Punching die for wood board

A wooden board and punching technology, which is applied in wood processing equipment, wood stamping, manufacturing tools, etc., can solve the problems of affecting the efficiency of secondary punching, punching slot blockage, etc., to increase convenience, increase efficiency, and facilitate removal The effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments.

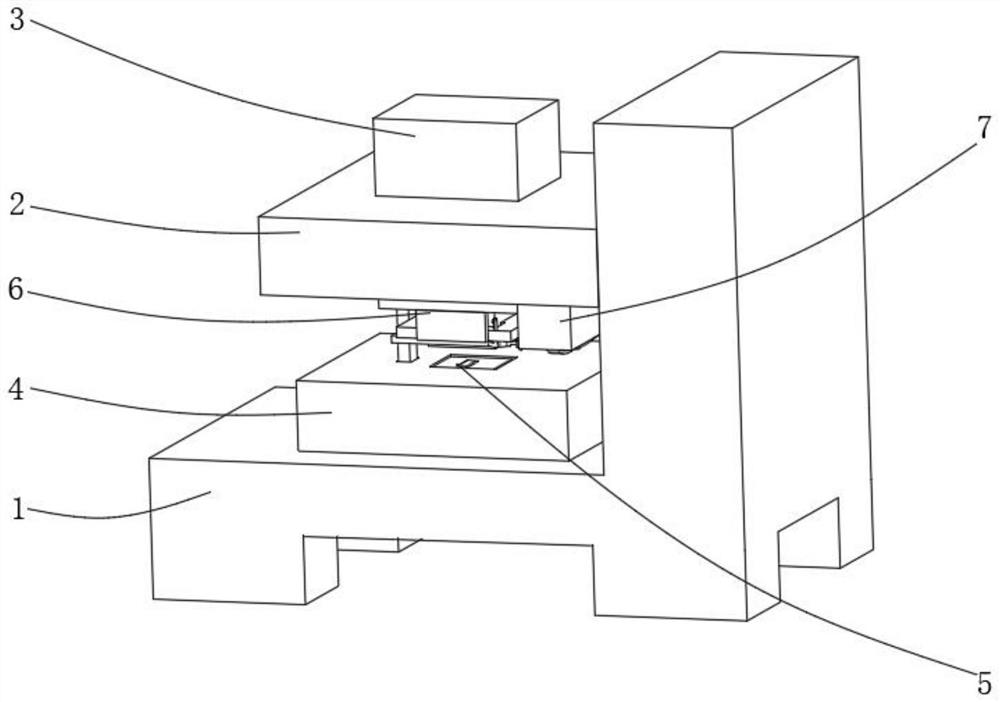

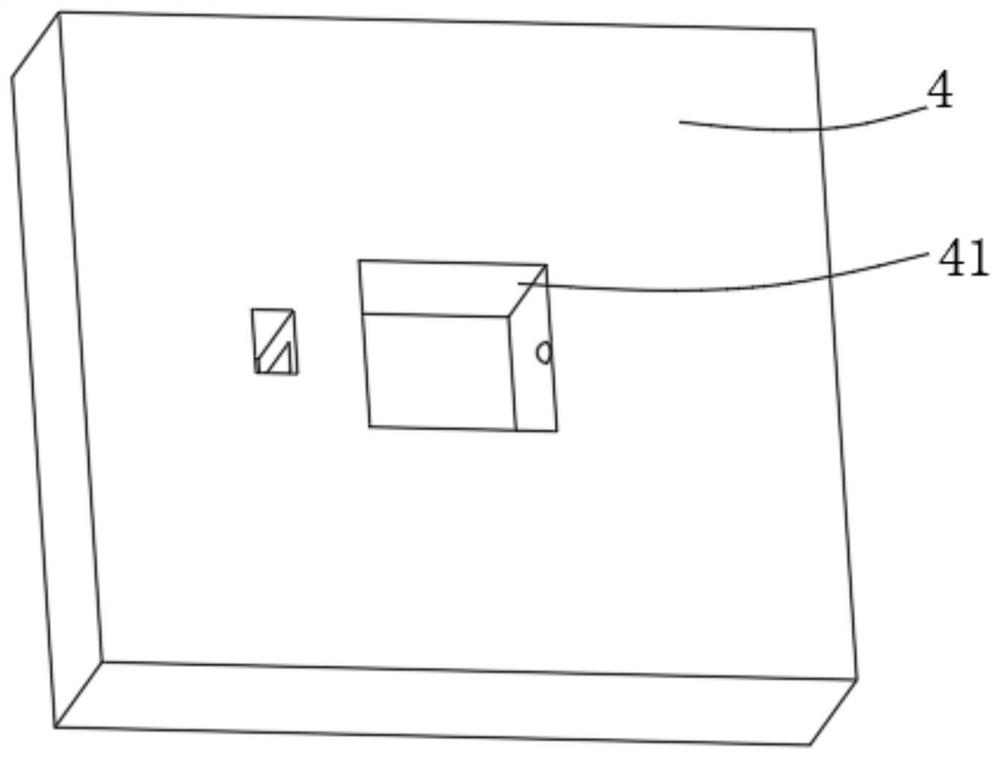

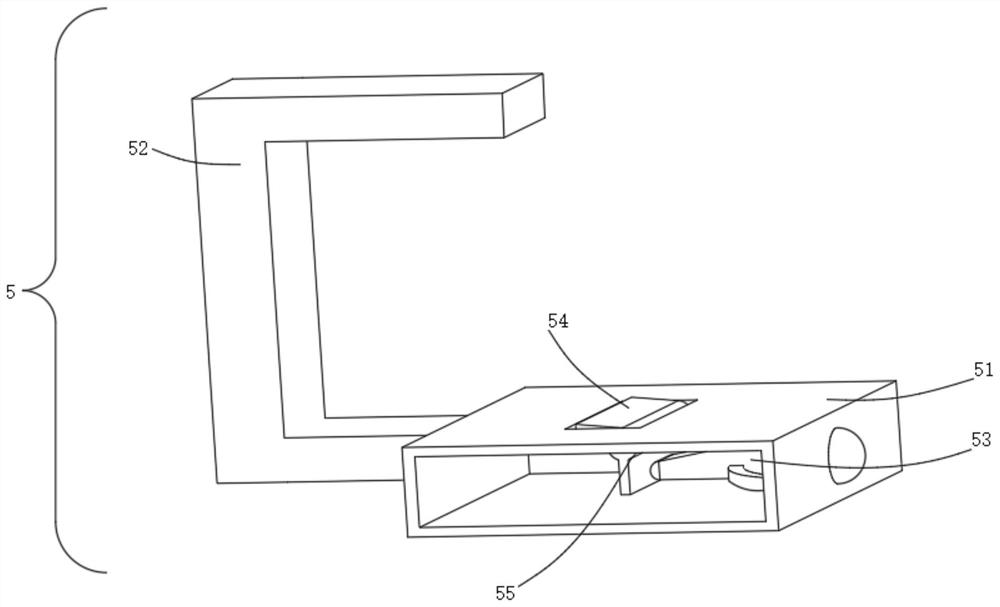

[0029] See Figure 1-8 , the present invention provides a technical solution: a punching die of a wooden plate, comprising a support base 1, the upper surface of the support base 1 is fixed with a mold base 4, the upper surface of the mold base 4 is opened with a punching groove 41, the upper right end of the inner wall of the punching groove 41 is fixed with an impact ball one, the internal of the mold base 4 is provided with an ejector device that facilitates the ejection of the scrap 5, the side wall of the support base 1 is fixed with a transverse support plate 2, and the internal embedded intrinsic stamping machine 3 of the lateral su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com