Vibration speed testing device for bearing

A technology of vibration velocity and testing device, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc. It can solve the problem of inability to realize auxiliary docking reverse acceleration test, affecting the accuracy of detection data, and the limit data is not complete enough and other problems to achieve the effect of improving detection efficiency, fast detection efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

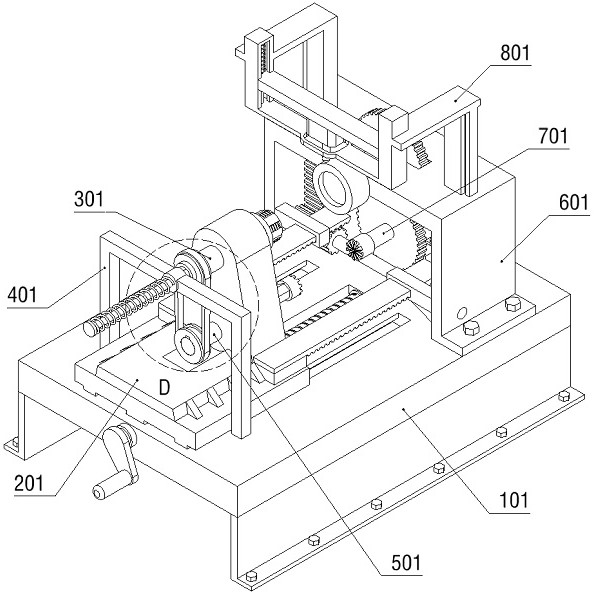

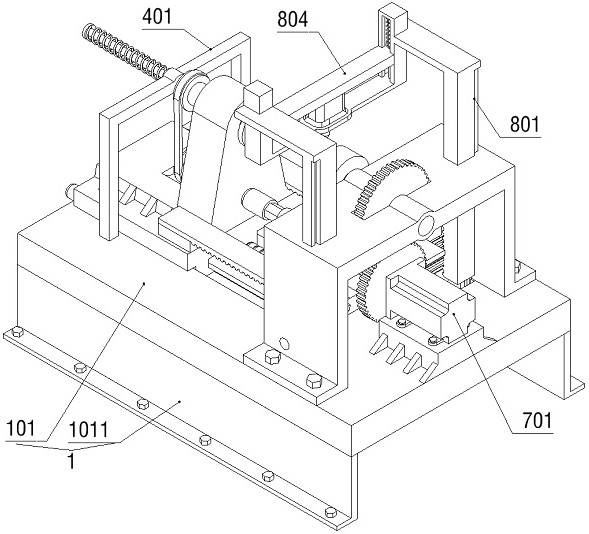

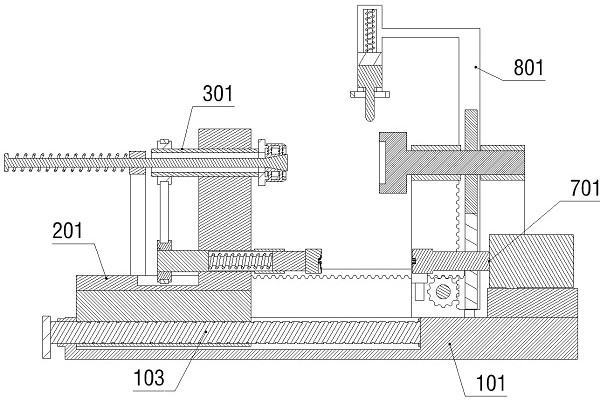

[0044] Example: Please refer to Figure 1 to Figure 17 :

[0045] The present invention proposes a vibration velocity testing device for bearings, which includes a support device 1: a linkage propulsion part 2 is installed on the support device 1; a mounting part 3 is rotatably connected to the linkage propulsion part 2; The displacement expansion part 4; the bottom of the linkage propulsion part 2 is rotatably connected with a docking drive part 5; the support device 1 is fixedly connected with a reverse acceleration device 6; the support device 1 is fixedly connected with a spindle drive part 7; the reverse acceleration device 6 is slidably connected with a The floating detection part 8; the reverse acceleration device 6 includes: a stable bracket 601, which is fixedly connected to the support base plate 101 on the support device 1; a linkage gear shaft 602, which is rotatably connected to the stabilization bracket 601; The two sides of the shaft 602 are respectively meshed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com