Frame type stopper of ramp of underground mine

A ramp and frame-type technology, which is applied in the direction of compulsory railway car stopper, railway car body parts, transportation and packaging, etc., can solve the problems of mine car weight, mine car derailment, casualties, etc., and achieve a good car stop effect , to avoid the effect of wheel damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

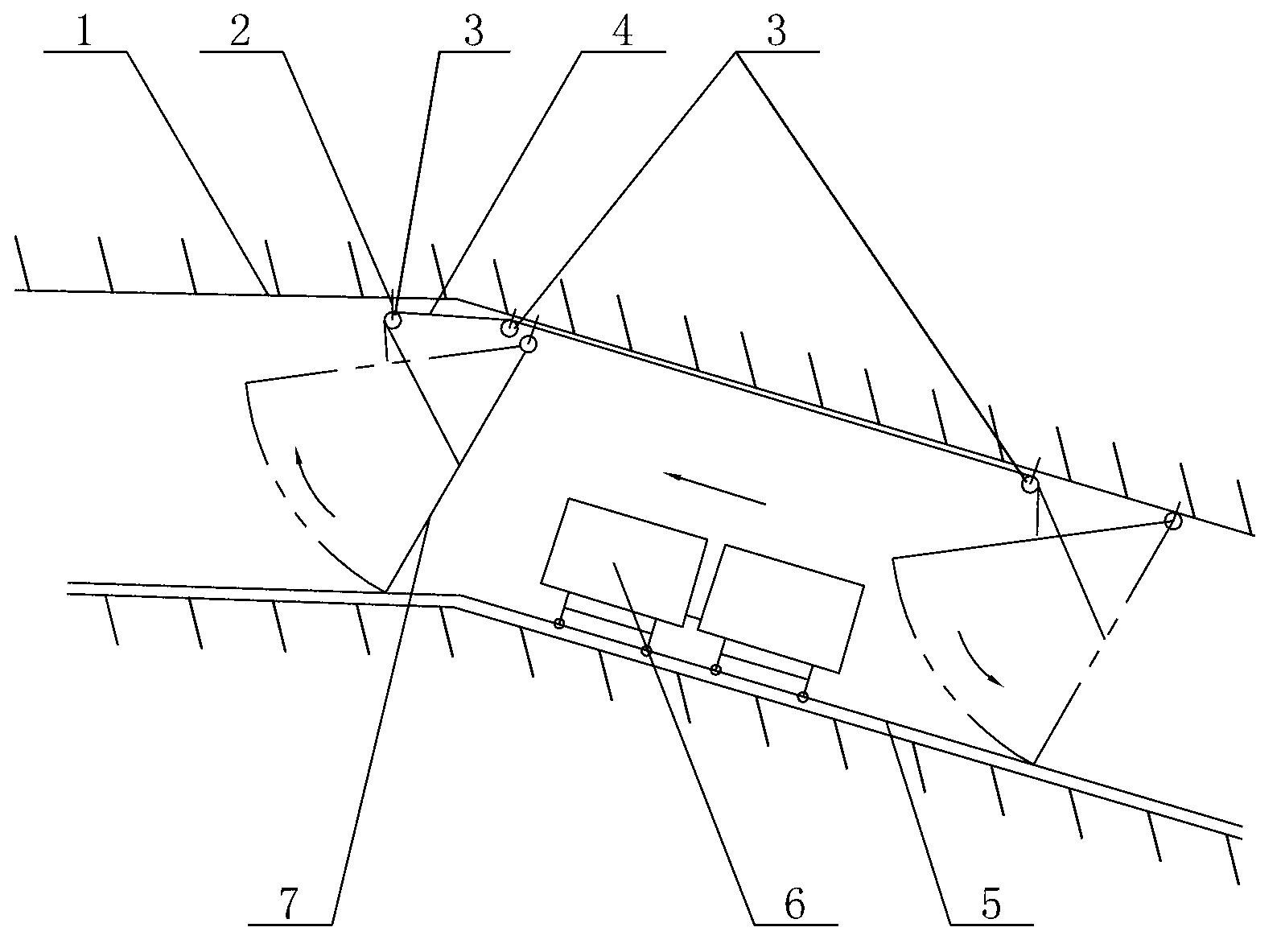

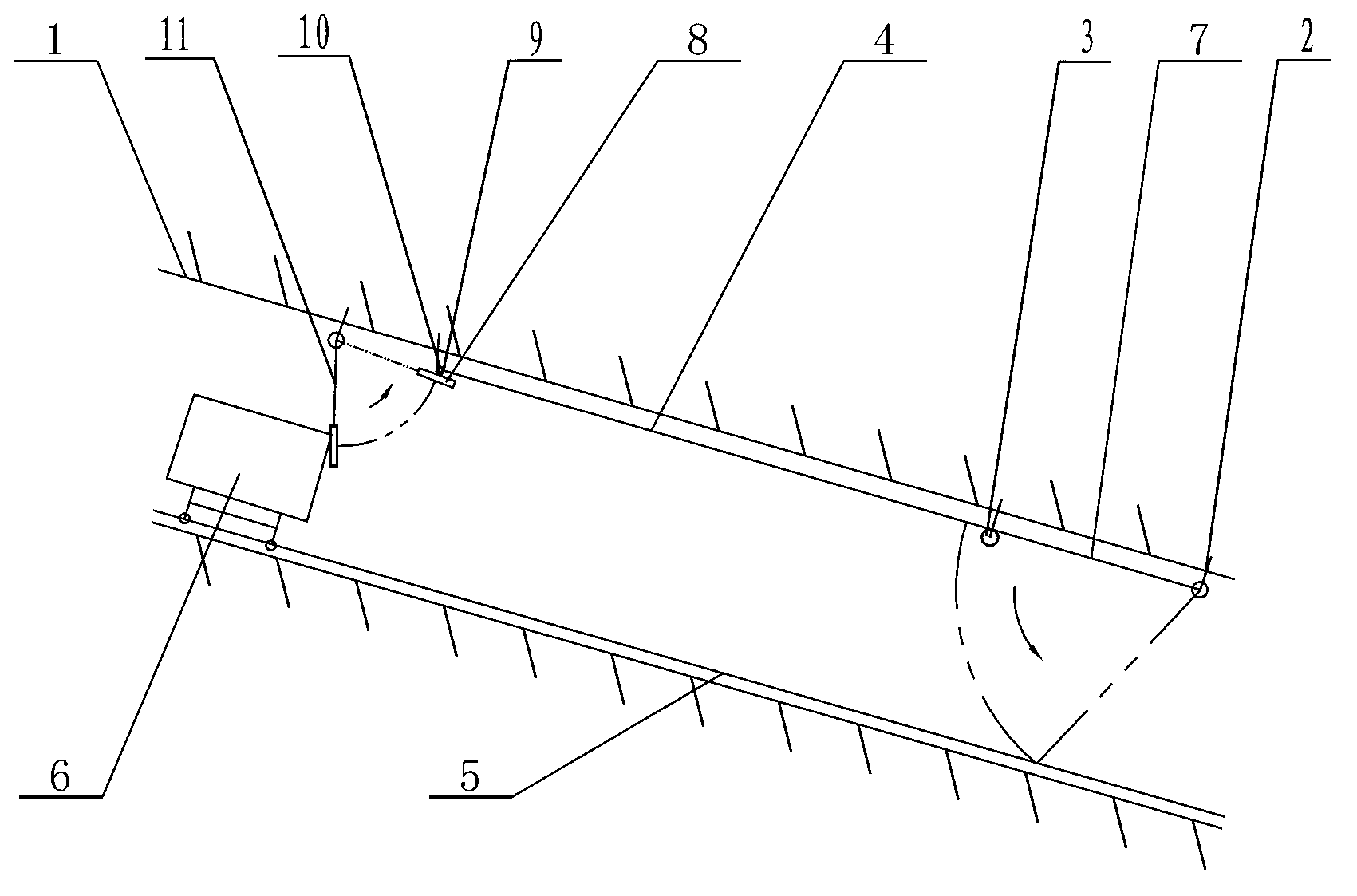

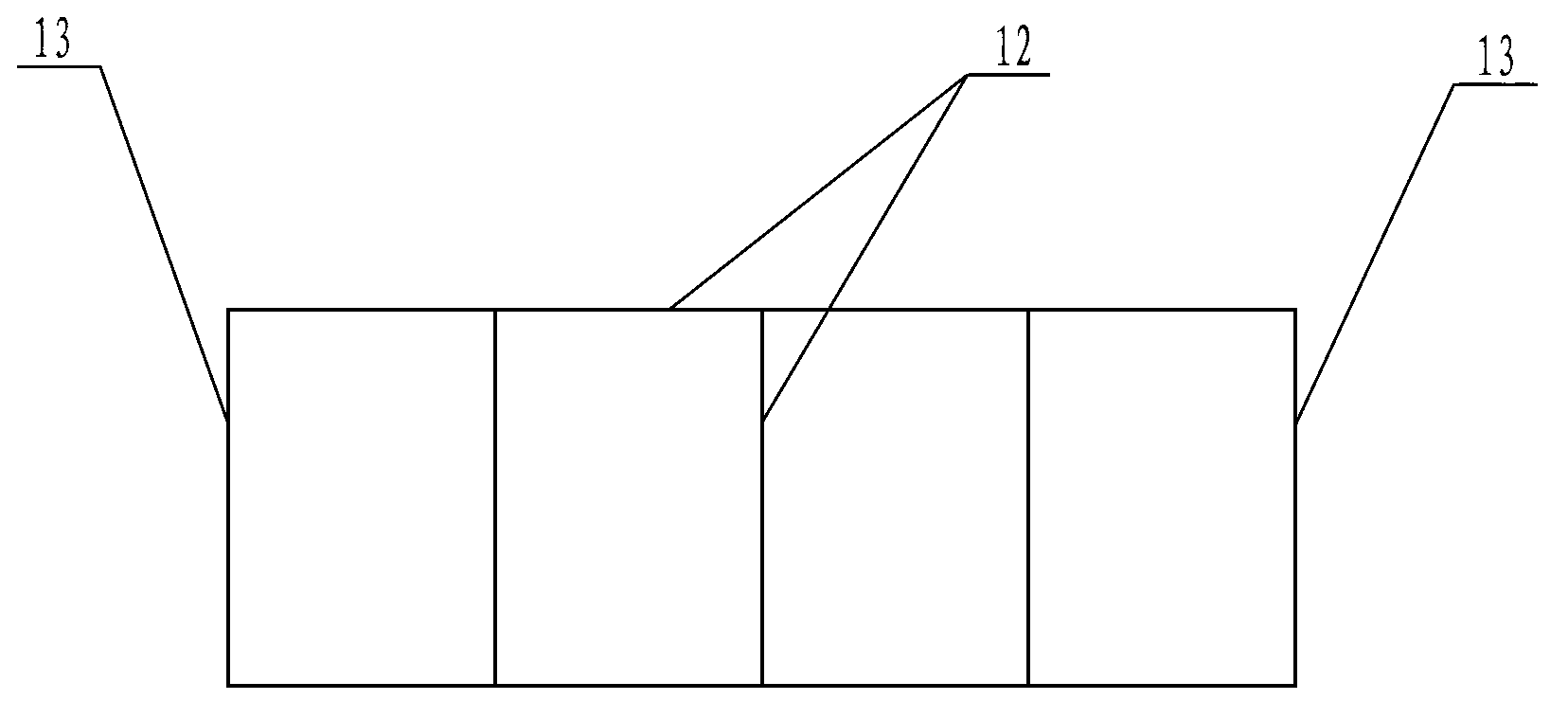

[0019] Such as figure 1 As shown, this embodiment includes a car-stopping plate 7, one end of the car-stopping plate 7 is hinged to the anchor rod 2, the anchor rod 2 is fixed on the top wall 1 of the ramp, and the car-stopping plate 7 is set on the same side as the rising direction of the ramp The pulley block consists of two pulleys 3, both of which are fixed pulleys, and the pulley block is fixed on the top wall 1 of the ramp through the anchor rod 2; the front and rear two sets of pulley blocks are connected by a steel wire rope 4, and the two ends of the steel wire rope 4 are respectively connected to the front and rear two car stop plates 7 , front and rear two car stop plates 7, steel wire rope 4 and pulley block etc. form a working group, according to the mine car number of actual application, a plurality of working groups are set along the ramp distance.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com