Multifunctional, efficient, energy-saving and environment-friendly boiler for both heating and steaming

A high-efficiency, energy-saving and multi-functional technology, applied in steam generation, steam generation devices, fluid heaters, etc., can solve the problems of absorption, inconvenient use, insufficient heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

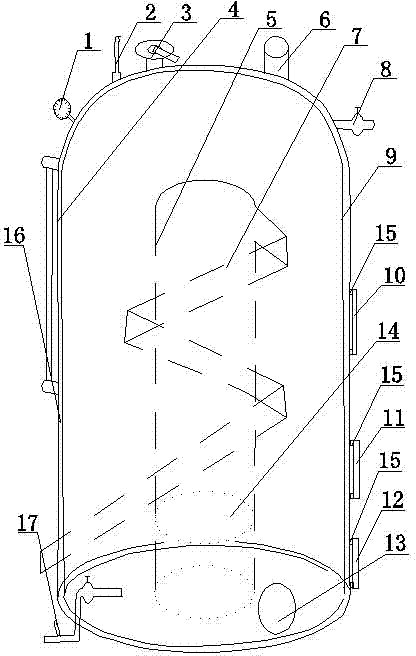

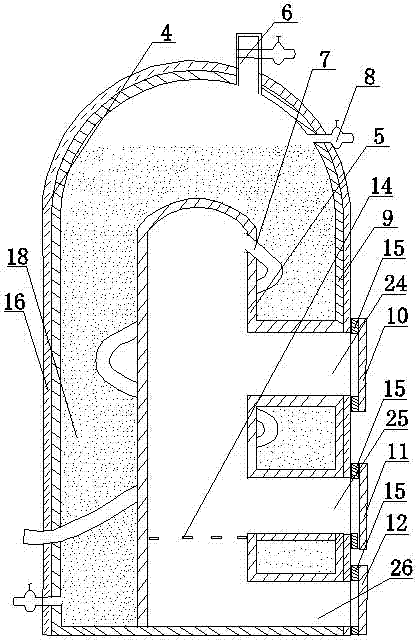

[0045] Embodiment 2: as figure 1 , 2 , 3 and 4, a multifunctional, high-efficiency, energy-saving, environment-friendly heating and steam dual-purpose boiler has a set inner shell 9 and an outer shell 4, the inner shell 9 and the outer shell 4 are connected by a bracket, and the inner shell 4 and the outer shell The interlayer between 9 is filled with heat insulating material, the inner shell 9 is provided with a stove chamber 5, and the interlayer between the inner shell 9 and the stove chamber 5 constitutes a water tank 18, and the side of the outer shell 4 is arranged with the water tank 18 A connected water inlet pipe 8, a water discharge pipe 17 provided with a control valve, and a steam conduit 6, a grate 14 is arranged inside the furnace 5, and a smoke chamber communicating with the inner cavity of the furnace 5 and passing through the water tank 18 is arranged on the upper side of the furnace 5. The gas conduit 7, the upper end of the inner shell 9 and the furnace 5 a...

Embodiment 3

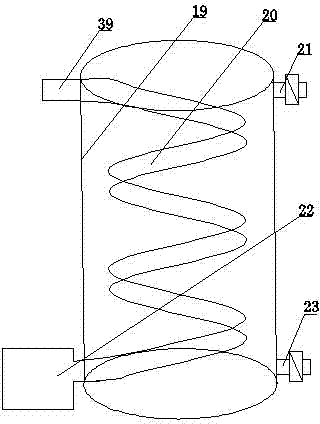

[0058] Such as figure 1 , 2 , 3, 4, and 5, a multifunctional high-efficiency energy-saving environmental protection heating and steam dual-purpose boiler has a set inner shell 9 and an outer shell 4, the inner shell 9 and the outer shell 4 are connected by a bracket, and the inner shell 4 The interlayer between the outer shell 9 and the outer shell 9 is filled with heat insulating material, and the inner shell 9 is provided with a stove chamber 5, and the interlayer between the inner shell 9 and the stove hearth 5 constitutes a water tank 18, and the side of the outer shell 4 is arranged to be connected to the inner shell 9. The water inlet pipe 8 connected to the water tank 18, the water discharge pipe 17 provided with the control valve and the steam conduit 6, the furnace grate 14 is arranged inside the furnace 5, and the upper side of the furnace 5 is provided to communicate with the inner cavity of the furnace 5 and pass through the water tank 18 The flue gas duct 7, the ...

Embodiment 4

[0071] Embodiment 4: as figure 1 , 2 , 3, 4, and 5, a multifunctional high-efficiency energy-saving environmental protection heating and steam dual-purpose boiler has a set inner shell 9 and an outer shell 4, the inner shell 9 and the outer shell 4 are connected by a bracket, and the inner shell 4 The interlayer between the outer shell 9 and the outer shell 9 is filled with heat insulating material, and the inner shell 9 is provided with a stove chamber 5, and the interlayer between the inner shell 9 and the stove hearth 5 constitutes a water tank 18, and the side of the outer shell 4 is arranged to be connected to the inner shell 9. The water inlet pipe 8 connected to the water tank 18, the water discharge pipe 17 provided with the control valve and the steam conduit 6, the furnace grate 14 is arranged inside the furnace 5, and the upper side of the furnace 5 is provided to communicate with the inner cavity of the furnace 5 and pass through the water tank 18 The flue gas duc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com