Method for preparing rounded pre-vulcanized tyre surface of giant-scale tyre for mining by screw-type pushing-in process

A pre-vulcanized tire and screw-type technology is applied in the field of remanufacturing pre-vulcanized treads for mining giant tires. The effect of improving the performance and densification of the rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

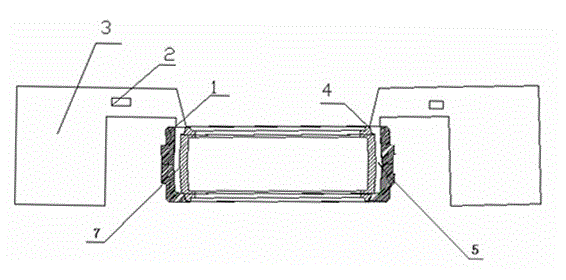

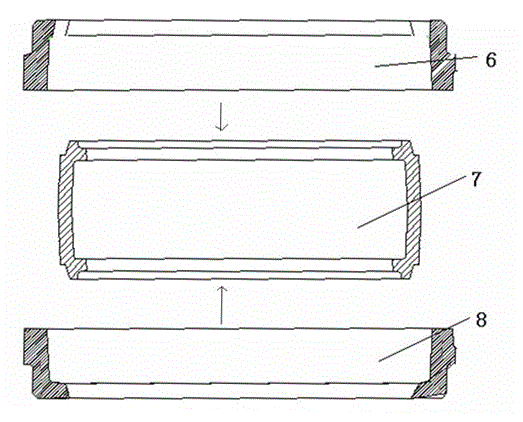

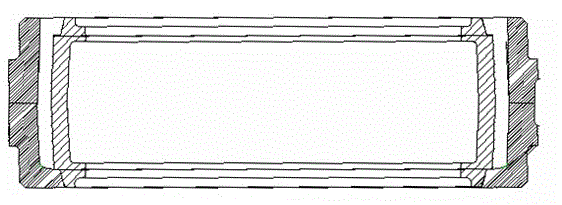

[0027] Firstly, a full circle pre-vulcanized tread mold is designed according to the size of the giant tire. The mold includes an upper outer mold 6, a lower outer mold 8 and an inner mold 7. The upper outer mold 6 and the lower outer mold 8 are fixed and locked with bolts. The mold 7 is fixed by engaging and locking with the upper outer mold 6 and the lower outer mold 8, and forms a closed tread inner cavity after being combined, that is, the mold cavity 5, and the upper outer mold 6 is provided with 2 glue inlets; The mouthpiece of the feed screw extruder 3 is closely connected and locked with the mold inlet 1 and the glue inlet 4, and the pressure sensor is installed on the glue inlet 1 and the glue inlet 4 and the cold feed screw extruder 3 The control system is connected; at the same time, start the cold-feed screw extruder 3 and continue to enter the tread rubber through the feeding port 2 of the cold-feed screw extruder, and continue to push the rubber into the Mold, se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com