An automatic straightening mechanism used on a bushing press-in machine

A press-in machine and automatic technology, applied in the field of press-fitting machines, can solve the problems of inaccurate press-fitting position of bushings, lower production efficiency, and low pressure, and achieve improved product qualification rate, simple structure, and increased pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

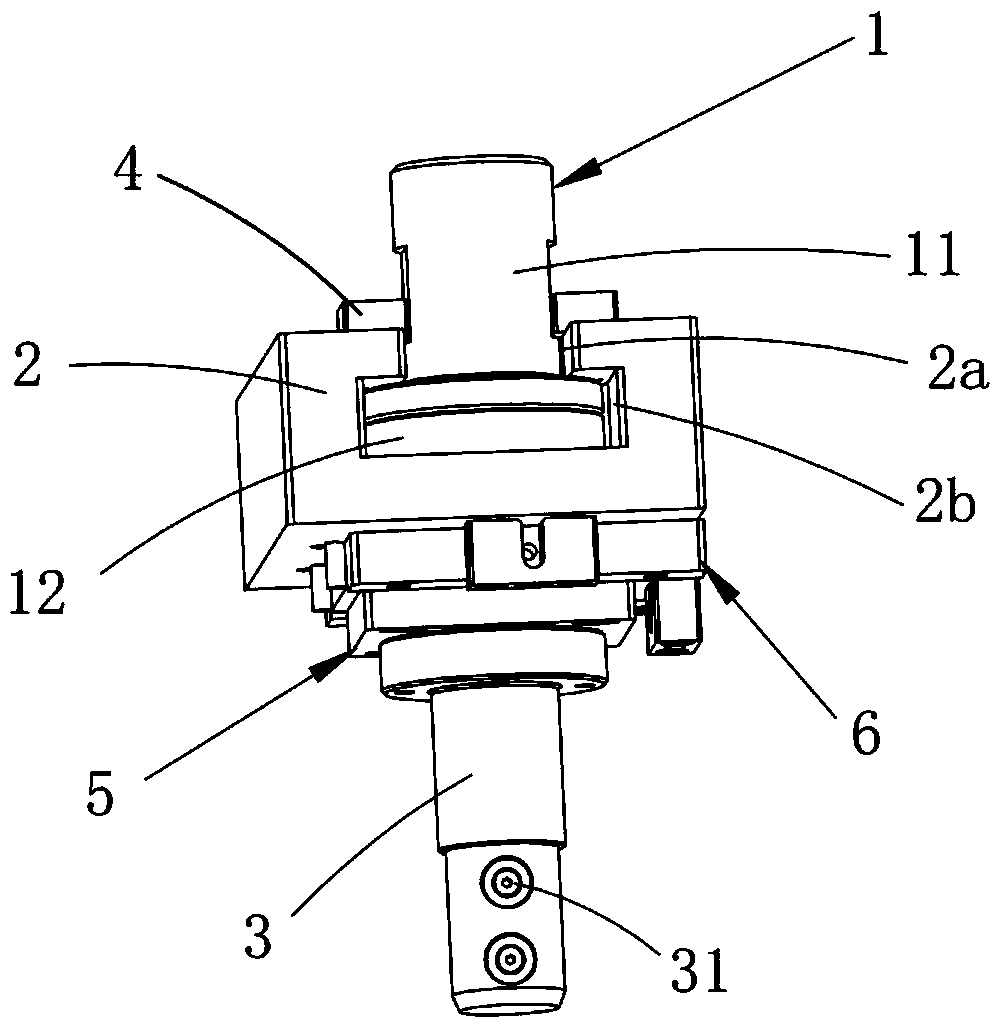

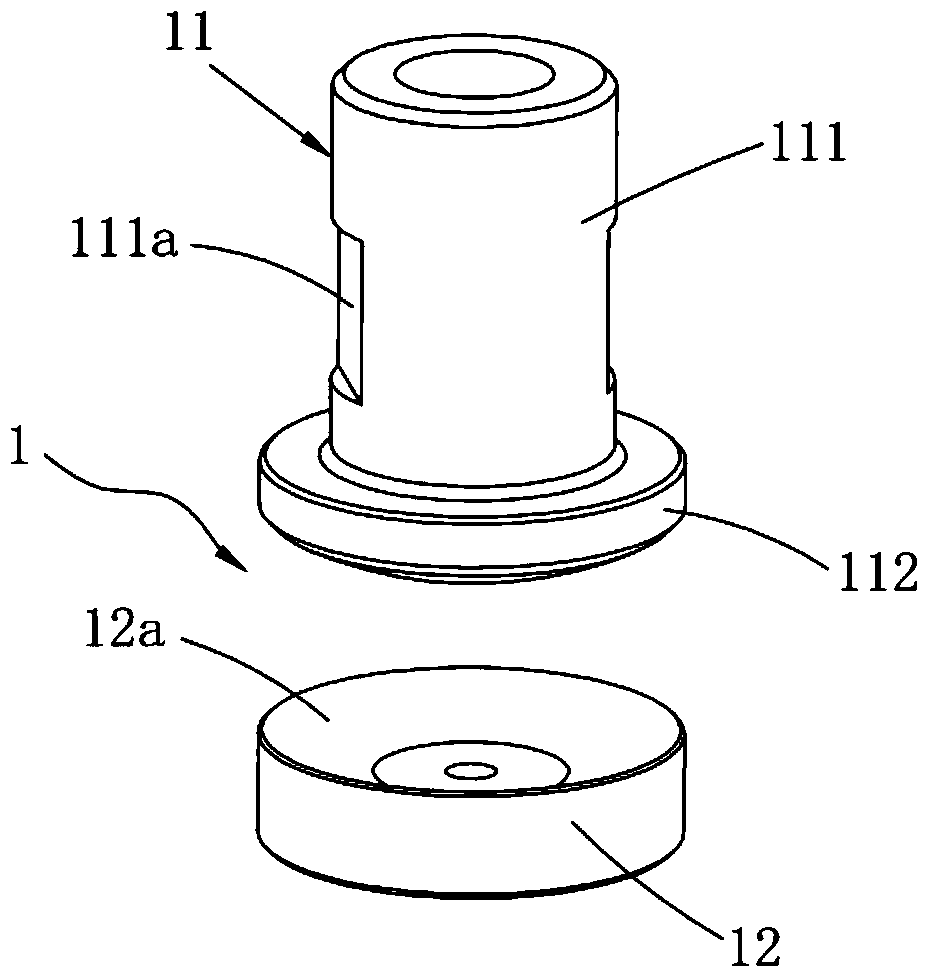

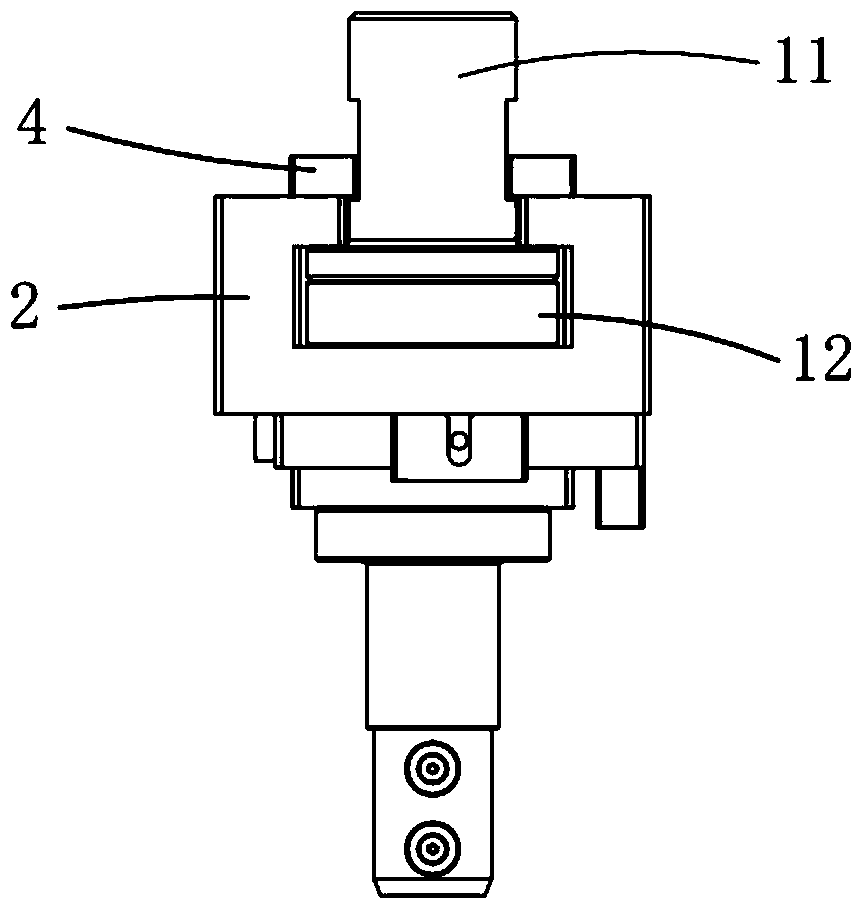

[0025] Such as figure 1 with figure 2 As shown, the present invention provides an automatic guiding mechanism for a bushing press-in machine, comprising a cylinder joint 1, a cylinder connection block 2 and a pressure head 3, and the cylinder connection block 2 is symmetrically located on both sides of the cylinder joint 1, and the cylinder The connection block 2 is provided with a narrow groove 2a and a wide groove 2b from top to bottom; the cylinder joint 1 includes an upper joint 11 and a lower joint 12, the upper joint 11 is fixedly connected with the piston rod of the cylinder, and the lower joint 12 is arranged on the cylinder. On the connection block 2, the upper joint 11 is provided with a cylindrical part 111 and an arc boss 112 in sequence from top to bottom, and an arc groove matching the arc boss 112 is processed on the upper end surface of the lower joint 12 12a, the cylindrical part 111 of the upper joint 11 is placed in the narrow groove 2a, and the lower join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com