Coal bed hydraulic cutting and sieve tube feeding linked gas extraction apparatus and method

A technology of hydraulic slotting and gas drainage, which is applied in the direction of gas discharge, safety devices, drill pipes, etc., can solve the problems of reducing gas drainage effect, poor drainage effect, and poor air permeability, so as to improve drainage effect and improve Slit effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

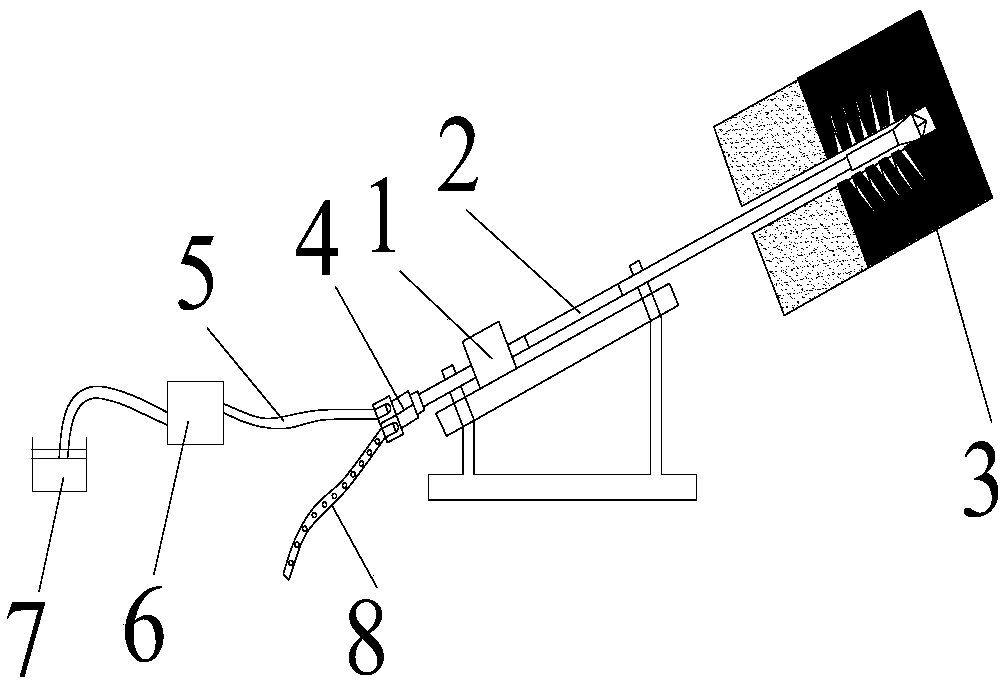

[0039] Such as figure 1 As shown, the method and device for synchronously measuring the amount of gas adsorbed by coal rocks, deformation and porosity provided by the embodiments of the present invention are used to measure the amount of gas adsorbed by coal samples under different adsorption equilibrium gas pressure conditions during the gas adsorption process of coal samples. , deformation and porosity, including drilling rigs, drill pipe connection devices, coal seams, drill pipe tail switching devices, high-pressure water pipes, high-pressure pump stations, softening pools, flexible screen pipes, special drill bits, drill pipes, high-pressure water flow outer pipes, and screen holes ,Fixtures.

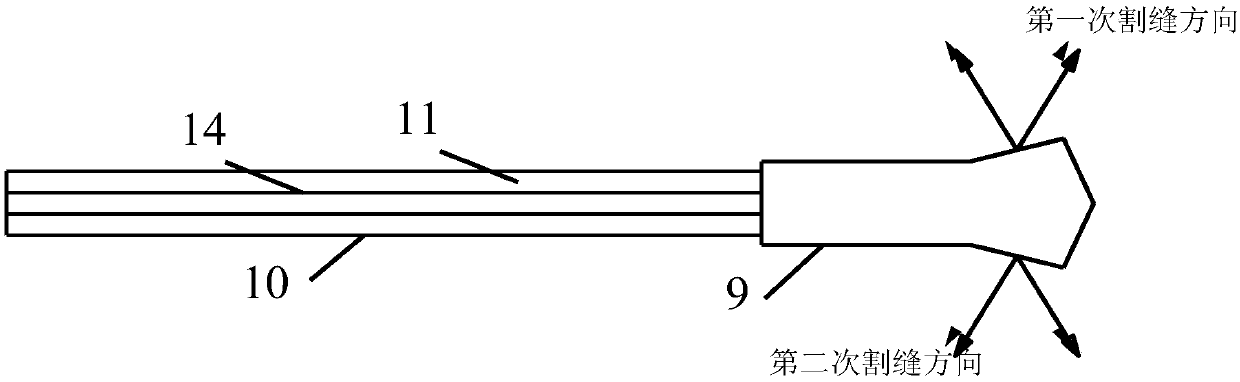

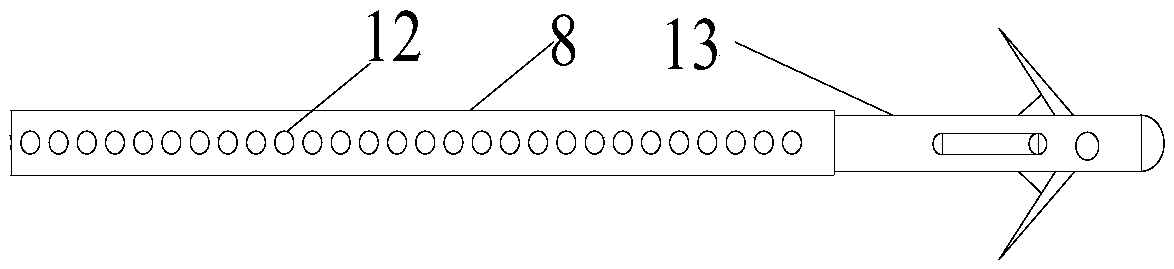

[0040] Such as Figure 1~3As shown, the coal seam hydraulic slitting and lower screen pipe linkage gas drainage device described in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com