Process and device for inner pressure type conduits interface pressure testing

A pipeline interface and internal pressure technology, which is applied in the field of pressure testing of water supply and drainage pipeline interfaces, can solve the problems of complicated operation, cumbersome device, poor airtightness, etc., and achieves the effect of high airtight reliability, convenient operation and less water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

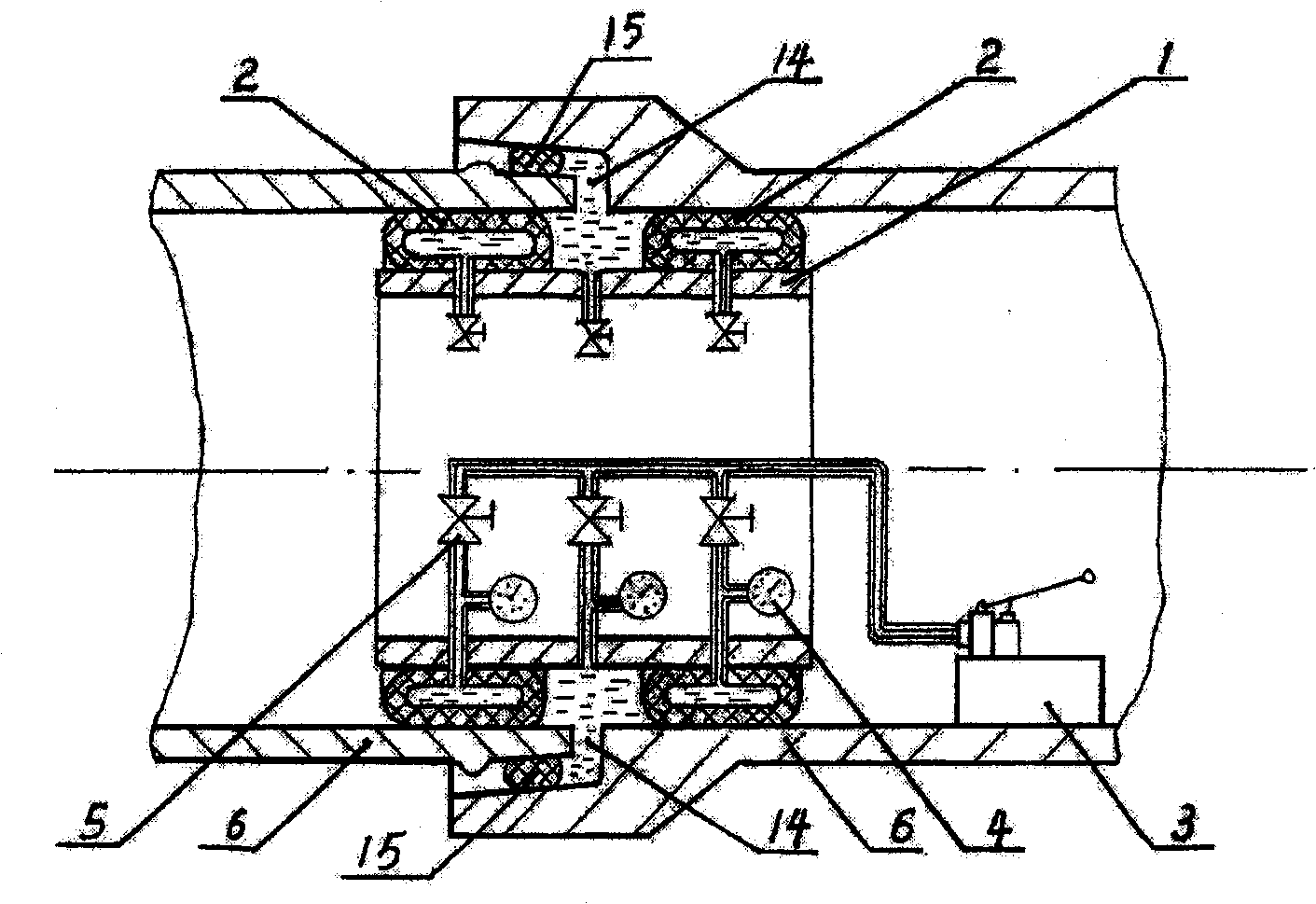

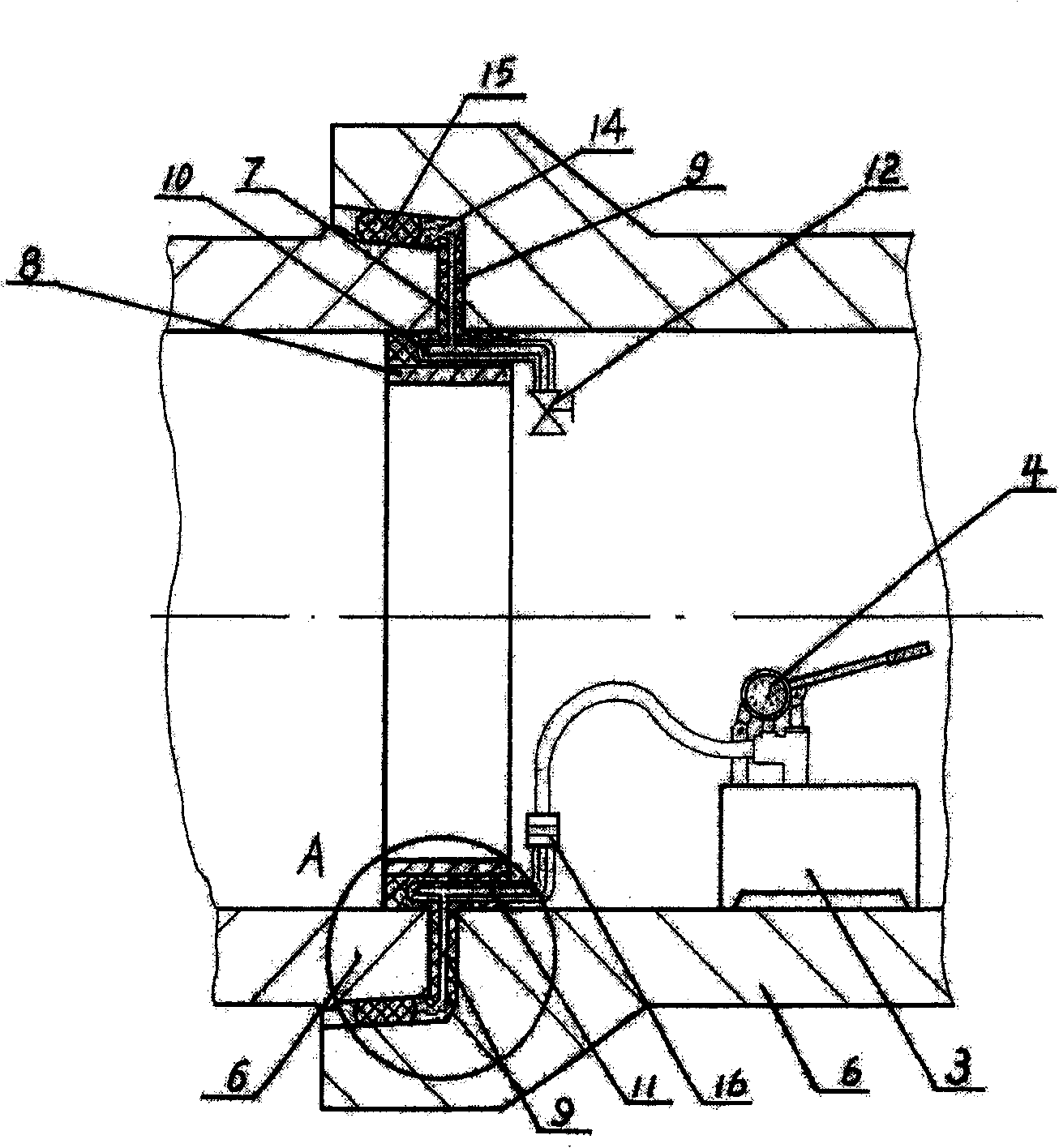

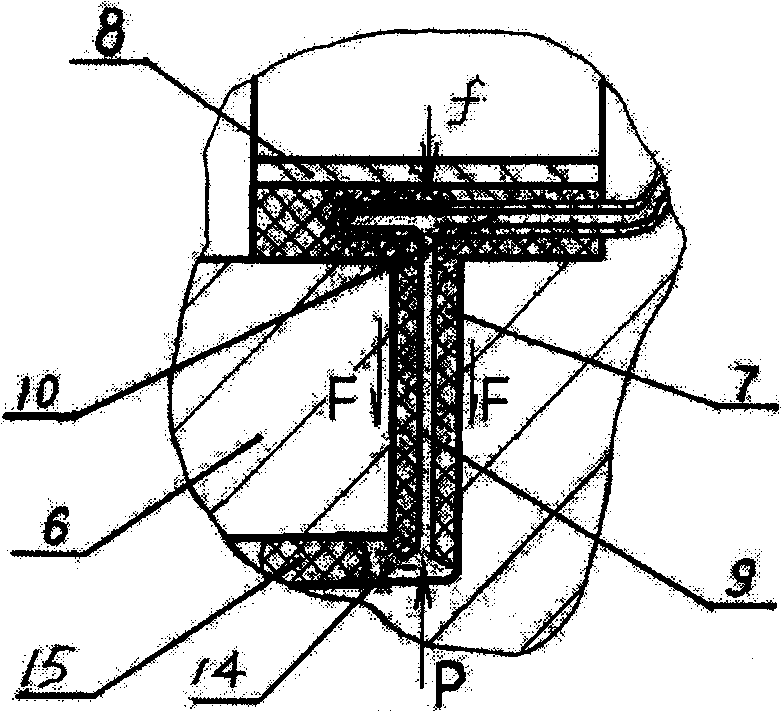

[0012] See attached figure 2 , the present invention is a pressure test method for internal pressure pipe joints. The method is to place a special-shaped rubber ring with a "convex" cross-section and an opening gap at the gap between the two ends of the pipe joint. After the ring is supported, open the exhaust valve and inject water into the gap of the special-shaped rubber ring. After the water is filled, close the exhaust valve and continue to fill with water and pressurize. After the gap between the two ends of the interface is sealed and a sealed cavity is formed at the pipe joint, continue to fill the special-shaped rubber ring with water and pressurize. Pressure bearing capacity, that is, to check whether the pipe interface is qualified.

[0013] The working principle of the internal pressure pipeline interface pressure test method is as follows:

[0014] Such as figure 2 As shown, a special-shaped rubber ring 7 with a "convex" cross-section and an opening gap is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com