Connecting mechanism capable of improving fixing efficiency

A connection mechanism and efficient technology, applied in the direction of connection components, sleeve/socket connections, mechanical equipment, etc., can solve the problems of loose clamps, loss of connection and fixed pipes, and pipe vibration, etc., to facilitate replacement, improve fixing efficiency, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

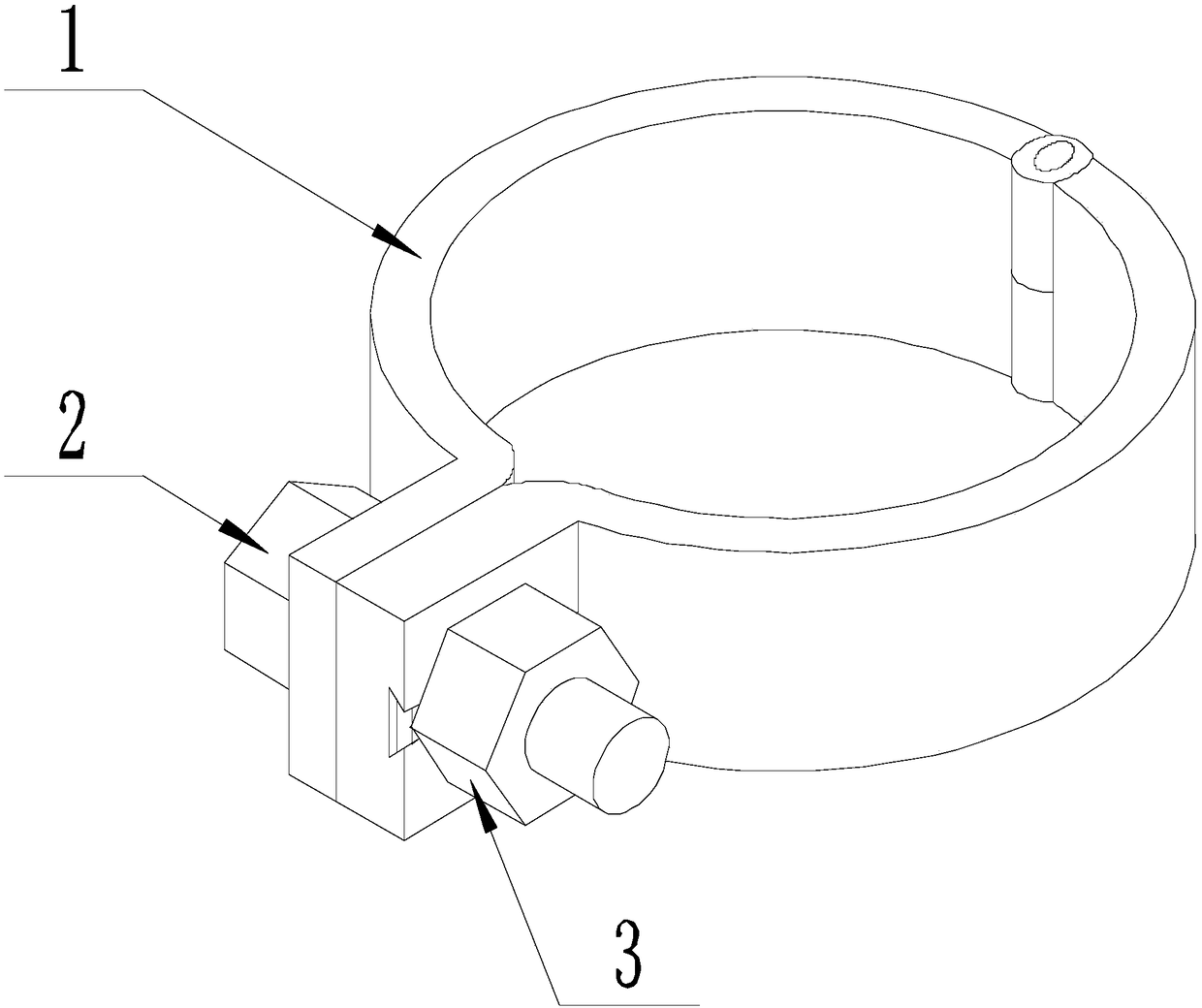

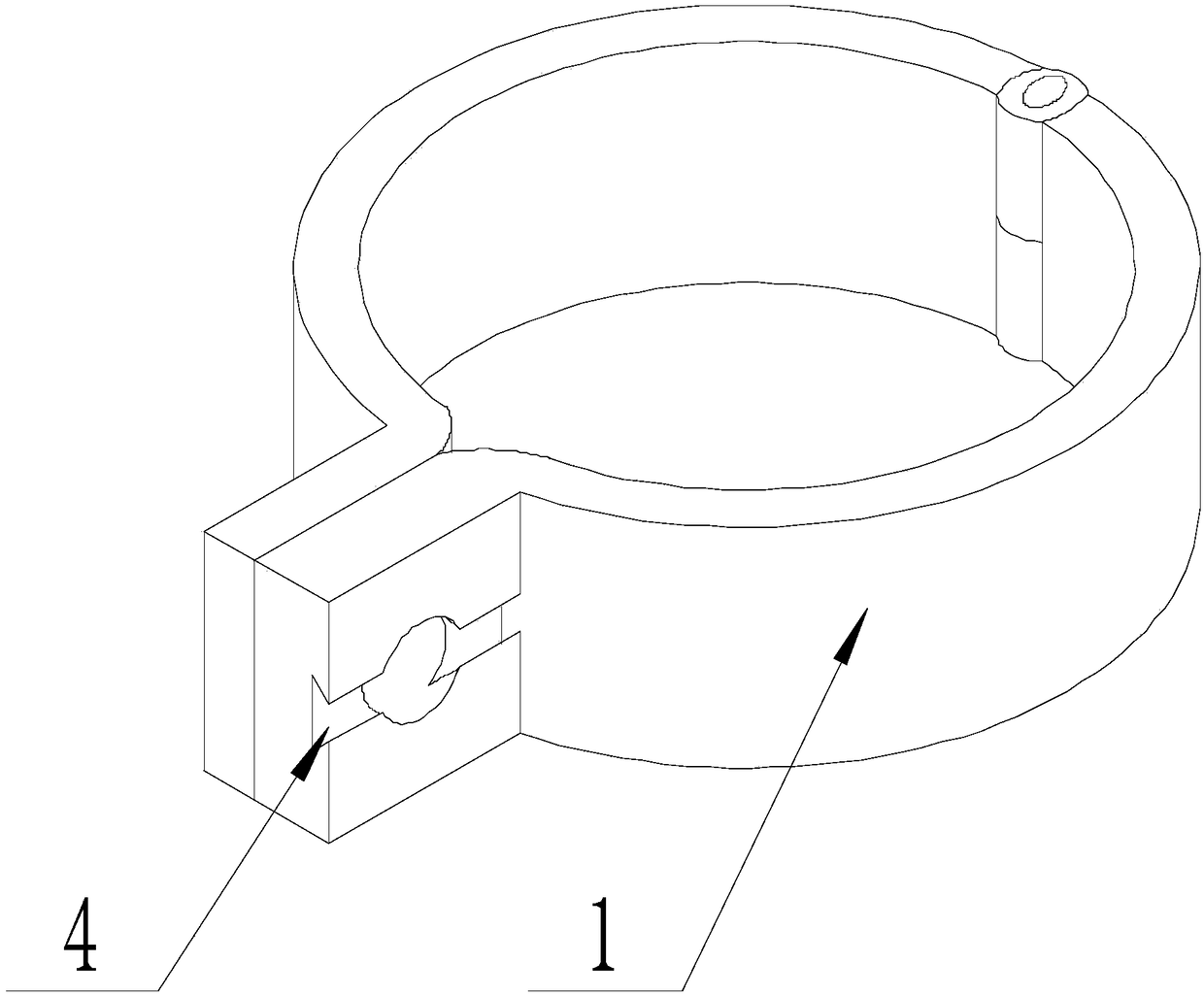

[0029] like Figure 1-Figure 4 As shown, the connection mechanism for improving fixing efficiency of the present invention includes two connection heads 1, bolts 2 and nuts 3, one end of the connection head 1 is hinged to each other, and the ends of the bolts 2 pass through the other ends of the two connection heads 1. One end is threadedly connected with the nut 3, and an installation groove 4 is arranged on the end surface of the connecting head 1 in contact with the nut 3. The extension axis of the installation groove 4 intersects the axis of the bolt 2 perpendicularly, and the opening of the installation groove 4 The size is smaller than the size of the bottom of the tank;

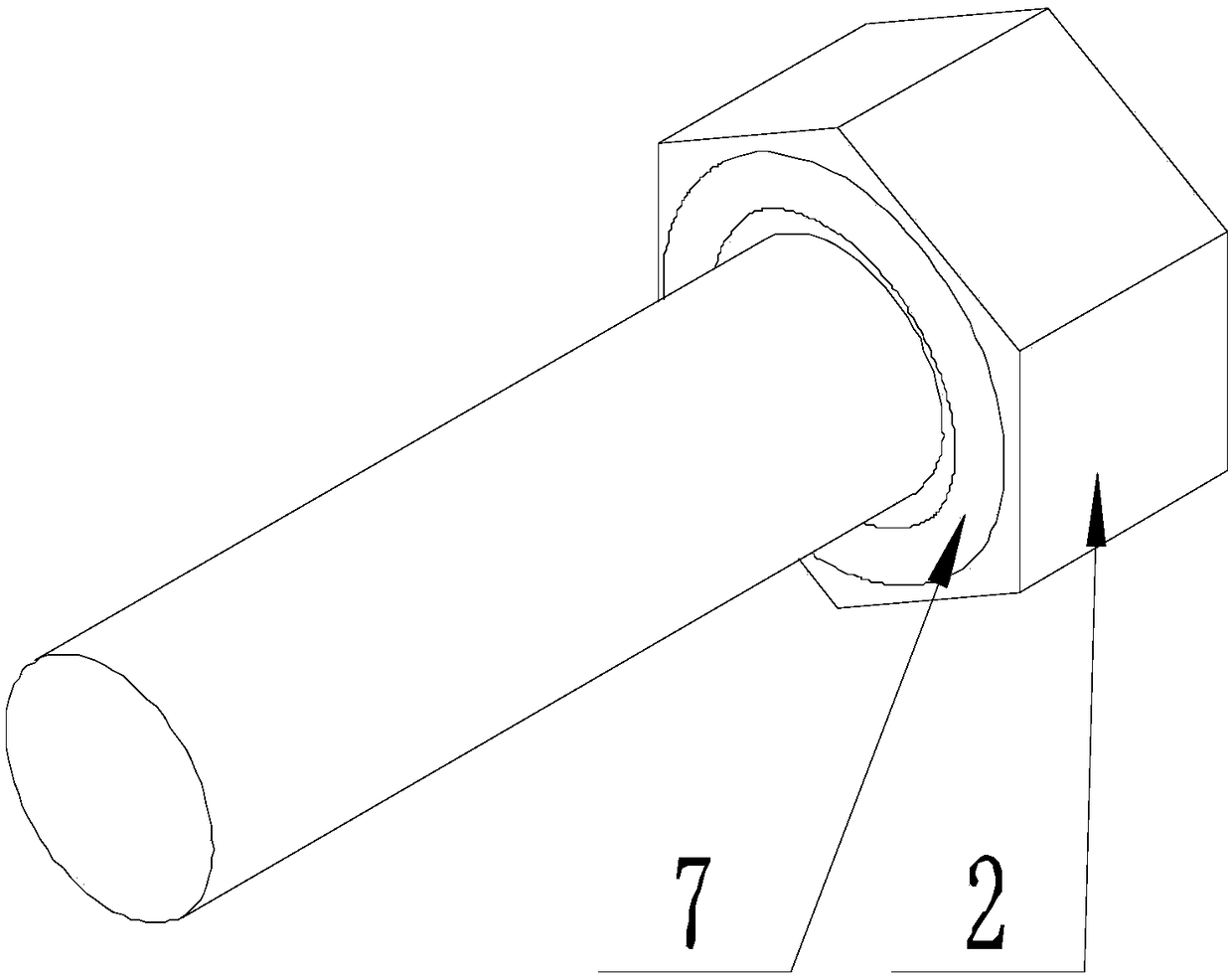

[0030] On the end surface of the nut 3 close to the head of the bolt 2, a mounting bar 5 is arranged, the cross-sectional size of the mounting bar 5 is consistent with the cross-sectional size of the mounting groove 4, and its axis is perpendicular to the axis of the nut 3. , and the threaded hole 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com