A production method for color cable core with color insulation layer

A production method and insulating material technology, applied in the direction of insulated cables, insulated conductors, marked conductors/cables, etc., can solve problems such as uneven distribution of electric field, difficulty in market promotion, and unclear marking, so as to simplify operation and ensure insulation quality , The effect of simplifying the operation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

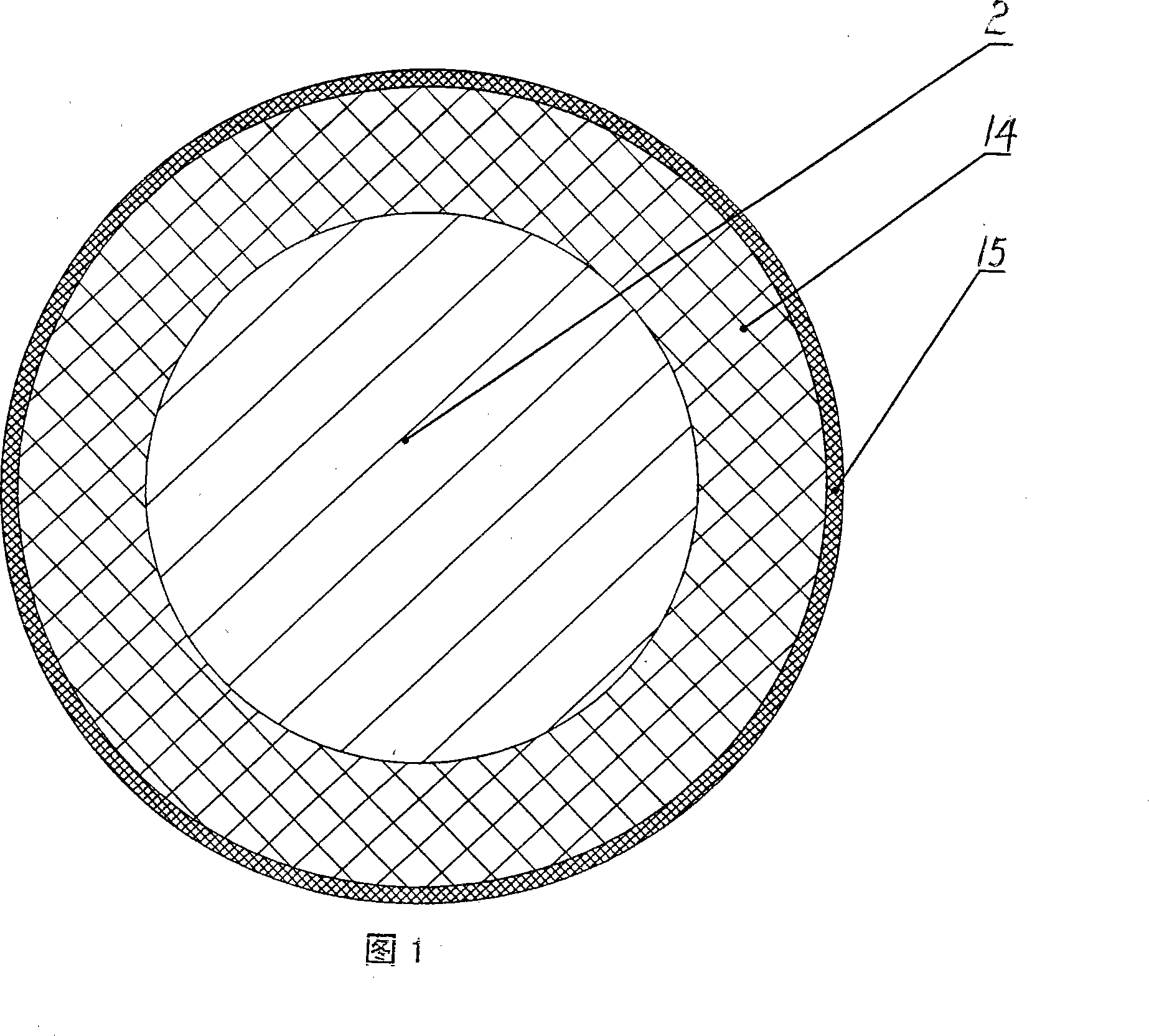

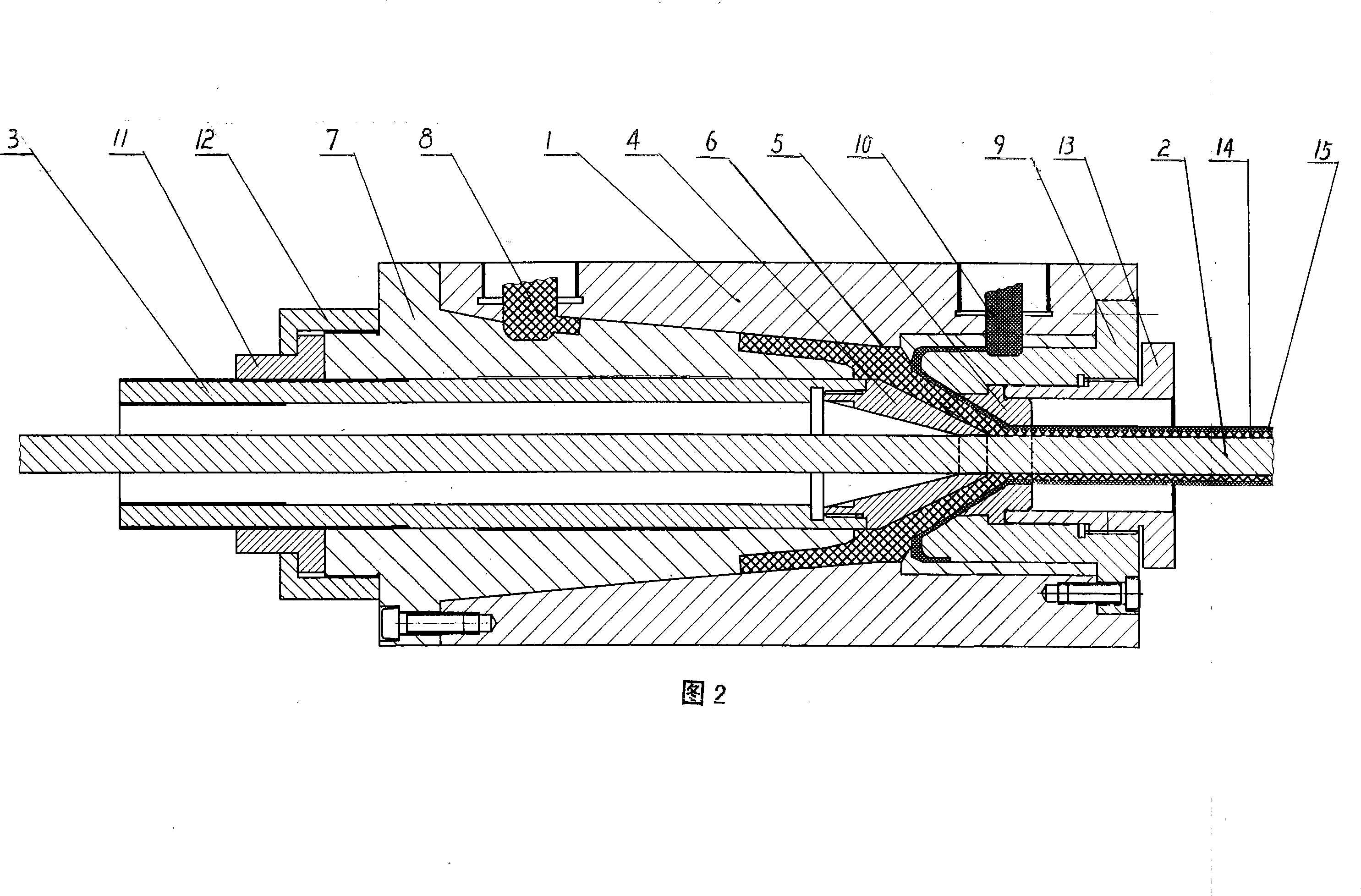

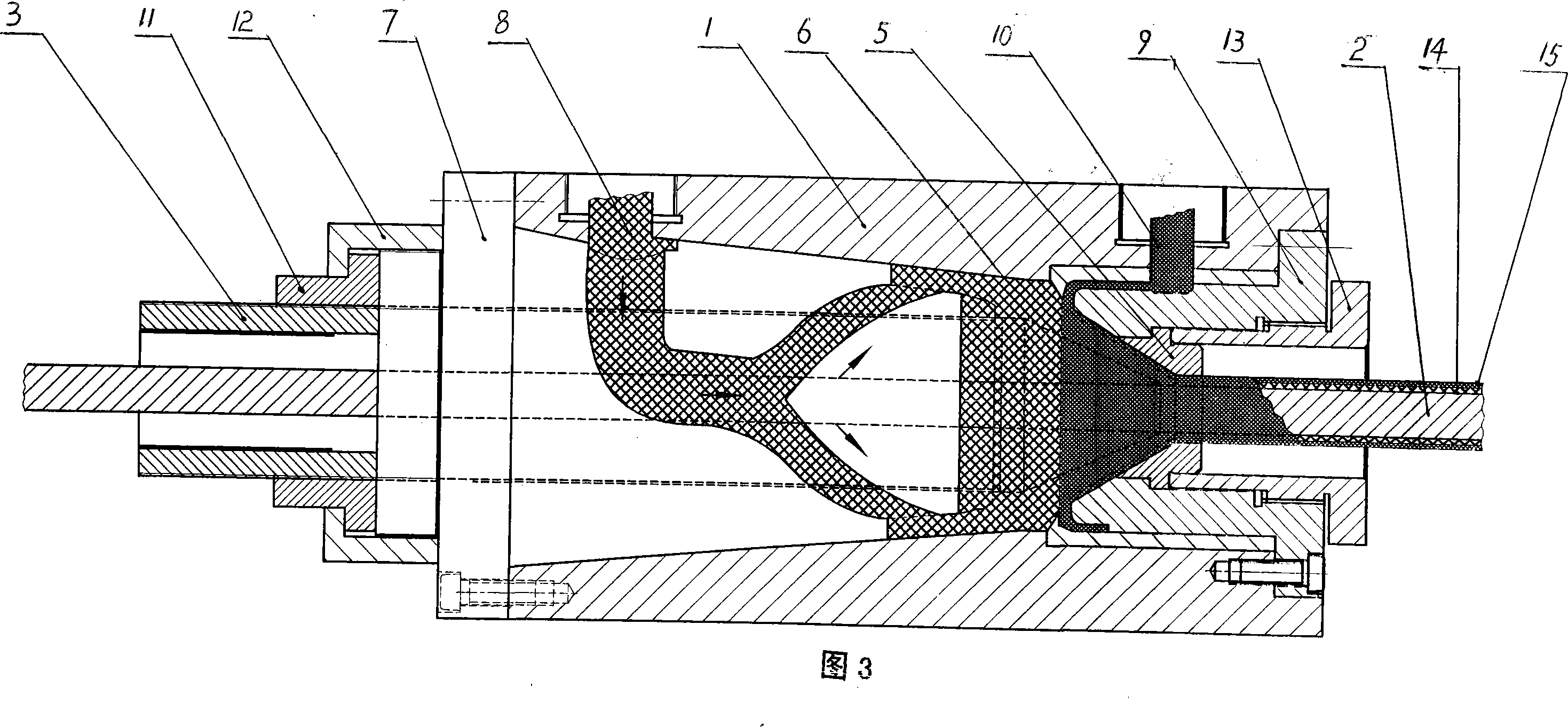

[0027] The specific embodiments of the present invention are as follows: The method of the present invention uses two extruders to complete the extrusion of the insulating material layer, and the two plastic extruders can be used in conjunction with the following models: (1) The main machine is SJ-90 and the auxiliary machine is SJ- 30; (2) The main engine is SJ-65 and the auxiliary machine is SJ-20; (3) The main machine is SJ-80 and the auxiliary machine is SJ-40. One of the large-size extruders is called "main machine", and its function is to realize the extrusion of the inner layer of natural insulating material layer to ensure the thickness of the insulating material layer; the other is a small-size extruder, called " Auxiliary machine", its function is to realize the extrusion of the outer layer of colored insulating material layer, the minimum thickness of this layer of insulating material can be controlled at about 0.2mm, and the color identification of the insulated cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com