Production system and production method of nano-scale molybdenum disulfide

A molybdenum disulfide, production system technology, applied in the directions of molybdenum sulfide, chemical instruments and methods, separation methods, etc., can solve problems such as low product quality and environmental pollution, achieve high input cost, solve environmental pollution problems, and high feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

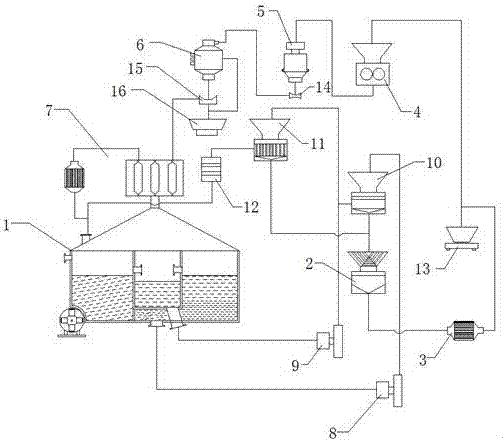

[0040] Such as Figure 1 to Figure 3 As shown, a nano-scale molybdenum disulfide production system includes a reaction sedimentation tank 1, a cleaning device 2, a vacuum dryer 3, a crusher 4, a powder crusher 5 and a gas-solid reactor 6.

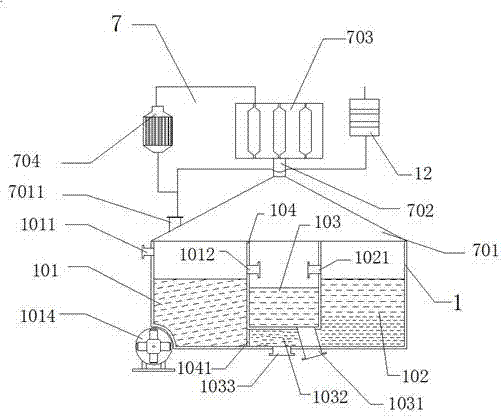

[0041] The reaction sedimentation tank 1 comprises a reaction tank 101, a concentration tank 102, a supernatant liquid pool 103 between the reaction tank 101 and the concentration tank 102, and a waste gas recovery device 7 on the top of the reaction tank 101. The reaction sedimentation tank 1 is used for Reaction and precipitation intermediates such as figure 2 As shown, the reaction pool 101, the supernatant pool 103 and the concentration pool 102 are arranged in sequence, and they are isolated from each other by the isolation plate 104. The upper side of the reaction pool 101 is provided with a raw material inlet 1011, which is used for raw materials to enter the reaction pool. In 101, the other side is provided with a clear liquid out...

Embodiment 2

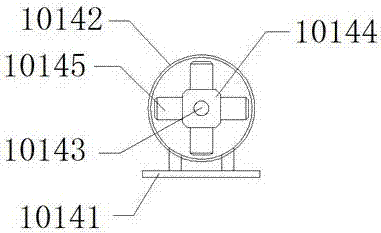

[0068] Embodiment two is the same as embodiment one, and its difference is that the structure of reaction sedimentation tank 1 is different, as Figure 4 As shown, the reaction sedimentation tank 1 includes a reaction tank 101 and a concentration tank 102. At least one bottom of the reaction tank 101 is recessed to form an inner recess 1013, and the inner recess 1013 is equipped with a permanent magnetic induction device 1014 that drives the solution to flow obliquely. The bottom of 102 is provided with slurry outlet 1033, reaction tank 101 and concentration tank 102 are separated by isolation plate 104, and isolation plate 104 bottom is provided with slidable movable plate 1041 or switch valve, and reaction tank 101 is connected with movable plate 1041 or switch valve. The concentration tank 102 is connected, the slurry outlet 1033 is connected to the slurry pump B9, and the output port of the slurry pump B9 is connected to the plate and frame filter 11, that is, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com