Manufacturing process of glass pot cover

A manufacturing process and glass pot technology, which is applied in the direction of manufacturing tools, stone processing equipment, cooking utensil lids, etc., can solve the problems of low degree of automation in the processing of glass fiber reinforced plastic pot lids, and achieve the effect of high degree of automation and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

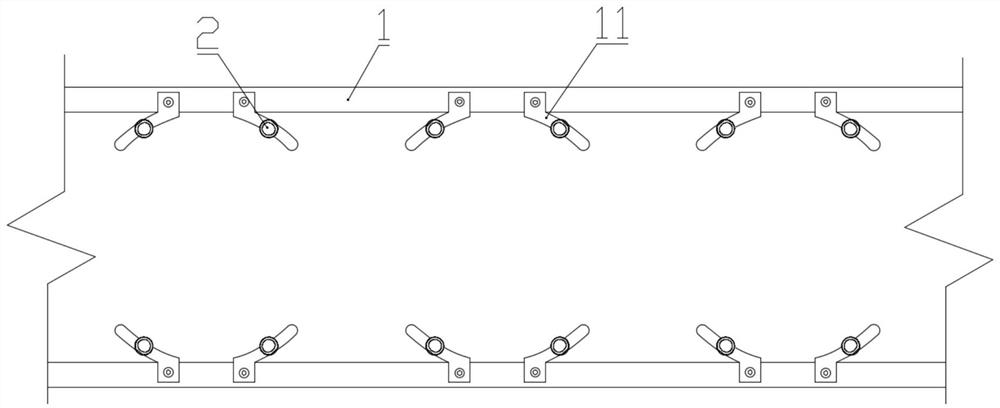

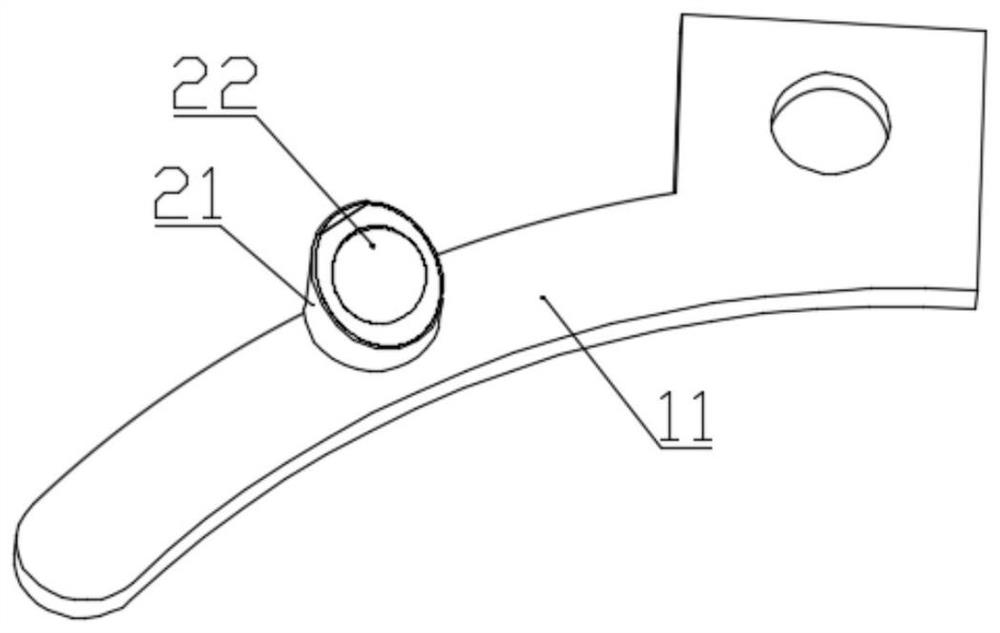

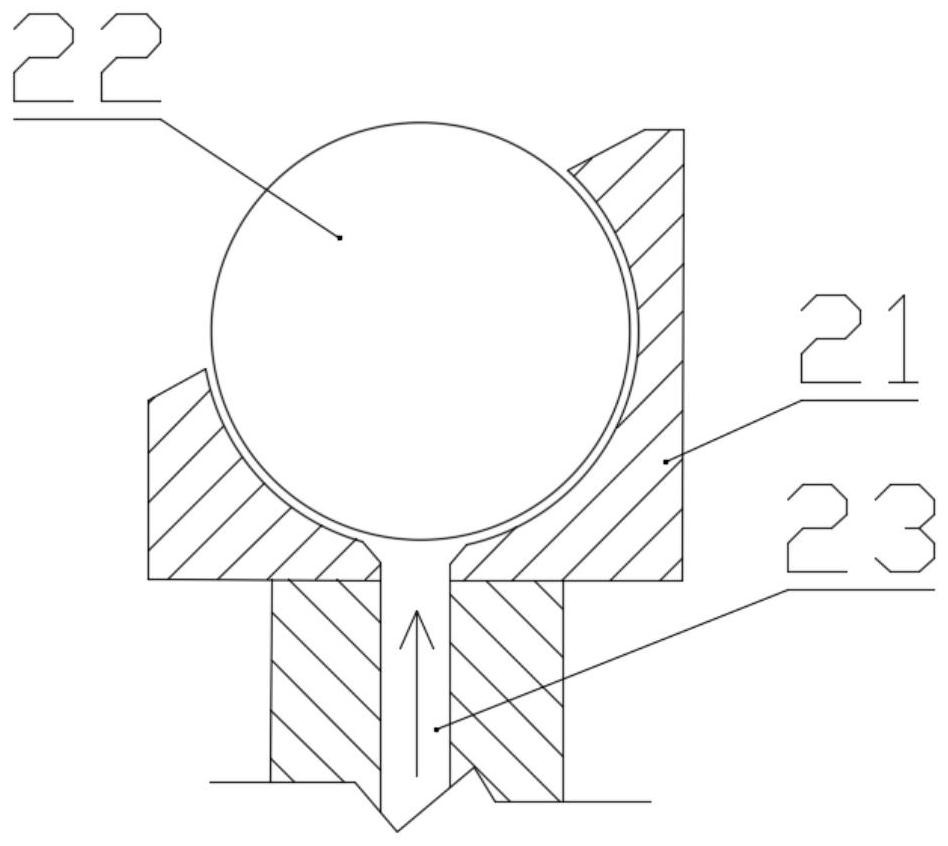

[0048]This embodiment discloses a manufacturing process for a glass pot lid: it includes the steps of laying flat and punching holes, edge grinding, and edge strip extrusion in sequence; in order to improve the automation of the above three processes, the present invention preferably adopts The conveyor belt 1 transports the product in a step-by-step manner to ensure that the three processes can be carried out simultaneously.

[0049] This embodiment is applicable to the rough pot lid body, and the so-called rough pot lid body refers to a spherical surface of glass fiber reinforced plastics whose edges have been roughly machined.

[0050] like Figure 1 to Figure 3 Shown: there are two conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com