Linked contact switch structure

A contact switch and linkage technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problem that multiple contact switches cannot be linked 100 times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

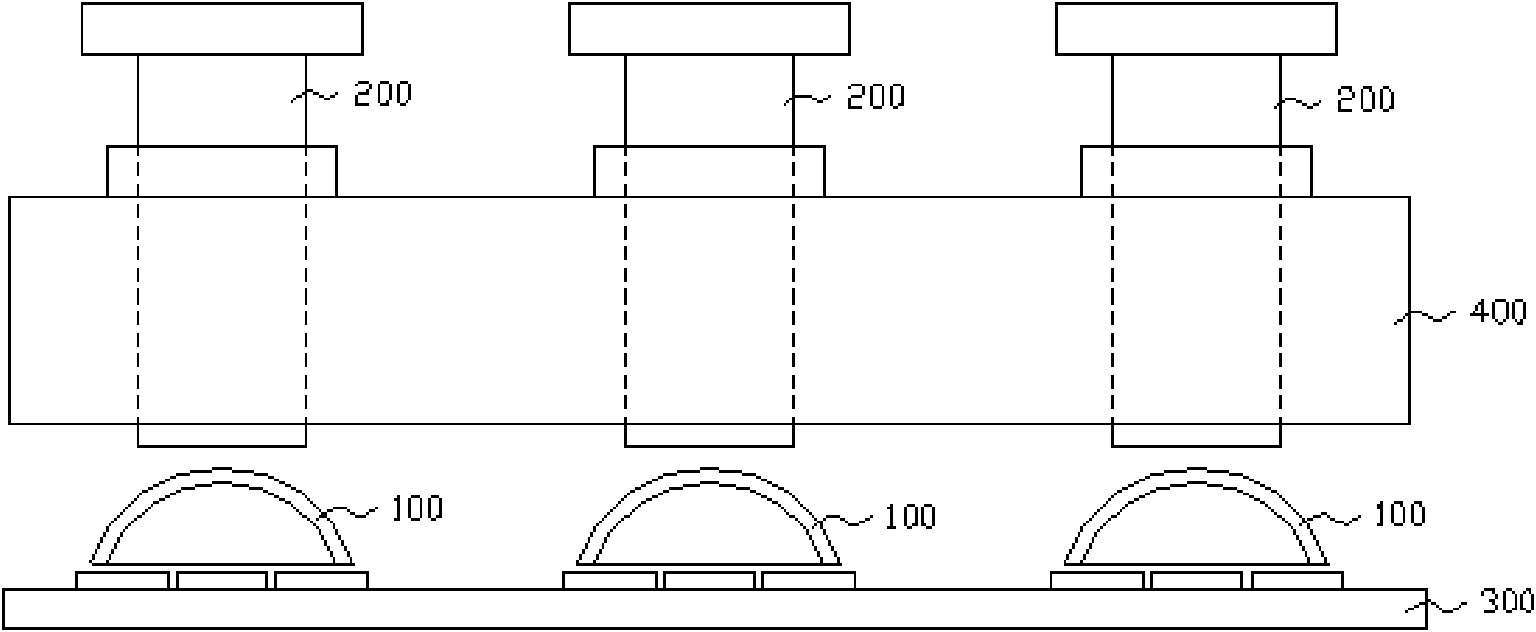

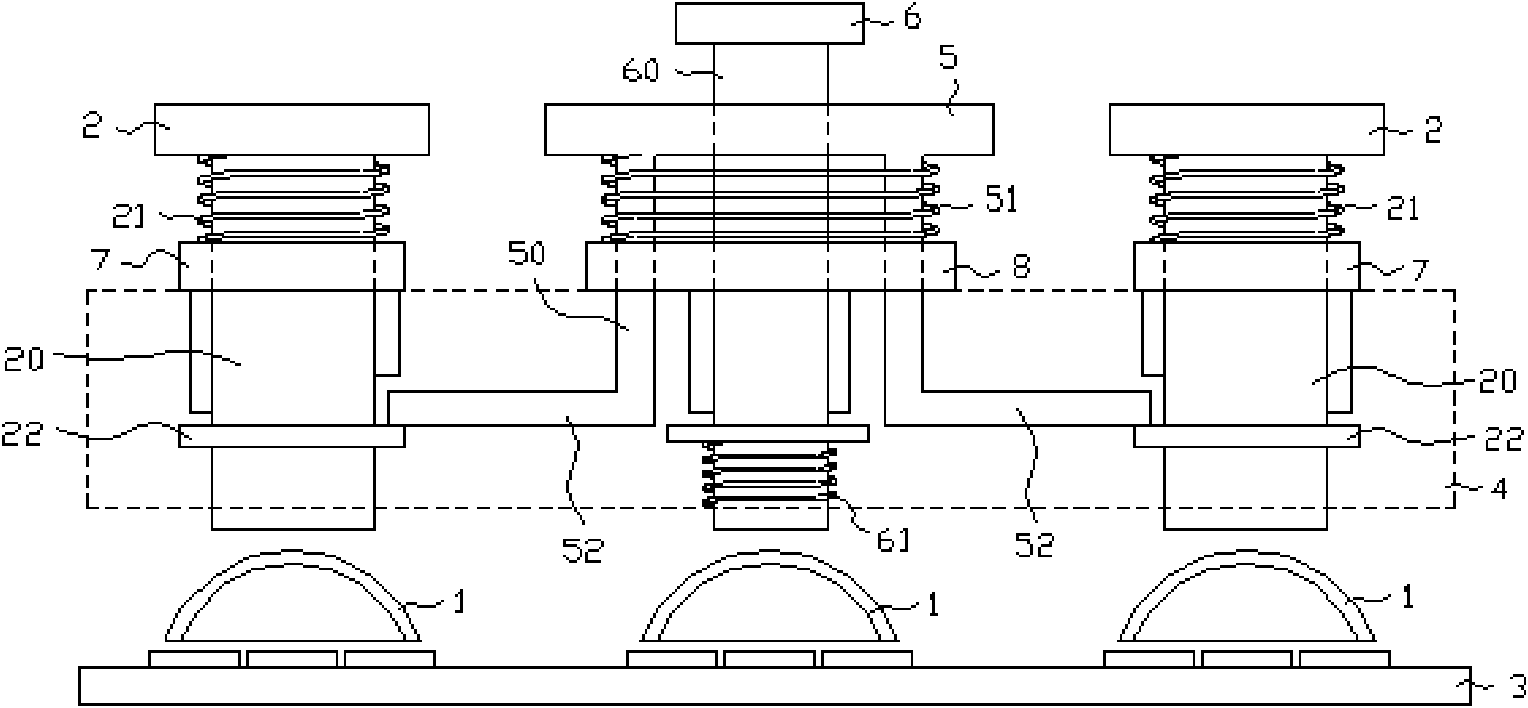

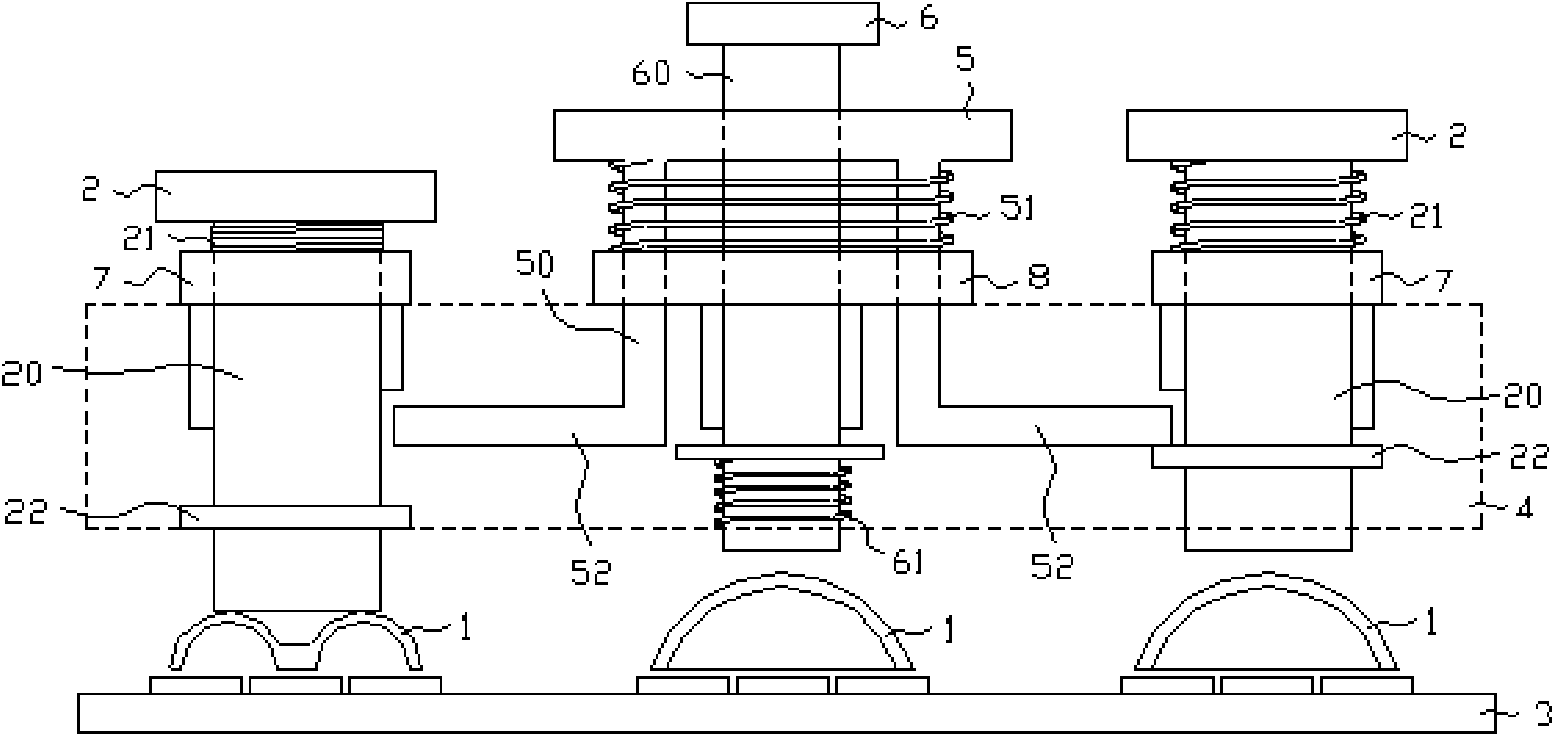

[0018] see figure 2 , figure 2 It is a side view of an unpressed state of a preferred embodiment of the linkage contact switch structure of the present invention.

[0019] The linkage contact switch structure provided by the present invention is provided on the circuit board 3 and the housing 4 of the electronic product. In this embodiment, the structure includes:

[0020] Three contact switches 1, the three contact switches 1 are arranged on the circuit board 3 and arranged on the same straight line;

[0021] Two side buttons 2, which respectively include a side pressing body 20 pierced through the above-mentioned shell 4 and a side spring 21 arranged between the side pressing body 20 and the surface of the shell 4, each side pressing body 20 is close to the bottom position A slave linkage side 22 is provided, and the bottom of each side pressing body 20 is correspondingly arranged above one of the contact switches 1 at the two ends;

[0022] A linkage button 5, which in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com