Method for utilizing waste building templates to manufacture regenerated building templates

A technology of building templates and building boards, which is applied to the preparation of building components on site, construction, building construction, etc. It can solve the problems of wasting forest resources, low wood utilization rate, and polluting the environment, and achieves the protection of forest resources and saving wood. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

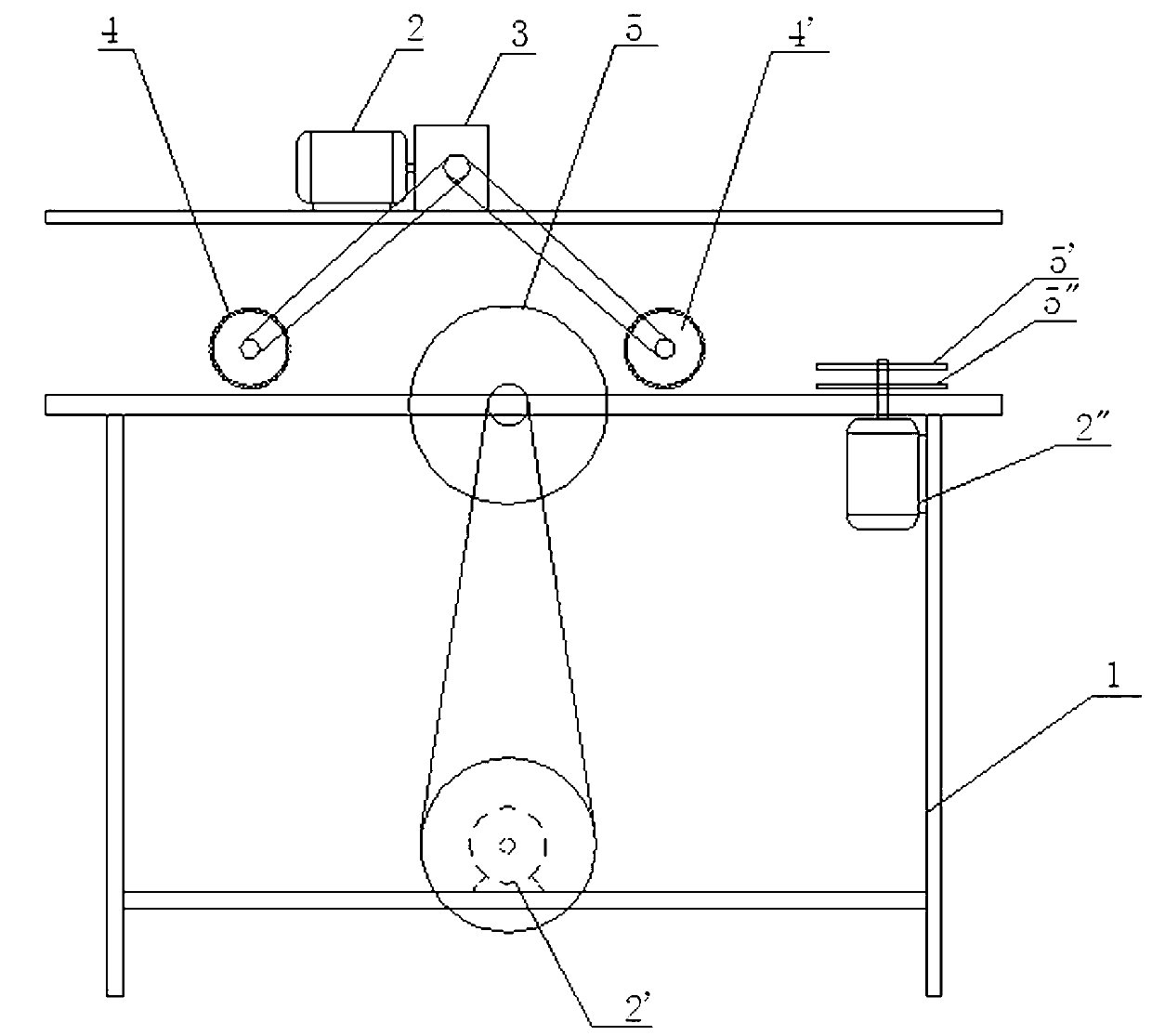

[0012] Attached below figure 1 The method for making regenerated building panels by utilizing waste and old building templates of the present invention is further described;

[0013] figure 1 It is a structural schematic diagram of the width-limiting and thickness-limiting saw in the present invention.

[0014] The present invention utilizes the waste and old building formwork to make the method for regenerated building board, comprises the following steps:

[0015] a) Use an air nail gun to drive out the iron nails on the waste building formwork;

[0016] b) Put the waste building formwork in step a on the support 1, powered by the first motor 2 and drive the two travel gears 4, 4' through the gearbox 3 to rotate, so as to move the waste building formwork forward on the support 1, After passing through the width-limiting sawing disc 5, the edge of the opened board is smooth, and then passing through two thickness-limiting sawing discs 5', 5", the cement on the waste buildi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com