Cylindrical plastic methane generator

A biogas generator and plastic technology, used in gas production bioreactors, biochemical instruments, waste fuels, etc., can solve problems such as leakage, insufficient hardness, and low pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

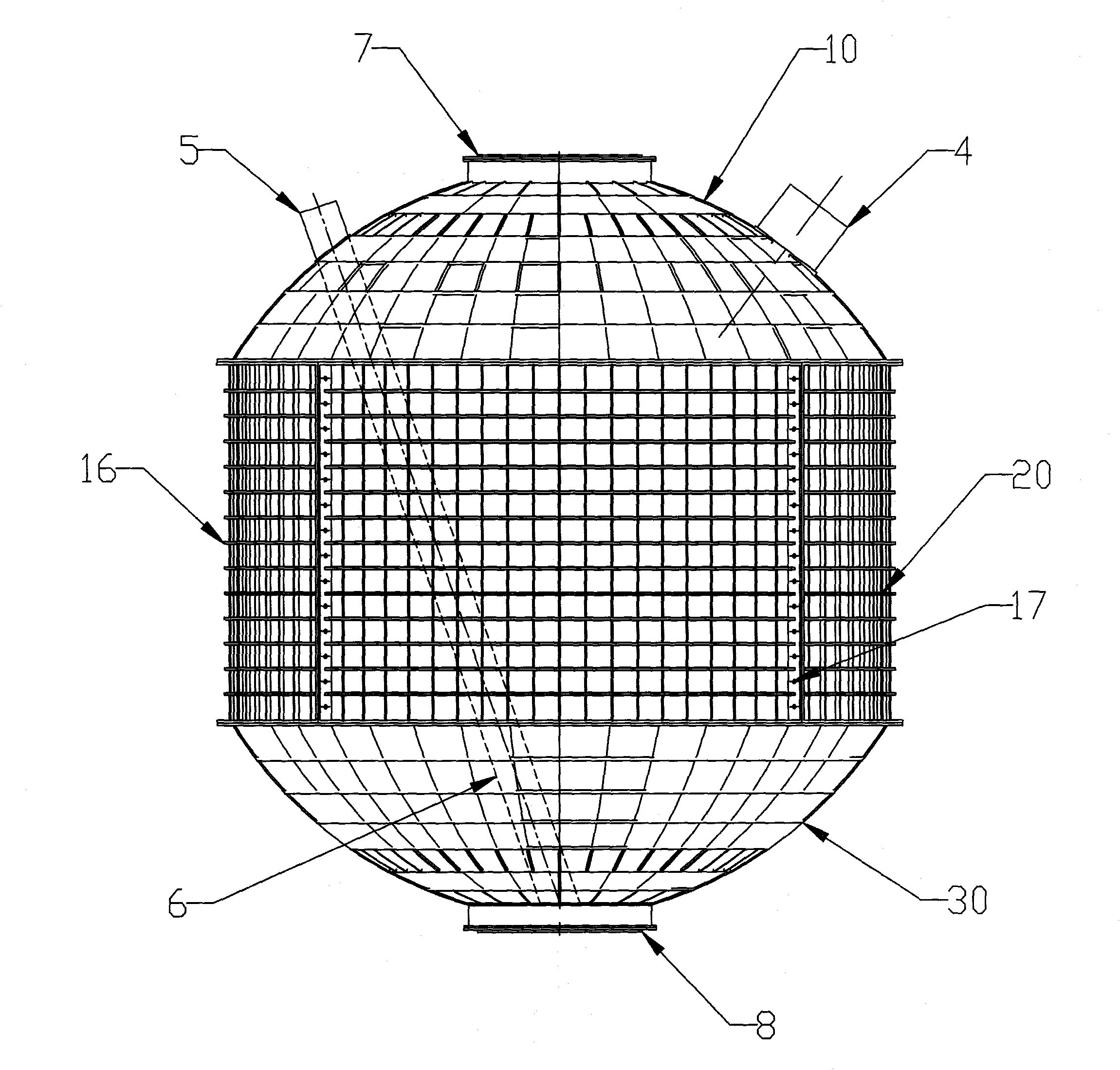

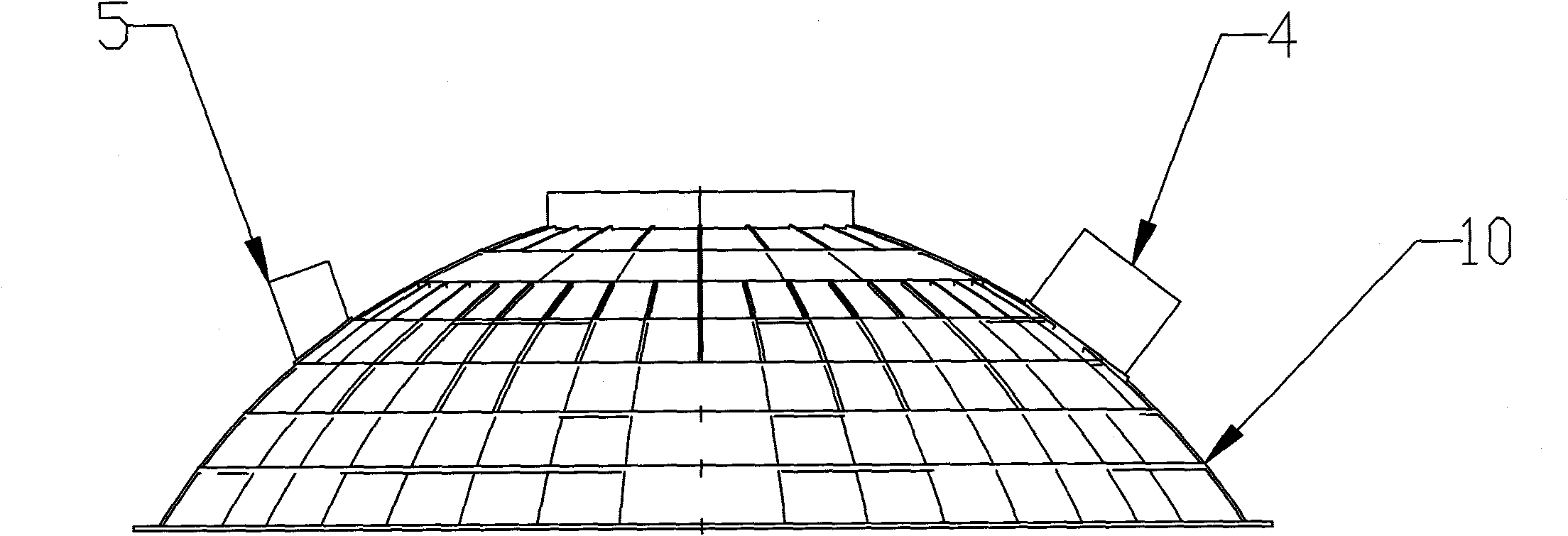

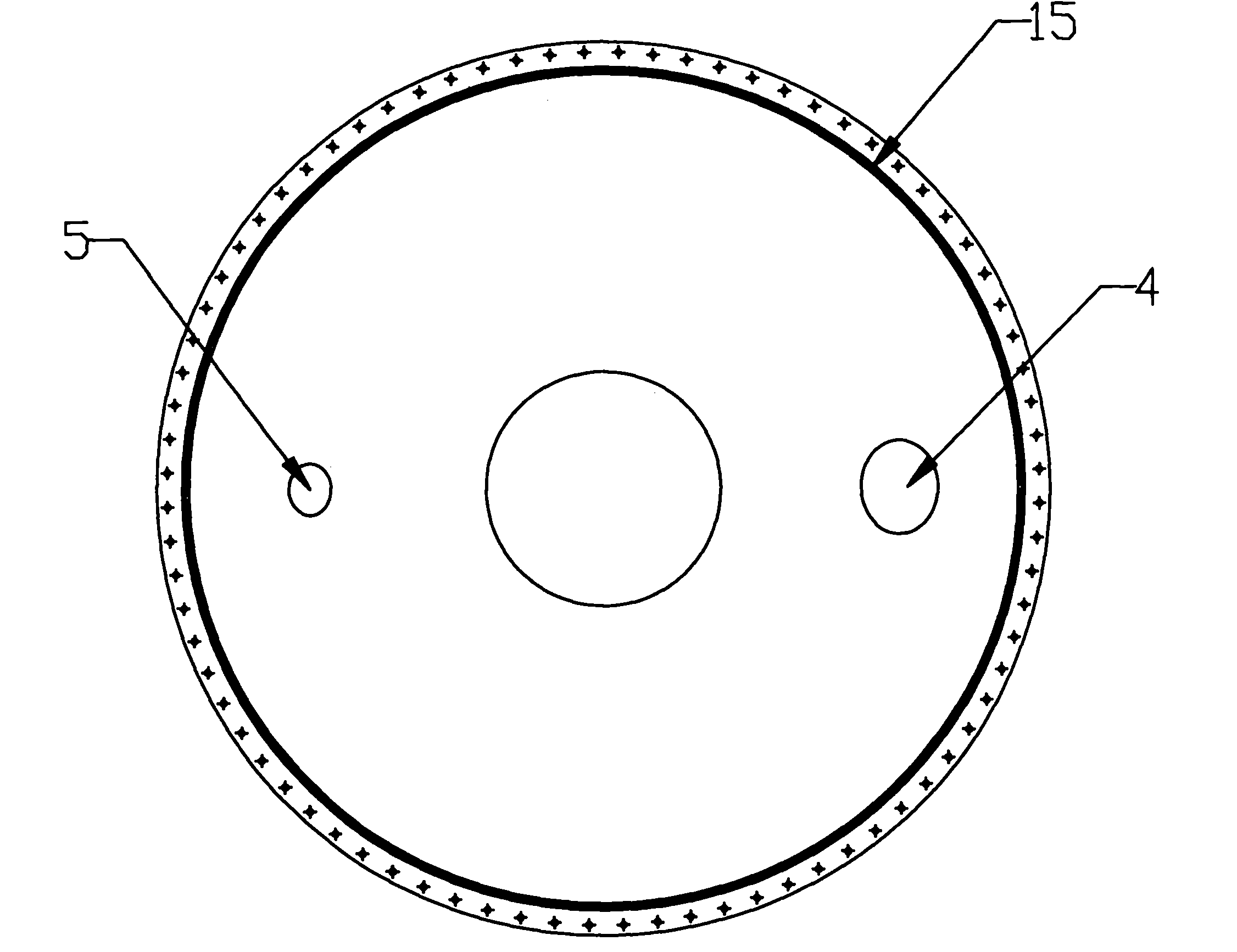

[0032] Such as Figure 1-16 Shown, the cylindrical plastic biogas generator of the present invention comprises the cylindrical container that plastics is made, and described cylindrical container is by hemispherical (the hemispherical shape here is the hemispherical surface along the center of the sphere or the height is less than the radius of the sphere) Spherical crown surface) top 10, cylindrical middle part 20 and hemispherical bottom 30 are sequentially connected to form, and the hemispherical top 10 and bottom 30 are spherical crown surfaces or are formed by splicing at least two fan-shaped tiles respectively, so The fan-shaped tiles are part of the spherical crown; the cylindrical middle part includes at least one section of cylinders, and each section of cylinders is formed by splicing at least two rectangular tiles 2, and the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com