Patents

Literature

125results about How to "Under pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

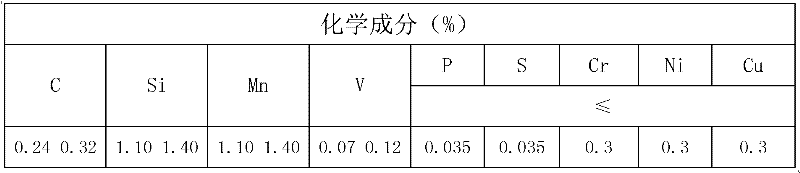

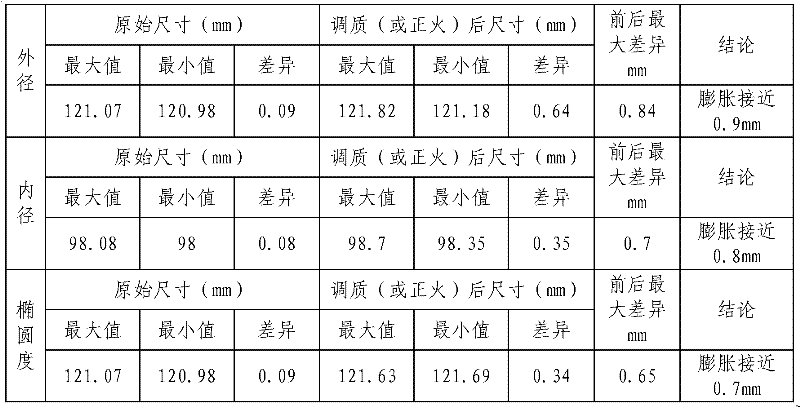

Hardening and tempering technology of alloy-steel tube

ActiveCN102676780AStress reliefUniform internal organizationFurnace typesHeat treatment furnacesHydraulic cylinderFree cooling

The invention discloses a hardening and tempering technology of an alloy-steel tube, and through the technology, the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The technology comprises the following steps of: (1) annealing treatment: warming to 870-880 DEG C at the speed of 20-25 DEG C / minute, keeping the temperature for 35-40 minutes, and then cooling to 500 DEG C below; (2) quenching treatment: warming to 930-935 DEG C at the speed of 5-10 DEG C / minute, keeping the temperature for 50-60 minutes, then cooling rapidly at the speed of 190-200 DEG C / second to 320-325 DEG C, and cooling naturally to 30-40 DEG C; and (3) tempering treatment: warming to 500-510 DEG C at the speed of 5-10 DEG C / minute, then keeping the temperature for 230-240 minutes, and then cooling naturally to room temperature, thus the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The hardening and tempering technology of the alloy-steel tube provided by the invention is mainly applied to the hardening and tempering of the alloy-steel tube for a hydraulic cylinder barrel.

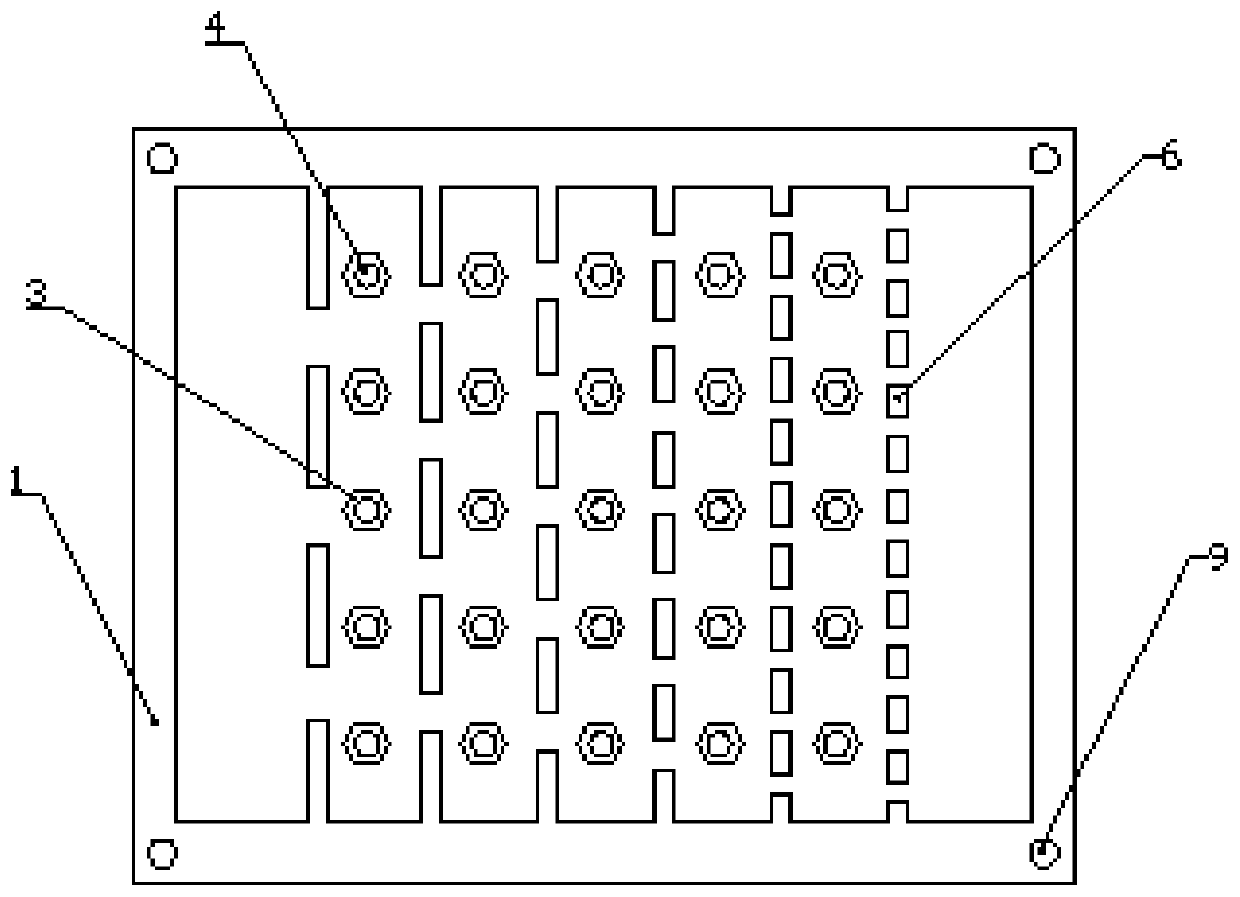

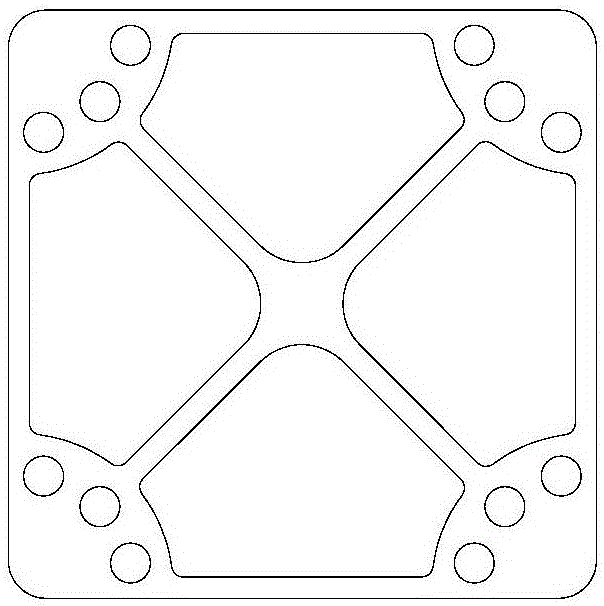

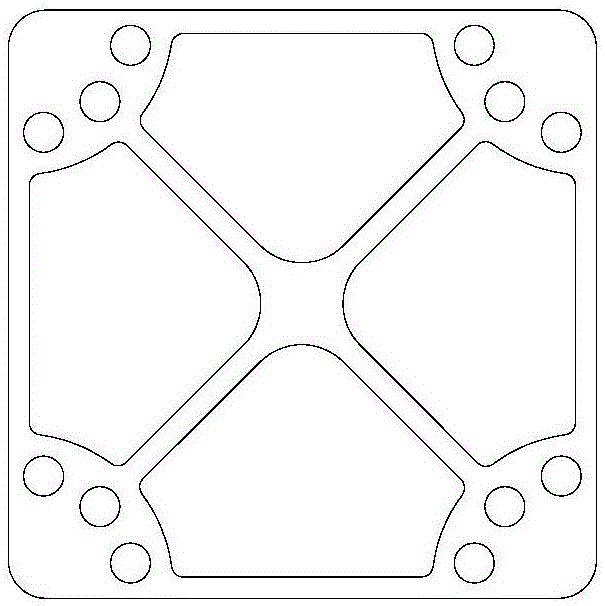

3D printing integrated radiator and application thereof in phased-array antenna

InactiveCN110165355ALowered byHelp passIndividually energised antenna arraysDe-icing/drying-out arrangementsEngineeringTemperature difference

The invention relates to the field of heat dissipation, in particular to a micro-channel radiator, integrated manufacturing and an application of the micro-channel radiator in a control array antenna.The radiator is manufactured through 3D printing. Through a fluid channel which is distributed in a gradually changed manner and a liquid injection port and a liquid outlet which are respectively formed at the biggest end and the smallest end of the flow channel, cooling liquid uniformly passes through the whole fluid channel. When the radiator is in use, the highest temperature of the radiator is 298K, the lowest temperature of the radiator is 295K, and the temperature difference after heat dissipation is 3 DEG C. Compared with a pure runner structure, the radiator is stronger in heat dissipation capability and more uniform in temperature distribution after heat dissipation, and has the characteristics of good heat dissipation performance and temperature uniformity, one-time forming, noneed of using a nut sealing ring and the like for packaging.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

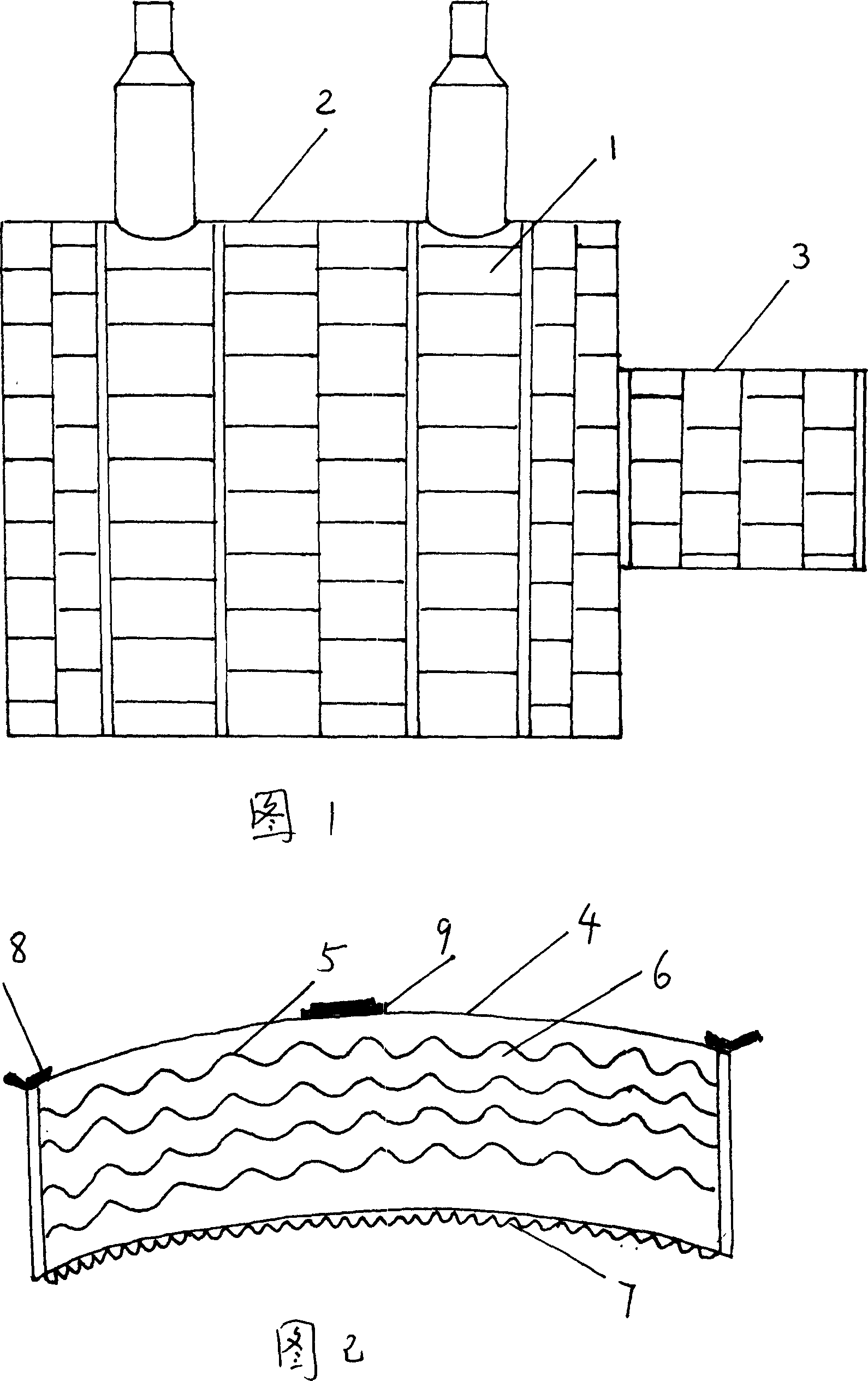

Metal insulation layer for equipment and pipe

InactiveCN101004238AReduce cloggingEasy surface cleaningThermal insulationPipe protection by thermal insulationInsulation layerMetal

The present invention relates to a metal heat-insulating layer for equipment and pipeline. It is made up by splicing at least two heat-insulating plate blocks, said heat-insulating plate block is a thin-type box body formed from internal and external stainless steel sheets, in the thin-type box body interior a radiation-type heat-insulating filling material composed of two stainless steel radiation sheets is mounted.

Owner:岑保卫

Multifunctional, efficient, energy-saving and environment-friendly boiler for both heating and steaming

The invention discloses a multifunctional, efficient, energy-saving and environment-friendly boiler for both heating and steaming. The boiler is provided with an inner shell and an outer shell. The inner shell is sleeved with the outer shell and connected with the outer shell through a support. An interlayer between the inner shell and the outer shell is filled with heat insulation materials. The inner shell is internally provided with a boiler chamber. An interlayer between the inner shell and the boiler chamber forms a water tank. A water inlet pipe, a water draining pipe and a steam guiding pipe are arranged on the side of the outer shell, wherein the water inlet pipe is communicated with the water tank, and the water draining pipe is provided with a control valve. Grate bars are arranged inside the boiler chamber. A smoke guiding pipe is communicated with an inner cavity of the boiler chamber, penetrates through the water tank and is arranged on the upper side of the boiler chamber. The upper end of the inner shell and the upper end of the boiler chamber are sealed. A coal throwing inlet, a flame observing opening and a slag outlet are sequentially formed in one side of the outer shell from top to bottom, wherein the coal throwing inlet, the flame observing opening and the slag outlet penetrate through the inner shell to be communicated with the boiler chamber. According to the multifunctional, efficient, energy-saving and environment-friendly boiler for both heating and steaming, the defect that the bottom of a traditional water tank cannot be directly heated is overcome, water is rapidly heated, and efficiency is higher; due to the fact that flame energy is recycled, losses are reduced, and energy is saved.

Owner:张子春

Raw material formula and production process of low carbon polymer plastic steel template

The invention discloses a raw material formula and a production process of a low carbon polymer plastic steel template. The formula comprises the following components, by weight: 75-100 parts of PVC resin, 15-25 parts of active calcium carbonate, 3-10 parts of wood powder, 0.5-0.9 part of an internal lubricant, 0.4-1 part of an external lubricant, 0.2-0.4 part of a heat release foaming agent, 0.5-1 part of an endothermic foaming agent, 4-15 parts of ACR resin acrylate, 0-10 parts of an ACR modifying agent, 0-10 parts of an ACR impact resistant modifier, 3-5 parts of a stabilizer, 0-5 parts of soybean oil, 0-1 part of a plasticizer, and 0-0.1 part of a pigment. The invention provides the raw material formula and the production process of the low carbon polymer plastic steel template, which has advantages of low carbon content, energy saving, environment-friendliness, wide temperature adaptation range, and strong specification adaptability.

Owner:新疆永利森高新建材有限公司

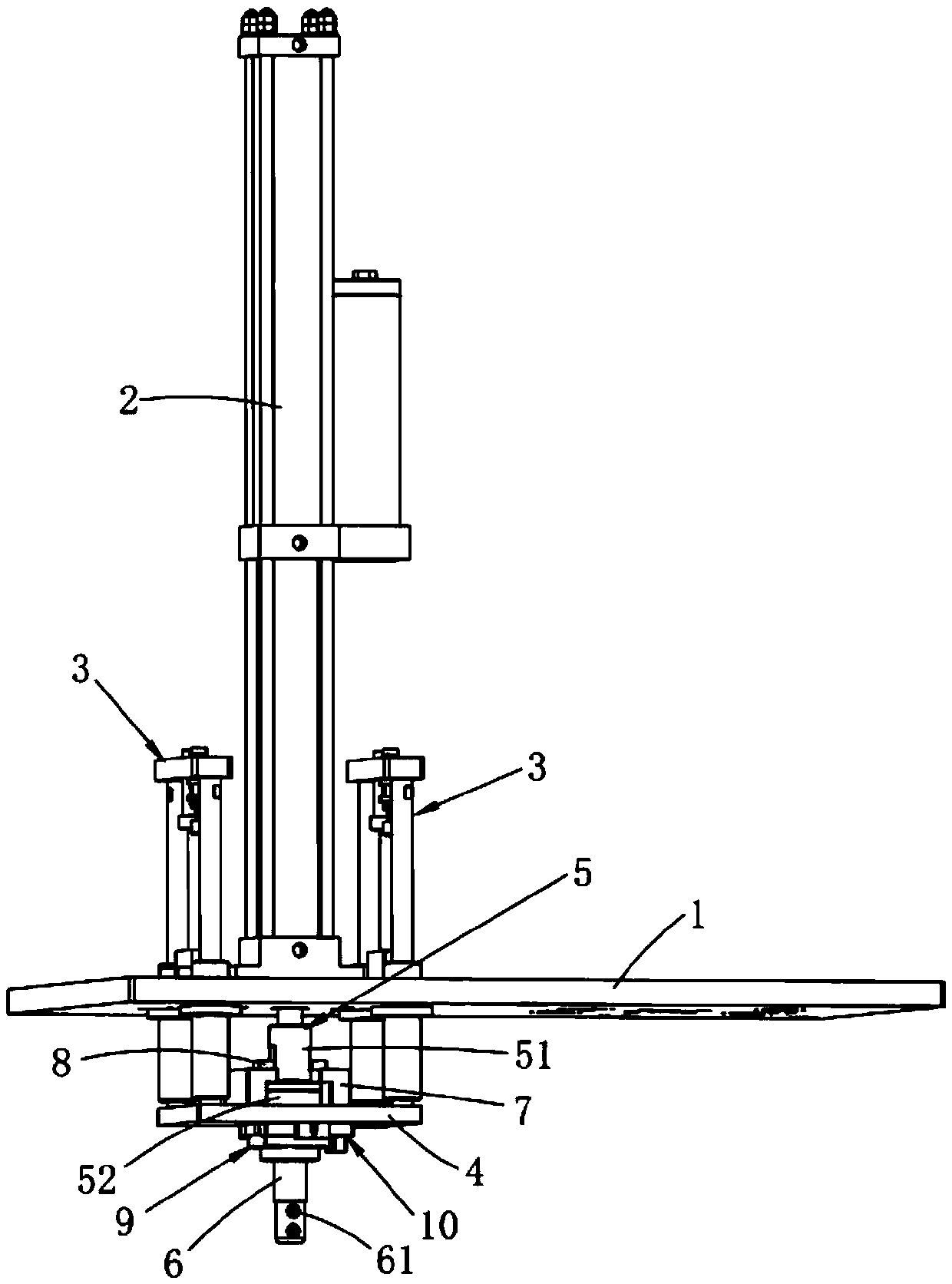

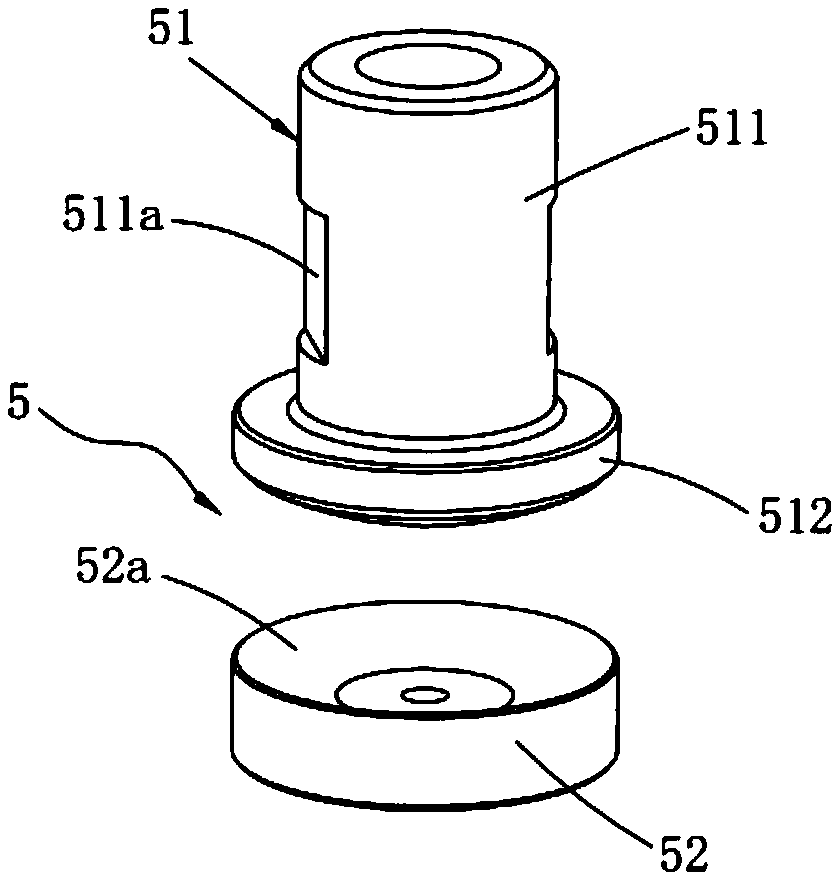

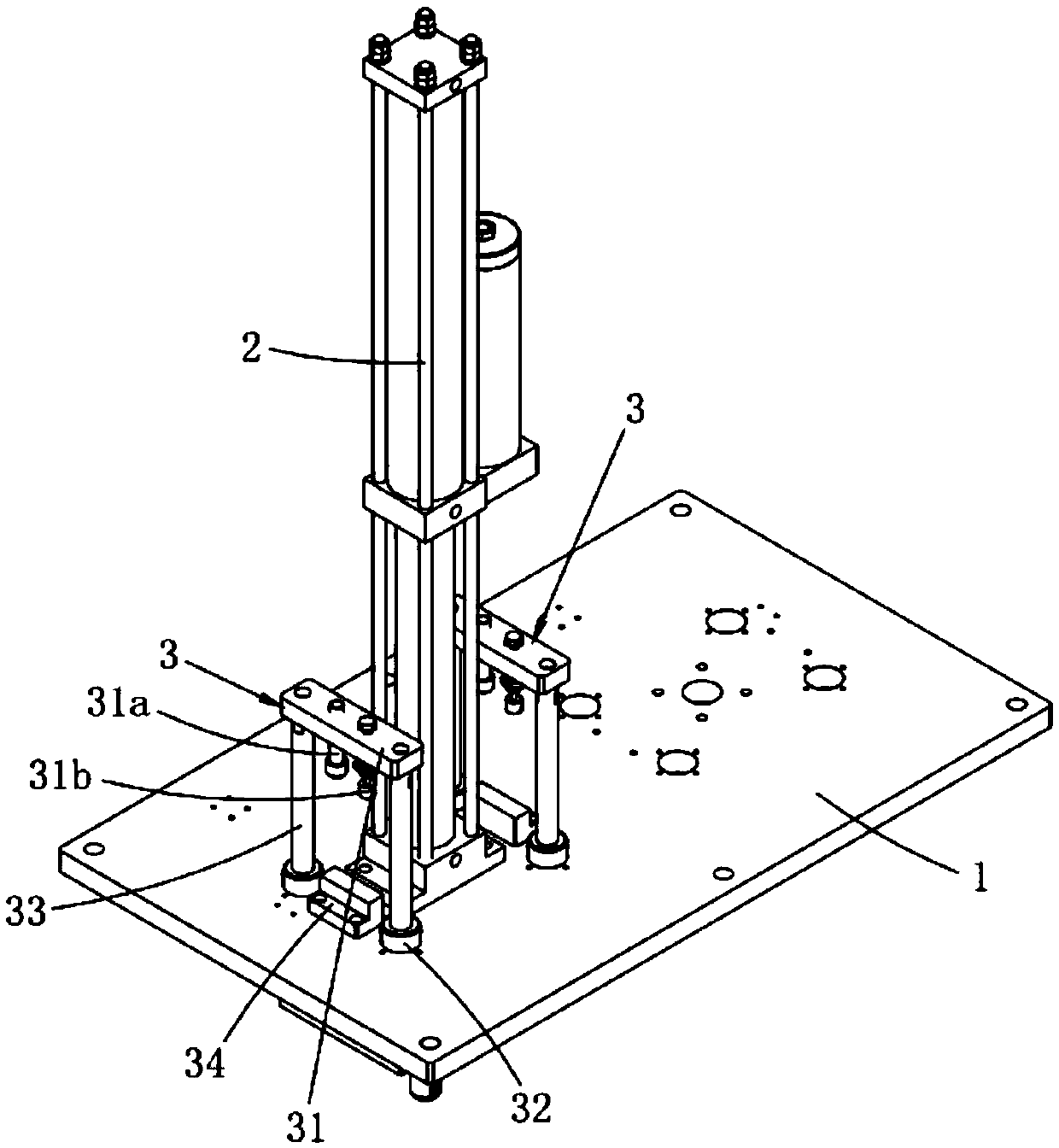

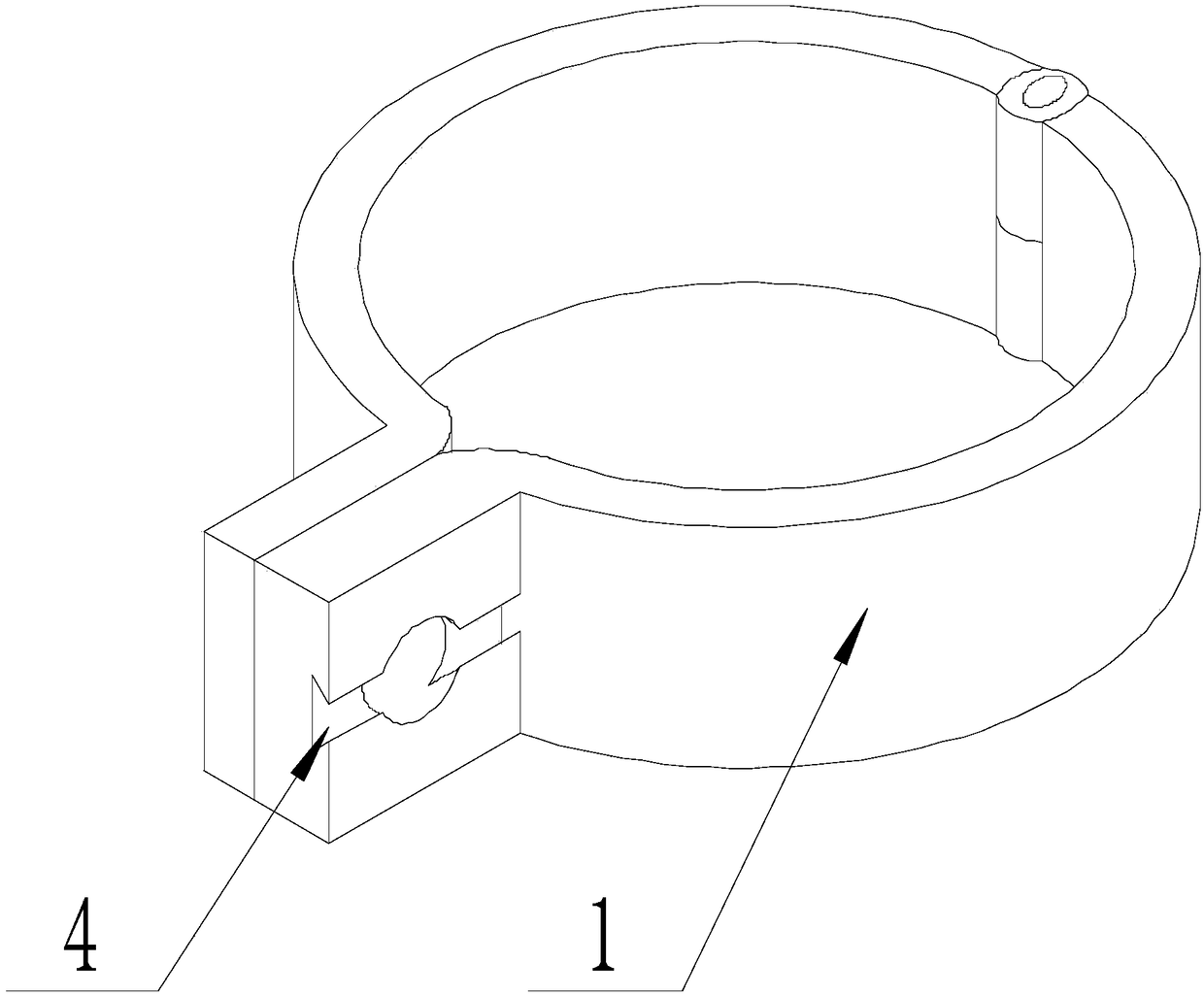

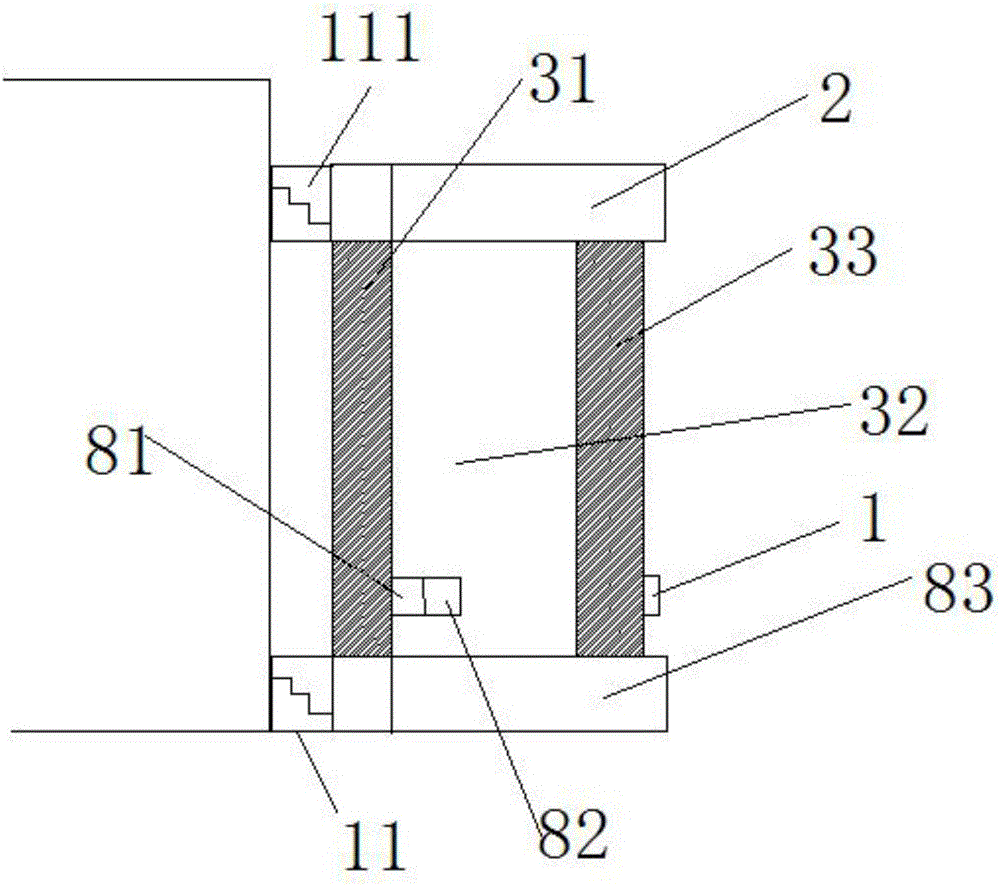

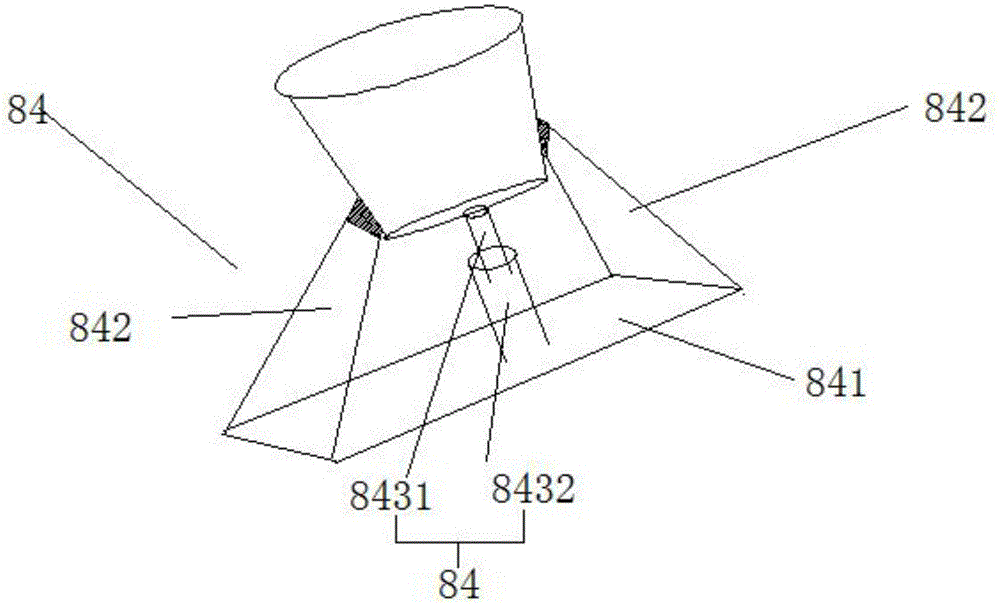

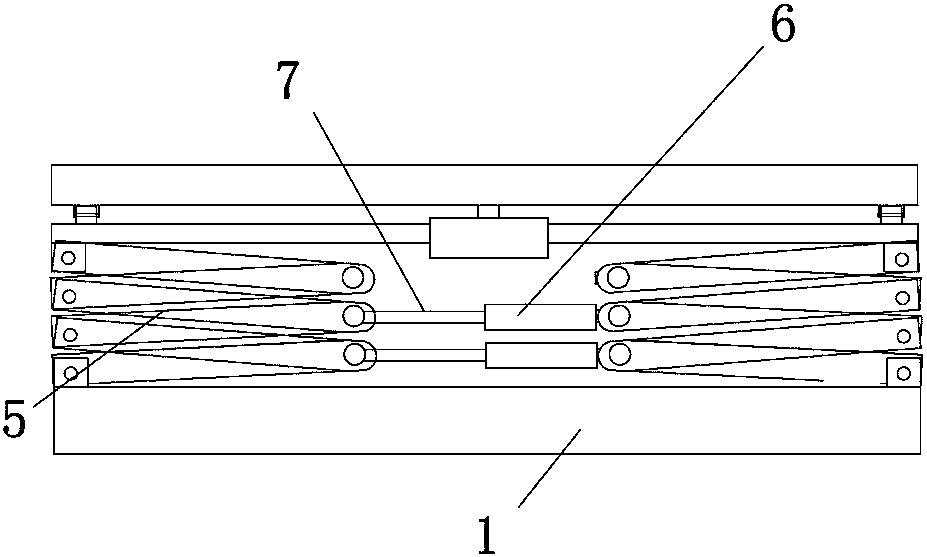

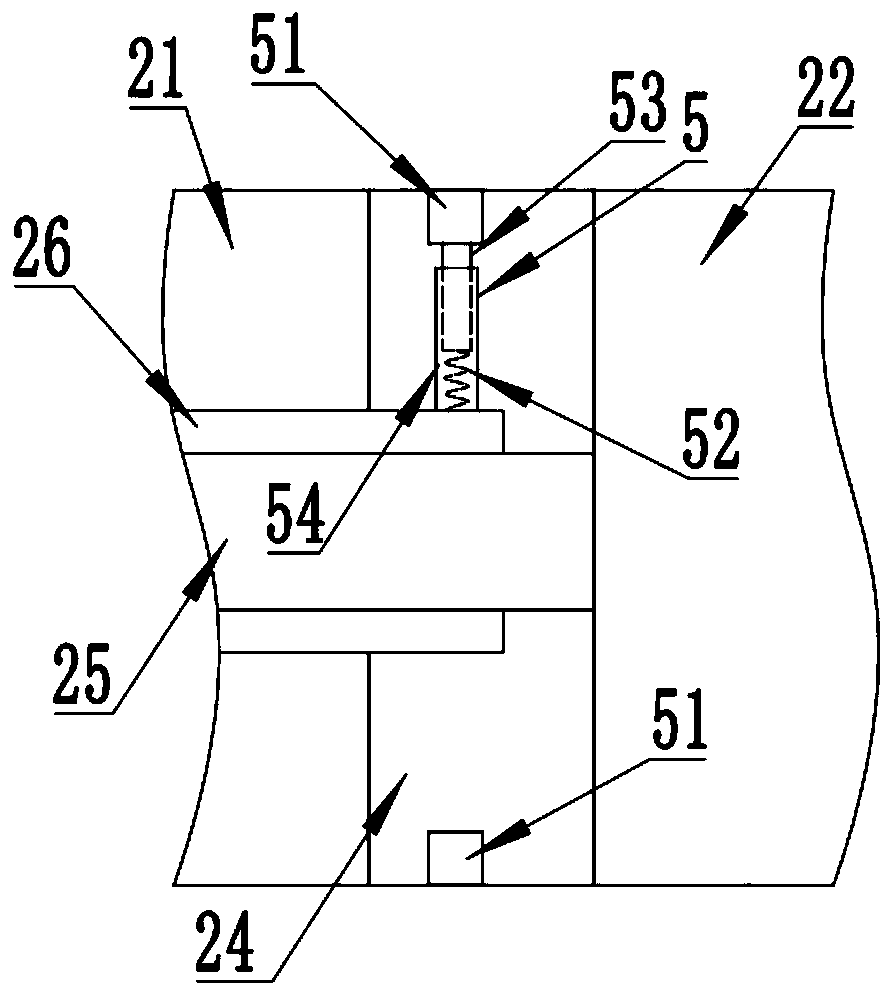

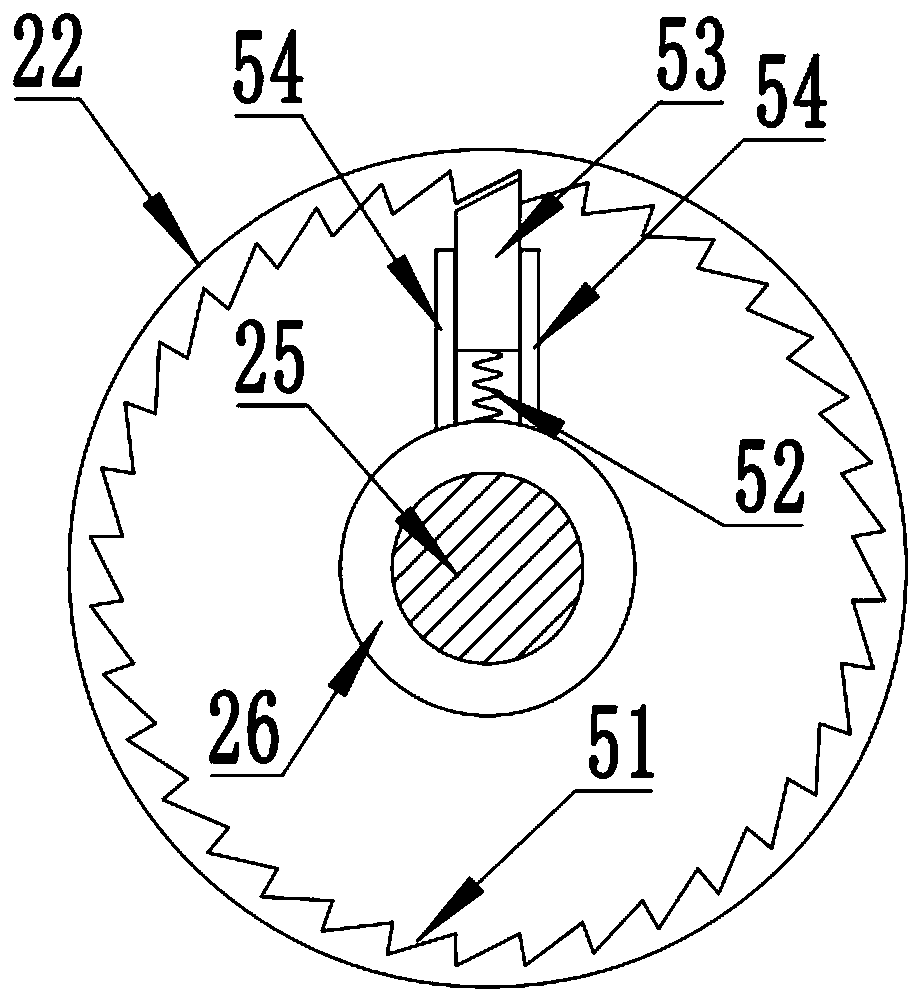

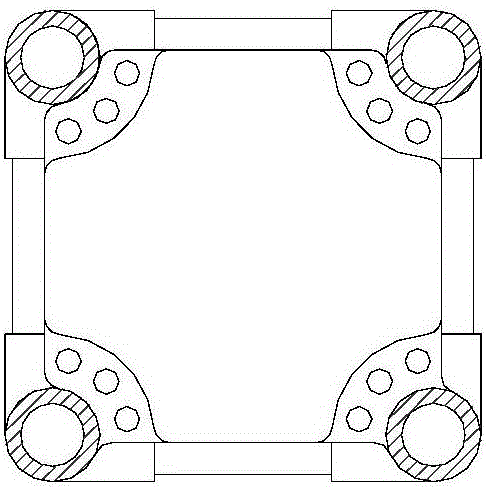

Bush pressing mechanism

ActiveCN105499967AIncrease contact areaRealize automatic guidanceMetal working apparatusMetal-working hand toolsUpper jointEngineering

The invention relates to a bush pressing mechanism, comprising a bottom plate, an air cylinder, guiding limiting mechanisms, a pressure head installation plate, an air cylinder joint and a pressure head, wherein the air cylinder is arranged on the bottom plate; the guiding limiting mechanisms are oppositely arranged at two sides of the air cylinder; the tail ends of the guiding limiting mechanism are fixedly provided with the pressure head installation plate; the air cylinder joint comprises an upper joint and a lower joint; the upper joint is arranged on a piston rod of the air cylinder; the lower joint is arranged at the upper part of a pressure head connection plate; the upper joint is sequentially provided with a cylinder part and an arc convex platform from top to bottom; an arc groove is formed in the upper end face of the lower joint; the pressure head is fixedly connected with the lower joint; the pressure head is provided with an electromagnet. The bush pressing mechanism has the advantages that a separation-designed air cylinder joint is utilized, and the deviation in front-rear direction, left-right direction and coaxial direction in the vertical downward pressing process is compensated through the arc surface matching manner between the upper joint and the lower joint, therefore an automatic piloting function is realized, the downward pressing position precision is guaranteed with combination of an X-axis adjusting mechanism and a Y-axis adjusting mechanism, and the pressure borne by the pressure head is improved.

Owner:BOZHON PRECISION IND TECH CO LTD

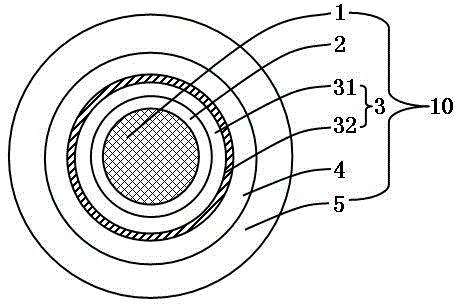

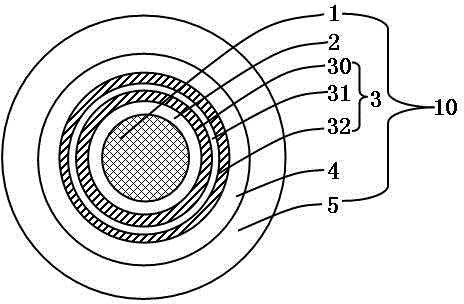

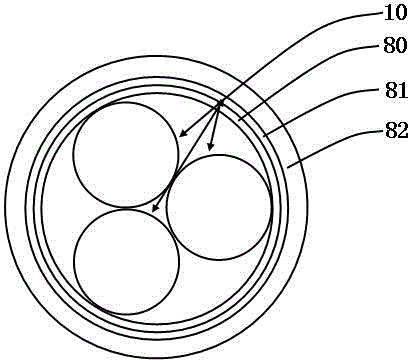

Capacity-increasing and energy-saving flexible cable used in power station

InactiveCN103165239AUnder pressureImprove cooling effectNon-insulated conductorsPower cables with screens/conductive layersPower stationFlexible cable

The invention provides a capacity-increasing and energy-saving flexible cable used in a power station. A conductor screen layer, an insulative layer, an insulative screen layer, a copper strip armor layer, an outer insulative layer, a flame retardant layer and a protective sleeving layer are wrapped outside a conductor in sequence. The capacity-increasing and energy-saving flexible cable used in the power station has the advantages of being energy-saving, pulling resistant, flame resistant, weather resistant, good in bending radius and the like, thereby being especially suitable to be used as a main line cable of a power station unit.

Owner:上海上力电线电缆有限公司

Connecting mechanism capable of improving fixing efficiency

InactiveCN108087398APrevent rotationImprove stabilitySleeve/socket jointsFriction grip releasable fasteningsRubber ringMechanical engineering

The invention discloses a connecting mechanism capable of improving fixing efficiency. The connecting mechanism comprises two connecting heads, bolts and nuts. One ends of the connecting heads are hinged to each other, and the ends of the bolts are in threaded connection with the nuts thread after passing through the other ends of the two connecting heads. A mounting groove is formed in the end face of the connecting head with the nut, and the opening size of the mounting groove is smaller than the bottom size. A end face, near the head of the bolt, of the nut is provided with a mounting bar The cross-sectional dimension of the mounting bar is the same as the cross-sectional dimension of the mounting groove, and the axis of the mounting bar intersects with the axis of the nut perpendicularly, and the threaded hole in the nut runs through the mounting bar; a rubber ring is disposed on the end face of the bolt near the nut. The axis of the rubber ring coincides with the axis of the bolt,and the rotary bolt enables the rubber ring and the connecting head to make contact. The installation of the mounting groove and the mounting bar not only fix the nuts and prevent the nuts from rotating, then enhance the stability of the clamp in use.

Owner:CHENGDU DAMO PETROLEUM TECH CO LTD

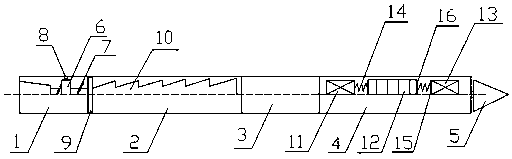

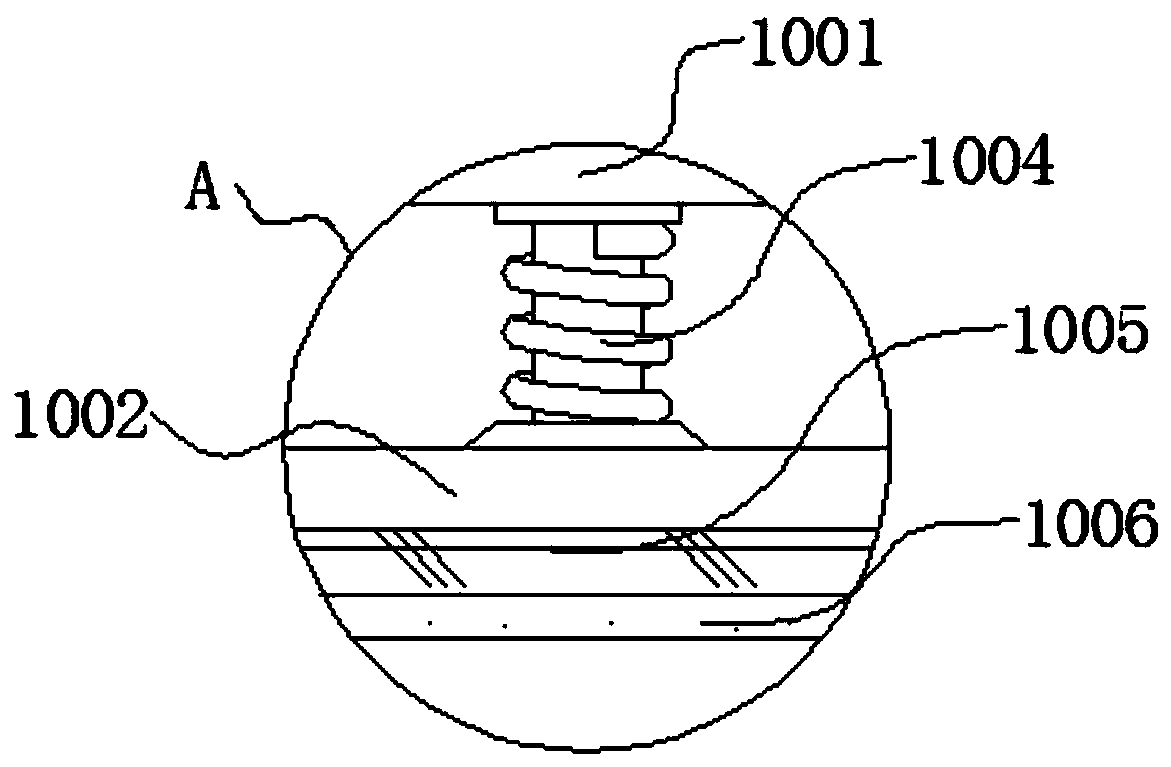

Anti-shaking screw drilling tool

InactiveCN109267933ANovel structureCompact structureSpringsNon-rotating vibration suppressionHydraulic motorDrive shaft

The invention discloses an anti-shaking screw drilling tool which comprises a bypass valve assembly, a hydraulic motor assembly, a universal shaft, a transmission shaft assembly and a drill bit, and the bypass valve assembly, the hydraulic motor assembly, the universal shaft, the transmission shaft assembly and the drill bit are connected sequentially; the bypass valve assembly comprises a piston,a spring and a bypass hole; the hydraulic motor assembly comprises a stator and a rotor, the rotor is located in the stator, the rotor and the stator are mutually meshed, and the gear ratio of the stator is larger than that of the rotor by one; the upper end of the universal shaft is connected with the rotor, and the lower end of the universal shaft is connected with a transmission shaft; the transmission shaft assembly comprises an upper transverse bearing, a thrust bearing, a lower transverse bearing and a buffering mechanism, and the buffering mechanism is fixedly arranged between the thrust bearing and the upper transverse bearing and between the thrust bearing and the lower transverse bearing. According to the anti-shaking screw drilling tool, the structure is novel, the conditions of shaking and bit jumping of the screw drilling tool in the drilling process can be effectively reduced, and the service life of the screw drilling tool is prolonged greatly.

Owner:YANCHENG XINYONGJIA PETROLEUM MACHINERY MFG

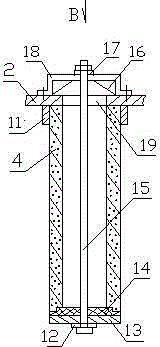

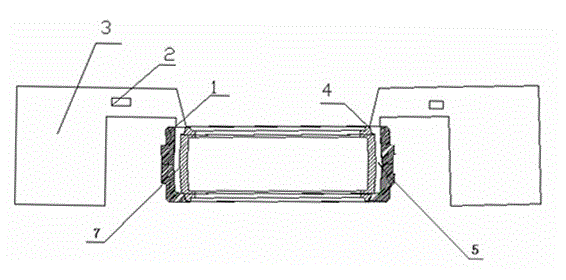

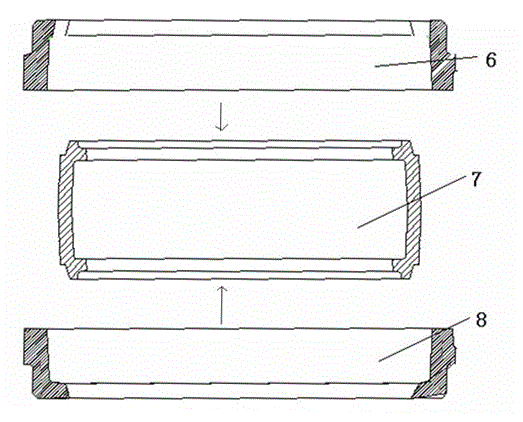

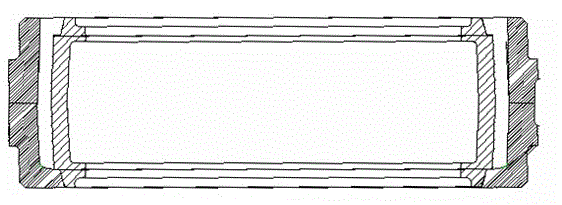

Glass window for observing high-pressure vessel

The invention provides a glass window for observing a high-pressure vessel. The glass window comprises a base connected with the high-pressure vessel in a sealing way, a glass window body and a fixing cover, wherein the glass window body is mounted on the base; the fixing cover is tightly pressed against the glass window body; the glass window body is provided with double layers of glass, namely first glass and second glass; the space between the first glass and the second glass is filled with clear liquid; the glass window further comprises a pressurization device; the pressurization device is used for pressurizing the liquid between the first glass and the second glass to manyfold improve the compressive capacity of the glass window; the glass window can be used for observing the conditions in the high-pressure vessel; the glass window further comprises lighting systems; the conditions in the high-pressure vessel can be observed more clearly through additional arrangement of the lighting systems; and the lighting systems can rotate, and the lighting directions of the lighting systems can be adjusted optionally according to the needs during use, so that the pertinence of an observation port and the practicability of the lighting systems are improved.

Owner:南通市飞宇石油科技开发有限公司

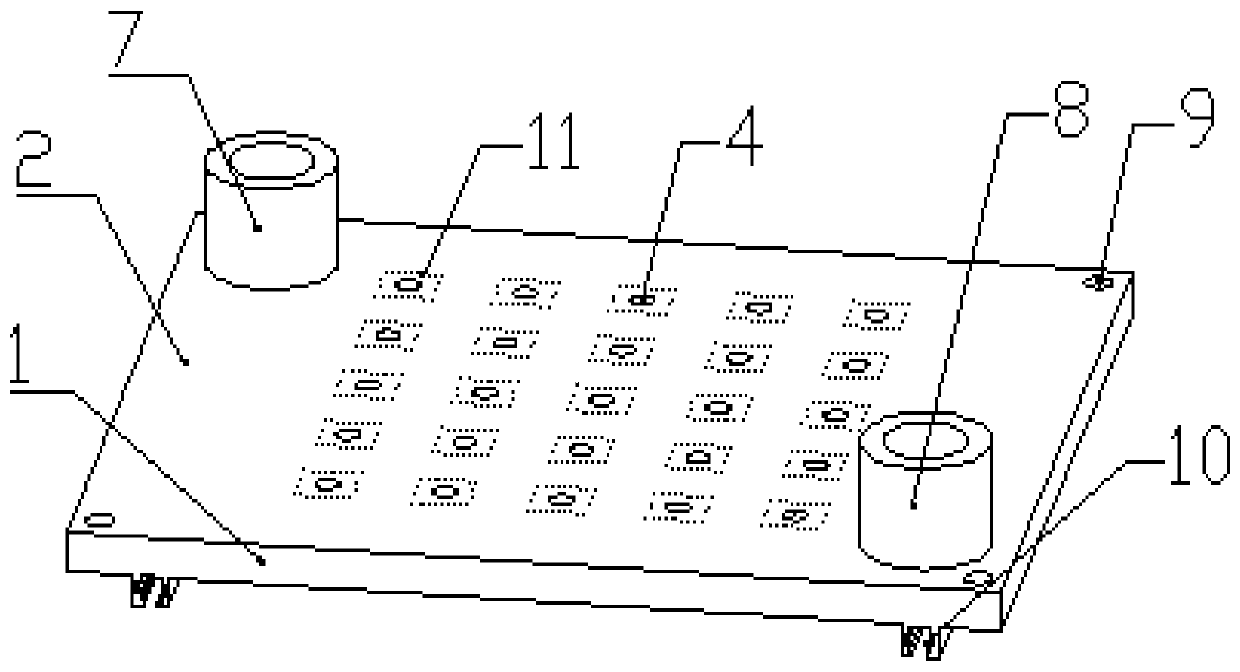

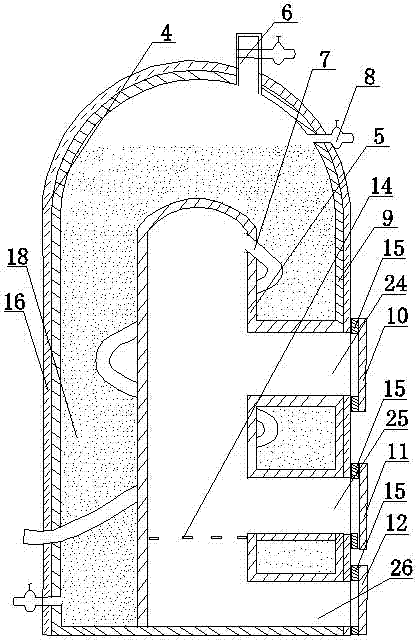

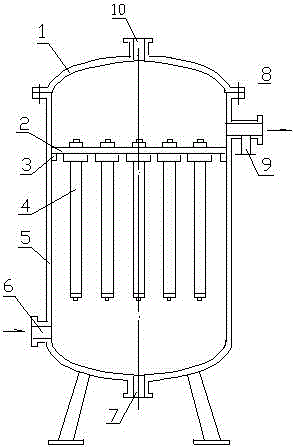

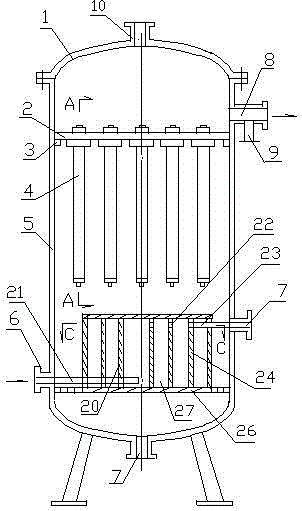

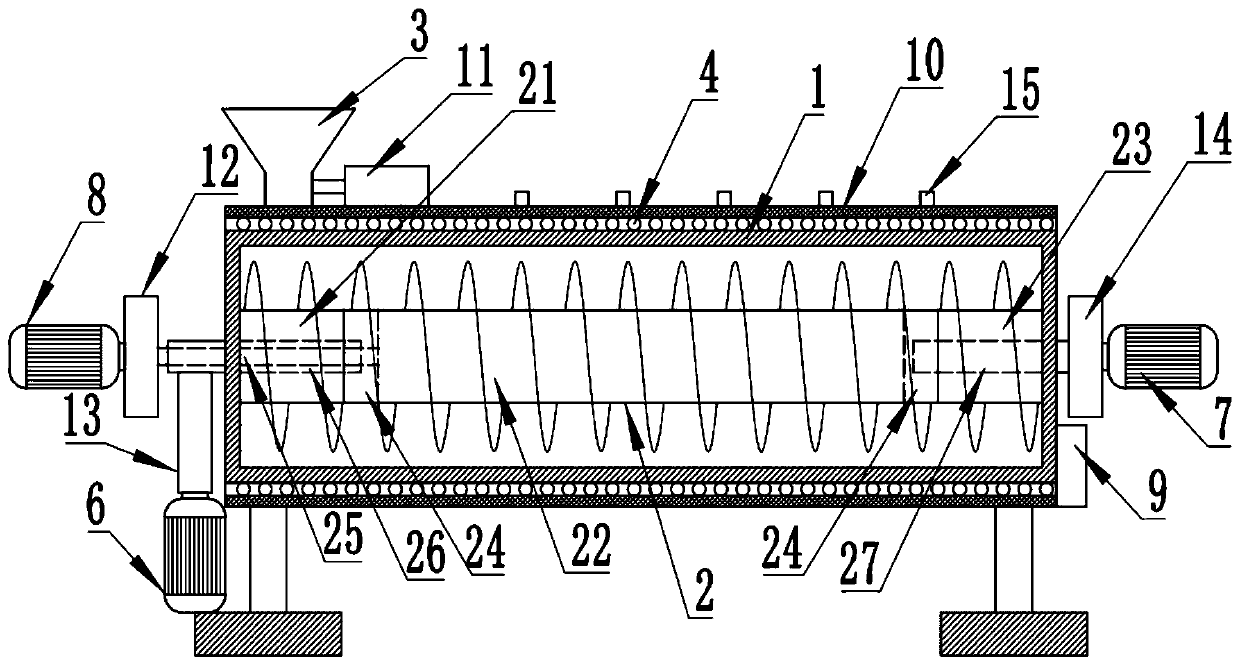

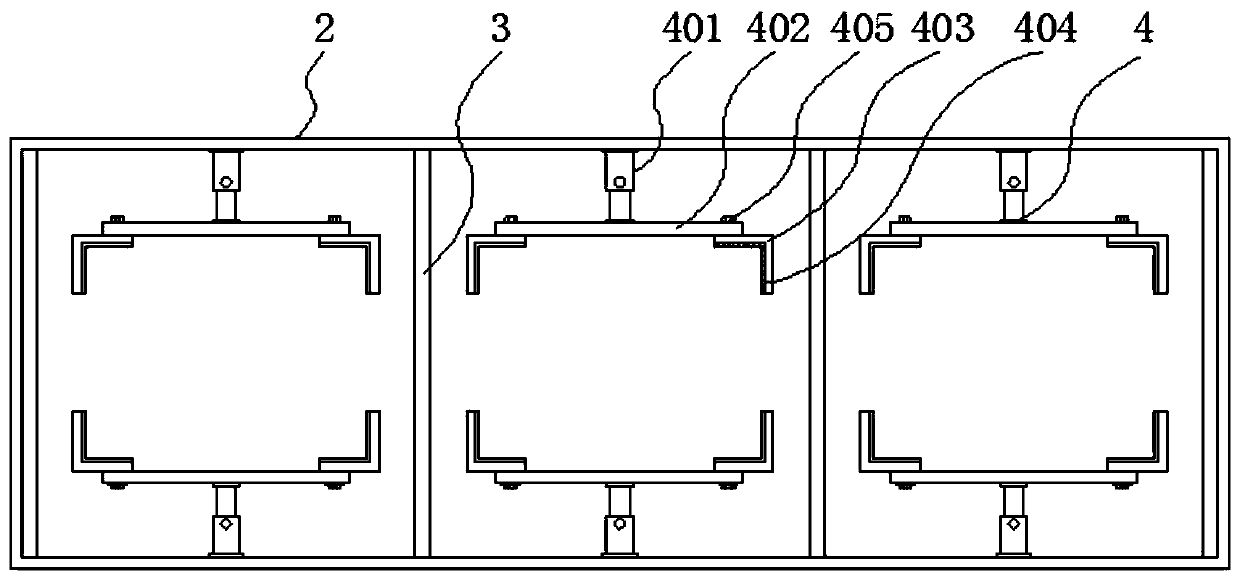

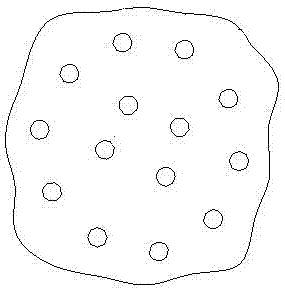

High-efficiency desulfurization waste liquor salt extraction recycling device

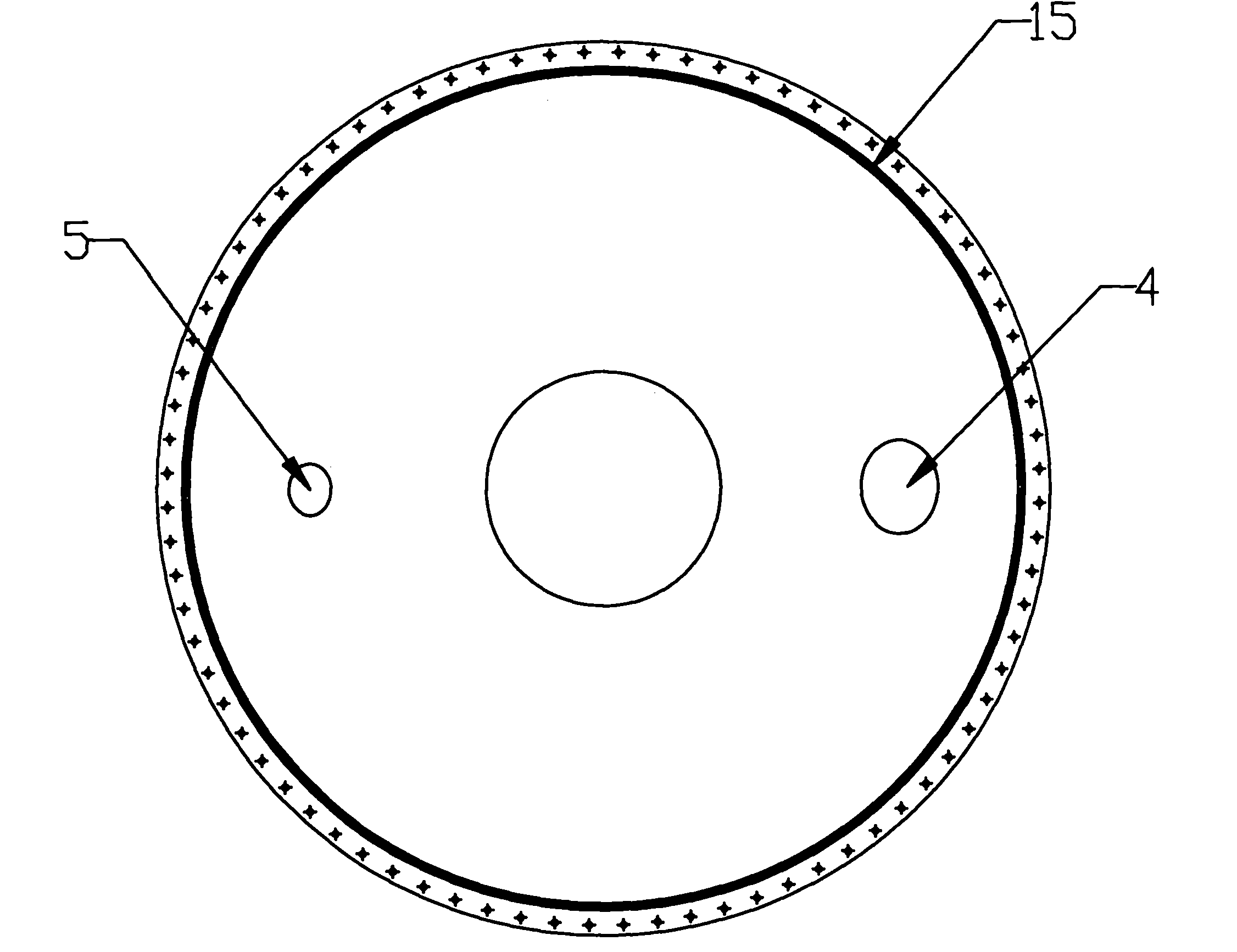

ActiveCN104645830AIncreased Filtration ThroughputIncreased filtration surface areaDispersed particle separationFiltration circuitsLiquid wasteDevice form

The invention discloses a high-efficiency desulfurization waste liquor salt extraction recycling device. The device comprises a two-stage filtering device formed by connecting two micro-porous ceramic filtering devices with each other, wherein each micro-porous ceramic filtering device comprises a tank body (5) and a seal head (1); a liquid inlet (6) is formed in the lower part of the tank body; a liquid outlet (8) is formed in the upper part of the tank body; a backwash opening (9) is formed in the liquid outlet; a supporting disc (2) is arranged in the tank body; liquid outlet holes (19) are formed in the supporting disc at intervals; limiting sleeves (3) are fixedly arranged on the lower bottom surface of the supporting disc at intervals; the limiting sleeves are tightly connected with the outer diameters at the upper ends of micro-porous ceramic pipes in a matched mode; the micro-porous ceramic pipes are connected with a pressing plate (13); a riding fixing rack (18) is fixedly arranged on the supporting disc; and pull rods (15) through which the micro-porous ceramic pipes can be fixedly arranged on the supporting disc in a suspended mode at the intervals are arranged between the riding fixing rack and the pressing plate. According to the device disclosed by the invention, the occupied space can be reduced, the construction cost is saved, the filtering effect of desulfurization waste liquor can be improved, desulfurization liquor is conveniently filtered, and the backwash is conveniently performed.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Pneumatic supporting structure

Owner:HUBEI ZHIQUAN PATENT TECH APPL DEV CO LTD

Method for utilizing waste building templates to manufacture regenerated building templates

InactiveCN103104088AUnder pressureLow costForming/stuttering elementsArchitectural engineeringWoodworking machine

The invention discloses a method for utilizing waste building templates to manufacture regenerated building templates and includes following steps that iron nails in the waste building templates are blown off by a pneumatic nail gun, long-strip plates with uniform width and thickness are sawed off through a width and thickness limited saw, gluing is carried out on sides of the long-strip plates, displacement fissures are glued, and by a woodworking machine joining-measuring press, joining and pressing are carried out and formed plates are obtained. Two faces of each formed plate are joined horizontally through first-class glued cross-band veneers, linings are affixed on the cross-band veneers on the two faces, a hot press presses for 15 minutes under temperature no lower than 100 DEG c and pressure of 300 tons, then waterproof surface glue is glued, and finally the regenerated building templates are formed after hot pressing and edge sawing and trimming. The method for utilizing the waste building templates to manufacture the regenerated building templates has the advantages of being capable of improving re-using efficiency of the waste building templates, and saving cost, and can be widely used in recycling of wood beams on a construction site and veneers used for building.

Owner:程进华

Hardening and tempering process of alloy-steel pipe

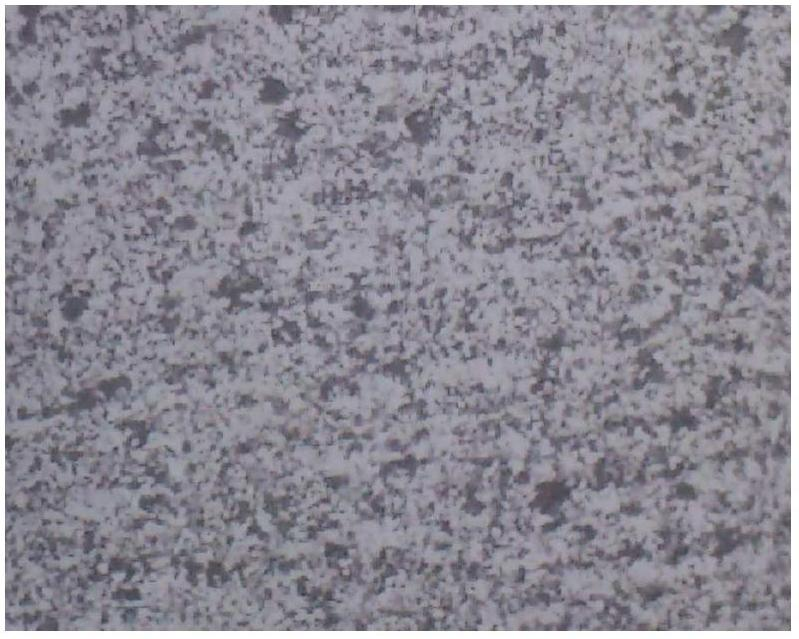

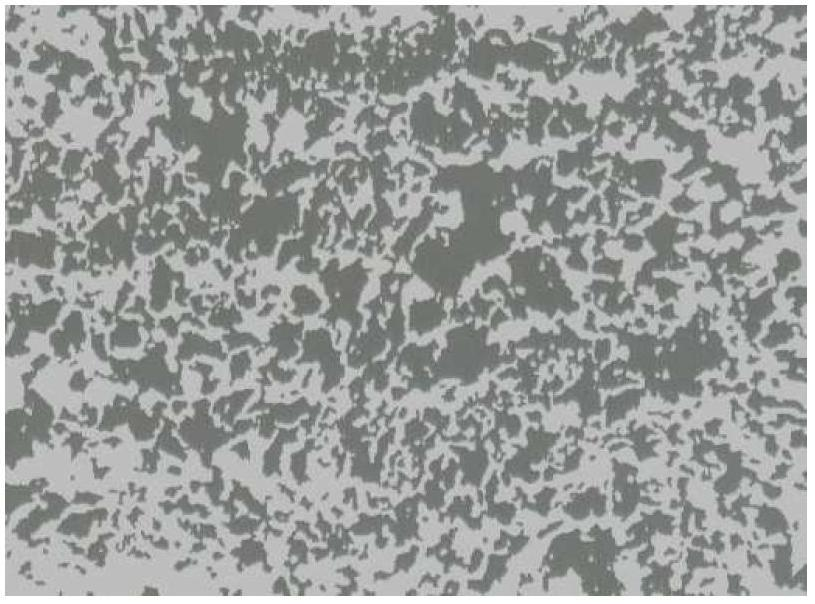

InactiveCN103725831AImprove plasticityHigh strengthFurnace typesHeat treatment furnacesRoom temperatureWear resistance

The invention discloses a hardening and tempering process of an alloy-steel pipe. The process comprises the following steps: 1) conducting annealing treatment: heating to the temperature up to 700-720 DEG C at the speed of 50-55 DEG C / min, and conducting heat preservation for 1.5-2.5 hours, cooling the temperature down to 570 DEG C at the speed of 30 DEG C / min, and cooling the temperature down to the room temperature at the speed of 5 DEG C / min; 2) conducting quenching treatment: heating to the temperature up to 800-810 DEG C at the speed of 20-25 DEG C / min, conducting heat preservation for 2.5-3.5 hours, spraying by brine with the concentration of 30-35% to rapidly cool the temperature down to 250-260 DEG C at the speed of 250-255 DEG C / s, and cooling the temperature down to 70-80 DEG C at the speed of 15 DEG C / min; 3) conducting tempering treatment: heating to the temperature up to 700-710 DEG C at the speed of 30-35 DEG C / min, conducting heat preservation for 7-8 hours, and cooling the temperature down to the room temperature at the speed of 10 DEG C / min. Through the adoption of the hardening and tempering process of the alloy-steel pipe, the alloy-steel pipe being subjected to hardening and tempering is high in plasticity, strength, pressure resistance, and hardness, low in deformation, and good in abrasive resistance.

Owner:佛山市统管金属制品有限公司

Cable plastic extrusion device

InactiveCN111037882AReverse Rotation RealizationReduce the temperatureDomestic articlesRatchetElectric machinery

The invention discloses a cable plastic extrusion device. The cable plastic extrusion device comprises a charging barrel, wherein a screw rod is arranged in the charging barrel; the screw rod comprises a charging section screw rod, a melting section screw rod and a discharging section screw rod which are arranged in sequence; a feeding hopper is fixed at the upper end of the charging barrel; a heating device is arranged on the side wall of the charging barrel; acceleration mechanisms are symmetrically arranged in hollow cavities at the two ends of the melting section screw rod; a non-return pawl can only rotate in one direction relative to an inner ratchet wheel; a driving motor is controlled by a controller to drive the melting section screw rod to rotate; the non-return pawl and the inner ratchet wheel are reversely clamped and locked, and the inner ratchet wheel can drive the non-return pawl to rotate so as to drive the charging section screw rod and the discharging section screw rod to synchronously rotate; and the non-return pawl can rotate in the same direction relative to the inner ratchet wheel, so that a first acceleration motor and a second acceleration motor can be controlled by the controller to drive the non-return pawl to rotate in an acceleration mode in the same direction relative to the inner ratchet wheel so as to drive the charging section screw rod and the discharging section screw rod to rotate in an acceleration mode in the same direction relative to the melting section screw rod, and therefore, the acceleration rotation of the front section and the rear section of the screw rod can be controlled.

Owner:ANHUI FUXING CABLE GRP

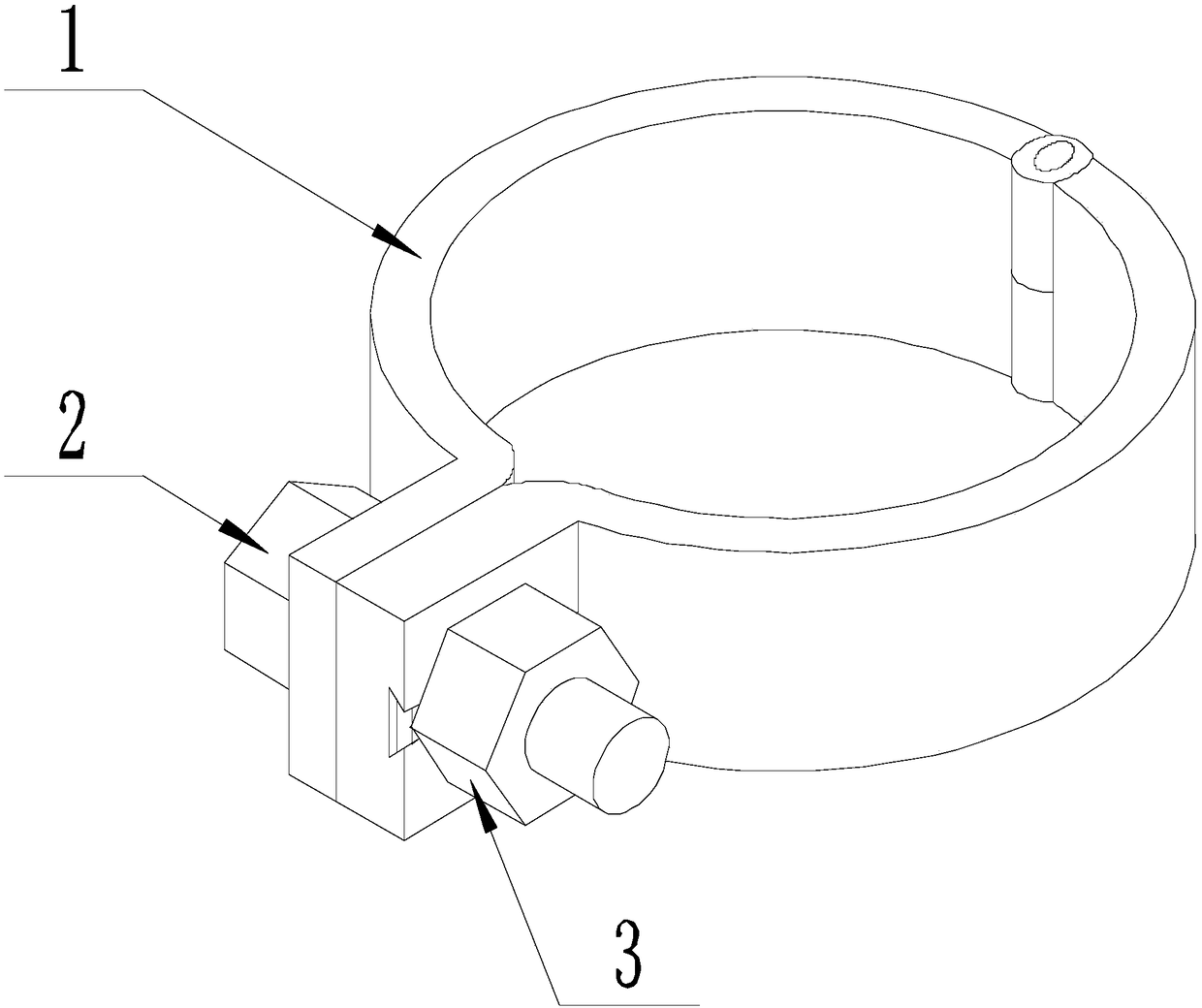

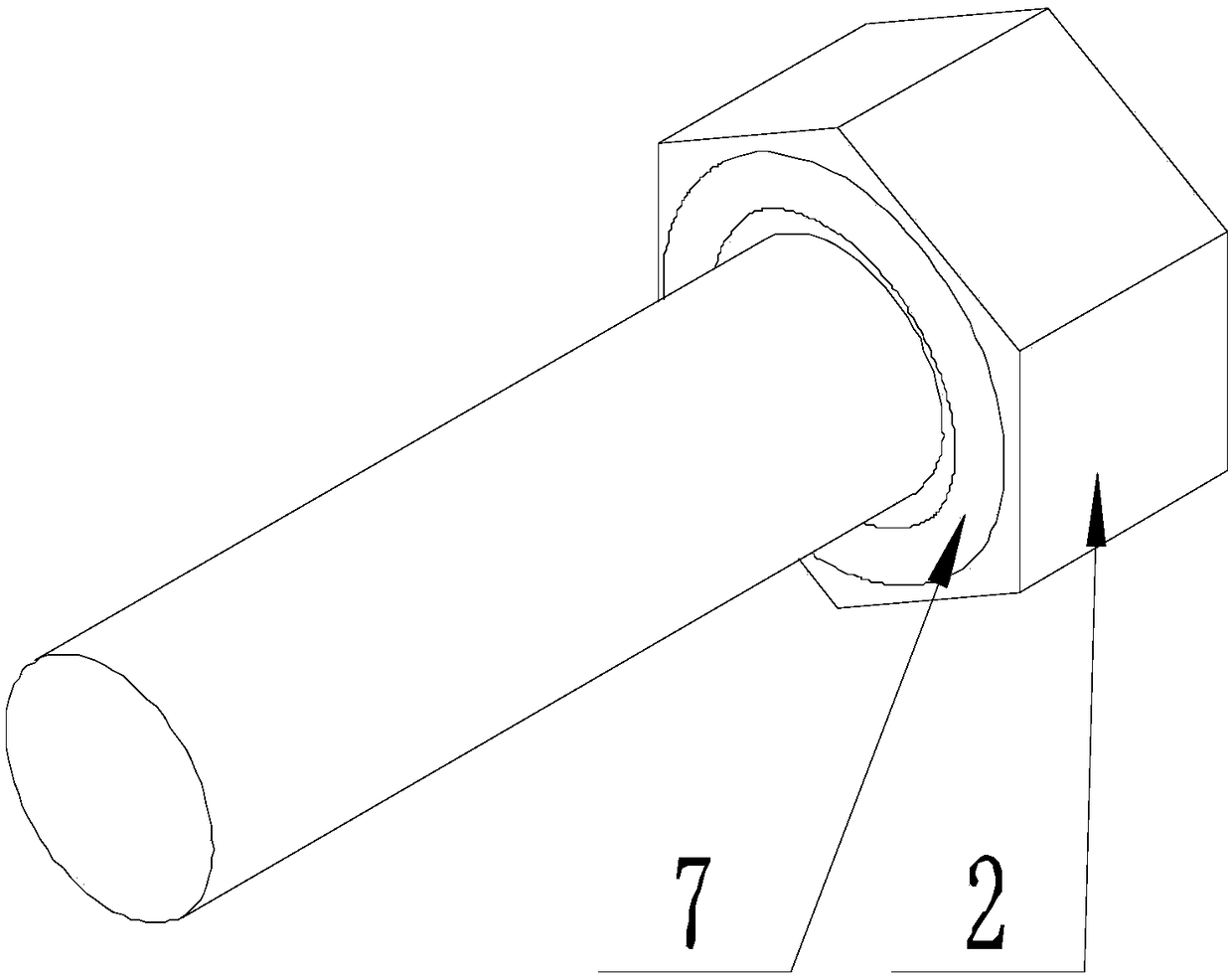

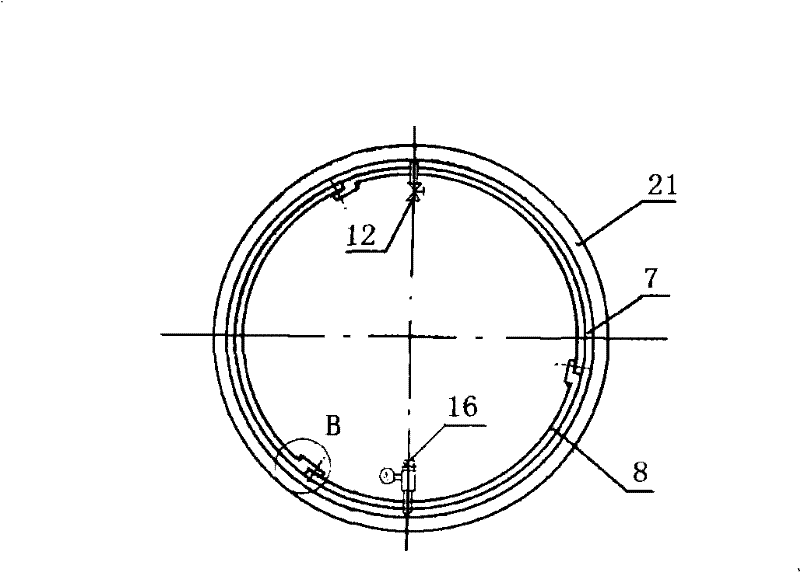

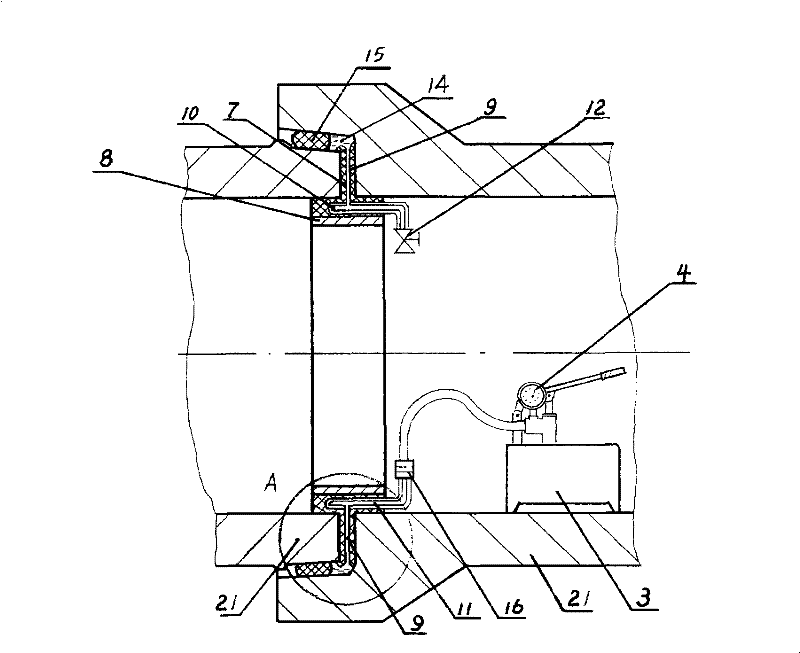

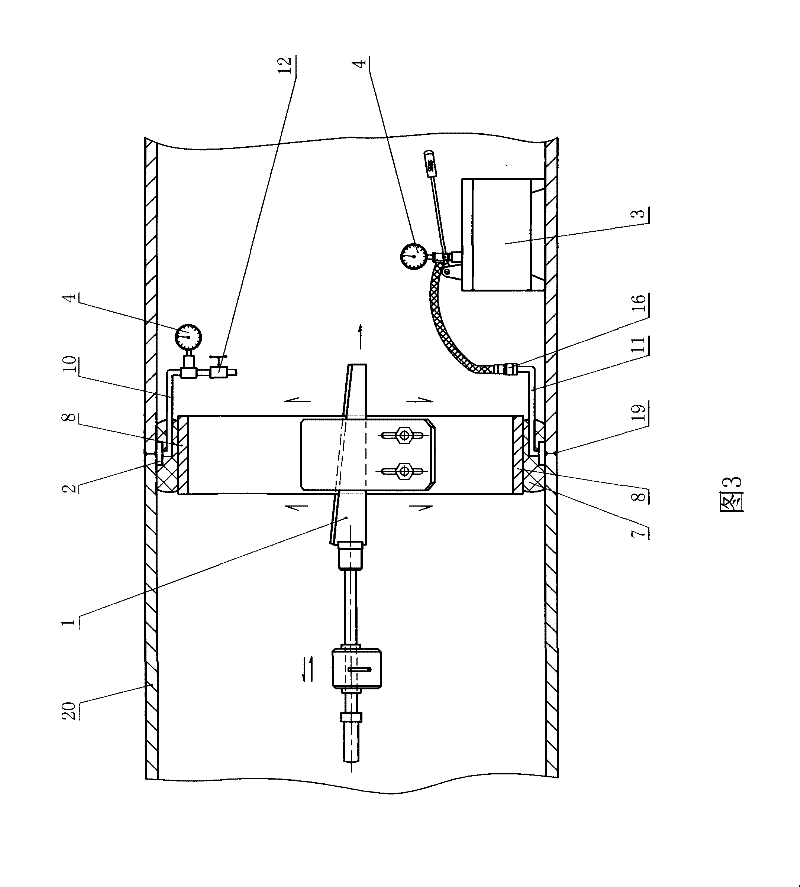

Pipeline pressure test method and device

ActiveCN101561338BSmart and lightweight structureEasy to operateMeasurement of fluid loss/gain rateRubber ringExhaust valve

The invention relates to a pipeline pressure test method and a device. The pipeline pressure test method comprises the steps of: arranging a sealing rubber ring the outer circle of which is provided with an annular groove at the welding location of a pipeline joint, using a tensioner ring jointed by sub-tensioner rings provided with embedded sub-ports to internally support the sealing rubber ring, using the variable diameter wedge to insert the jointed openings of the sub-tensioner rings and using bolts for locating; then using a double-direction impact hammer to beat the variable diameter wedge to tightly wedge and internally support the sealing rubber ring to lead the annular groove between the welding location of the pipeline joint and the middle of the outer surface of the sealing rubber ring to form a forced sealed space, opening an exhaust valve, achieving the specified pressure value by filling water and pressurizing, and then closing aninlet valve, thus being capable of inspecting the bearing pressure capability of the pipeline joint. The pressure test device mainly comprises a water injection pump, a pressure gauge, the sealing rubber ring, the tensioner ring and the variable diameter wedge; the outer circle of the sealing rubber ring is provided with the annular groove; the bottom end of the annular groove is provided with anexhaust pipe and the exhaust valve, which are communicated with the annular groove; and the tensioner ring is jointed by 3 to 6 sub-tensioner rings provided with embedded sub-ports.

Owner:BEIJING MUNICIPAL ENG RES INST

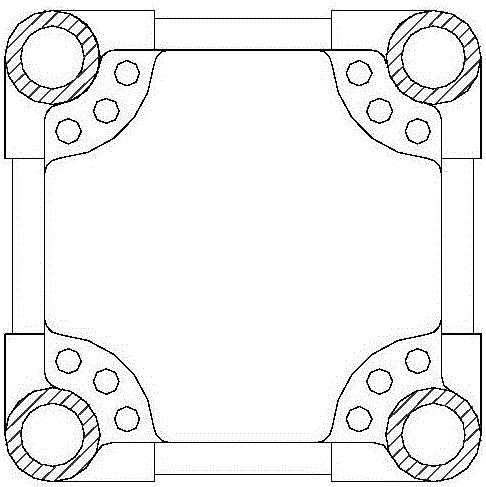

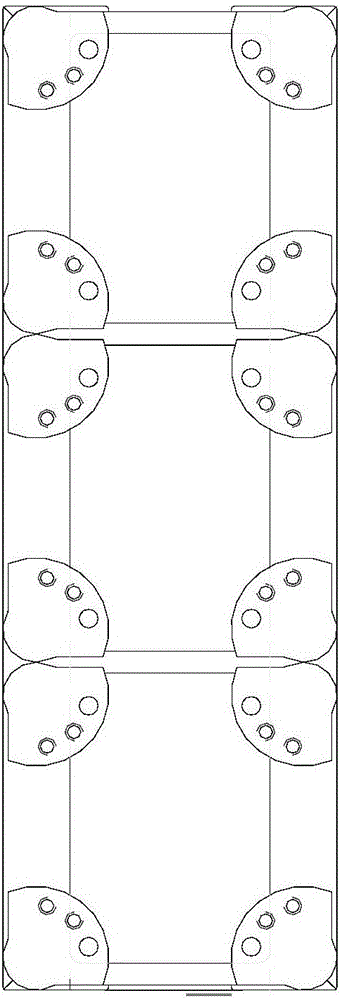

Strain tower used for emergency repair of extra-high voltage power transmission line

A strain tower used for emergency repair of an extra-high voltage power transmission line is formed by combining rectangular frame-shaped strain tower post modules. Each rectangular frame-shaped strain tower post module is formed by integrally combining three cubic strain tower post units. Four hollow cylinders are arranged at four corners of each rectangular frame-shaped strain tower post module correspondingly for bearing vertical loads of the strain tower used for emergency repair. The upper end face and the lower end face of each rectangular frame-shaped strain tower post module are each provided with 12-24 installing holes, and the installing holes are used for fixing the strain tower post modules which are vertically combined and installed. Four guiding and positioning pins are arranged at the four corners of the upper end face of each strain tower post module correspondingly, and the guiding and positioning pins are used for guiding and positioning when the strain tower post modules are vertically combined and installed. The strain tower post columns of the strain tower used for emergency repair can be manufactured integrally and do not need to be combined after being manufactured in a split mode, so that the efficiency is improved, the cost is lowered, and use is convenient; the strain tower is resistant to axial pressure and tension force and is high in bending moment and shearing force; and the strain tower is handy to transport, the erecting process is simple, and the manufacturing cost is low.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

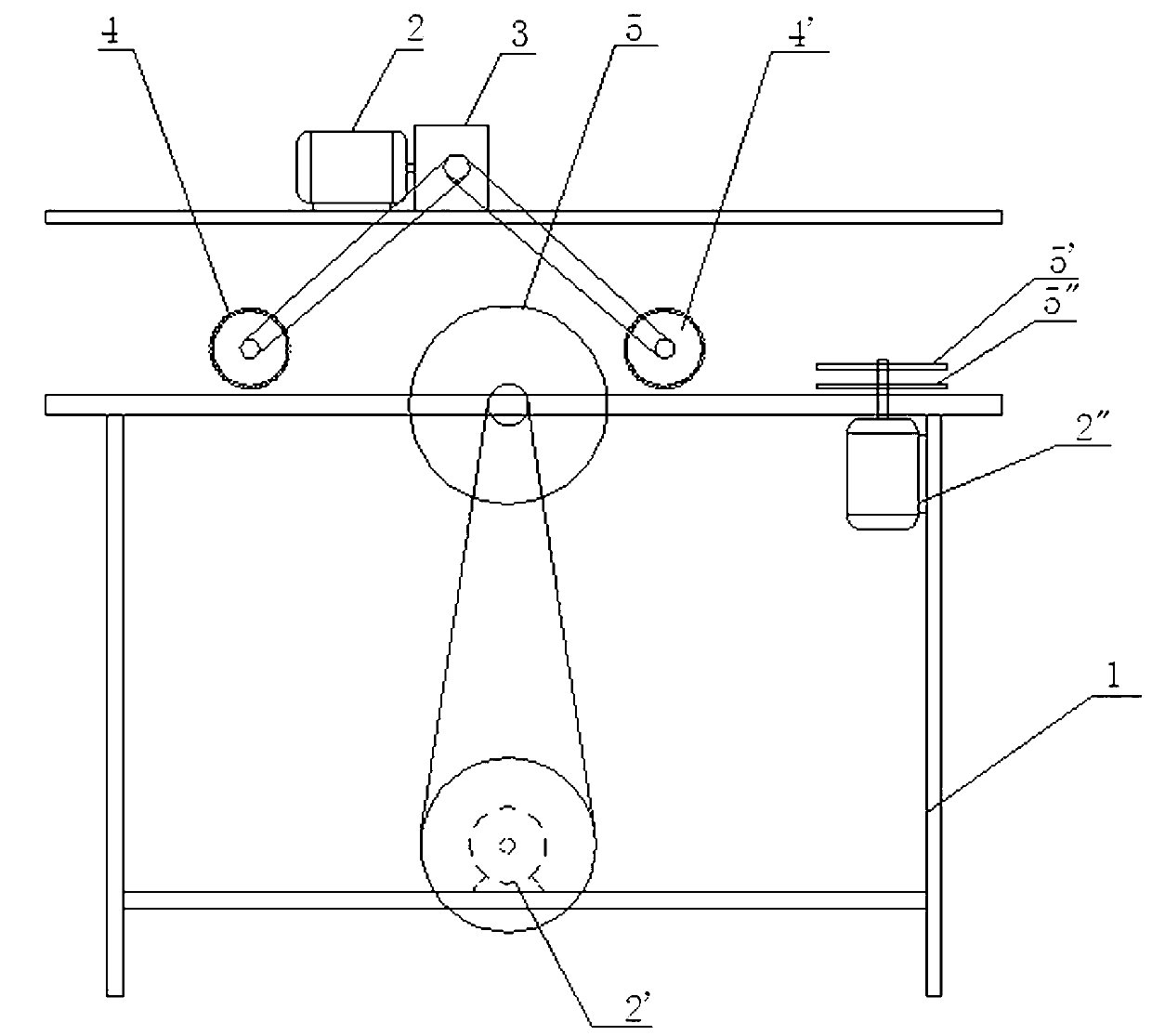

Method for preparing rounded pre-vulcanized tyre surface of giant-scale tyre for mining by screw-type pushing-in process

The invention relates to a method for preparing a rounded pre-vulcanized tyre surface of a giant-scale tyre for mining by a screw-type pushing-in process. The method realizes refurbishment and re-manufacture of the existing giant-scale tyre for mining. The method comprises the following steps of pushing rubber into a mold from a rubber inlet of the mold by a cold feeding screw extruder to fill the mold with the rubber under the action of continuous spiral thrust, and applying higher pressure for the rubber by pulse so that the rubber is compact and the vulcanized tyre surface physico-mechanical properties and wear resistance are improved.

Owner:QINGDAO TIANDUN RUBBER

Preparing process of alloy-steel pipe used for hydraulic cylinder tube

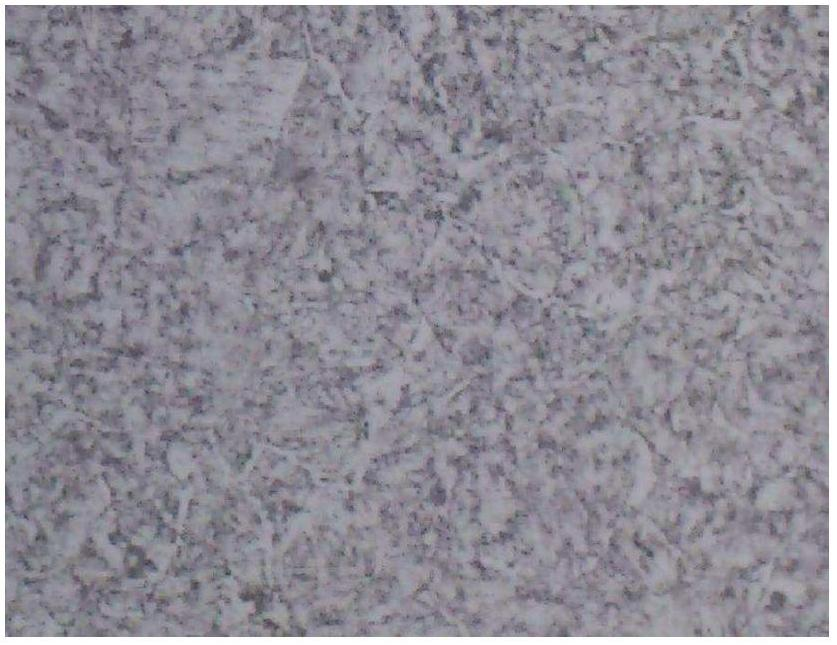

ActiveCN102653816AMinimizes the effect of surface finishHigh strengthFurnace typesHeat treatment furnacesHydraulic cylinderFree cooling

The invention discloses a preparing process of an alloy-steel pipe used for a hydraulic cylinder tube, which can avoid a surface decarburization phenomenon and deformation. The preparing process comprises the following steps of: a, surface treatment: the external surface polishing and inner hole honing are carried out on a hot rolling round alloy-steel pipe; b, annealing heat treatment: the hot rolling round alloy-steel pipe after the surface treatment is heated to 880-900 DEG C, and the heat preservation is carried out for 50-60 minutes; c, drawing molding: the hot rolling round alloy-steel pipe after annealing treatment is subjected to natural cooling, the surface of the hot rolling round alloy-steel pipe is lubricated and then drawn into the required size; and d, aging heat treatment: the hot rolling round alloy-steel pipe after drawing molding is heated to 300-320 DEG C, the heat preservation is carried out for 250-300 minutes, and the alloy-steel pipe used for the hydraulic cylinder tube is obtained after cooling. The preparing process provided by the invention has the advantages that the aging heat treatment process is adopted, and the hydraulic cylinder tube which has the advantages of high intensity, high hardness, good wearability, strong plasticity, large bearing pressure, no transformation and no decarburization phenomenon is obtained.

Owner:JIANGSU HUACHENG IND PIPES

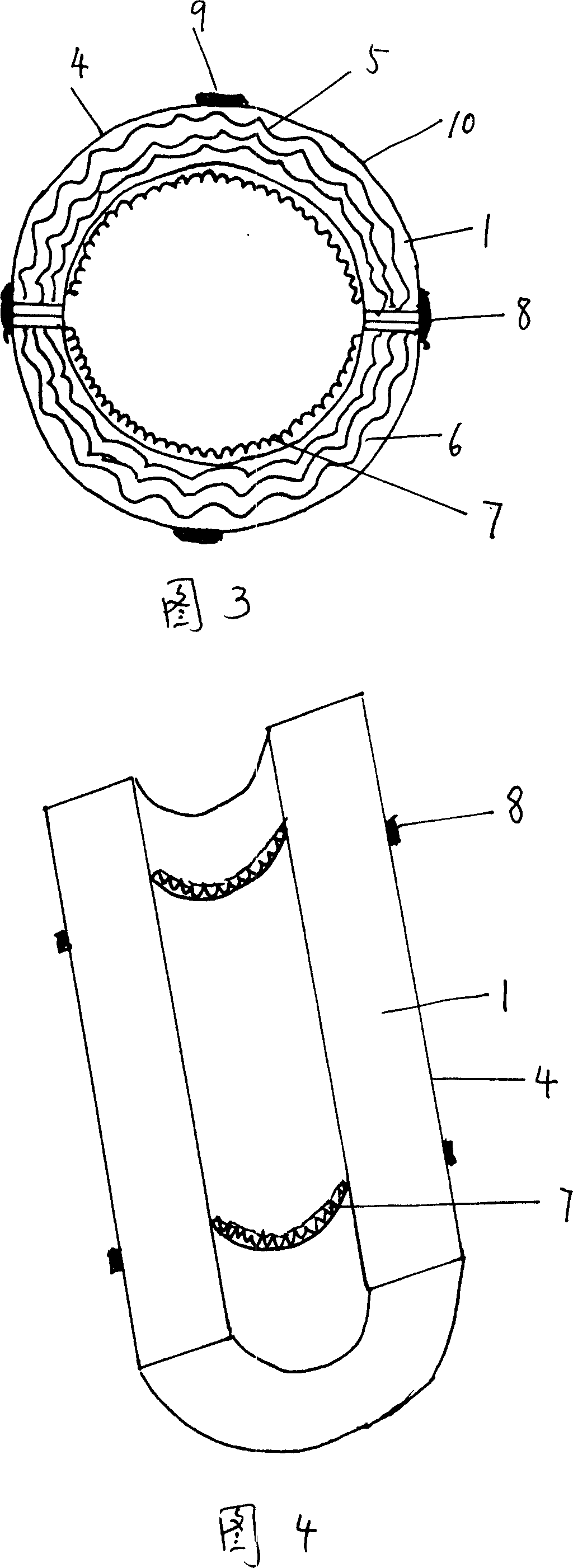

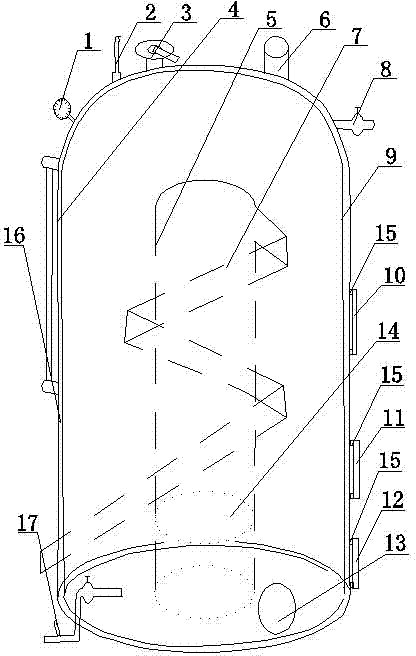

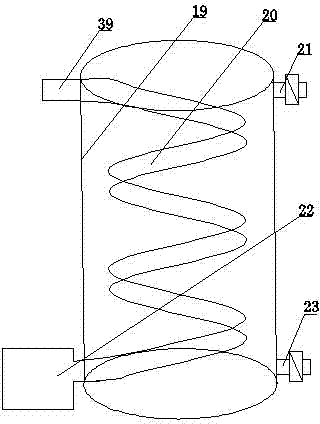

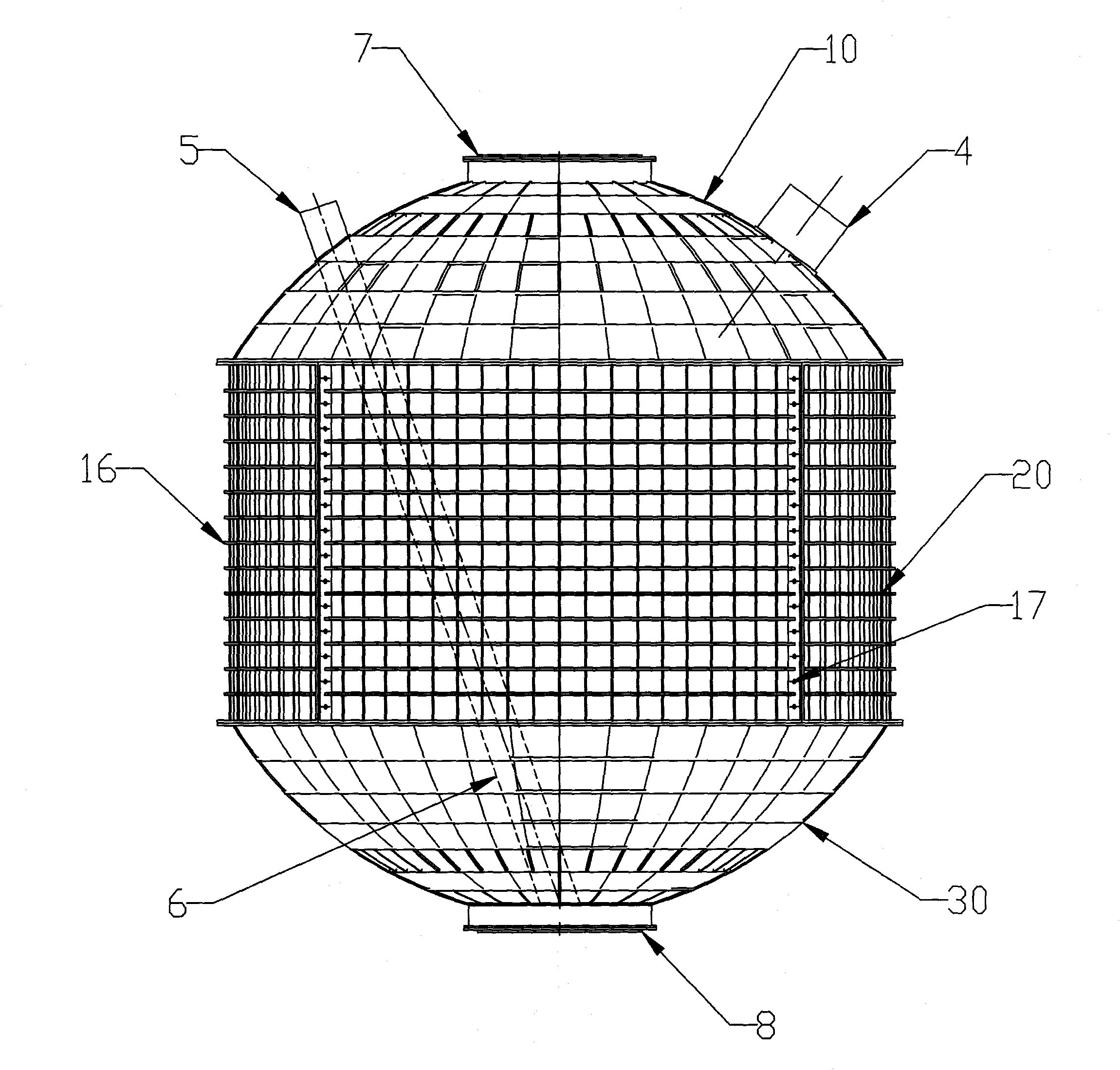

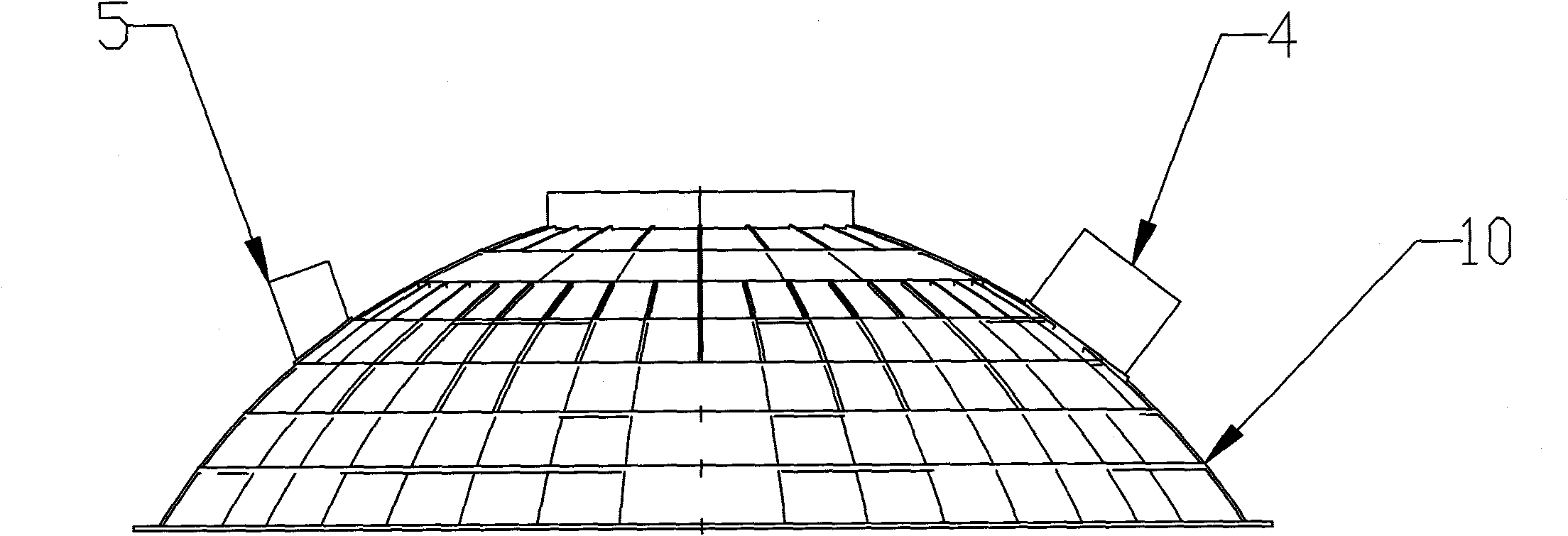

Cylindrical plastic methane generator

ActiveCN101831380AImprove airtightnessUnder pressureGas production bioreactorsWaste based fuelEngineeringCistern

The invention discloses a cylindrical plastic methane generator which aims to solve the problems of unadjustable generator volume in the prior art. A hemispheric top part and a hemispheric bottom part are connected with a cylindrical middle part to form a cylindrical container, wherein the hemispheric top part and the hemispheric bottom part consist of spherical crown surfaces or at least two fan-shaped tile petals which are a part of the spherical crown surface; the cylindrical middle part comprises at least one segmental cylinder body, and each segmental cylinder body at least consists of two rectangular tile petals which are a part of a cylindrical surface; the edges of the fan-shaped tile pedals and the rectangular tile petals respectively outwards extend to form outer edges, and a sealing strip is arranged between every two connected outer edges of every two adjacent tile pedals; and every two adjacent outer edges are connected outside the cylindrical container through a plurality of connecting pieces. The section number of combined cylinders is determined according to the scale of the manufactured methane generator, which has great flexibility, reduces the part specification and the mould cost and is economical and applicable. The cylinders are connected outside the cylindrical methane generator, which reduces the corrosion and is convenient to disassemble. The sealing strips improve the tightness and the internal bearing pressure of the methane generator, so that the methane generator is durable and can be used as a cistern for storing water.

Owner:保定广釜塑料制品有限公司

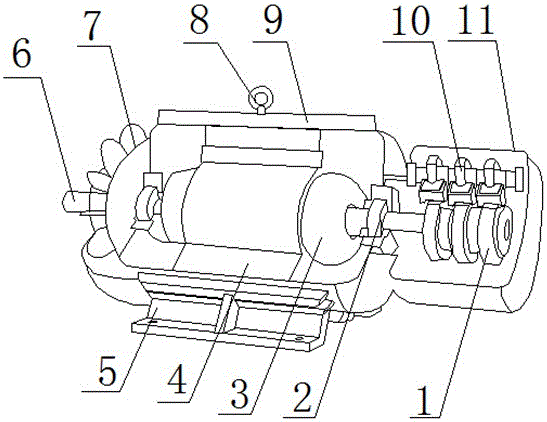

Novel motor structure

InactiveCN105162284AGood cooling performanceUnder pressureAsynchronous induction motorsCooling/ventillation arrangementStatorStructural engineering

The invention discloses a novel motor structure comprising a collector ring, a bearing, a rotor winding, a stator iron core, a pedestal, a shaft, a fan, a lifting ring, a housing, a brush and a brush cover. The collector ring is installed at one end of the shaft and the shaft is fixed inside the bearing. The bearing is installed inside the housing and the lifting ring is installed at the surface of the housing; the bottom of the housing is connected to the pedestal; and the stator iron core is arranged inside the housing. The rotor winding is arranged at one end of the stator iron core. The fan is installed at one end of the bearing and the shaft passes through the inside of the fan. One end of the housing is connected with the brush cover and the brush arranged at one side of the collector ring is installed inside the brush cover. The provided novel motor has the good cooling performance. The motor is resistant to great pressure and is not easy to deform; and the anti-electrometric radiation capability is high. The service life is long and the working efficiency is high. Great economic benefits and social benefits are created. Therefore, the novel motor structure is suitable for popularization.

Owner:WUXI D WO SEIKO EQUIP

Water-tree-retardant crosslinked polyethylene cable material and cable prepared from same

InactiveCN104910503AEffective protectionNot easily oxidizedInsulated cablesInsulated conductorsLinear low-density polyethyleneLow-density polyethylene

The invention belongs to the technical field of materials and wire cables, and relates to a water-tree-retardant crosslinked polyethylene cable material. The invention is characterized in that the cable material is prepared from linear low-density polyethylene, styrene, polyurethane thermoplastic elastomer, polyethyleneglycol, ethylene-ethyl acetate copolymer, polyethylene wax or paraffin, commercially available nucleator 4030 for wire cable plastics, di-tert-butyl peroxide, benzoperoxide, commercially available antioxidant 300 for plastics or commercially available antioxidant 1010 for plastics or commercially available antioxidant 168 for plastics, and carbon black, wherein the weight ratio of the linear low-density polyethylene to the styrene is 8-10. The invention also relates to a preparation method of the cable material and a water-tree-retardant cable using the cable material. The cable has the advantages of favorable waterproofing effect, simple structure, more stable electric / mechanical / environmental properties, higher reliability and the like, is easy to produce and does not generate water trees.

Owner:JIANGSU ZHONGLI GRP CO LTD

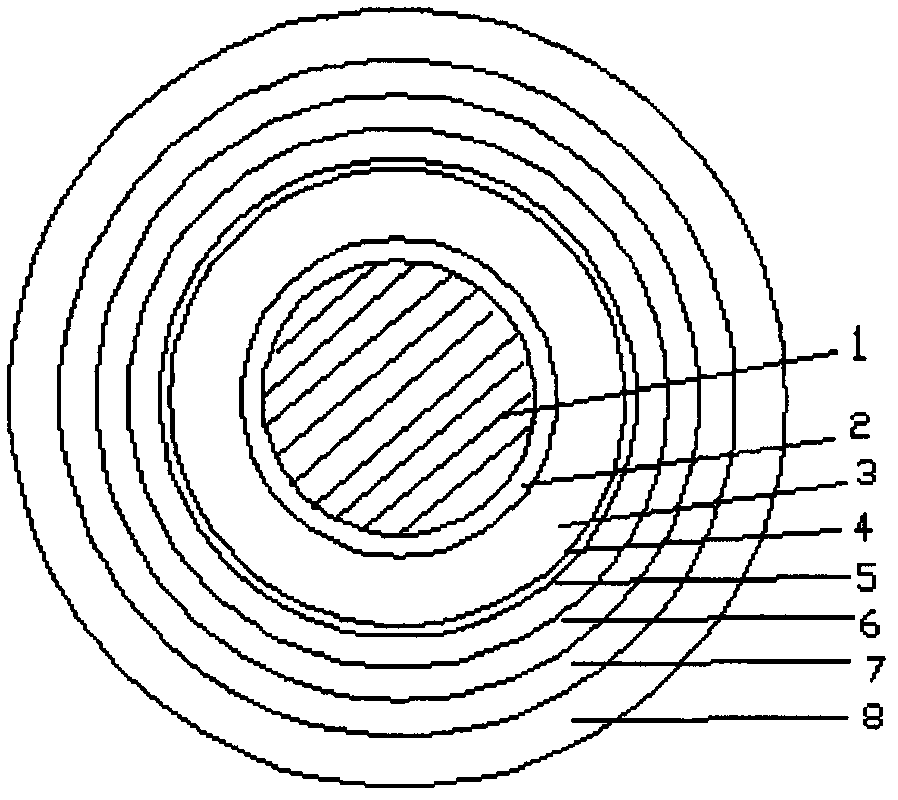

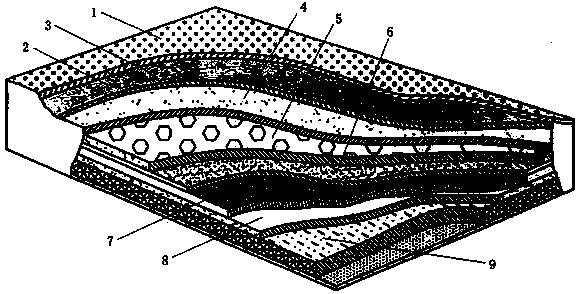

Bionic sleep multifunctional multi-layer structure mattress

InactiveCN108324007AImprove microcirculationImprove immunityElectrotherapyStuffed mattressesMedicineFar infrared

The invention discloses a bionic sleep multifunctional multi-layer structure mattress, which comprises a mattress main body and a mattress outer coating layer, wherein a bamboo fiber antibacterial carbon crystal cloth weaving layer, a magnet layer, a silver fiber anti-radiation layer, a latex pressure-retarding layer, a far infrared heat generation element layer, a negative ion cotton layer, a Chinese herb fiber layer and an elastic multi-layer coconut fiber layer are sequentially superposed from top to bottom to form the mattress main body, the mattress main body is coated with the mattress outer coating layer, the mattress outer coating layer and the bamboo fiber antibacterial carbon crystal cloth weaving layer are fixed through sewing, and the layers are adhered through natural latex. The bionic sleep multifunctional multi-layer structure mattress of the present invention has characteristics of water resistance, oil resistance, antibacterial property, negative ion release, good elasticity, toughness, durability, safety, comfort, health and environmental protection.

Owner:黄 建华

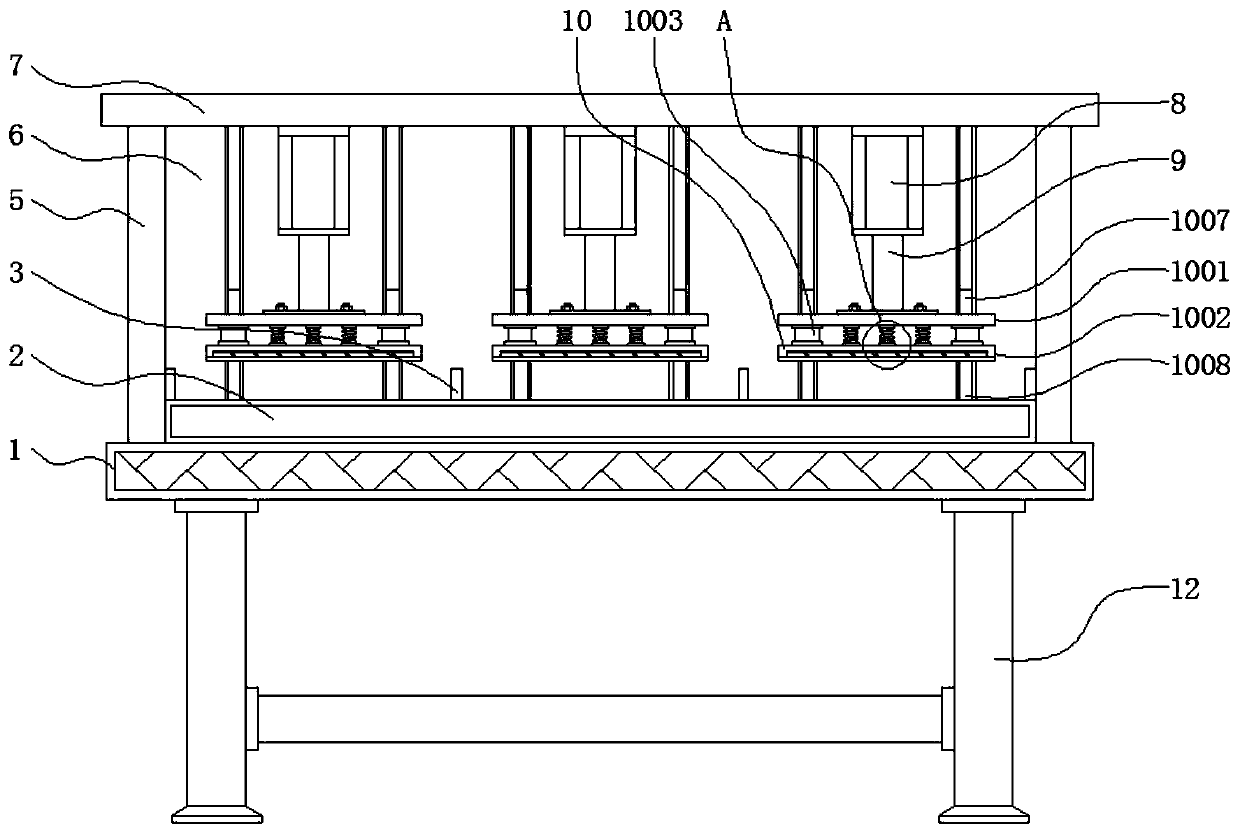

Stamping device with stamping terminal capable of being subjected to shape fixing and position fixing and machining process thereof

The invention discloses a stamping device with a stamping terminal capable of being subjected to shape fixing and position fixing and a machining process thereof, and relates to the technical field ofstamping terminals of stamping devices. The device comprises a mounting base, a fixing mechanism and a stamping mechanism, a stamping table is arranged in the middle of the upper portion of the mounting base, a partition plate is fixed above the stamping table, the fixing mechanism is mounted on the inner side above the stamping table, supporting rods are welded to the two sides of the upper portion of the mounting base, a back plate is fixed to the rear side of the upper portion of the mounting base, a top plate is fixed above the supporting rods, and an air cylinder is arranged below the middle of the top plate. The device has the beneficial effects that through a telescopic rod, the position of a positioning plate can be telescopically adjusted conveniently, the device can convenientlyadapt to stamping terminal molds of different widths, through cooperation of sliding blocks and sliding grooves, the position of a positioning block can be conveniently adjusted in a sliding manner,the device can conveniently adapt to stamping terminal molds of different lengths, the positioning block is of an L structure, and the four corners of the stamping terminal mold can be subjected to uniform limiting and fixing.

Owner:SHENZHEN JIBAISHUN TECH CO LTD

Method for filling liquid soy sauce and vinegar by inflation

InactiveCN1528642AUnder pressureMeet normal storagePackaging under vacuum/special atmosphereCorrosionProduct gas

The invention is a liquid sauce and vinegar air-pouring method, selecting food-grade hard plastic bottle, at the time of pouring, charging gas CO2 or N2, where inflation pressure is 1-2.5Kg / sq cm and the temperature of liquid sauce and vinegar is 3-4 deg.C, and finally cover to seal. Its advantages: strong pressure bearing ability, able to meet the demand of normal storage and transportation; good corrosion resistance and long shelf life; simple technique, low cost and small weight; the plastic bottle body does not distort when the product returns to normal temperature.

Owner:张志平

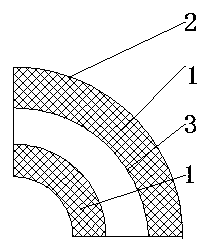

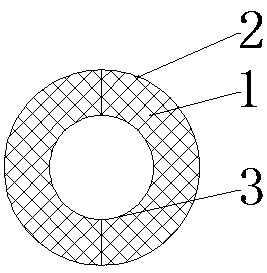

Heat preservation bend

PendingCN110701409ANice appearanceRetain rigidityThermal insulationPipe protection by thermal insulationInsulation layerEngineering

The invention provides a heat preservation bend. The bend comprises two parts which are in mirror symmetry and are in seal connection, each part sequentially comprises an outer protection pipe layer,a heat preservation layer and a bent pipe layer from outside to inside, the outer protection pipe layer and the bent pipe layer are pressed to an integrated cavity structure, and a cavity is filled with the heat preservation layer. The integrated structure is adopted, and the phenomena that in the prior art, the heat preservation bend is prone to cracking and detaching can be avoided.

Owner:丛志有

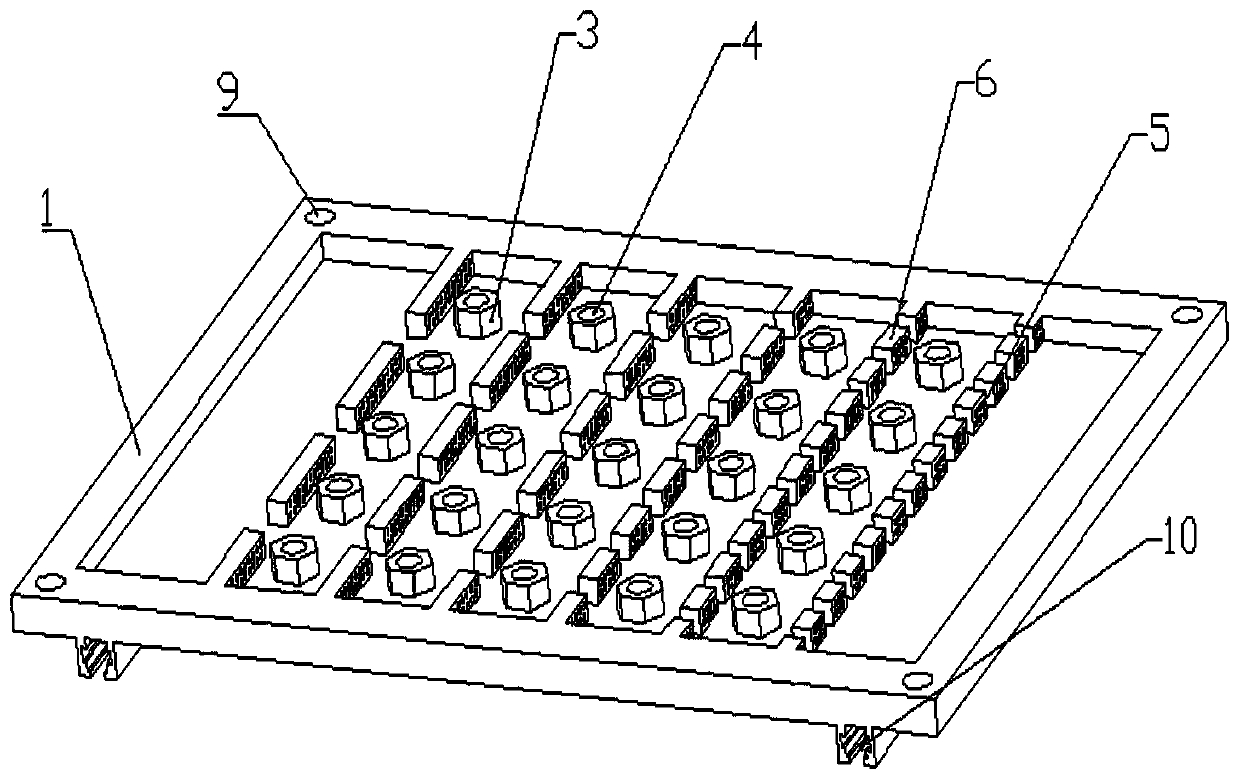

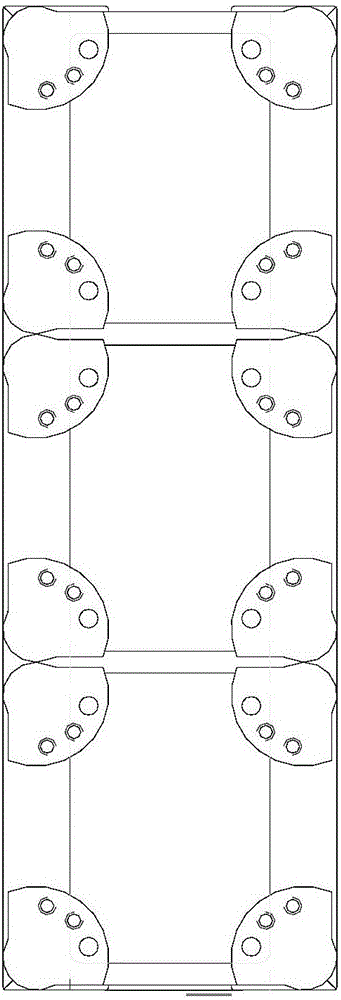

Strain tower column module for emergency repair of ultra-high-voltage power transmission line

The invention discloses a strain tower column module for emergency repair of an ultra-high-voltage power transmission line. The strain tower column module is used for temporarily combining and constructing an emergency repair tower for the ultra-high-voltage power transmission line, is in a rectangular frame shape and is manufactured integrally by three three-dimensional square strain tower column units, wherein four hollow cylinders are arranged at four corners of the rectangle to bear vertical load of the strain tower for emergency repair; 12-24 mounting holes are formed in the upper end surface and the lower end surface of the strain tower column module and used for fixing the strain tower column module for straight combination and mounting, and four guiding and locating pins are arranged at four corners of the upper end surface of the strain tower column module and used for guiding and locating the strain tower column module for straight combination and mounting. The strain tower column module can be manufactured integrally instead of combination after split manufacture, so that the efficiency is increased, the cost is reduced, and the strain tower column module is convenient to use. The strain tower column module is resistant to axial pressure and tension, large in bending moment and shear force, light and convenient to carry and low in manufacture cost and adopts a simple construction technology.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Leakage stoppage strengthening method for vibration disturbance resistance honeycomb pitted furnace for underground engineering

InactiveCN106939619AEffective compactionSolve the problem of water seepageArtificial islandsUnderwater structuresEpoxyWater leakage

The invention discloses a plugging and reinforcement method for anti-vibration and disturbance honeycomb pitted surface used in underground engineering. Firstly, cement grouting is used to stop the water of the structure with large leakage water, and the method of pinhole grouting is used to pour low-type modification Epoxy grout, apply cement-based permeable crystalline waterproof material to the leaking parts of the tiny gaps that cannot be grouted, use concrete to squeeze water out of the cracks and pores of the secondary lining, and then use cement-based rigid anti-seepage mortar to spray or Scrape coating, and after the plugging of the root of the embedded parts is completed, slot and fill the sealant; finally, use a drilling tool to drill through the lining structure to release pressure and drain water at the serious water leakage, forming an effective new drainage blind pipe. The method of the invention can effectively tamp the uncompacted honeycomb pitted surface, thereby solving the problems of water seepage and water leakage, and has good treatment effect and high pressure.

Owner:贵州维修大师科技有限公司

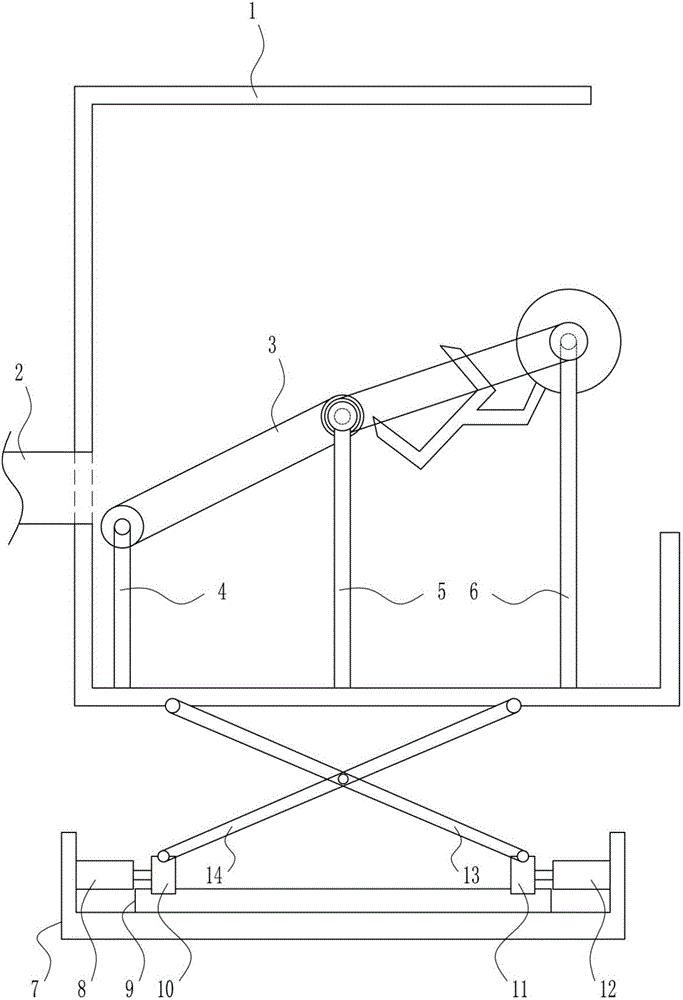

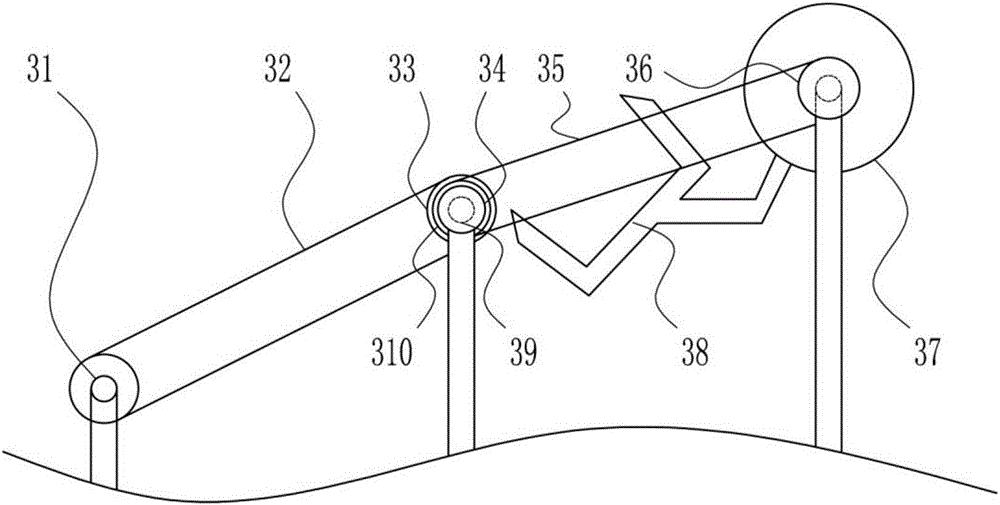

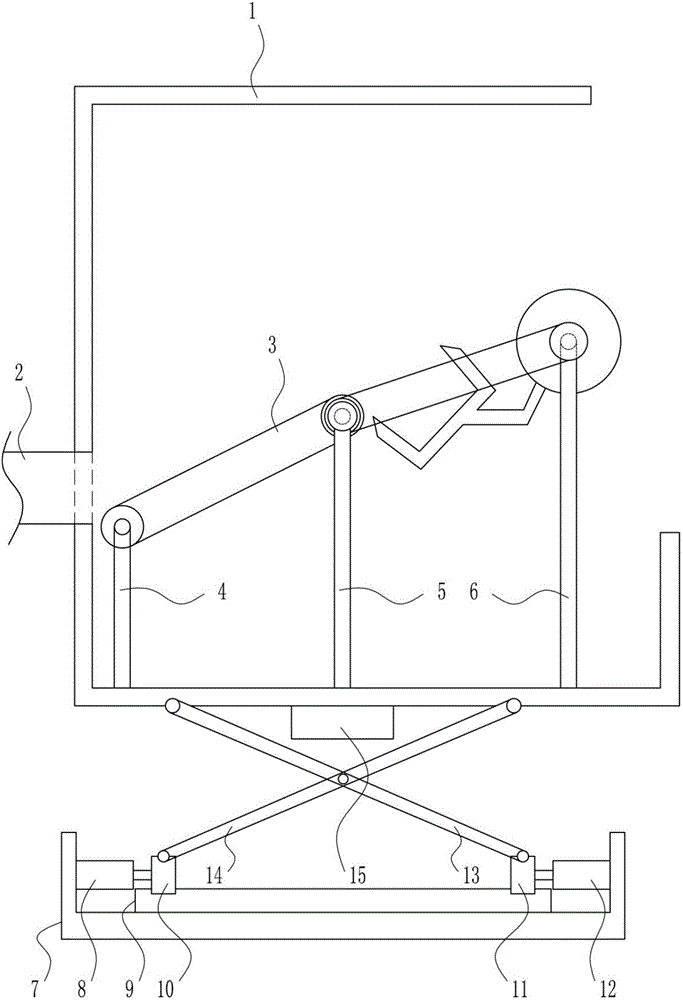

Cement transportation device for high-altitude operation

The invention relates to a cement conveying device, in particular to a cement conveying device for aerial work. The technical problem to be solved by the present invention is to provide a cement conveying device for aerial work. In order to solve the above technical problems, the present invention provides such a cement conveying device for aerial work, which includes a transport box, a transport device, a first pole, a second pole, a third pole, a bottom bracket, a left cylinder, a sliding Rail, left slider, right slider, right cylinder, etc.; the bottom of the bottom bracket is provided with a slide rail, the slide rail is provided with a left slider and a right slider, and the left wall of the bottom bracket is provided with a left cylinder. A right air cylinder is arranged on the right side wall in the bottom bracket, and the right end of the left air cylinder is connected with the left slide block. The invention achieves the effects of reducing the severity of dust flying with the wind, ensuring the cleanliness of the working space, cleaning the air, saving resources, reusing resources, high safety performance, and high pressure.

Owner:刘春燕

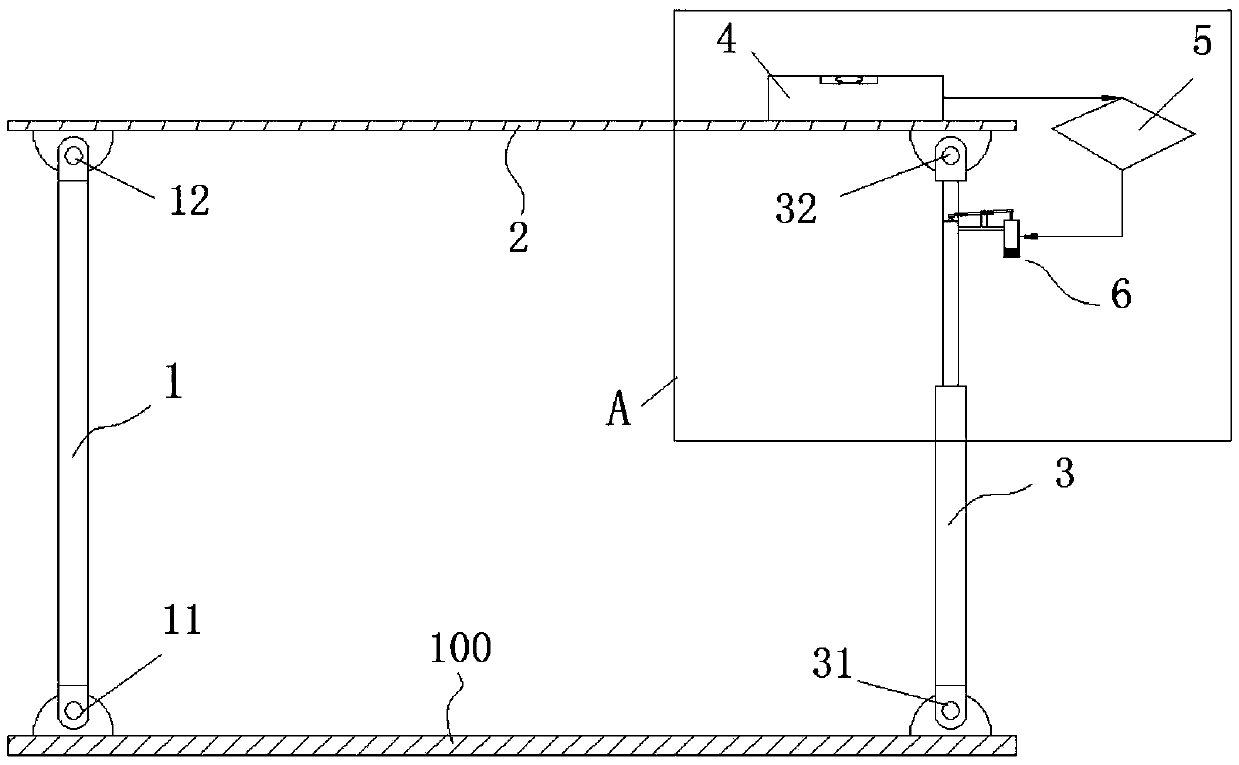

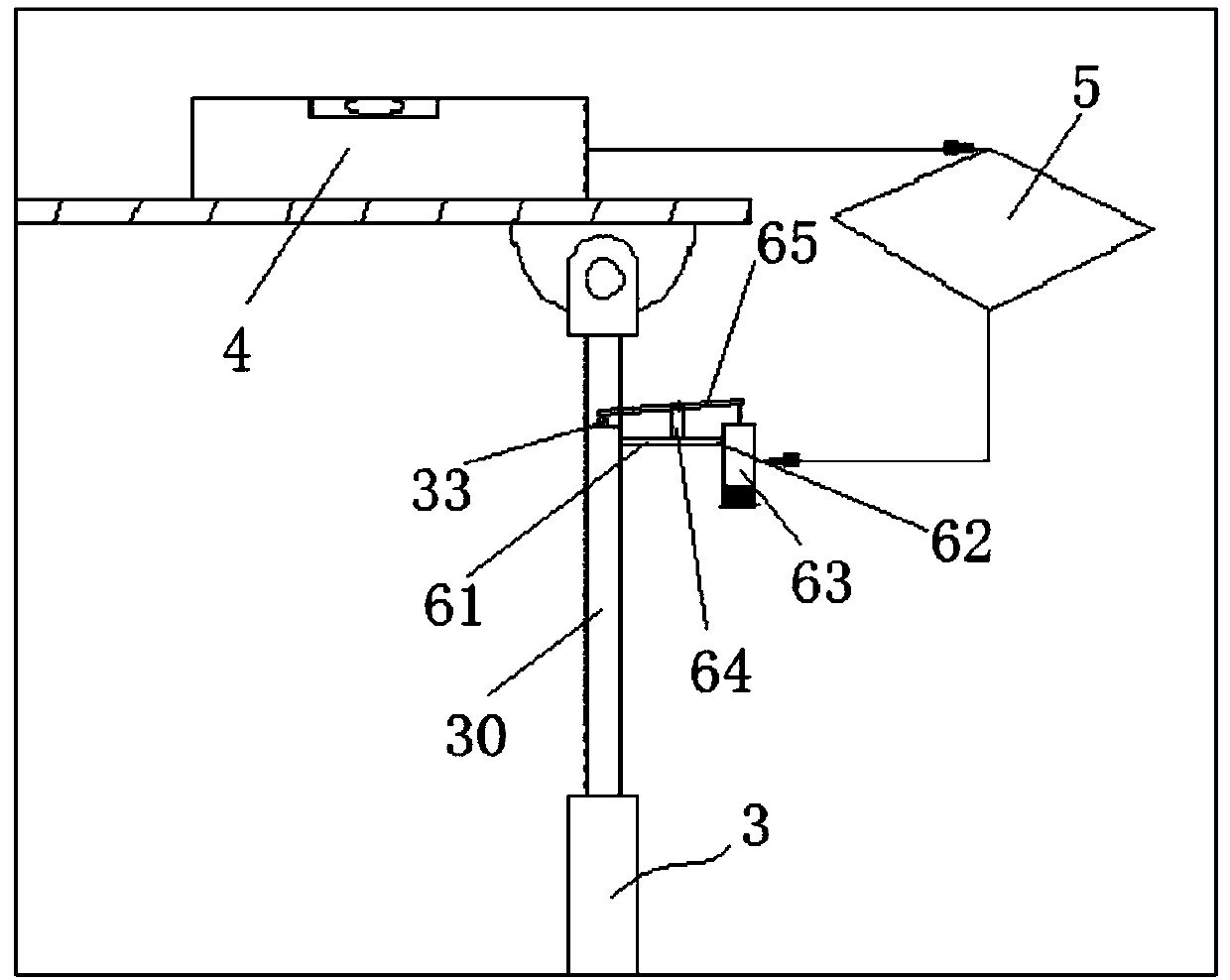

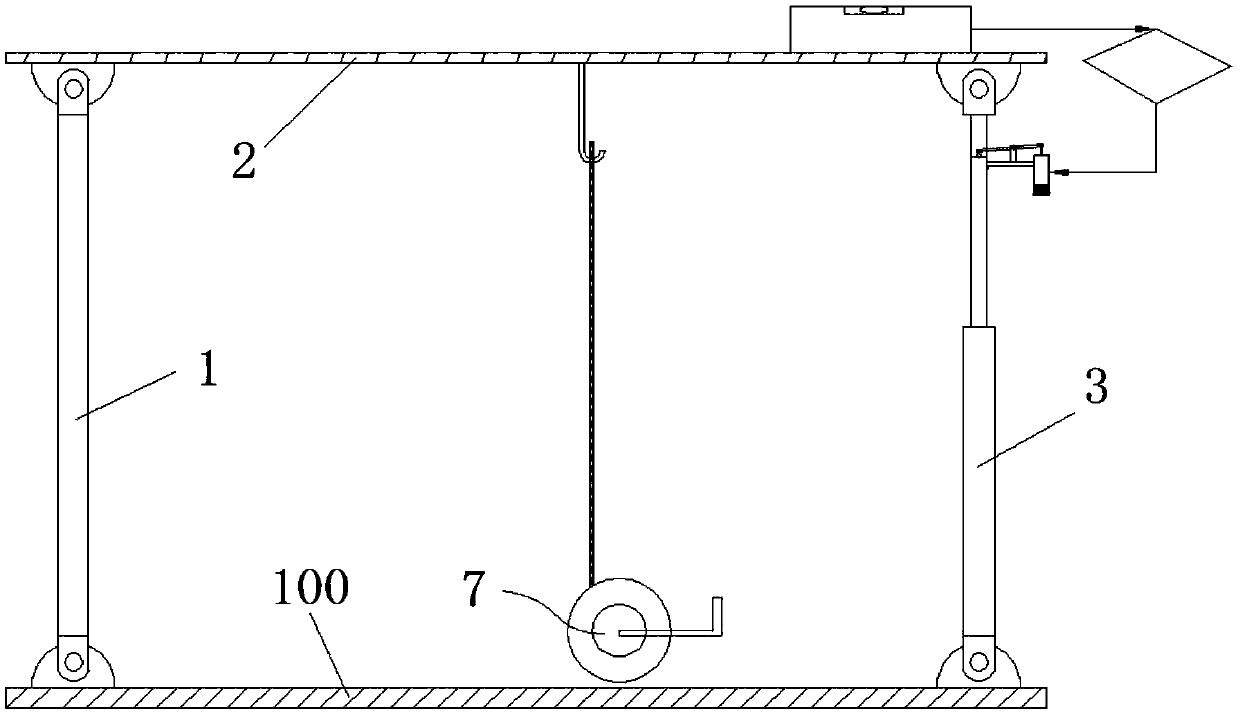

a leveling device

Owner:AERODYNAMICS NAT KEY LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com