An automatic blank cutting device for the production of civil building glazed tiles

A technology for civil buildings and glazed tiles, which is applied to ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., and can solve problems such as inability to perform mechanized changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

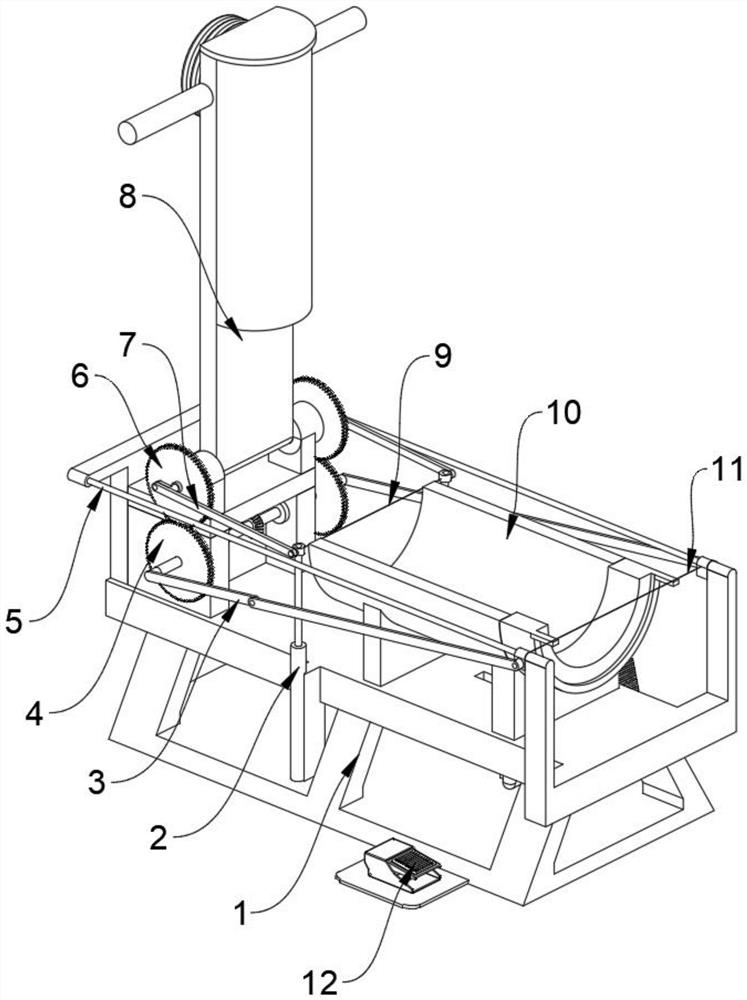

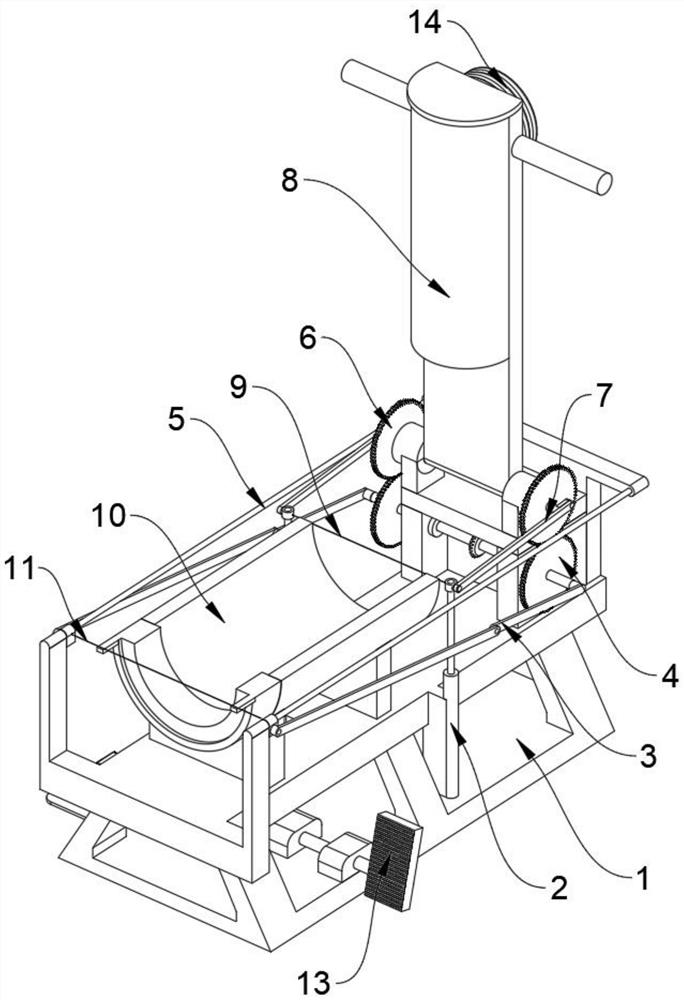

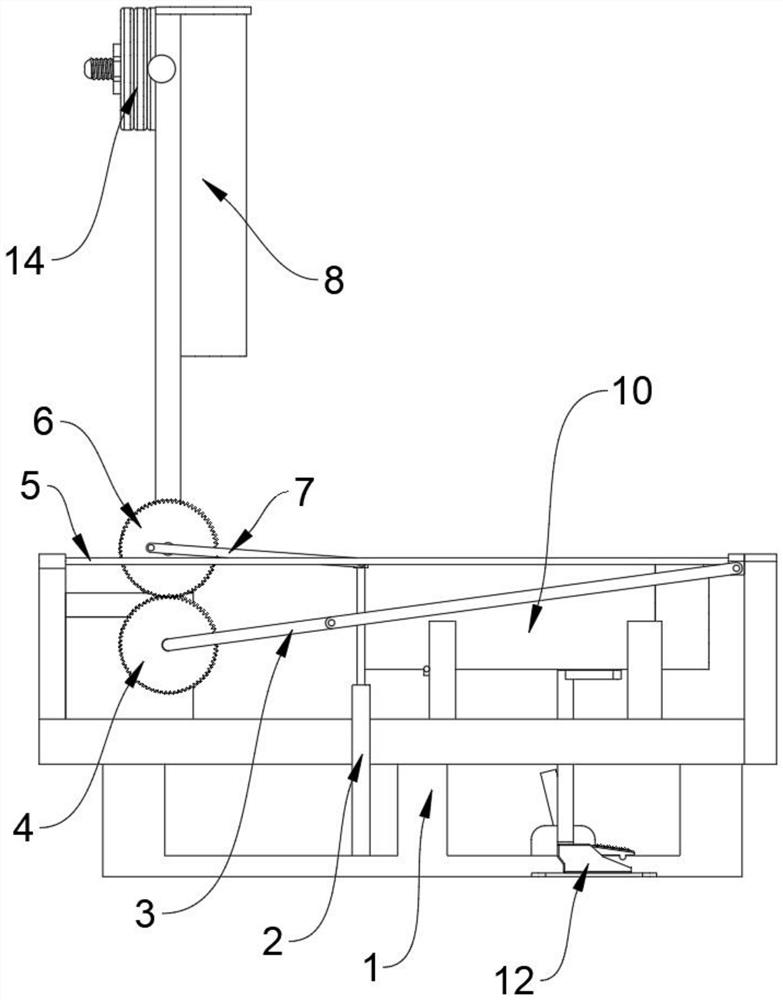

[0039] as attached figure 1 to attach Figure 10 Shown:

[0040] The present invention provides an automatic embryo cutting device for the production of glazed tiles for civil buildings, comprising: a base mold 10 at the bottom of the glazed tile; Two limit slide bars 5 are symmetrically arranged, and the transverse cutting wire 11 is slidably installed on the limit slide bar 5 through the sliders at both ends, and the transverse cutting stroke of the transverse cut wire 11 is in line with the top of the glazed tile bottom embryo mold 10. The walls are parallel to each other, so that the horizontal cutting wire 11 can be limited and moved on the limit slide bar 5, so that the horizontal cutting wire 11 can always be stably cut on the top and bottom walls of the glazed tile bottom blank mold 10, and the horizontal cutting wire 11 11, the outer side of the fixed slider is axially connected with the transverse cutting control arm 3, and the transverse cutting control arm 3 adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com