Metal insulation layer for equipment and pipe

A technology of thermal insulation layer and pipeline, applied in pipeline protection, thermal insulation, mechanical equipment, etc., can solve the problems of limited range of internal and external temperature drop, inability to achieve thermal insulation, limited use effect, etc., achieve small blockage, convenient surface cleaning, and decontamination easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

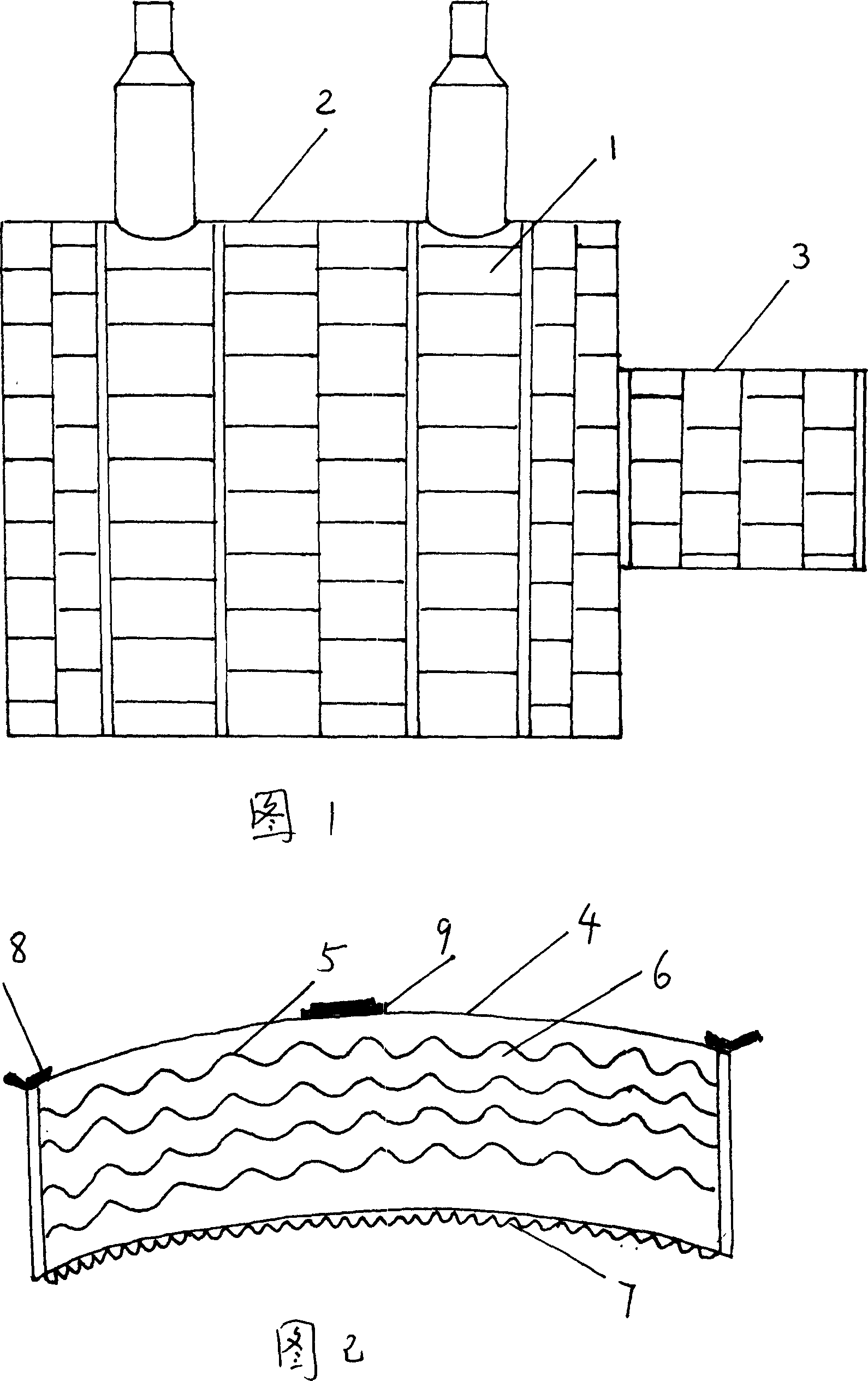

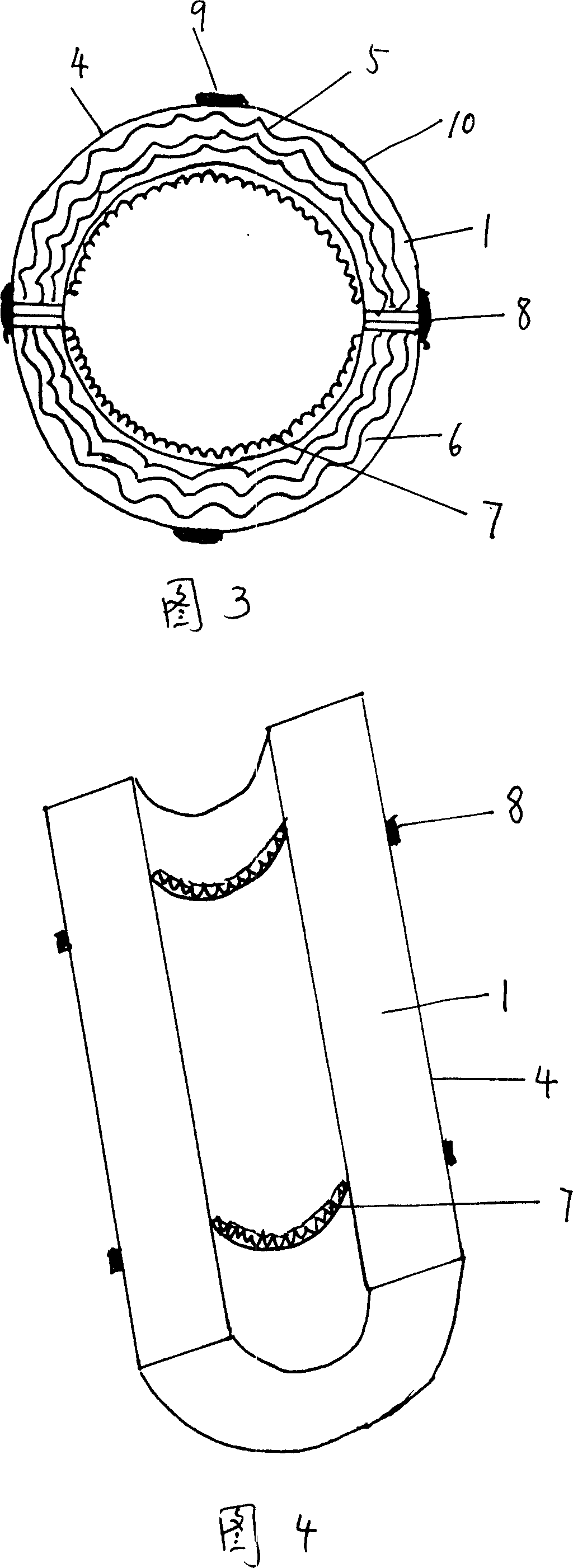

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings: As shown in Figure 1, the present invention is spliced by at least two heat preservation plates 1, and is coated on the surface of the thermal vessel 2 and pipeline 3 of nuclear reactor. The heat preservation plate 1 is composed of inner and outer stainless steel sheets 4 to form a thin box body, and a reflective heat preservation filler 6 composed of at least two stainless steel sheets 5 is installed inside, as shown in FIG. 2 .

[0017] The thin box body insulation board 1 is at least one of a plane board and an arc board. FIG. 2 shows a structure similar to a plane board, and FIG. 4 shows a structure similar to an arc board. In other embodiments, it can be applied to a combination of the above two insulation boards 1 .

[0018] The thin box body insulation plate 1 shown in Fig. 2 is equipped with reflective thermal insulation fillers 6 composed of at least three c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com