Mattress surface layer and preparation method thereof

A production method and surface technology, applied to mattresses, spring mattresses, stuffed cushions, etc., to achieve the effect of clear stitches, flexible operation, and clear stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

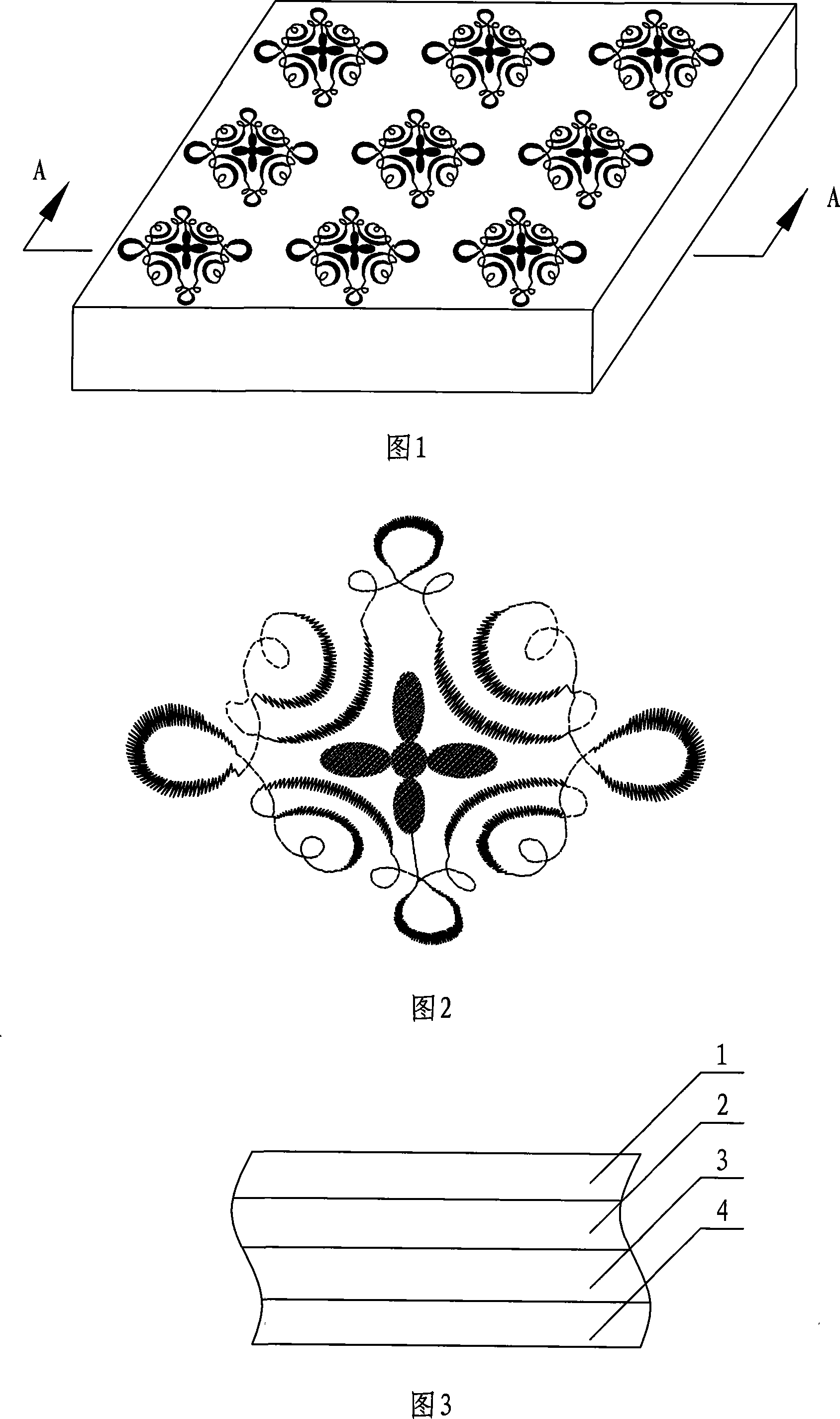

[0018] Referring to Fig. 1-Fig. 12, the surface layer of this mattress includes fabric layer 1, sponge layer 2, glue spray layer 3 and non-woven fabric layer 4, the thickness of the surface layer is 5-7cm, and the edges and middle of the surface layer are embroidered with Computer patterns to ensure that there is no blank area at the interface. The surface quilting has closed or semi-closed patterns.

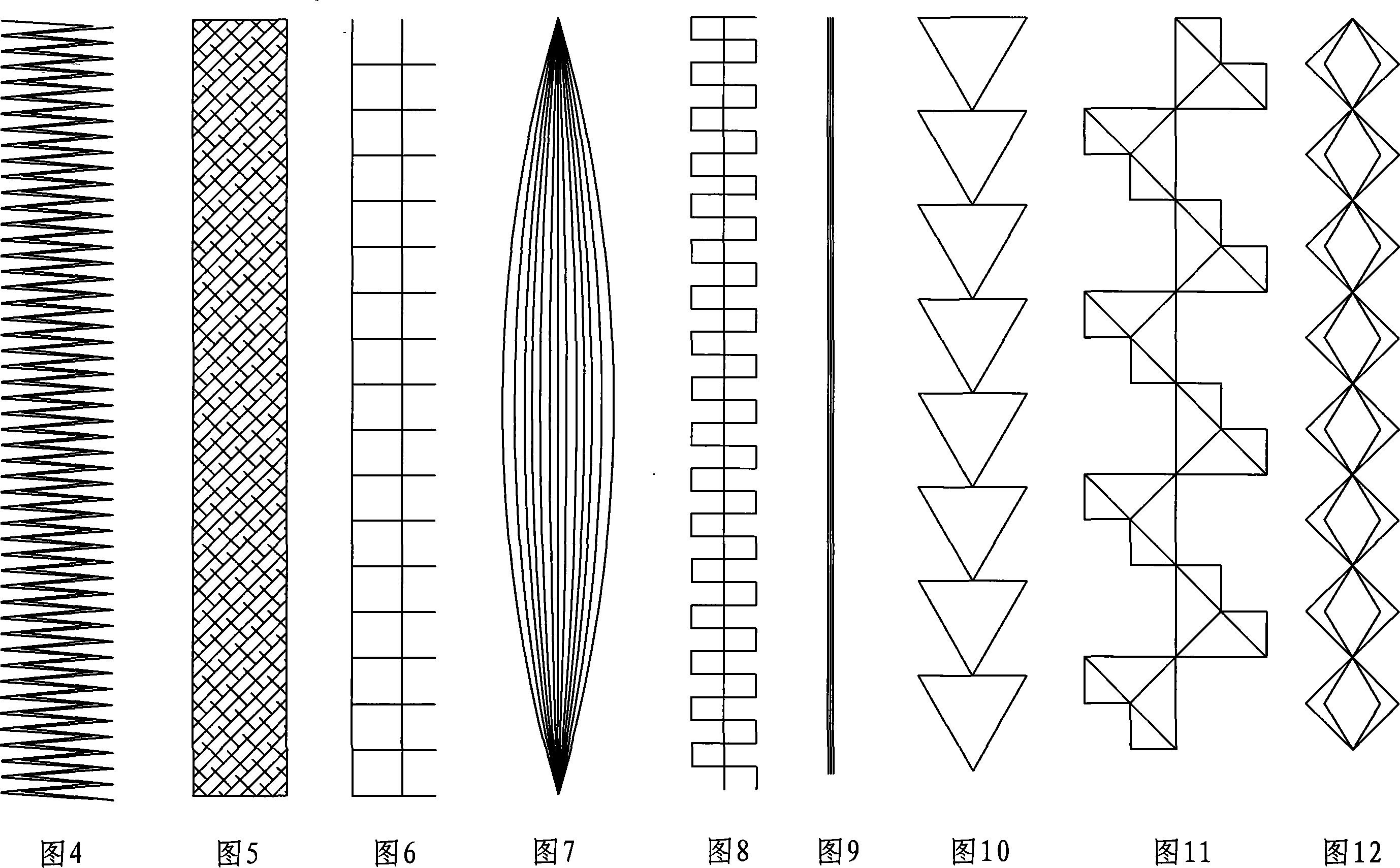

[0019] The production method is as follows: the surface layer is quilted and embroidered with double-needle, multi-needle and flower-needle methods. In the process of quilting embroidery, mixed stitches such as piercing stitches, tatami stitches, E-shaped stitches, circular stitches, straight stitches, triple stitches, chain stitches, heart-to-heart stitches, and marquise stitches can be used. The quilted embroidery pattern on the surface is completed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com