Lever Type Tensile Tester

A tensile tester and lever-type technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of waste of power and manpower of the base metal and welding materials, and the inability to perform tensile tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

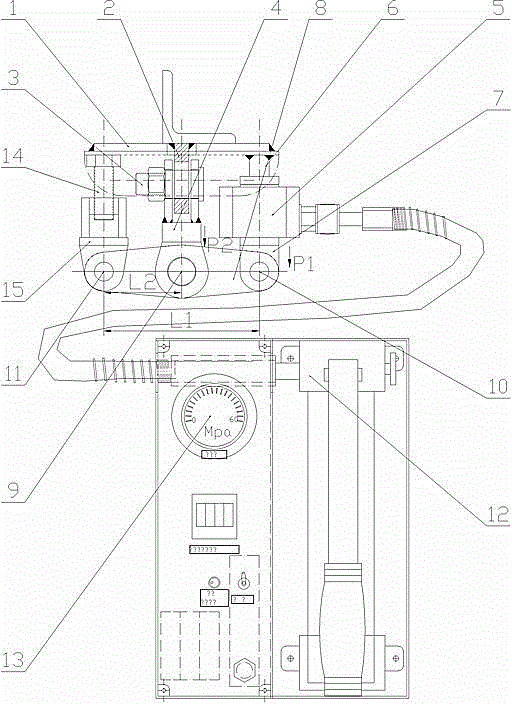

[0008] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: a lever-type tensile tester, which includes a test piece 2 fixed on the lower end of the base plate 1, the test piece 2 is connected to the test piece connecting plate 4 through the connecting pin 3, and the test piece connecting plate 4 The lower end is provided with a first connection hole 9; a hydraulic jack 5 is provided on one side of the test piece 2, and the pressure rod 6 arranged at the upper end of the hydraulic jack 5 is pushed against the bottom surface of the base 1, while the lower end of the hydraulic jack 5 is a jack Seat 7, a second connection hole 10 is provided on the jack seat 7; a push rod seat 15 is provided on the side of the test piece 2 away from the hydraulic jack 5, and the upper end of the ejector rod seat 15 is threadedly connected with a push rod 14, by adjusting The push rod 14 can ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com