Capacity-increasing and energy-saving flexible cable used in power station

A technology of flexible cables and power stations, which is applied to power cables, circuits, and electrical components with shielding layers/conductive layers, and can solve problems such as heavy cable laying workload, lack of production capacity, and unbalanced three-phase loads. Good for heat dissipation, good tensile strength, and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are preferred embodiments of the present invention, and the present invention can be implemented by any method according to the content described in the description.

[0023] Describe in detail below in conjunction with accompanying drawing:

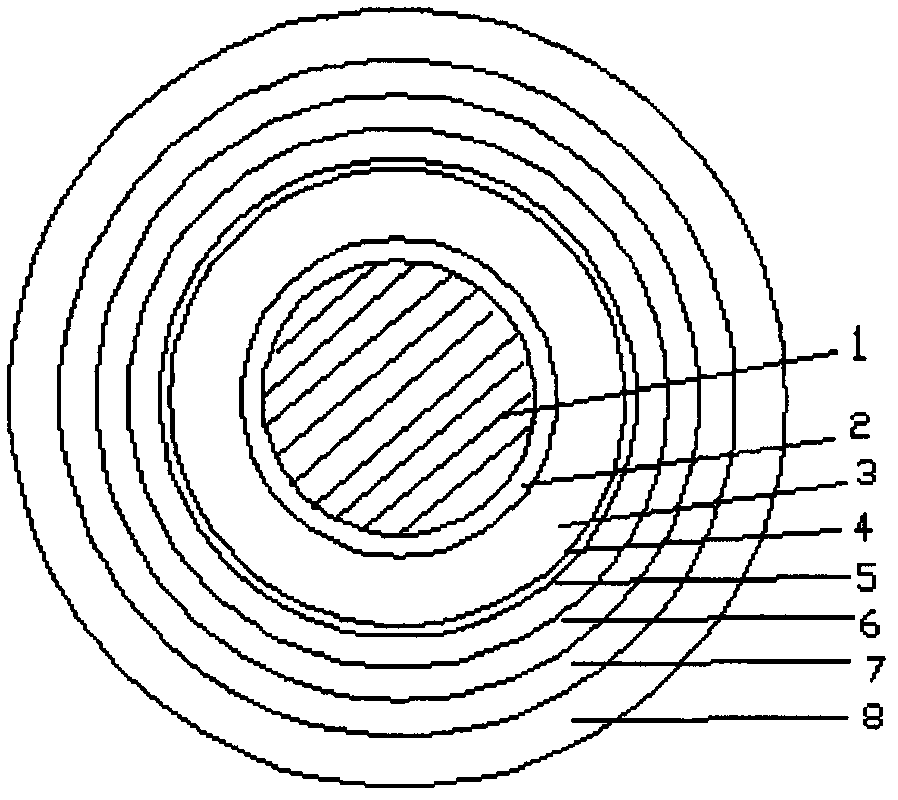

[0024] See attached figure 1 , the capacity-increasing energy-saving flexible cable for power stations includes: conductor (1), conductor shielding layer (2), insulation layer (3), insulation shielding layer (4), copper tape armor layer (5), outer insulation layer (6) , flame retardant layer (7), sheath layer (8).

[0025] The conductor (1) is made of multiple strands of tinned copper wire; the conductor shielding layer (2) and the insulating shielding layer (4) are extruded from semi-conductive rubber; the material of the insulating layer (3) is ethylene-propylene rubber; copper tape armor The armor layer (5) adopts S-shaped double-button armor structure; the outer insulating layer (6) is made of multi-layered pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com