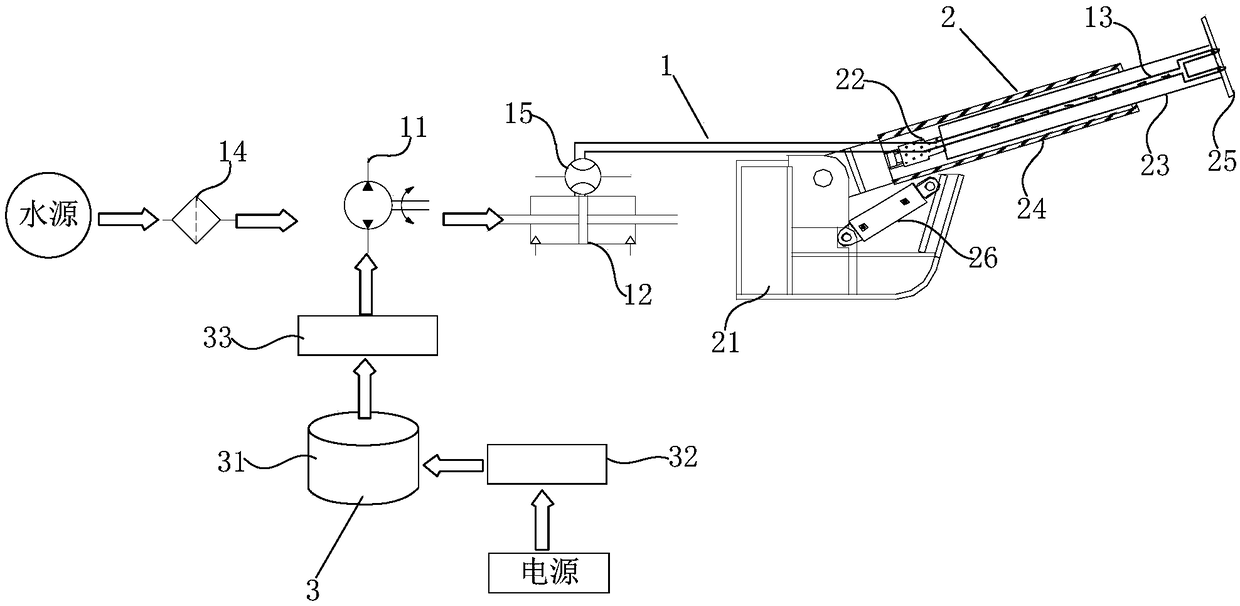

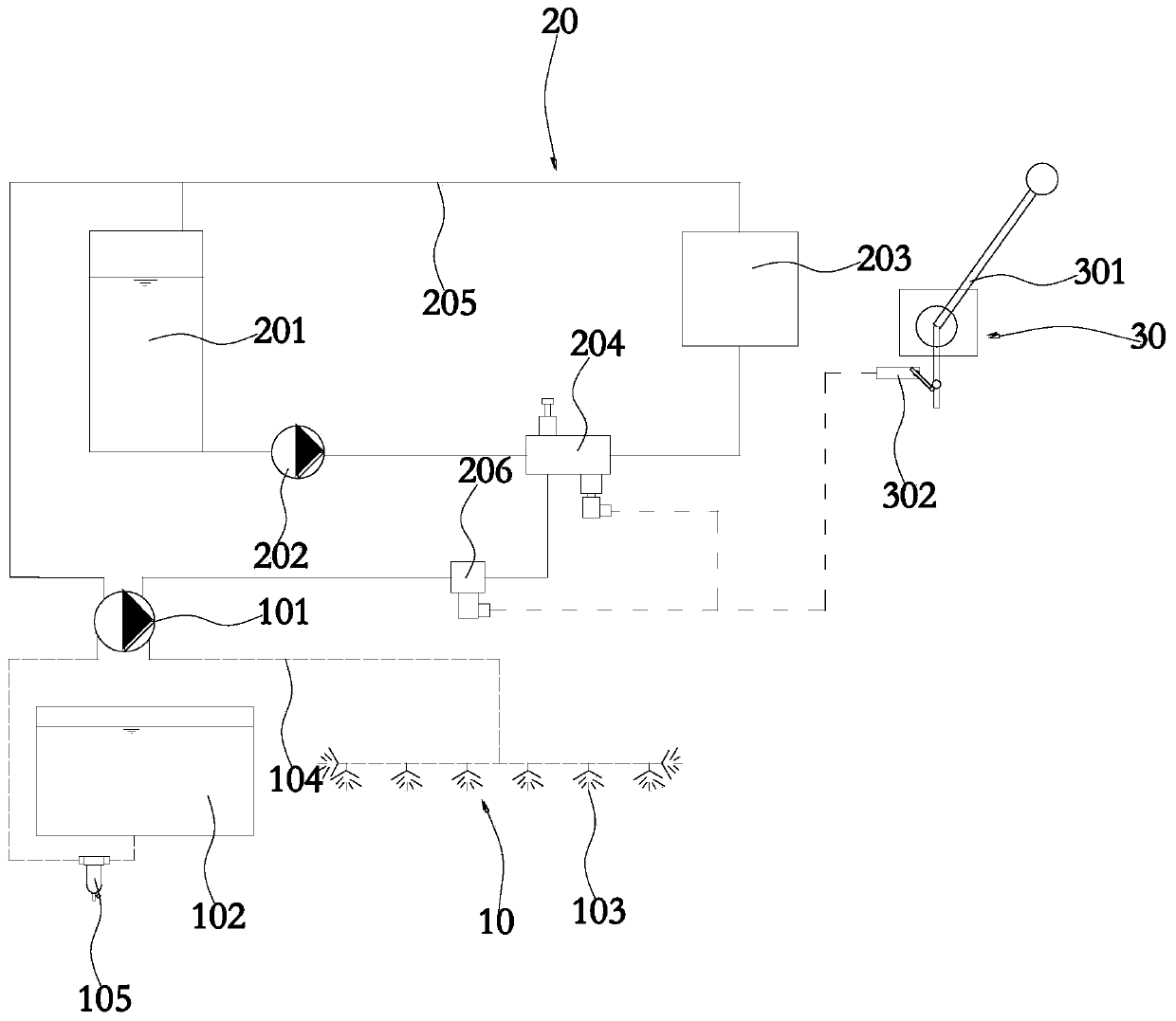

Automatic high-pressure spray dust-settling device

InactiveCN105114078ARealize remote controlRealize linkage operationSlitting machinesWater dischargeElectronic control system

The invention discloses an automatic high-pressure spray dust-settling device which comprises a base plate. A water tank, a high-pressure spray pump and a motor are arranged on the base plate; the high-pressure spray pump is connected with a spraying device; and the water tank is connected with the high-pressure spray pump which is driven by the motor. A vacuum electromagnetic starter and a master control box are also arranged on the base plate; the vacuum electromagnetic starter is connected with the motor and the master control box, and an electronic control system is installed in the master control box. An electric ball valve I is arranged on a water inlet pipe, and an electric ball valve II is arranged on a water pipe which is used for connecting the high-pressure spray pump and the spraying device. A water level sensor is arranged in an inner cavity of the water tank, and a flow pressure sensor is arranged at a water discharge outlet of the high-pressure spray pump. A remote control signal receiver is arranged in the master control box which is further connected with an on-off sensor. The automatic high-pressure spray dust-settling device can be controlled remotely, can run automatically and can be in linkage operation with a coal mining machine; besides, spray efficiency of the automatic high-pressure spray dust-settling device is improved while water usage for spray can be saved.

Owner:HUAINAN RUNCHENG TECH

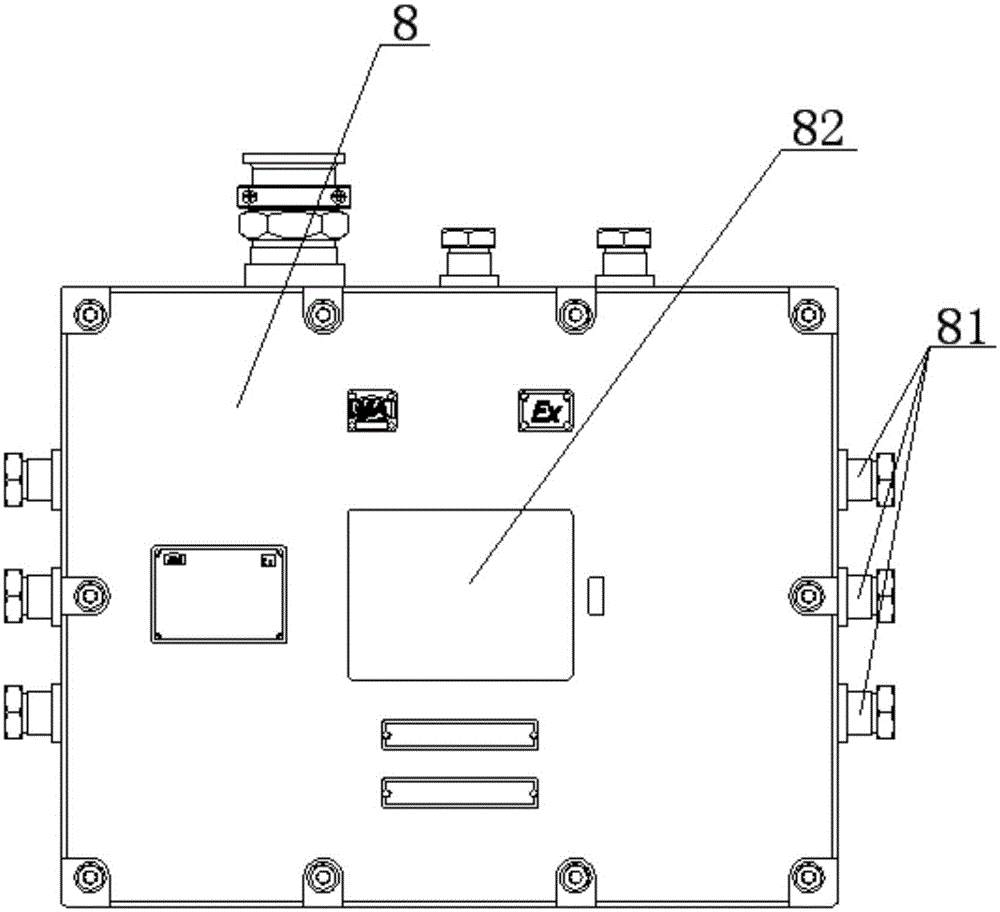

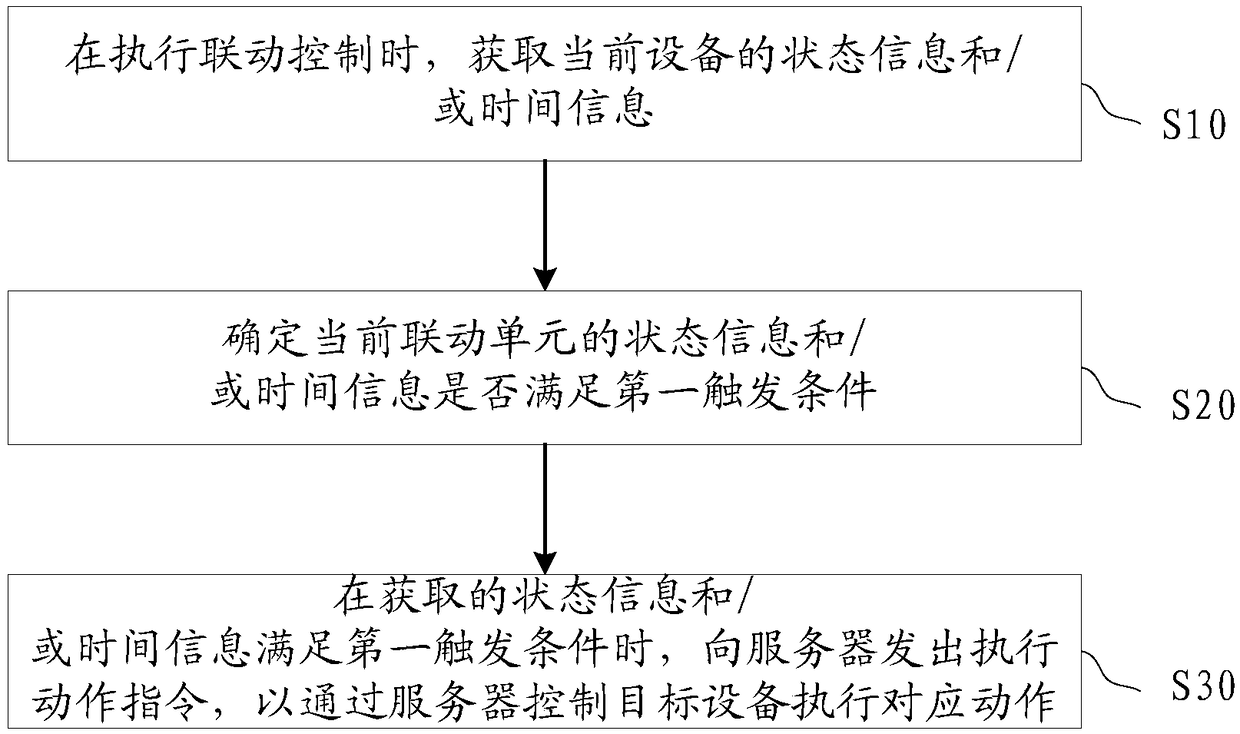

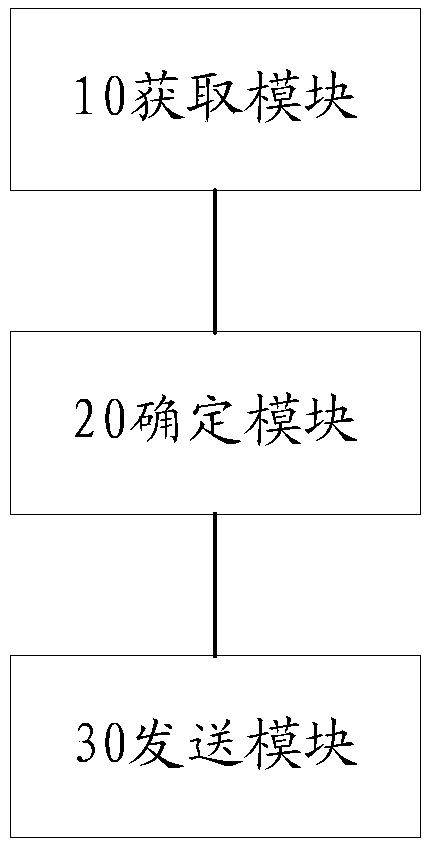

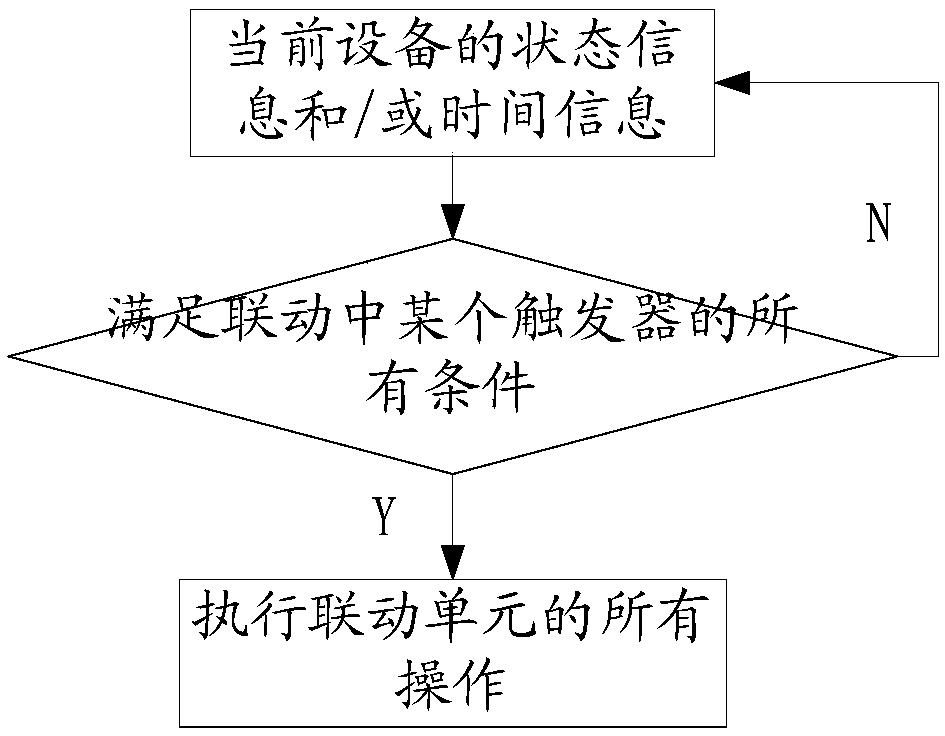

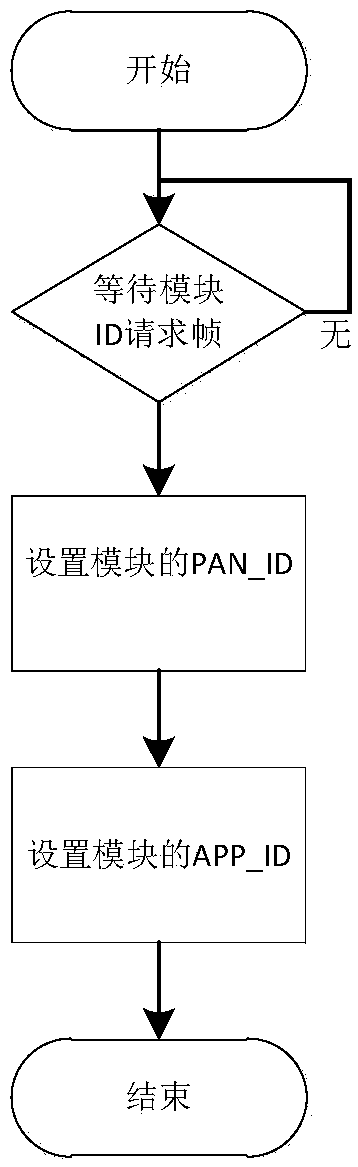

Programmable linkage control method and device based on internet of things

InactiveCN109388391AImprove experienceRealize linkage operationCreation/generation of source codeTime informationThe Internet

The invention discloses a programmable linkage control method and a device based on the internet of things, wherein, the programmable linkage control method based on the internet of things comprises the following steps: when the linkage control is executed, the state information and / or the time information of the current equipment are obtained; when the linkage control is executed, the state information and / or the time information of the current equipment are obtained. Determining whether the state information and / or the time information of the current linkage unit satisfies the first triggering condition; When the acquired state information and / or time information satisfy the first trigger condition, an execution action instruction is issued to the server to control the target device to execute the corresponding action through the server. The technical proposal of the invention can realize the linkage operation of each device in the internet of things, without the need of controllingeach device by the user, saves the operation, realizes the intelligent control, and is favorable for improving the user experience.

Owner:深圳市二八智能家居有限公司

Frame type stopper of ramp of underground mine

InactiveCN103241265ARealize linkage operationGuaranteed uptimePositive railway stopsBlock and tackleEngineering

The invention relates to a stopper, particularly to a ramp stopper and belongs to the mine production equipment field. The frame type stopper of a ramp of an underground mine comprises stopper plates; one ends of the stopper plates are in hinged connection with an anchor rod which is fixed on the top wall of the ramp; one side of the stopper plates, which has the same ascending direction with the ramp, is provided with pulley groups which are fixed on the top wall of the ramp through the anchor rod; the two front and rear pulley groups are connected through a steel wire rope; and two ends of the steel wire rope are respectively connected with the two front and rear stopper plates. The frame type stopper of the ramp of the underground mine has the advantages of performing integral stopping when a tramcar slides on the premise of guaranteeing unobstructed traffic of the tramcar on the ramp, avoiding conditions such as derail or wheel damage of the tramcar and being good in stopping effect.

Owner:SHANDONG HUALIAN MINING

Method of producing condom used by man with self-stand skirt structure and the products thereof

InactiveCN101032852ASolve flipExtended sex timeMale contraceptivesCoatingsEngineeringSexually transmitted disease

The process of producing male condom with self erected skirt structure includes the following steps: increasing one conic structure to the bottom of condom mold, covering the condom mold with a hood while exposing the root, the conic structure and the central line part of the mold, spraying coagulant with a nozzle to the exposed mold parts, stoving the mold in an oven, and soaking in conventional method to produce the integrally formed condom. The male condom with self erected skirt structure is convenient and comfortable similar to available ones, and can isolate the contamination of body fluid and prevent sexually transmitted diseases.

Owner:冷博

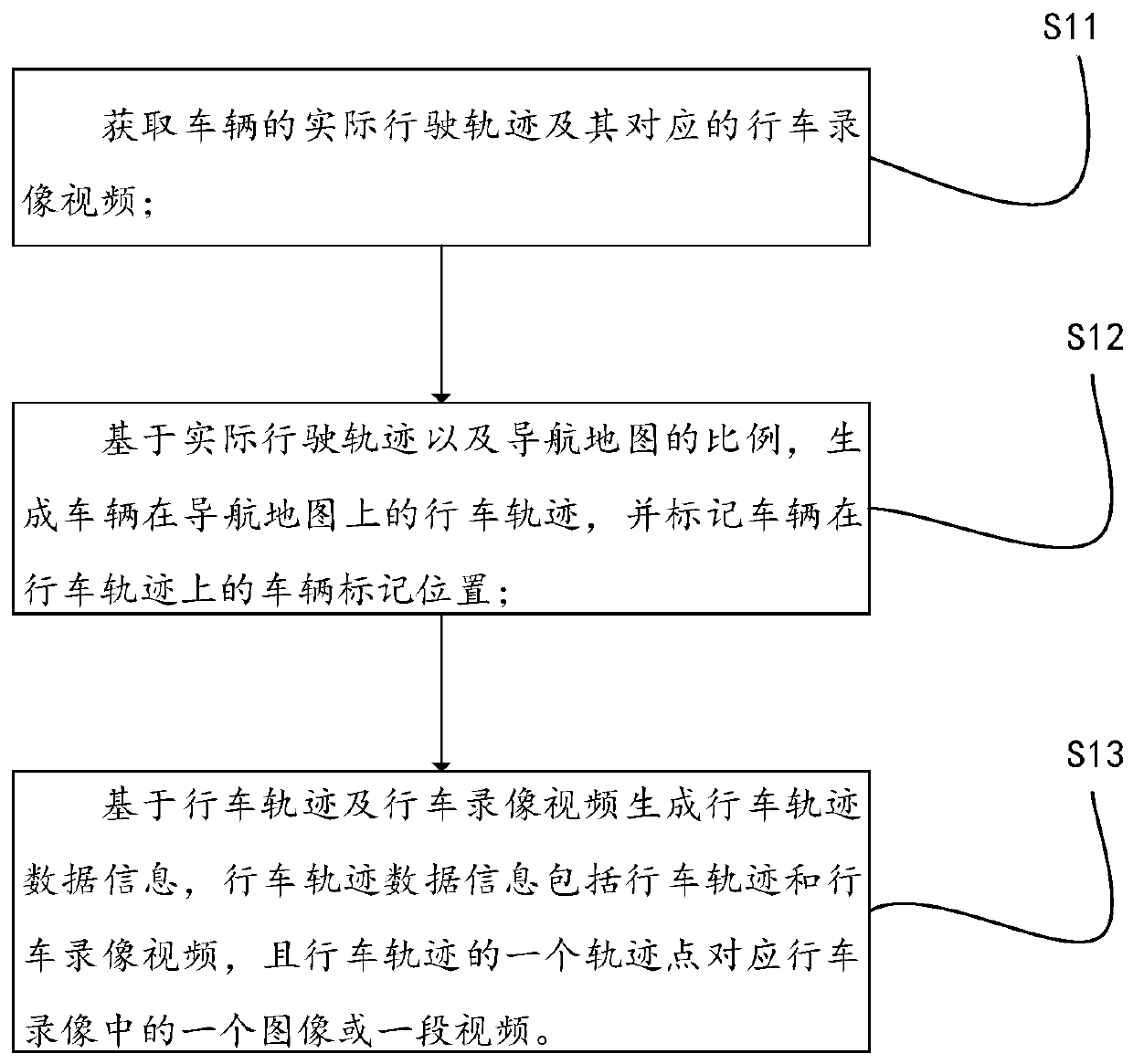

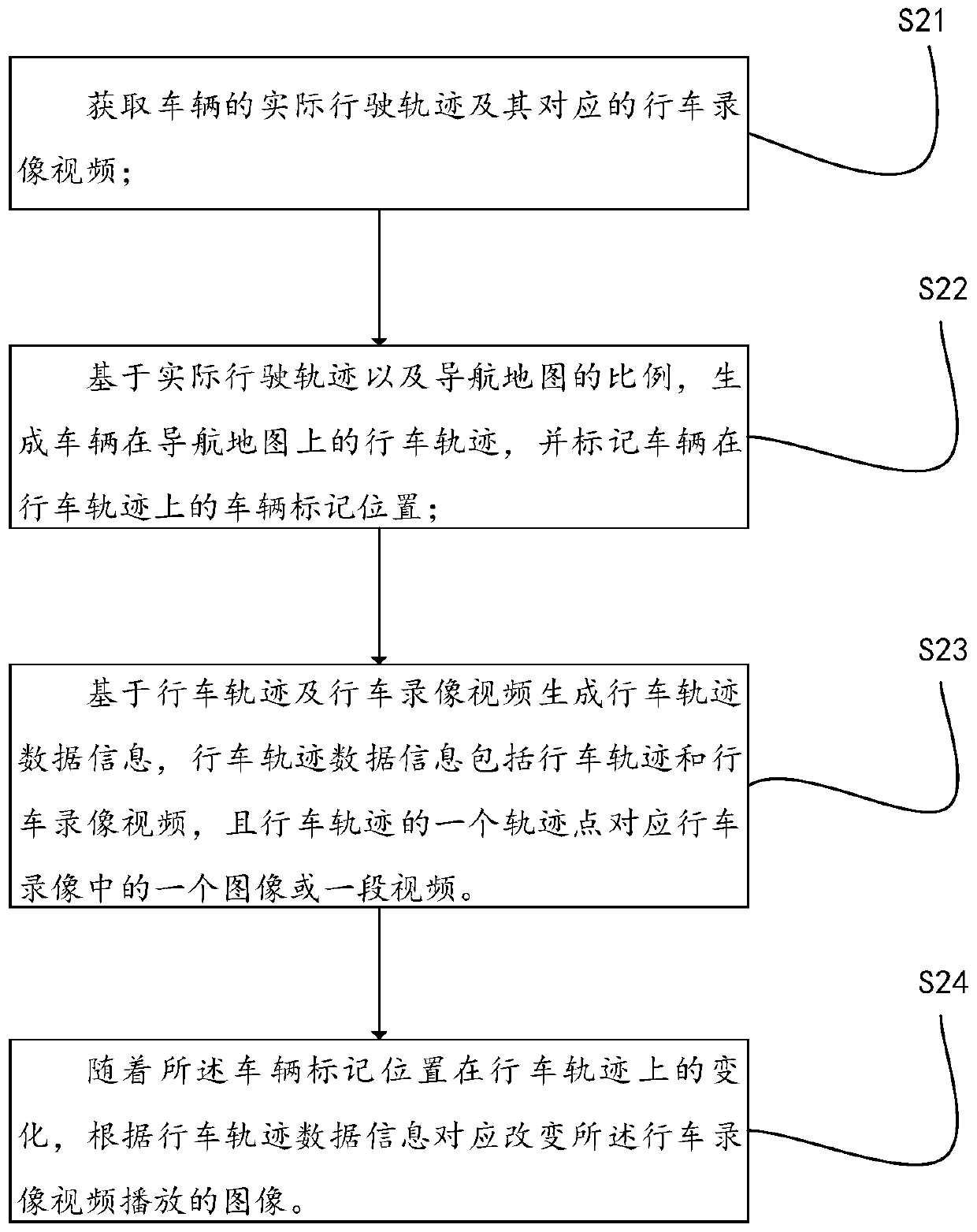

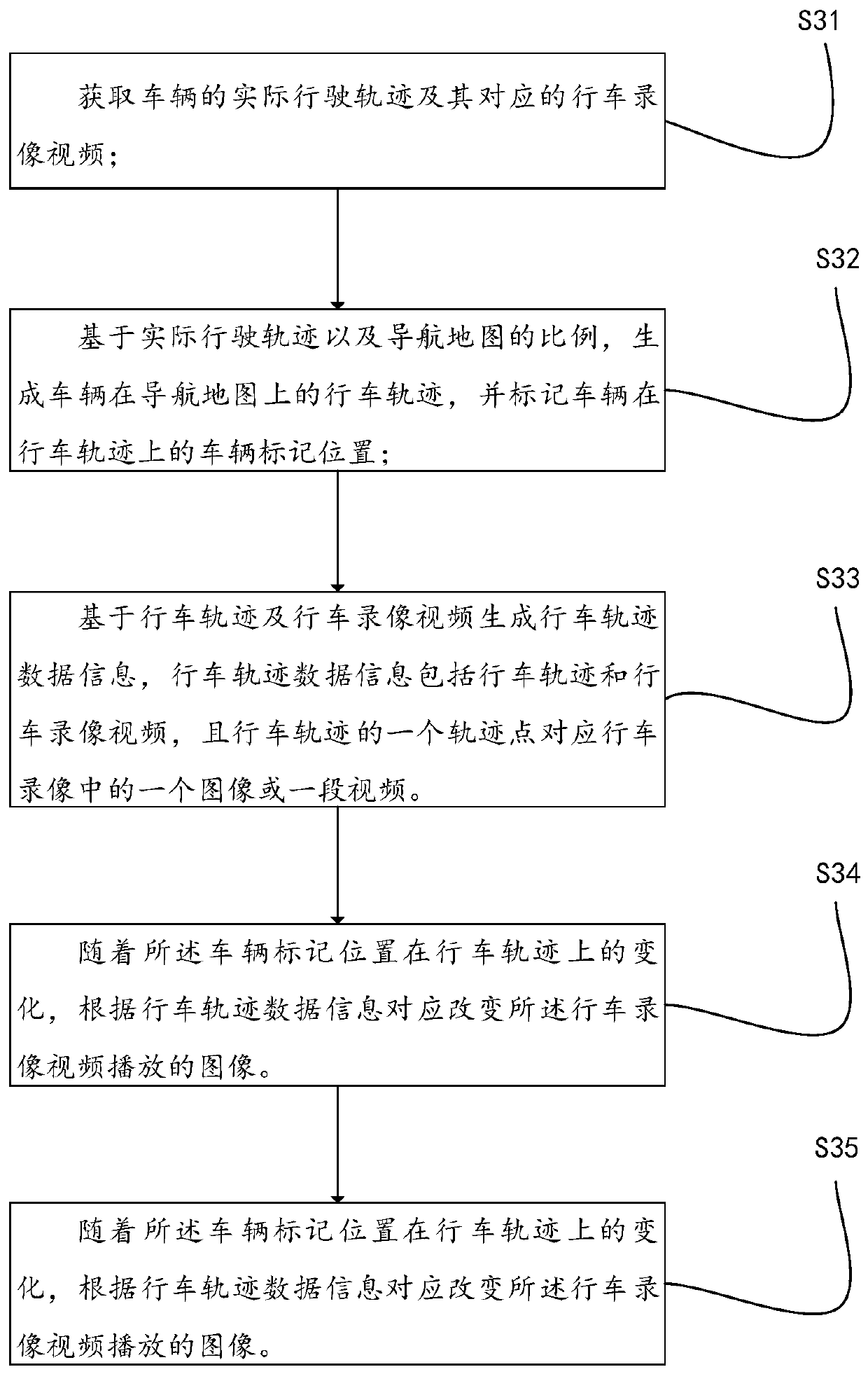

Driving track recording method and device and driving track sharing system

InactiveCN110753199AEasy to viewRealize linkage operationTelevision system detailsRegistering/indicating working of vehiclesData informationSimulation

The invention discloses a driving track recording method and device and a driving track sharing system. The method comprises the steps of obtaining an actual driving track of a vehicle and a driving video corresponding to the actual driving track; generating a forming track of the vehicle on the navigation map according to the acquired actual driving track in combination with the proportion of thenavigation map; after the driving track is obtained, driving track data information is generated in combination with the obtained driving video, the driving track data information comprises the driving track and the driving video, and one track point of the driving track corresponds to one image or one section of video in the driving video; the technical problem that in the prior art, a navigation system cannot provide video data corresponding to all position points on a navigation route while providing a historical navigation route for a user is solved, and the driving track recording methodcapable of obtaining the video data of the corresponding geographic position according to the driving track is provided.

Owner:深圳市海雀科技有限公司

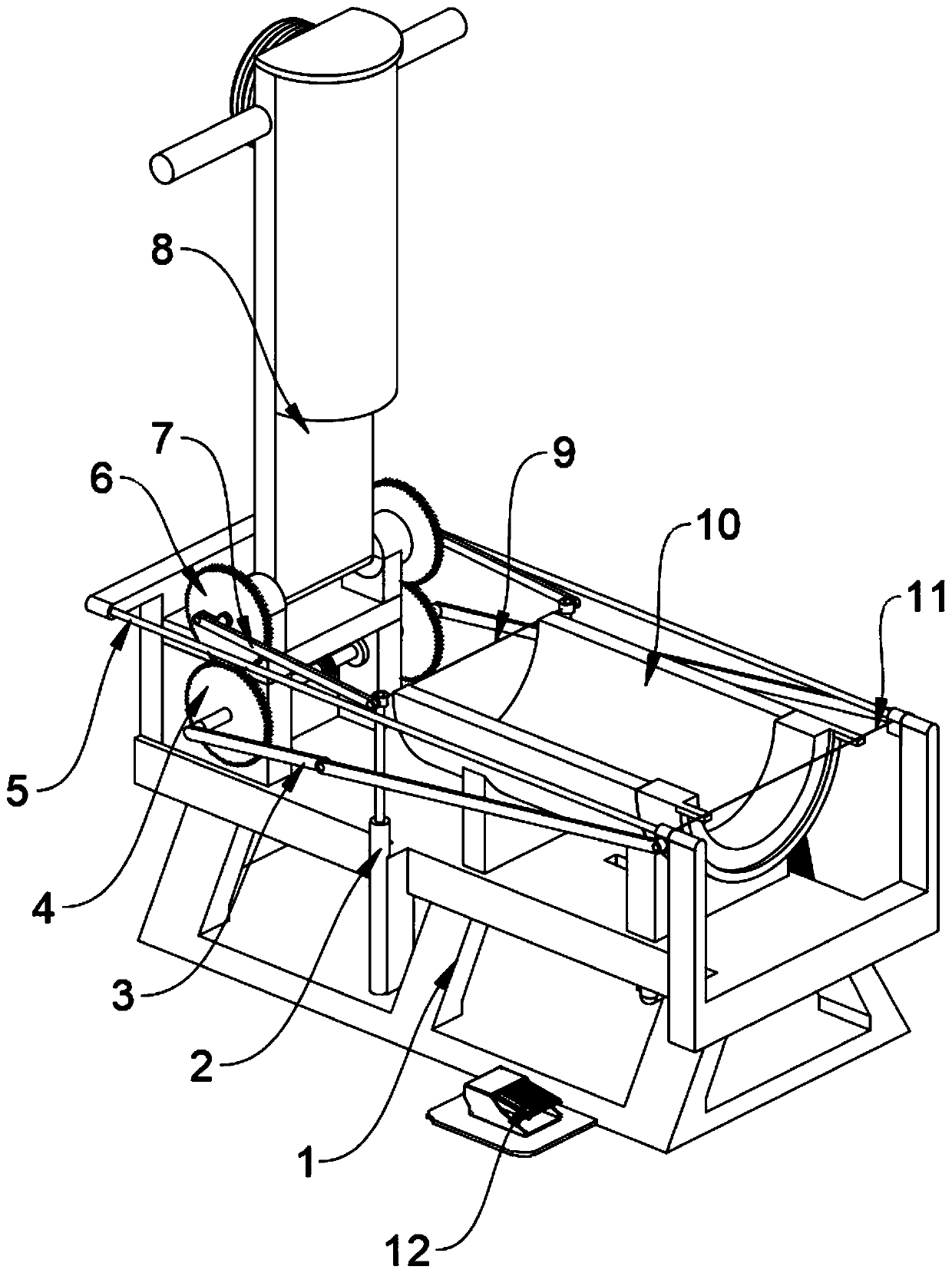

Automatic blank cutting device for civil building glazed tile production

ActiveCN111283849AEasy to moveEasy to operateAuxillary shaping apparatusConstruction engineeringStructural engineering

The invention discloses an automatic blank cutting device for civil building glazed tile production. The automatic blank cutting device for civil building glazed tile production comprises a glazed tile bottom blank die, wherein the glazed tile bottom blank die is arranged at a position of the top side of a support base; a bottom blank die ejection pedal is coupled to and arranged at the right sideof the support base, and the other shaft end of the bottom blank die ejection pedal is abutted against the bottom of the glazed tile bottom blank die; and a glazed tile top die blank-pressing deviceis rotationally connected to a part at one side adjacent to the glazed tile bottom blank die, of a top side support of the support base. Two limit slide rods are symmetrically arranged on supports atthe two ends of the top side of the support base of the automatic blank cutting device for civil building glazed tile production, a transversal cutting wire is slidably installed on the limit slide rods in a limit manner through slide blocks at the two ends, and moreover, a transversal cutting stroke of the transversal cutting wire and the top wall of the glazed tile bottom blank die are bonded inparallel, so that limit movement for the transversal cutting wire on the limit slide rods is benefited, and then the transversal cutting wire is enabled to always stably carry out cutting operation on the top wall and the bottom wall of the glazed tile bottom blank die.

Owner:安徽华丰建筑装饰有限公司

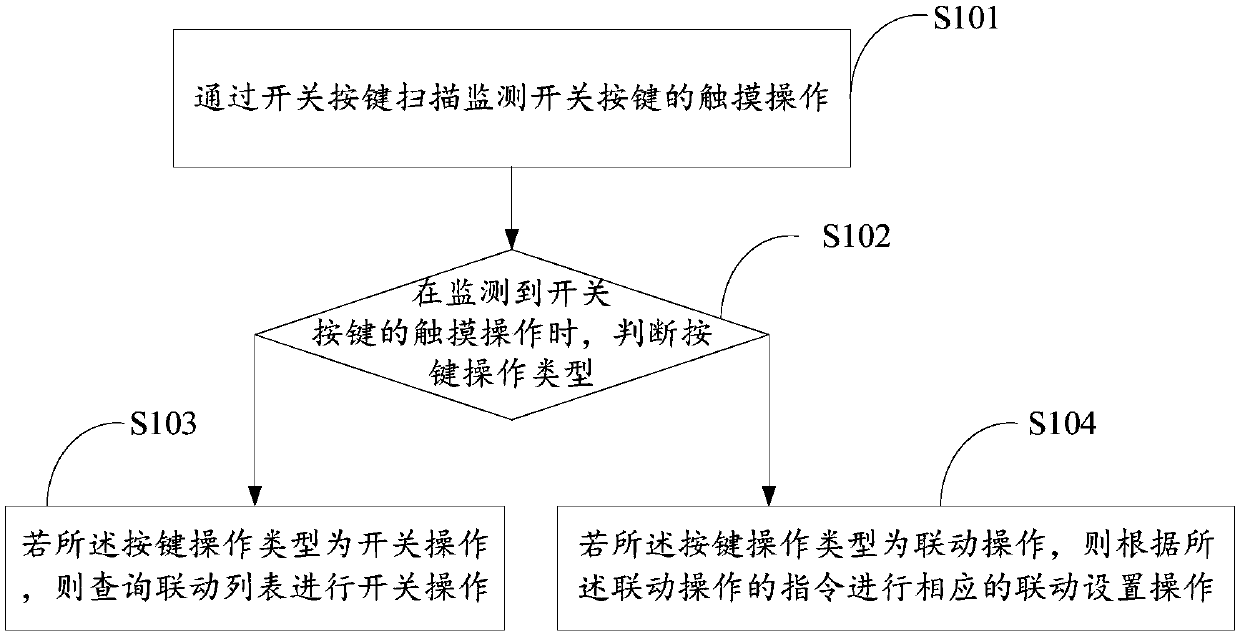

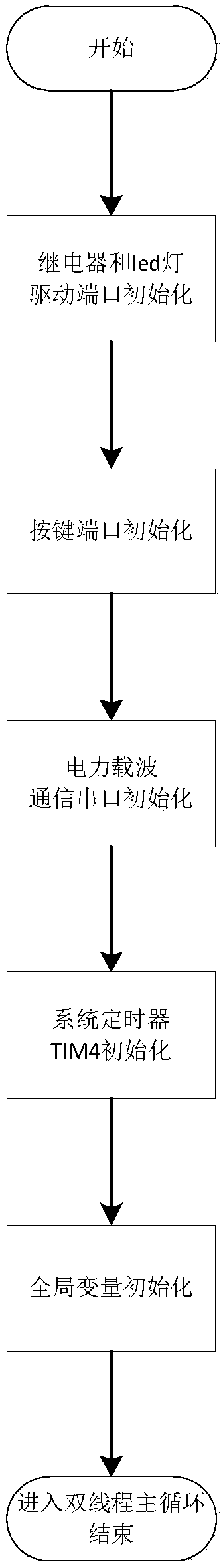

Switch linkage control method and device

ActiveCN107678344AEasy to operateEasily pass through wallsProgramme controlComputer controlLinkage conceptKey pressing

The invention discloses a switch linkage control method and device. The switch linkage control method comprises scanning and monitoring a touch operation of a switch key through the switch key; judging the key operation type when the touch operation of the switch key is monitored; if the key operation type is a switching operation, querying a linkage list to carry out the switching operation; if the key operation type is a linkage operation, carrying out a corresponding linkage setting operation according to an instruction of the linkage operation. According to the invention, a power line carrier communication technology is employed, the linkage operation among a plurality of switches is achieved, one switch controls a plurality of switches or a plurality of switches control one switch, and a plurality of switches are synchronously controlled. The whole setting process does not employ a computer host and is completed by composite keys, and is simple and convenient to operate, and is stable and reliable.

Owner:深圳市劲码科技有限公司

Raw material treatment process for health care product processing

PendingCN112958267ARealize linkage operationImprove work efficiencyDrying solid materials with heatDrying solid materials without heatProcess engineeringIndustrial engineering

The invention discloses a raw material treatment process for health-care product processing, and relates to the technical field of health care product production. The raw material treatment process specifically comprises the following steps of step 1, soaking and cleaning raw materials; step 2, taking out the raw materials; step 3, spin-drying the raw materials; step 4, drying the raw materials; and step 5, discharging and collecting. According to the raw material treatment process for the health-care product processing, after the raw materials are put into a scum cleaning barrel, water can enable impurities such as broken leaves in the raw materials to float up, then part of the impurities are removed, scum in the scum cleaning barrel can be automatically discharged to an outer layer through the arrangement of the scum cleaning barrel, the water can continuously filter the scum, the residual impurities in the raw materials can be screened out through a residue cleaning cover, the raw materials can be automatically taken out from the water through an auger elevator, the whole process works continuously, continuous processing can be achieved, the working efficiency is high, the scum cleaning barrel and the residue cleaning cover can be synchronously driven through the auger elevator, linkage operation of a whole system is achieved, and the equipment cost is saved.

Owner:尹海涛

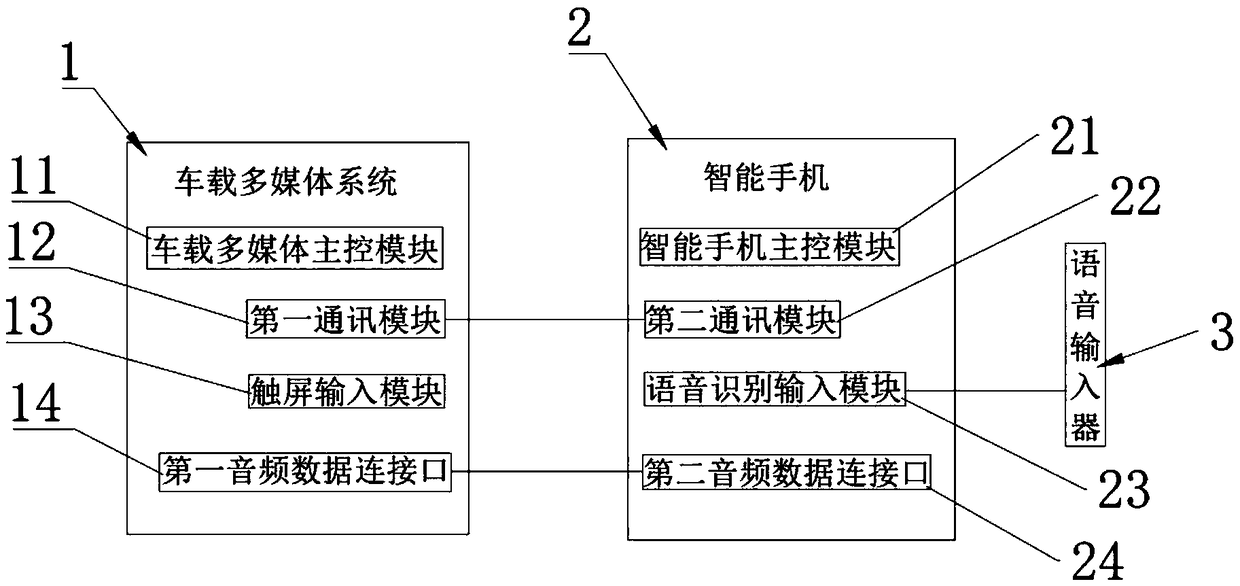

System for intelligently controlling vehicle-mounted display

InactiveCN109151771ARealize linkage operationEasy to operateParticular environment based servicesSubstation equipmentIn vehicleTraffic accident

The invention discloses a system for intelligently controlling vehicle-mounted display, which comprises a vehicle-mounted multimedia system, a smart phone and a voice input device. The vehicle-mountedmultimedia system comprises a vehicle-mounted multimedia master control module and a first communication module. The smart phone comprises a main control module of the smart phone, a second communication module and a speech recognition input module. The second communication module is adaptively connected with the first communication module. The speech input device is connected with a speech recognition input module. According to the system, voice commands are input through a voice input device, recognized by a speech recognition input module and converted into corresponding mobile phone operation instructions, and are transmitted to the main control module of the smart phone, The system realizes the operation of the smart phone, and synchronously maps the operation instructions to the vehicle-mounted multimedia system, so that the user can complete the operation of the smart phone through voice input, and realizes the linkage operation of the vehicle-mounted multimedia, the operationis convenient, the experience sense is high, and the mobile phone is swung against the driving regulations, and the traffic accident is avoided.

Owner:MINGSHANG TECH CO LTD

Injection mould for base of wine bottle packing box

PendingCN108638462AShorten the timeImprove efficiencyDomestic articlesAgricultural engineeringWine bottle

The invention relates to the field of an injection mould and discloses an injection mould for the base of a wine bottle packing box. The injection mould comprises a rack, and an upper mould is connected on the rack in a sliding mode. A lower mould is arranged on the rack and is positioned below the upper mould, a driving groove is fixedly formed in the rack, and the lower mould is connected in thedriving groove in the sliding mode. A piston cylinder is fixedly arranged on the rack and communicates with the driving groove, and a piston is connected in the piston cylinder in the sliding mode and is fixedly connected with the upper mould. A first wedge rod is fixedly arranged on the upper mould, a second wedge rod is connected on the rack in the sliding mode, and the first wedge rod butts against the second wedge rod. A vacuum pipe is fixedly arranged on the rack, and a sliding rod is fixedly arranged on the upper mould and is connected in the vacuum pipe in the sliding mode. Compared with the prior art, according to the scheme, after the upper mould moves, the lower mould is linked to move together, and therefore the efficiency of mould closing is improved; by the arrangement of thevacuum pipe, after mould closing is finished, the upper mould can continue to move for a distance to the direction close to the lower mould, so that the upper mould and the lower mould are more tighter, and therefore the purpose of saving raw materials is achieved.

Owner:重庆技嘉模具有限公司

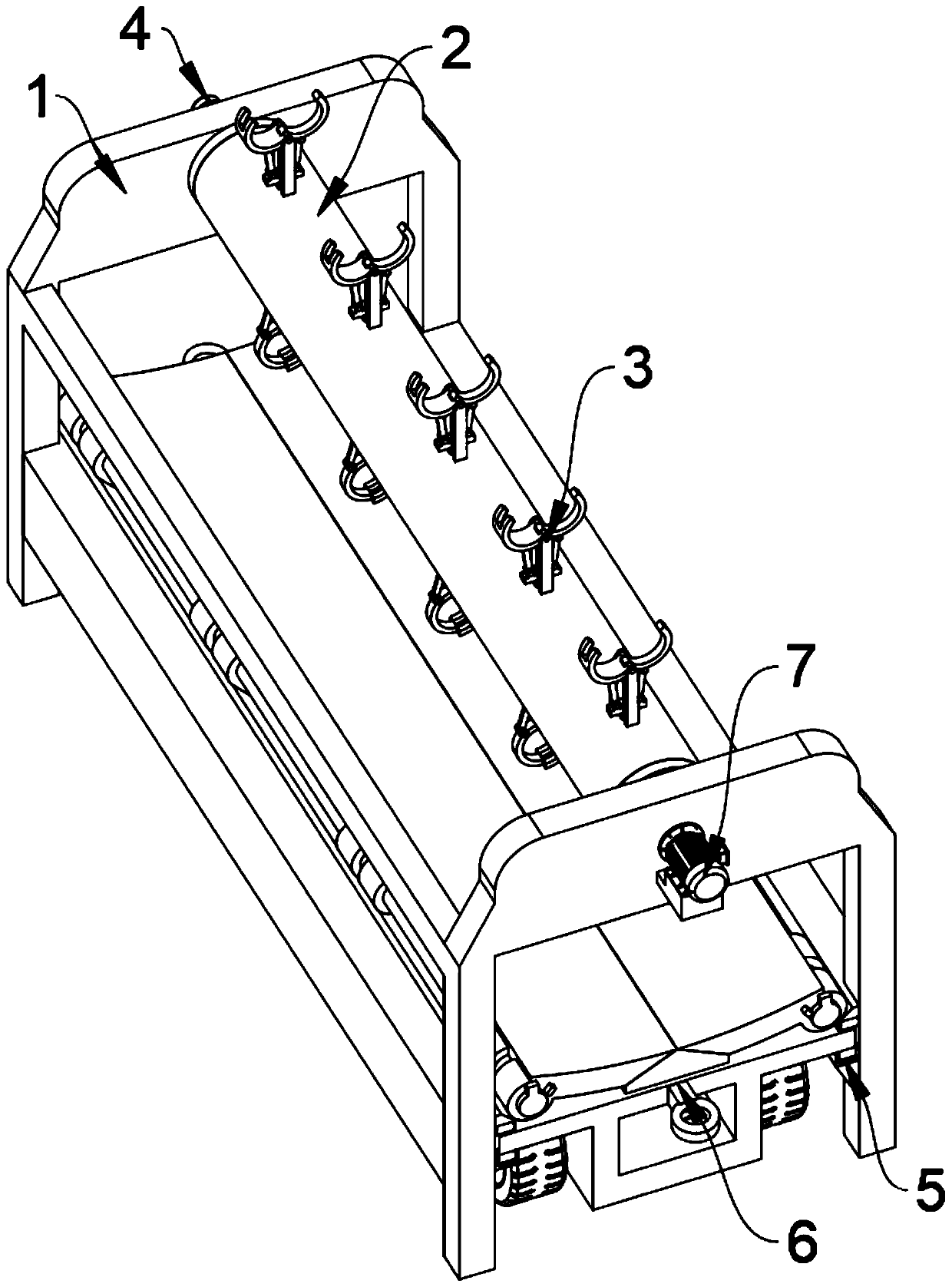

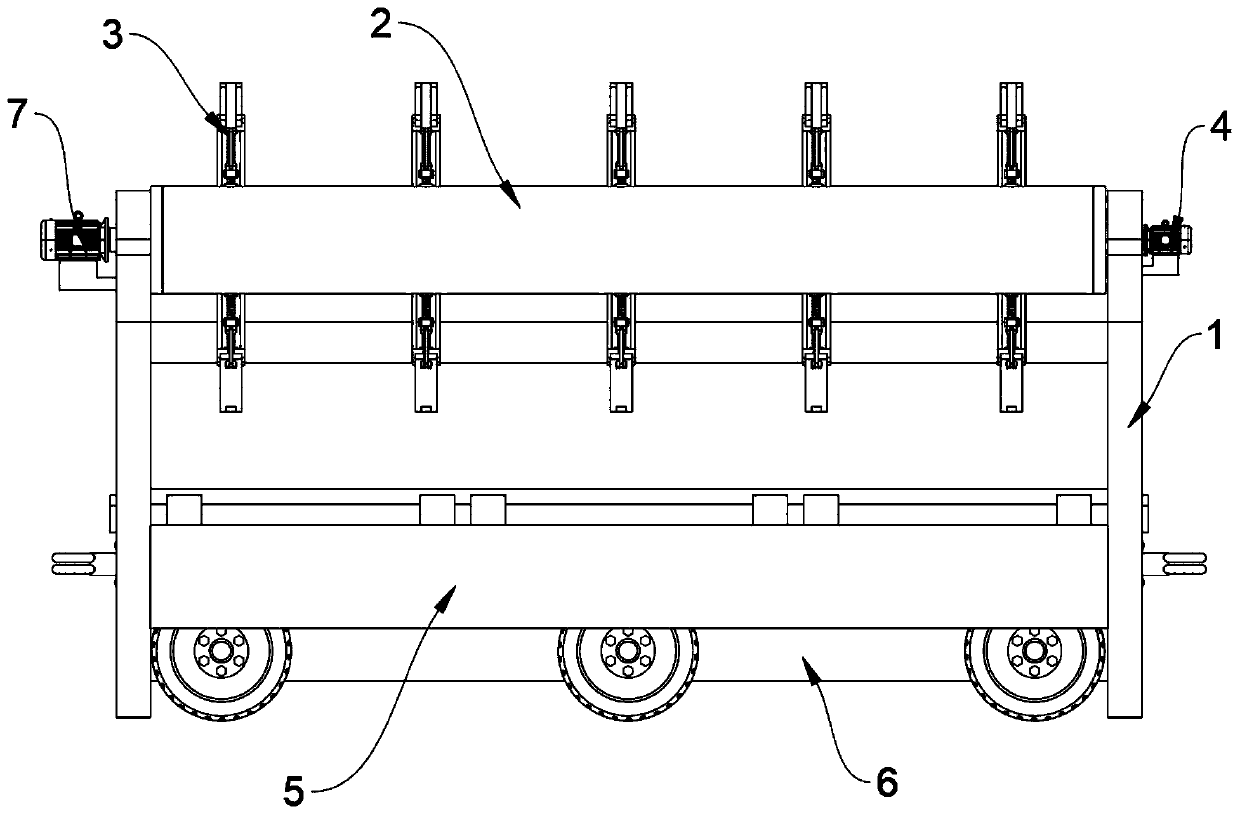

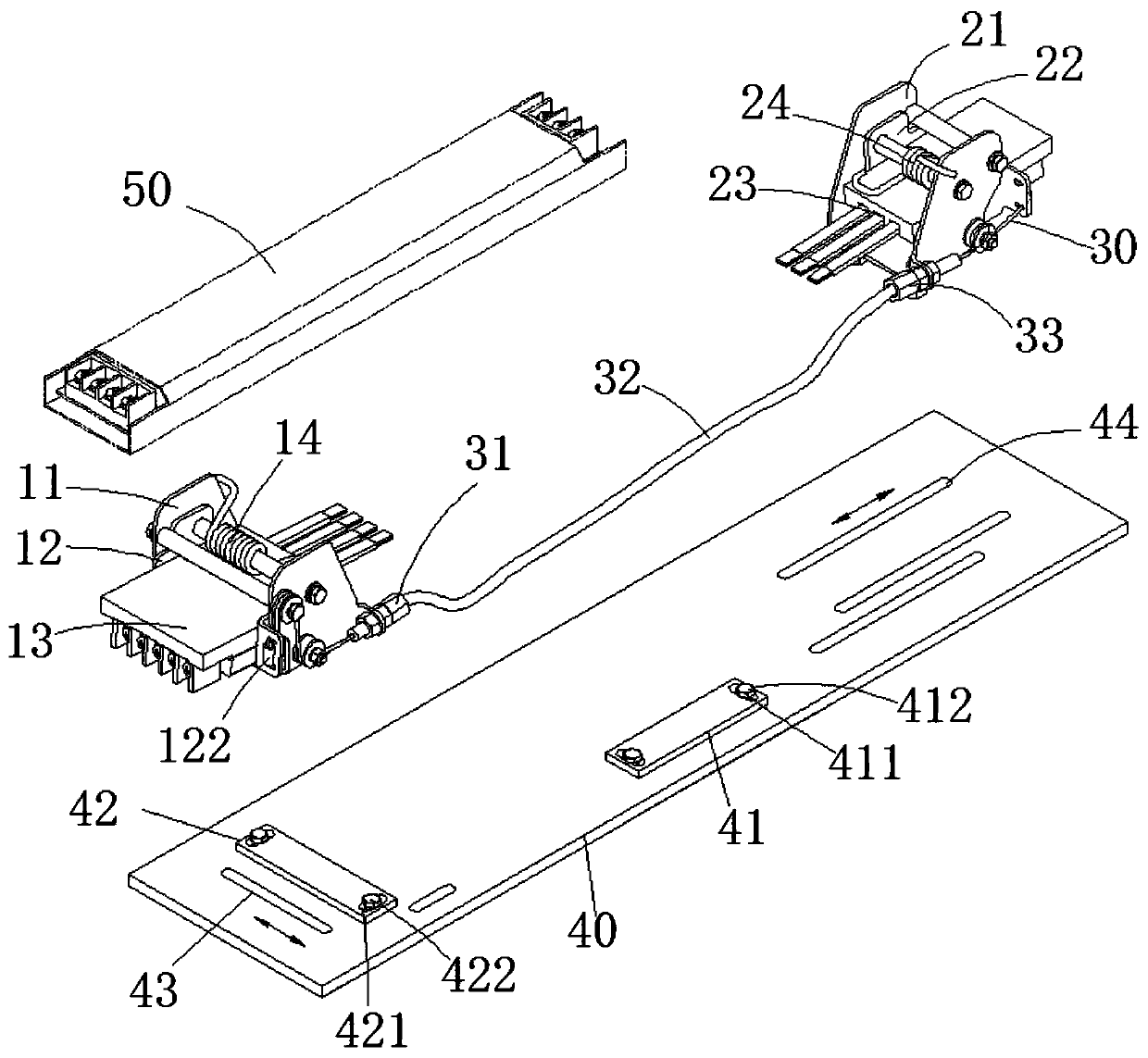

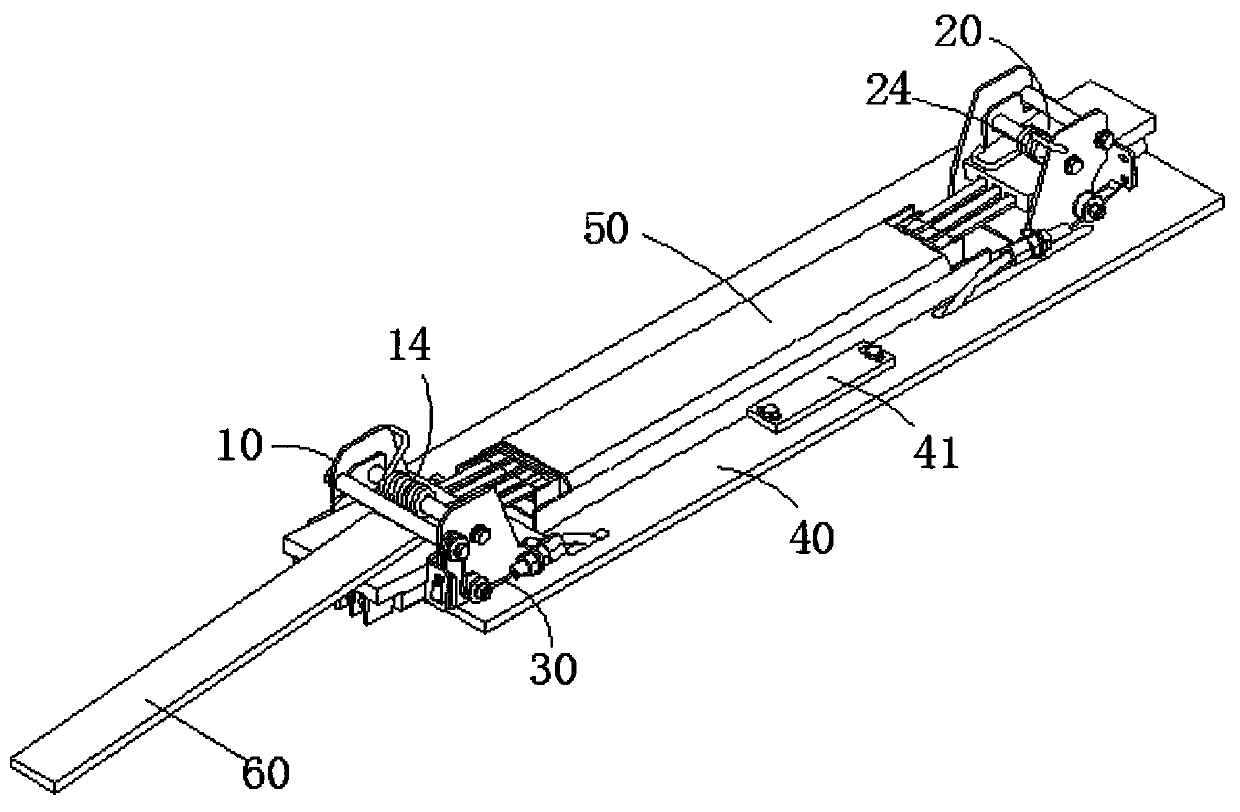

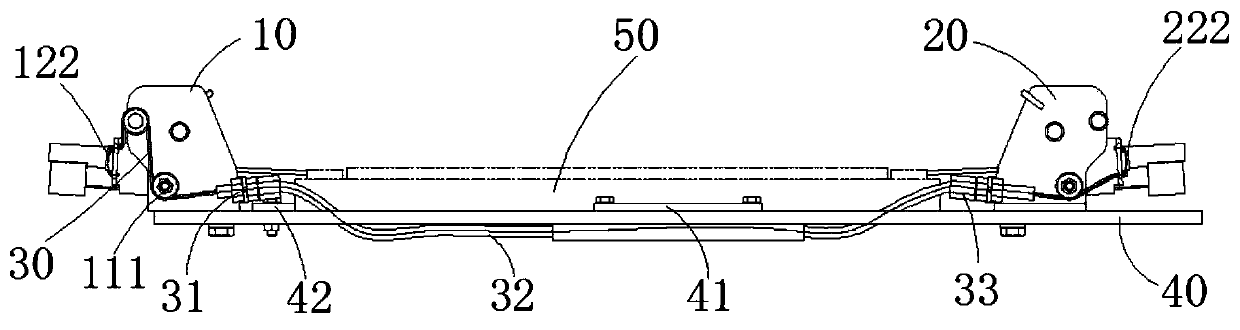

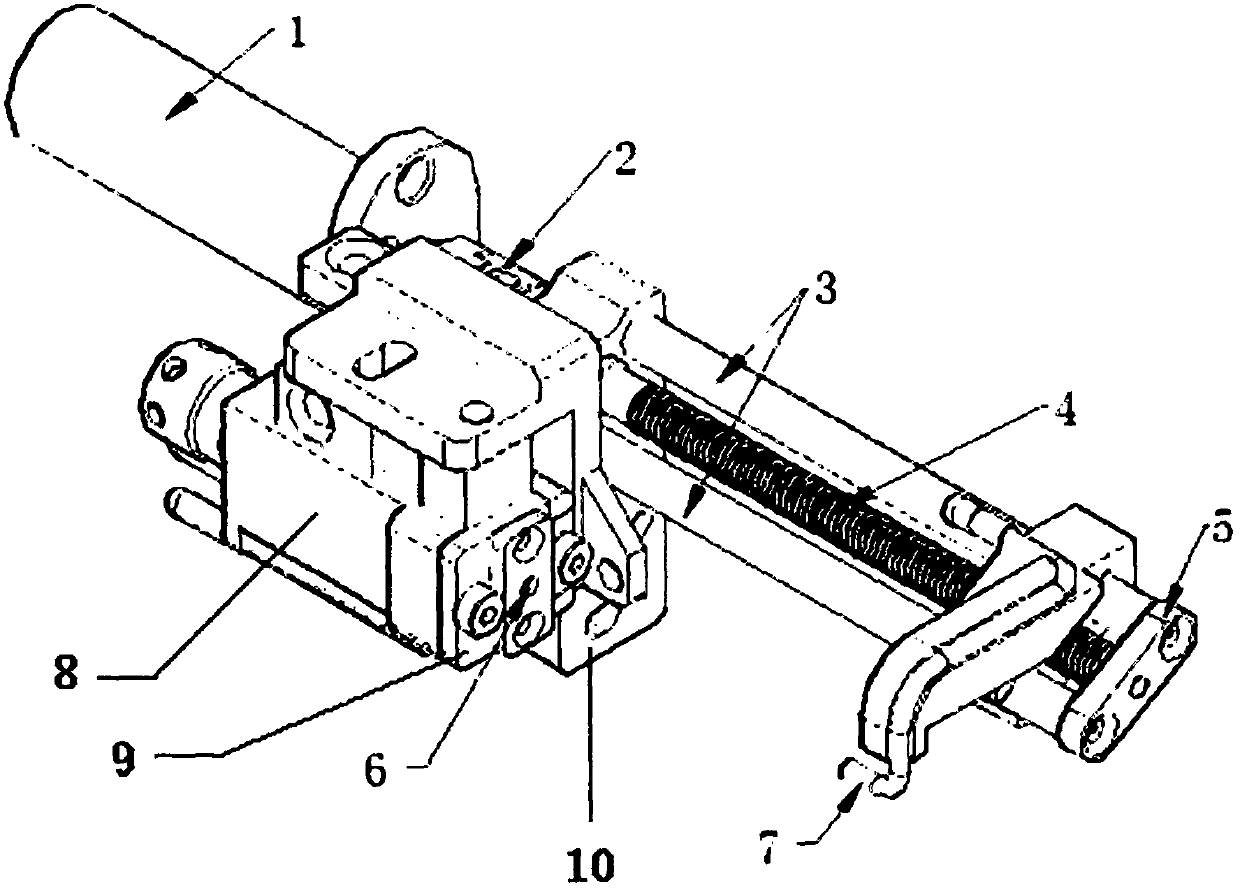

Linkage type switching power source aging clamp

ActiveCN110568379AAchieve adaptiveMeet aging needsPower supply testingMeasurement instrument housingEngineeringMechanical engineering

The invention discloses a linkage type switching power source aging clamp. The linkage type switching power source aging clamp comprises a bottom plate, a driving end, a driven end, and a linkage rope; the bottom plate is used for placing a double-end-wired switching power source; the driving end is located on one side of the bottom plate and comprises a first fixed supporting plate, a first rotary supporting plate, a first wiring assembly and a first torsional spring, wherein the first torsional spring applies downward pressure to the first wiring assembly; the driven end is opposite to the driving end and is arranged on the other side of the bottom plate; the driven end comprises a second fixed supporting plate, a second rotary supporting plate, a second wiring assembly and a second torsional spring, wherein the second torsional spring applies downward pressure to the second wiring assembly; and one end of the linkage rope is connected with the first rotary supporting plate of the driving end, and the other end of the linkage rope is connected with the second rotary supporting plate of the driven end, and therefore, the second rotary supporting plate can be driven to rotate through the rotation of the first rotary supporting plate; the linkage rope is fixed to the bottom plate; and at least part of the linkage rope penetrates through the bottom plate from below. According tothe linkage type switching power source aging clamp of the invention, the aging of two ends of the switching power source is realized; and operation just needs to be performed at the driving end and the driven end, and therefore, the switching-on and switching-off of the switching power source are synchronously realized.

Owner:湖南华鑫电子科技有限公司

Nozzle recycling pipe moving seal device

The invention relates to the technical field of ink-jet printing machines, and particularly relates to a nozzle recycling pipe moving seal device. The device comprises a motor, a coupler, a guide sliding rod, a screw, a guide limiting block, a nozzle hole and a guide recycling bending pipe; the motor is connected with the screw through the coupler, the screw is arranged in the guide sliding rod, the outer side end of the guide sliding rod is provided with the guide limiting block, the guide sliding rod is arranged on a support, a spray nozzle is formed in one side on the support, the nozzle hole is formed in the position, on the right side face of the spray nozzle, in the middle of a nozzle piece, the guide recycling bending pipe is arranged on the guide sliding rod, and the guide recycling bending pipe is connected with the nozzle hole of the spray nozzle. The seal device has the advantages of being simple in structure, convenient to use, high in production efficiency, low in production cost and the like.

Owner:邓前军 +1

Goaf filling waste rock wet-spraying and tamping device and goaf filling waste rock filling method

PendingCN109441530ARealize linkage operationImprove work efficiencyMining devicesMaterial fill-upStart stopSpray nozzle

The invention discloses a goaf filling waste rock wet-spraying and tamping device and a goaf filling waste rock filling method, and relates to the technical field of mining and filling. The goaf filling waste rock wet-spraying and tamping device comprises a wet-spraying mechanism, a tamping mechanism and a control mechanism, the wet-spraying mechanism comprises a water pump, a regulating valve anda wet sprayer; the tamping mechanism comprises a machine seat, a telescopic rod, a tamping waste rock beam, a swinging arm and a baffle; the control mechanism comprises a controller, a sensor and a start-stop switch, and the water pump is connected with the wet sprayer through a water pipe; and the wet sprayer comprises a connecting pipe, a spraying head and a spraying nozzle, the connecting pipeis arranged in the tamping waste rock beam, the tamping waste rock beam is arranged in the swinging beam, the baffle is arranged at the front end of the tamping waste rock beam, the telescopic rod isarranged at the rear end of the tamping waste rock beam, a spraying opening is formed in the baffle, and a hydraulic connecting rod is arranged between the swinging beam and the machine seat. According to the method of completing goaf filling waste rock wet-spraying and filling by using the goaf filling waste rock wet-spraying and tamping device, the technical problem that wet-spraying and tamping cycle operation is discontinuous in the process of goaf waste rock filling is solved, and the goaf filling waste rock wet-spraying and tamping device and the goaf filling waste rock filling method have the advantages of high construction efficiency, controllable waste rock water contents, high filling body compression ratio and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Method of producing condom used by man with self-stand skirt structure and the products thereof

InactiveCN100553927CIsolate contaminationPrevent sexually transmitted diseasesMale contraceptivesCoatingsEngineeringSexually transmitted disease

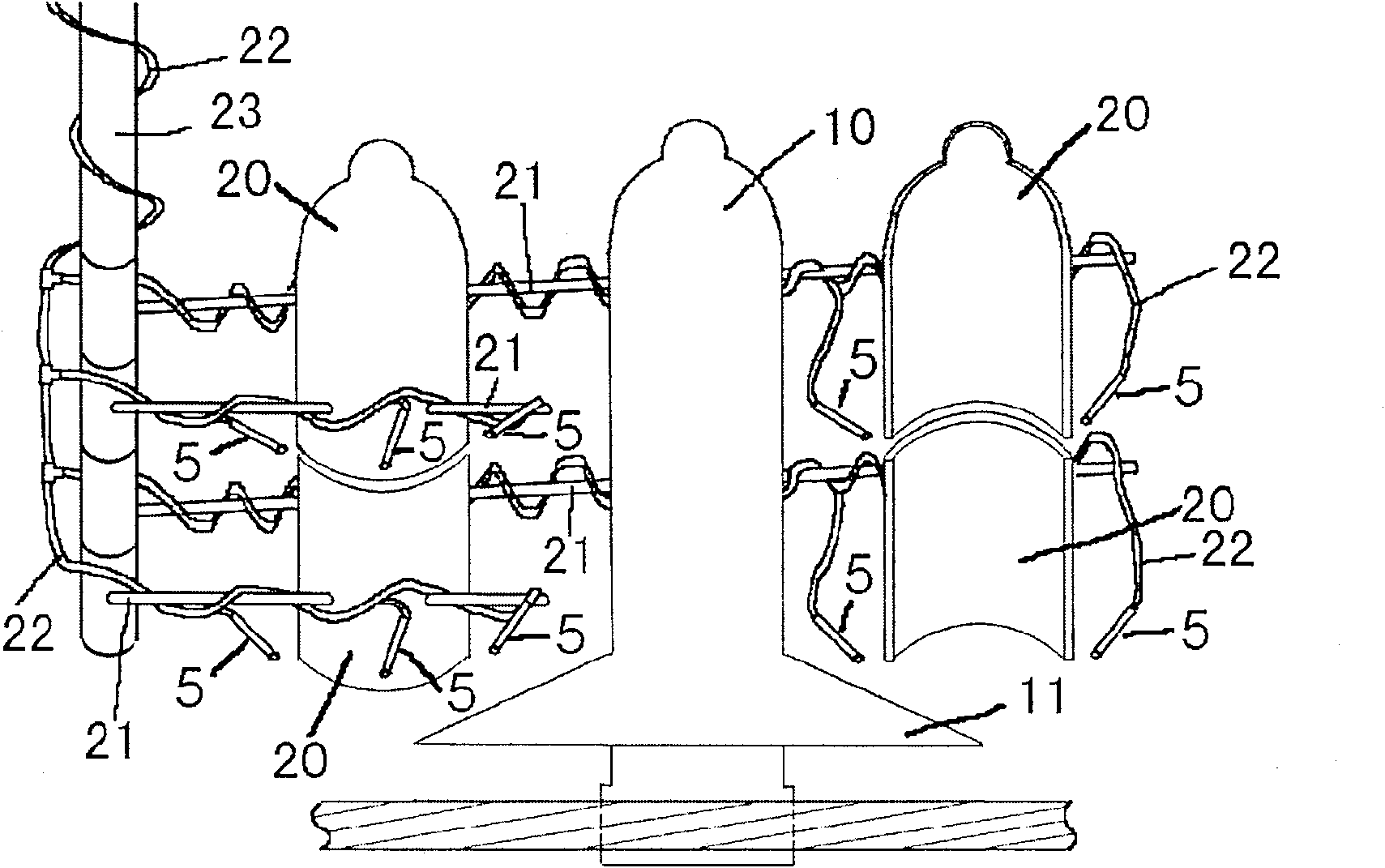

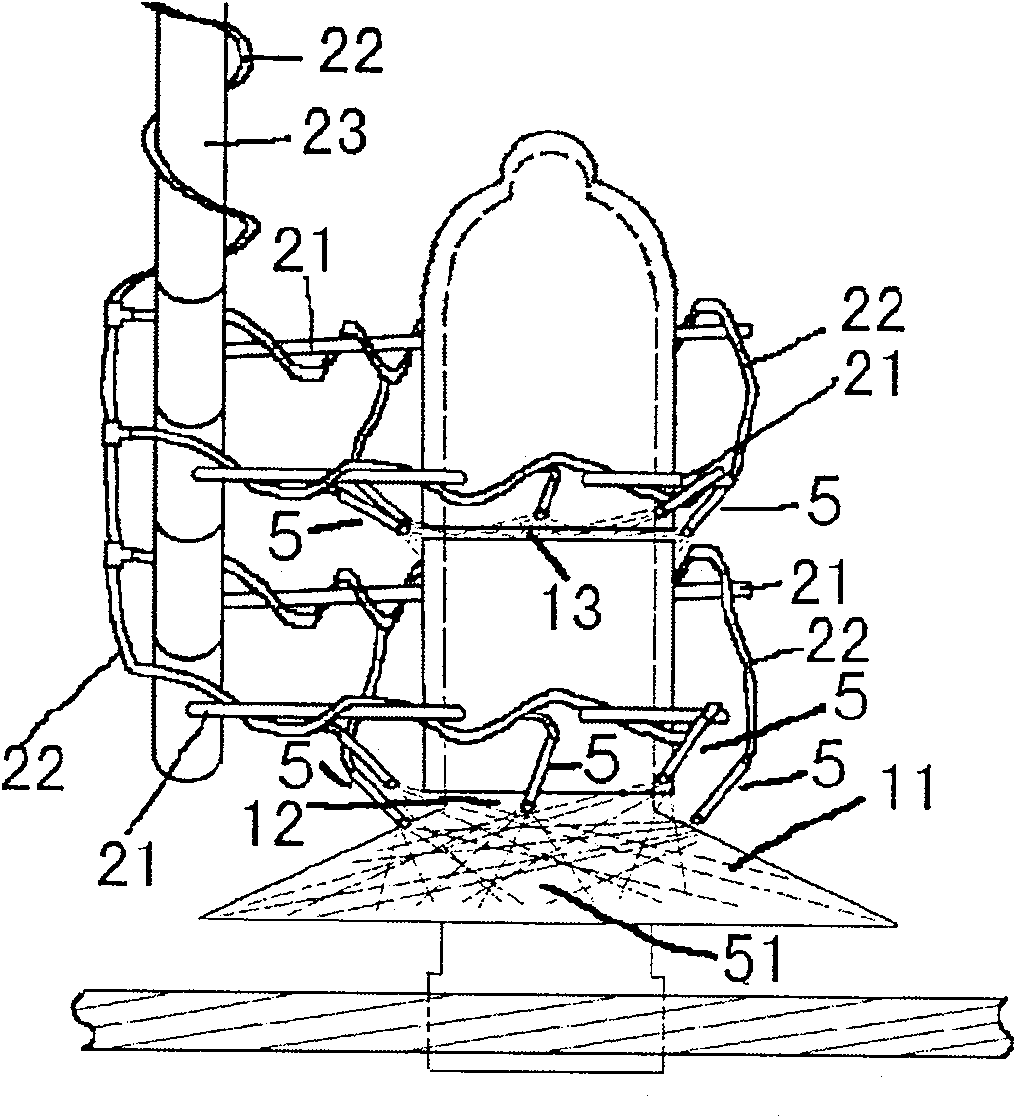

The invention discloses a manufacturing method of a male condom with a self-standing skirt-like structure, which comprises adding a conical structure to the bottom of a condom mold, covering the condom mold with a mold cover, and making the root of the condom, the conical structure and the centerline of the condom Part of the mold is exposed, use a nozzle to spray coagulant evenly on the exposed mold at the root of the sleeve, the conical structure and the centerline of the sleeve, dry the mold in an oven, and then impregnate it according to the conventional method, so that the tape can be obtained. The male condom has a stiff skirt-like structure, a root ring and a tendon-like protrusion in the middle of the sleeve body, and the condom is integrally formed. This new form of condom not only maintains the comfort and convenience of conventional condoms, but also has a self-standing skirt-like structure that can more completely isolate the contamination of body fluids to prevent sexually transmitted diseases, which is beneficial to both men and women.

Owner:冷博

Drilling device and method for metal doors and windows

ActiveCN114570980ARealize linkage operationRealize the punching operationAutomatic control devicesMeasurement/indication equipmentsDistance sensorsWorkbench

The invention relates to the technical field of door and window machining, and discloses a drilling device and method for metal doors and windows, and the drilling device for the metal doors and windows comprises a sliding table which is slidably arranged on the upper surface of a workbench. The push-pull piece is installed on the workbench. The two clamping rods are oppositely located on the sliding table in a sliding mode. And the drilling pressing piece is mounted on the workbench. The first pressure sensor is used for sensing the pressure of the lifting rod. The second pressure sensor is used for sensing the clamping force of the clamping rod. The distance sensor is used for sensing the end distance of the window lattice rod. The controller is used for controlling the push-pull piece to push the sliding table to enter the placing station, and the window lattice rod falls on the sliding table; the push-pull piece pulls the sliding table to move towards the machining station, the clamping rods are driven by the transmission structure to be close to each other, and the clamping rods are close to clamp the window lattice rod; and quantitative drilling and moving are carried out. Window lattice rods are clamped and pushed in a linkage mode, and fixed-position punching operation is achieved through pressure and size control.

Owner:徐州科美瑞门窗科技有限公司

A loader equipped with high-pressure spray and spray control method

ActiveCN107090867BSteering does not affectDoes not affect workSoil-shifting machines/dredgersFuel tankEngineering

The invention discloses a loading machine with a high-pressure spraying device. The loading machine comprises a machine body, the spraying device, a power system and a control device. The spraying device, the power system and the control device are fixedly installed on the machine body. The power system comprises a hydraulic oil tank, a steering oil pump, a steering device, a hydraulic force taking device and multiple hydraulic oil pipes. The hydraulic force taking device communicates with the steering oil pump and the steering device through the hydraulic oil pipes. The hydraulic oil tank communicates with the steering oil pump and the steering device through the hydraulic oil pipes. The spraying device comprises a spraying water pump, a water tank, integrated nozzles and multiple spraying water pipes. The spraying water pump communicates with the hydraulic oil tank and the hydraulic force taking device through the hydraulic oil pipes. The spraying water pump communicates with the water tank and the integrated nozzles through the spraying water pipes. The control device is electrically connected with the hydraulic force taking device. The invention further discloses a control method using the above loading machine for spraying. The driving manner of the spraying device of the loading machine with the high-pressure spraying device is simple, the production and maintenance cost is reduced, and steering of the loading machine is not affected.

Owner:广州普凯热伏微能源科技有限公司

An automatic blank cutting device for the production of civil building glazed tiles

An automatic embryo cutting device for the production of glazed tiles for civil buildings, comprising a base mold at the bottom of the glazed tile; the base mold at the bottom of the glazed tile is set on the top side of the supporting base; pedal, and the other shaft end of the bottom blank mold pushes out of the pedal to the bottom of the glazed tile bottom blank mold; the top side bracket of the supporting base on the adjacent side of the glazed tile bottom blank mold is rotatably connected with a glazed tile top mold blank device. The automatic blank cutting device for the production of glazed tiles for civil buildings is equipped with two limit slide bars symmetrically arranged on the support base at both ends of the support base, and the horizontal cutting wire is slid and installed on the limit slide bar through the slide blocks at both ends. and the transverse cutting stroke of the transverse cutting thread is parallel to the top wall of the glazed tile bottom mold, which is conducive to the limit movement of the transverse cutting thread on the limit slide bar, so that the transverse cutting thread is always stable on the glazed tile. The cutting operation is performed on the top and bottom walls of the bottom blank mold.

Owner:安徽华丰建筑装饰有限公司

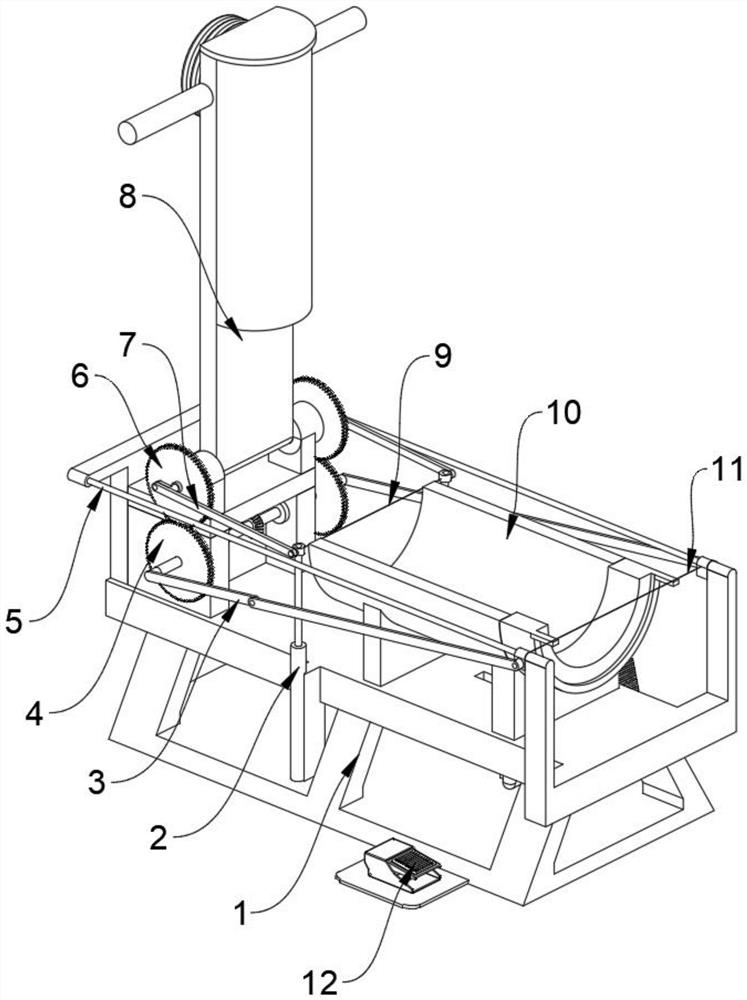

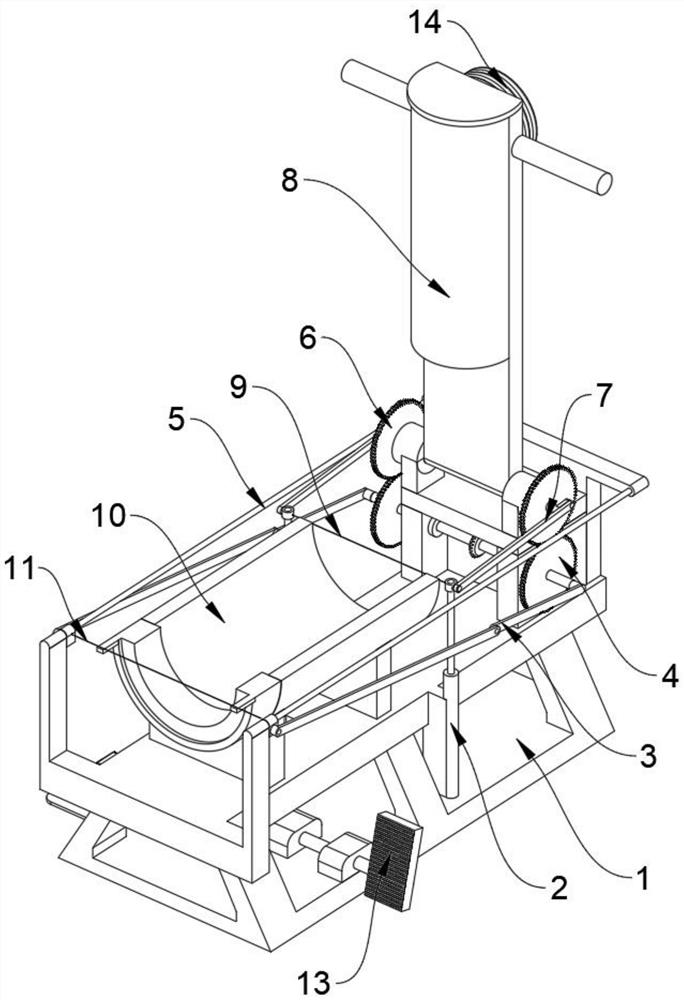

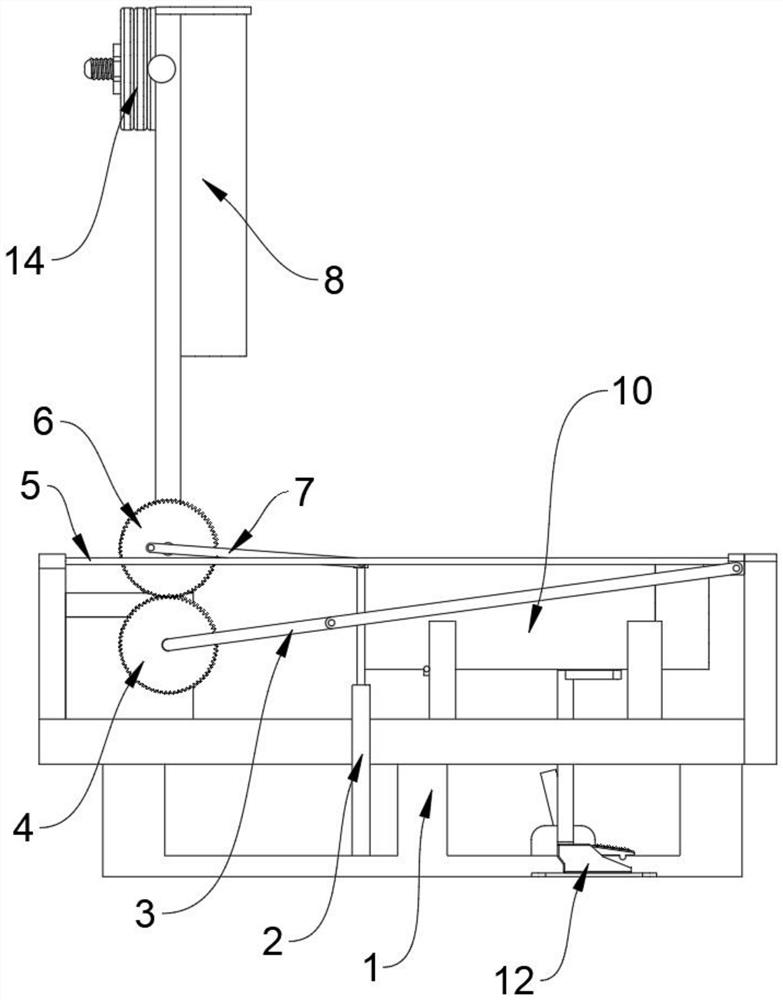

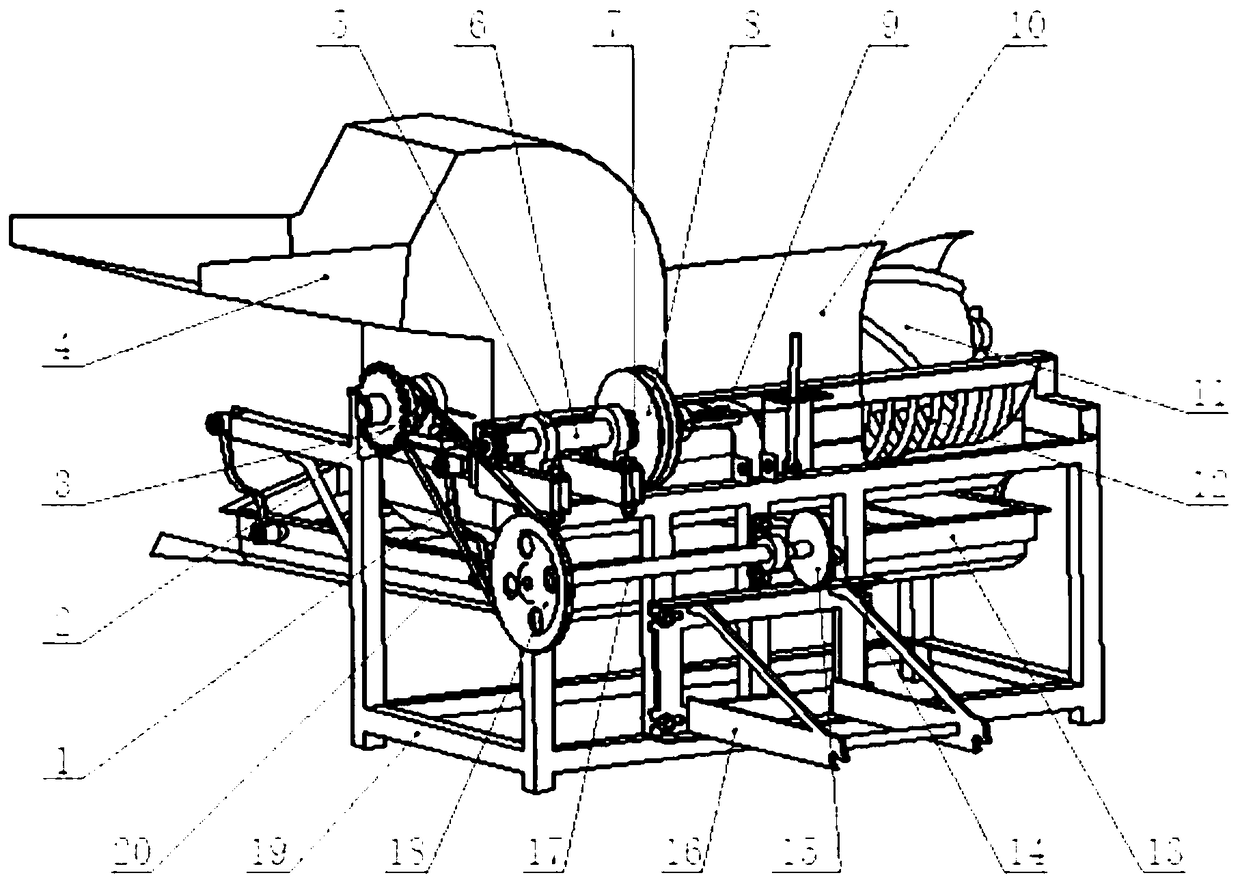

A new type of sunflower disc thresher

PendingCN108886973AReasonable designSimple structureThreshersSaving energy measuresClutchSunflower seed

The invention discloses a novel sunflower disc thresher, which comprises a compound drum composed of an upper cover, a roller shaft and a lower cover. A clutch, a power belt pulley and a shaft are respectively provided with a stop gear and a clutch at two ends of the shaft, the first shaft and the power belt pulley are connected through angular contact ball bearings, the second master belt pulleyis connected with the chain of the second slave belt pulley, the stop gear is meshed with the chain, a double-layer sieve bed, a crank disk and a connecting rod are arranged at one end of the shaft; Alow part of that lower cov is provided with a double-layer sieve bed, one end of the double-layer sieve bed is provided with a connecting rod, the connecting rod is connecte with a crank plate through a sieve bin, one end of the crank plate is provided with three shafts and a two-stage driven belt pulley, and the two-stage driven belt pulley is connected with the two-stage driving belt pulley through a belt, so as to realize synchronous operation. As that sunflower disk of the invention is thresh by the double-type drum, the integrity of the disk can be almost preserved, the utilization rateof the sunflower disk in the lat stage is improved, and the sunflower disk is convenient to dry. But also facilitate the screening and separation of sunflower seeds.

Owner:TIANJIN CHENGJIAN UNIV

A vibration velocity testing device for bearings

ActiveCN113834659BImprove operational efficiencyImprove coaxialityMachine part testingClassical mechanicsBearing vibration

The invention provides a vibration velocity testing device for bearings, which relates to the technical field of bearing testing, and includes a supporting device: a linkage propulsion part is installed on the support device; a mounting part is rotatably connected to the linkage propulsion part; A displacement expansion part is connected; the bottom of the linkage propulsion part is connected with a docking drive part; the support device is fixedly connected with a reverse acceleration device; the support device is fixedly connected with a main shaft drive part; the reverse acceleration device is slidably connected with a floating detection part; The structure is simple and efficient, the data is accurate, and the bearing coaxiality is high; the present invention solves the problem of low test efficiency of the current bearing vibration speed test device, which affects the accuracy of the test data, cannot realize the reverse acceleration test of the docking, cannot realize the floating detection, and has poor adhesion question.

Owner:山东凤鸣新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com