High-efficiency desulfurization waste liquor salt extraction recycling device

A desulfurization waste liquid and salt recovery technology, which can be used in filtration loops, fixed filter element filters, filtration and separation, etc. It can solve the problems of reduced adsorption and filtration effect, short operation cycle, difficult maintenance, etc., and achieve an increase in filtration specific surface area. , The effect of improving the filtration capacity, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

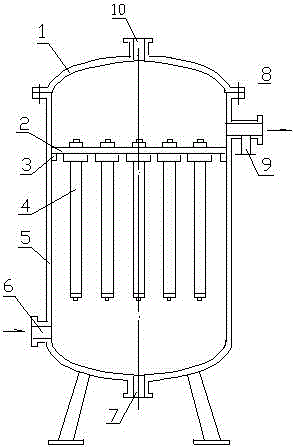

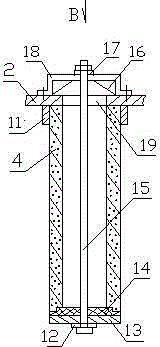

[0019] Example 1, the high-efficiency desulfurization waste liquid salt extraction recovery device is composed of extraction, evaporation, heat preservation, cooling, crystallization and filtration treatment devices combined according to a certain process flow, including a two-stage filter device (coarse filter and fine filter) Filtration), the two-stage filter device is formed by connecting two microporous ceramic filter devices, such as figure 1 , image 3 and Figure 4 The first kind of microporous ceramic filter device is shown. The microporous ceramic filter device includes a tank body 5 and a head 1 made of stainless steel. The lower part of the tank body is provided with a liquid inlet 6 and a sewage outlet 7 for desulfurization waste liquid. The upper part of the tank body is provided with a liquid outlet 8, the tank cover is provided with a backwash port 9 and an exhaust port 10, the backwash port communicates with the liquid outlet, and a stainless steel support pla...

Embodiment 2

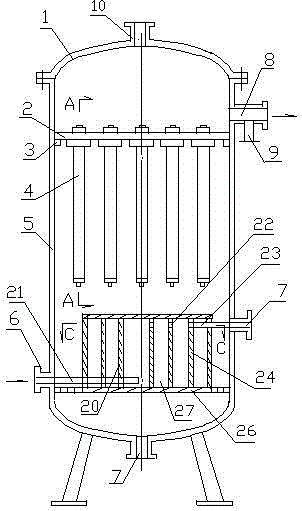

[0020] Embodiment 2, the microporous ceramic filter device described in embodiment 2 except as figure 2 and Figure 5 The structure shown is different from the microporous ceramic filter device of the first structure, and the other structures are the same as those in Embodiment 1. In order to remove particulate impurities in the desulfurization waste liquid entering the microporous filter device more cleanly, ensure that the microporous ceramic tube is not easy to block, improve the filtering effect of the microporous ceramic tube, prolong the filtration period of the microporous ceramic tube, and improve the filtration efficiency , before carrying out the microporous ceramic filtration treatment, pre-filter treatment is carried out, that is, the bottom of the microporous ceramic tube is provided with a base plate 26, a cover plate 20, a liquid pipe 21, a sewage pipe 23 and a separation plate 24 all made of stainless steel. The filter chamber 27 with a liquid port 25, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com