Anti-shaking screw drilling tool

An anti-seismic screw and drilling tool technology, which is applied in the direction of earthwork drilling, drilling equipment, springs/shock absorbers, etc., can solve the problems of large destructive force, affecting the service life of drilling tools, and poor stability, so as to reduce vibration and impact, Compact structure and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

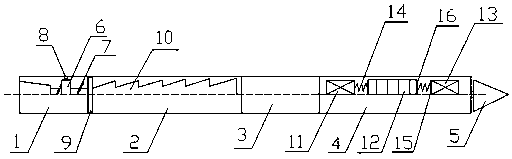

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0021] As shown in the figure, an anti-seismic screw drilling tool according to the present invention includes a bypass valve assembly 1, a hydraulic motor assembly 2, a cardan shaft 3, a transmission shaft assembly 4 and a drill bit 5. The bypass valve Assembly 1, hydraulic motor assembly 2, cardan shaft 3, transmission shaft assembly 4 and drill bit 5 are connected in sequence;

[0022] The bypass valve assembly 1 includes a piston 6, a spring one 7 and a bypass hole 8, the spring one 7 is connected to the piston 6, so that the piston 6 can move between the bypass position and the closed position;

[0023] The hydraulic motor assembly 2 includes a stator 9 and a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com