Pipeline pressure test method and device

A pipeline pressure test and pressure test technology, which is applied in the direction of measuring the increase and deceleration rate of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of bulky, undetectable leakage of pipeline joints, and influence on construction progress, etc. problems, to achieve the effect of light and handy structure, high pressure resistance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

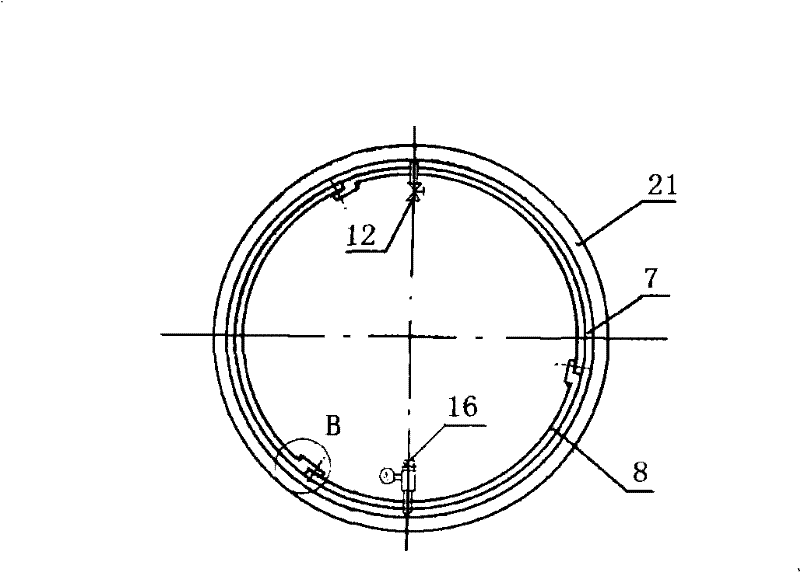

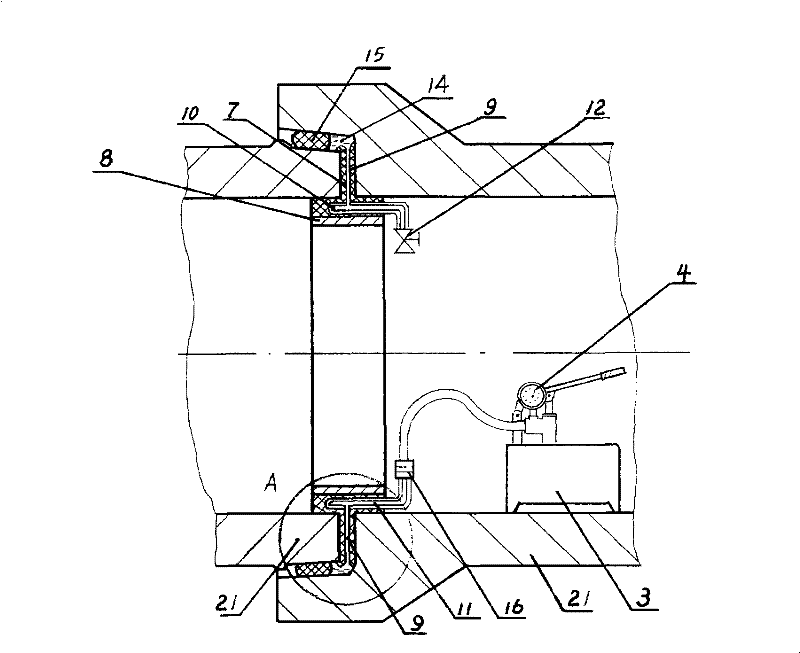

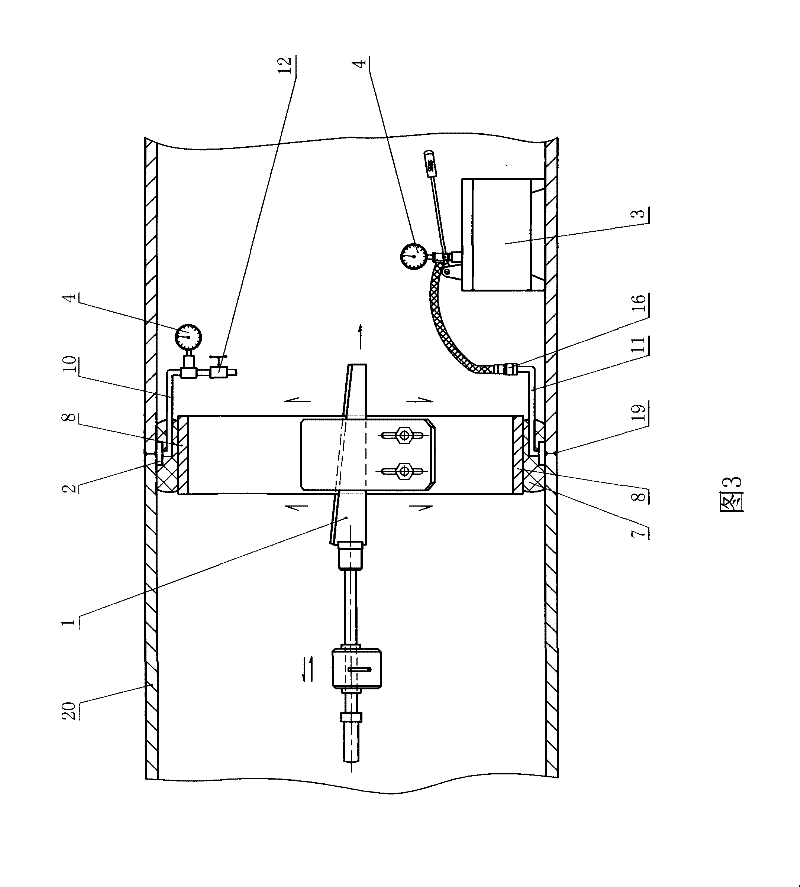

[0017] See image 3 , the pipeline pressure test method of the present invention is to place a sealing rubber ring with an annular groove on the outer circle at the welding place of the pipeline interface, and the sealing rubber ring is an inner supporting sealing rubber ring spliced with a sub-expanding ring with an inlaid slit. , insert a reducing wedge into the opening where the two expansion rings are spliced, position it with a screw, and then hit the reducing wedge with a two-way impact hammer, wedge the inner supporting sealing rubber ring of the expansion ring, open the exhaust valve, and start charging Water, after exhausting the air, close the exhaust valve, continue to fill water and pressurize, after reaching the specified pressure value, close the water inlet valve, and the pressure measurement is qualified when the closed pressure time reaches the predetermined value, and the pressure at the pipe interface is detected After the pressure test, it is convenient t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com