Goaf filling waste rock wet-spraying and tamping device and goaf filling waste rock filling method

A technology of compaction device and goaf, which is applied to mining devices, fillings, safety devices, etc., can solve the problems of difficulty in meeting filling requirements and low gangue compression rate, and achieves improvement of gangue moisture content, high compression rate, and simple construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

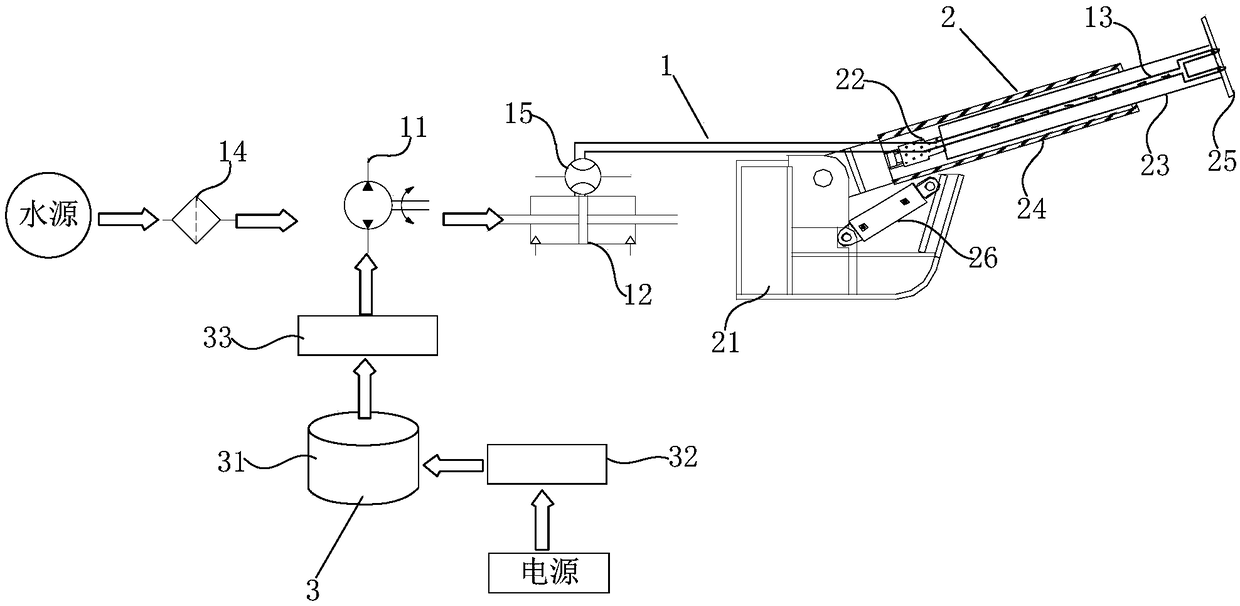

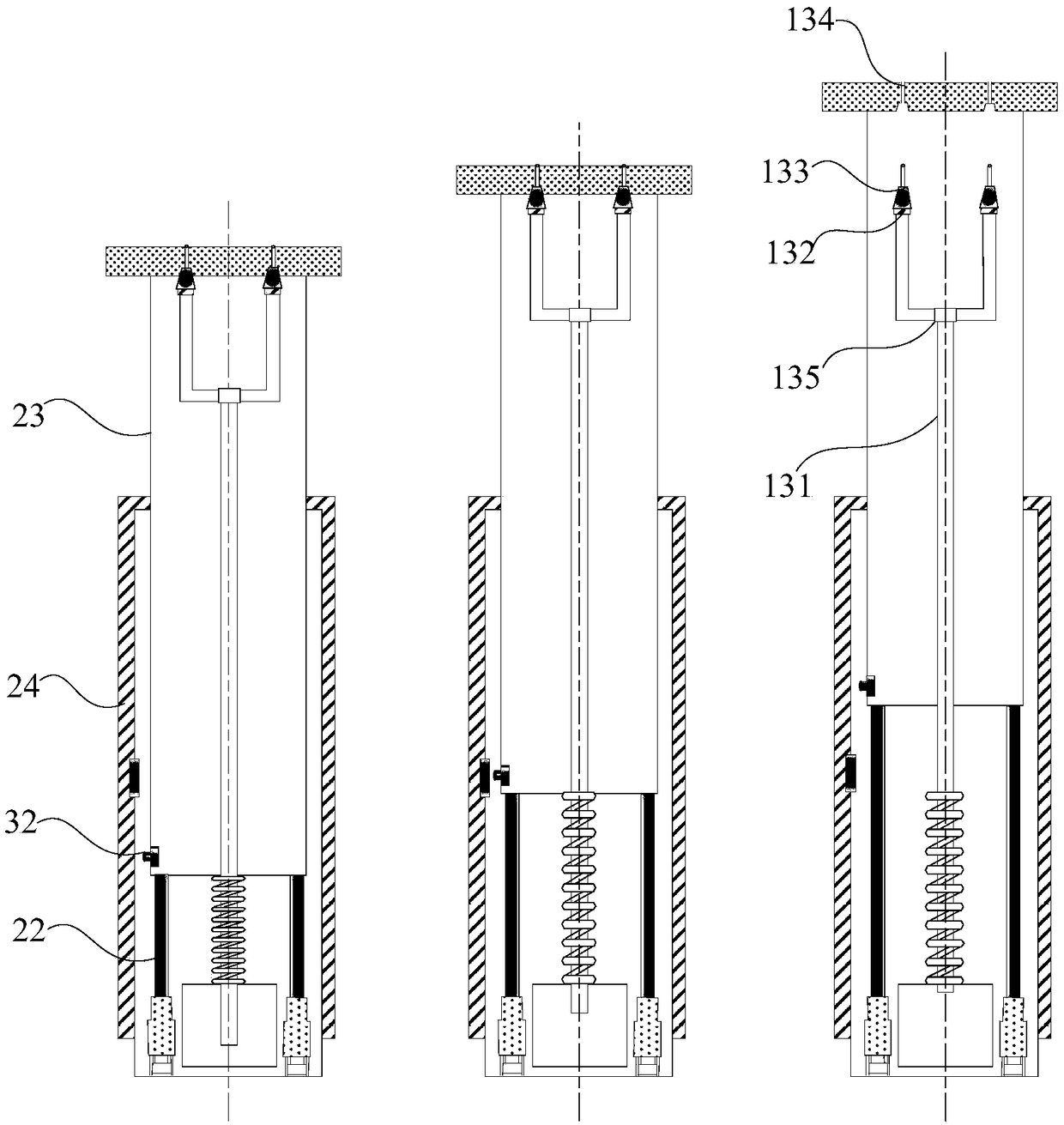

[0029] combine figure 1 and figure 2 As shown, the present invention provides a goaf filling gangue wet-spraying and compacting device and a gangue filling method, the specific implementation of which is as follows.

[0030] A wet spraying and compacting device for gangue filling in a gob, comprising a spraying mechanism 1, a compacting mechanism 2 and a control mechanism 3, the wet spraying mechanism 1 includes a water pump 11, a regulating valve 12 and a wet sprayer 13, and the compacting mechanism 2 includes a base 21 , telescopic rod 22, ramming gangue beam 23, swing beam 24 and baffle plate 25, control mechanism 3 comprises controller 31, sensor 32 and start-stop switch 33. The joint operation of spraying and compaction is realized, and the work of the spraying mechanism and compaction mechanism is controlled by the sensor, so as to realize the function of spraying and compaction cycle operation construction, and improve the work efficiency.

[0031] The water pump 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com