Injection mould for base of wine bottle packing box

A technology for injection molds and packaging boxes, which is applied to household appliances, other household appliances, household components, etc. It can solve the problems of insufficient contact between fixed molds and movable molds, low efficiency of mold closing, waste of raw materials, etc., and shorten mold closing time, gap avoidance, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

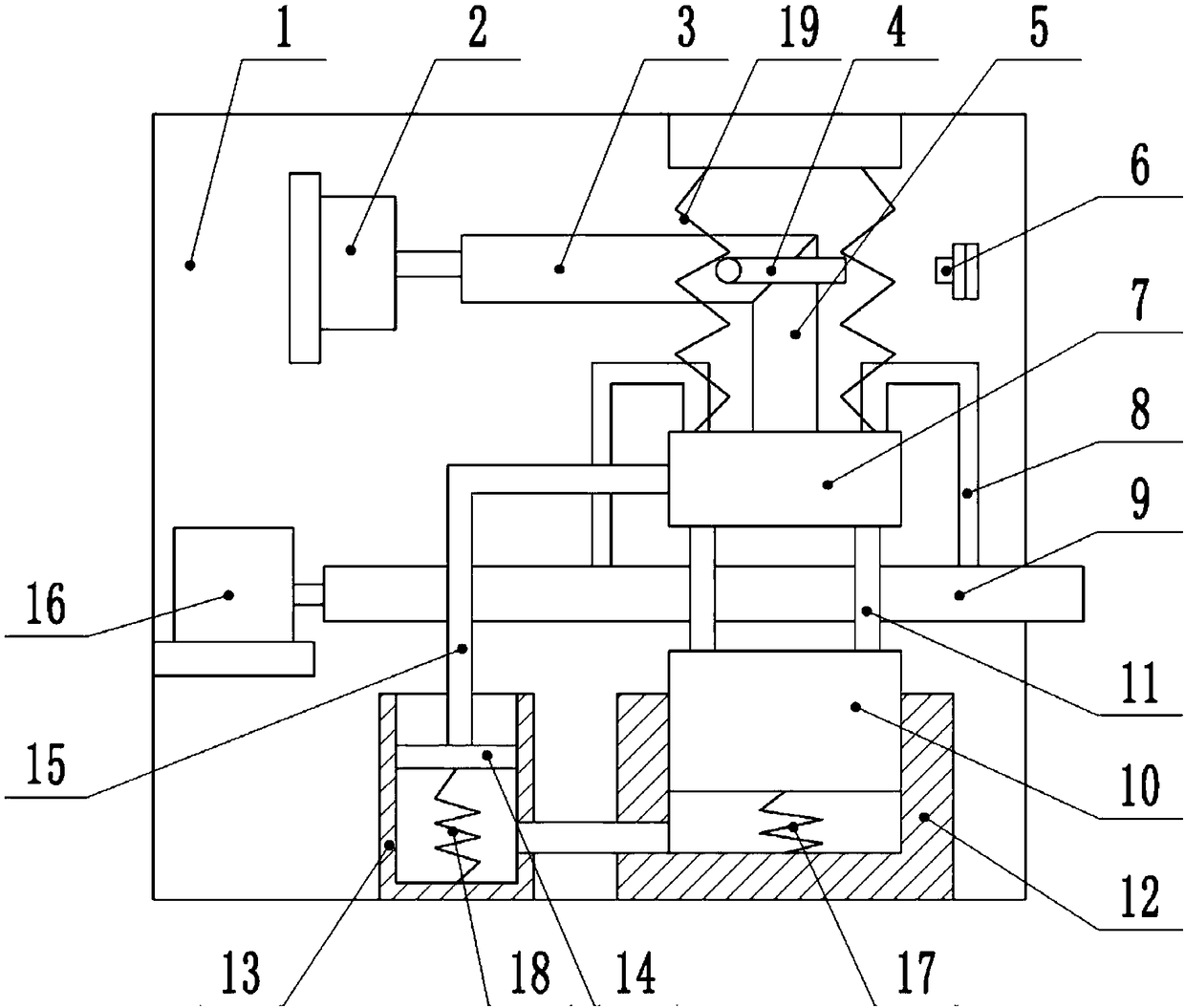

[0020] Embodiment one is basically as attached figure 1 Shown: the injection mold for the base of the wine bottle packaging box, including the frame 1, the upper mold 7 is slidably connected to the frame 1, the lower mold 10 is installed on the frame 1, the lower mold 10 is located below the upper mold 7, and the lower mold 10 is on the top The guide post 11 is welded, the upper mold 7 is slidably connected to the guide post 11, the drive groove 12 is fixed on the frame 1 by bolts, the lower mold 10 is slidably connected in the drive groove 12, and the bottom wall between the lower mold 10 and the drive groove 12 is The first spring 17 is connected between them, and the frame 1 is fixed with a piston cylinder 13 by bolts, the piston cylinder 13 communicates with the drive groove 12, the piston cylinder 13 is slidingly connected with a piston 14, and the piston 14 is connected to the bottom wall of the piston cylinder 13. There is a second spring 18, a piston rod 15 is welded b...

Embodiment 2

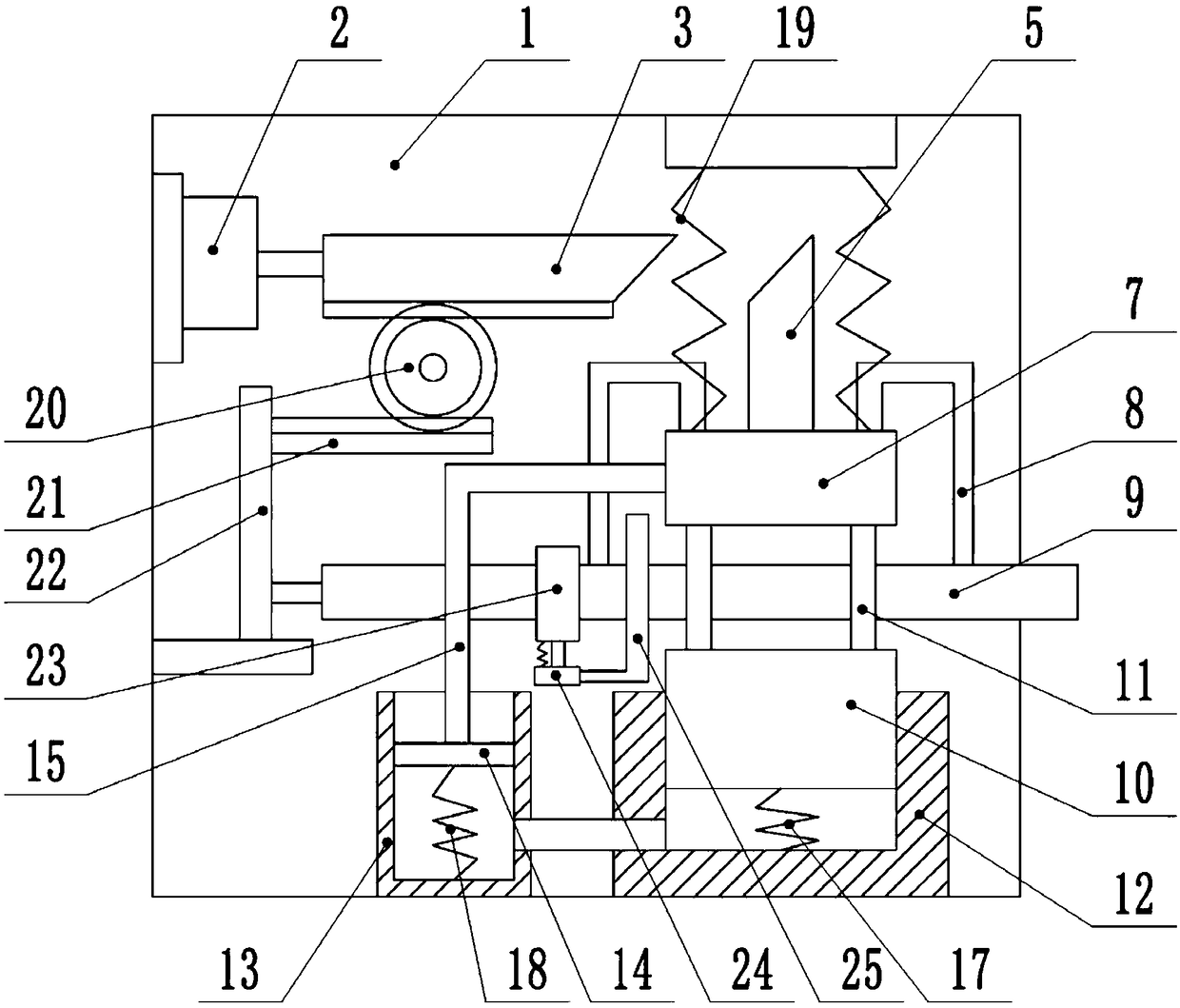

[0022] Embodiment two is basically as attached figure 2 As shown, the difference from Embodiment 1 is that the second wedge bar 3 is meshed with a gear 20, the gear 20 is meshed with a rack 21, the rack 21 is offset by a connecting rod 22, the vacuum tube 9 is slidably connected with a vacuum plug, and the connecting rod 22 Welded with the vacuum plug, a slide valve 23 is installed on the left side of the slide rod 8 on the vacuum tube 9, a fourth spring is connected between the slide valve stem 24 and the valve wall of the slide valve 23, and the slide valve stem 24 is welded with a The push rod 25 is used to abut against the piston rod 15 .

[0023] Slide the second wedge bar 3, the second wedge bar 3 drives the gear 20 to rotate, the gear 20 drives the rack 21 to slide, the rack 21 drives the connecting rod 22 to slide to the left, the connecting rod 22 drives the vacuum plug to slide to the left, and the vacuum tube 9 forms a Negative pressure, the second wedge rod 3 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com