Organic light-emitting diode production and recovery equipment

A technology of light-emitting diodes and recycling equipment, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to guarantee the overall quality of light-emitting diodes, poor guiding and positioning effects of light-emitting diodes, and inconvenient and stable feeding, so as to reduce collision damage, High practicality, convenient and precise cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

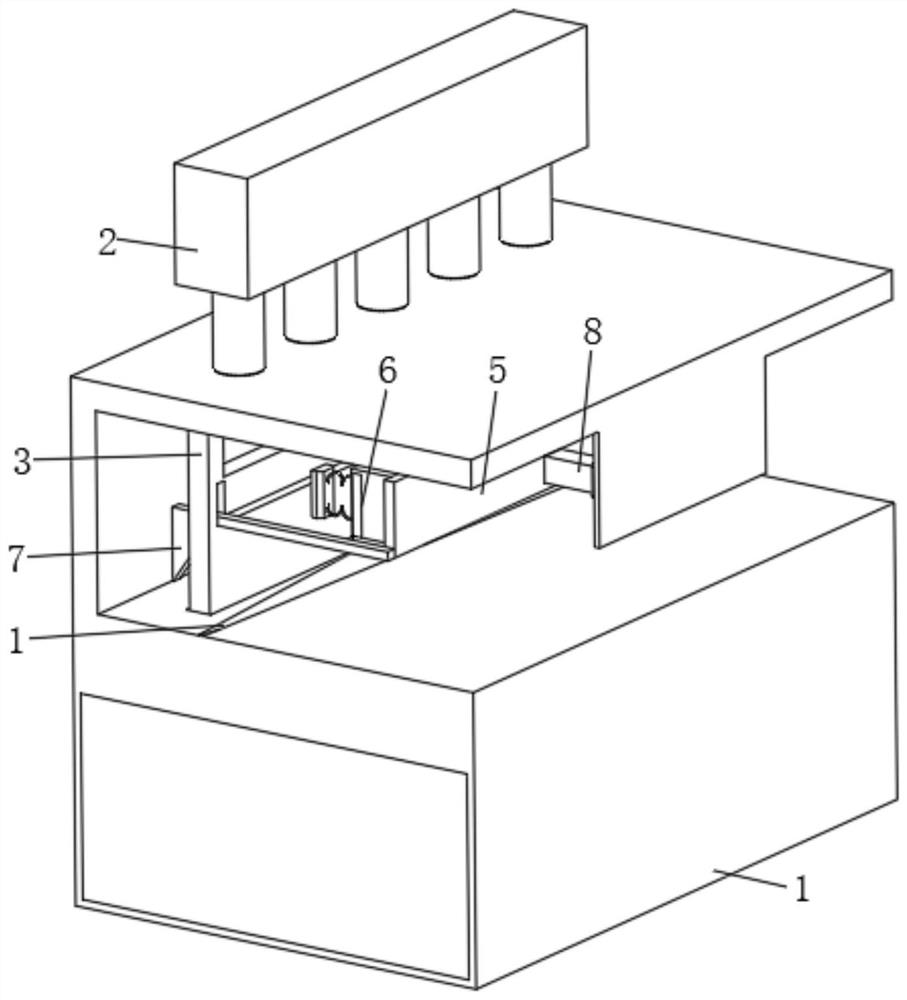

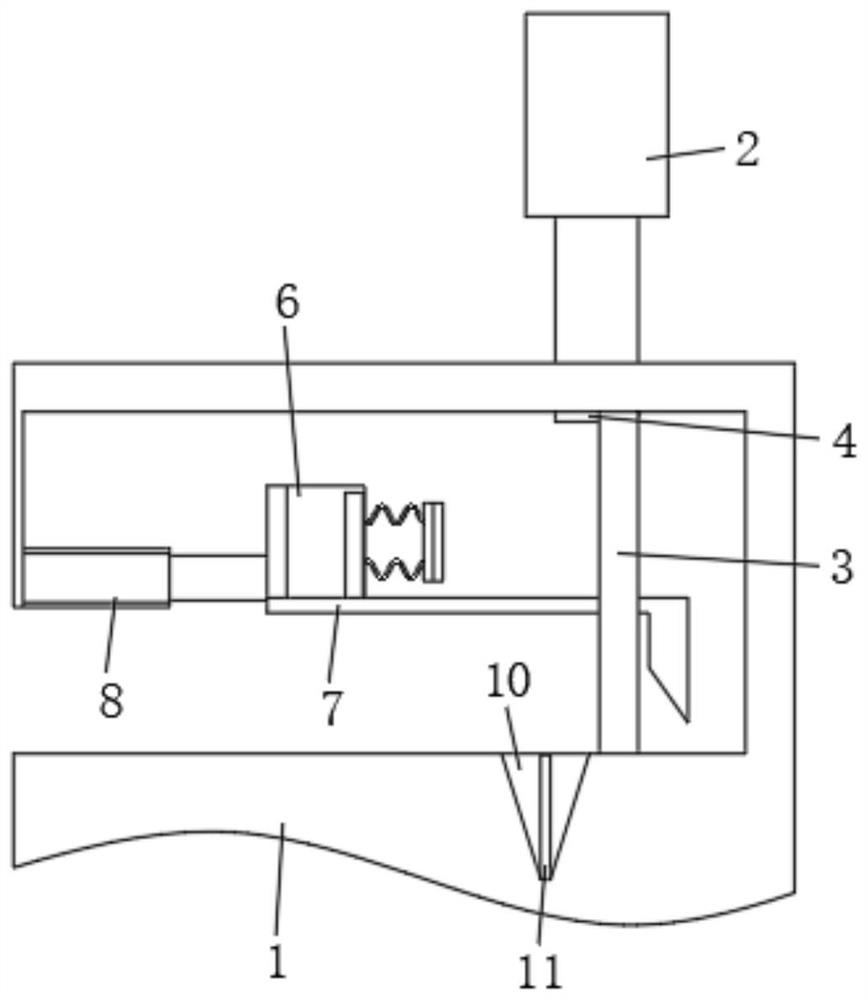

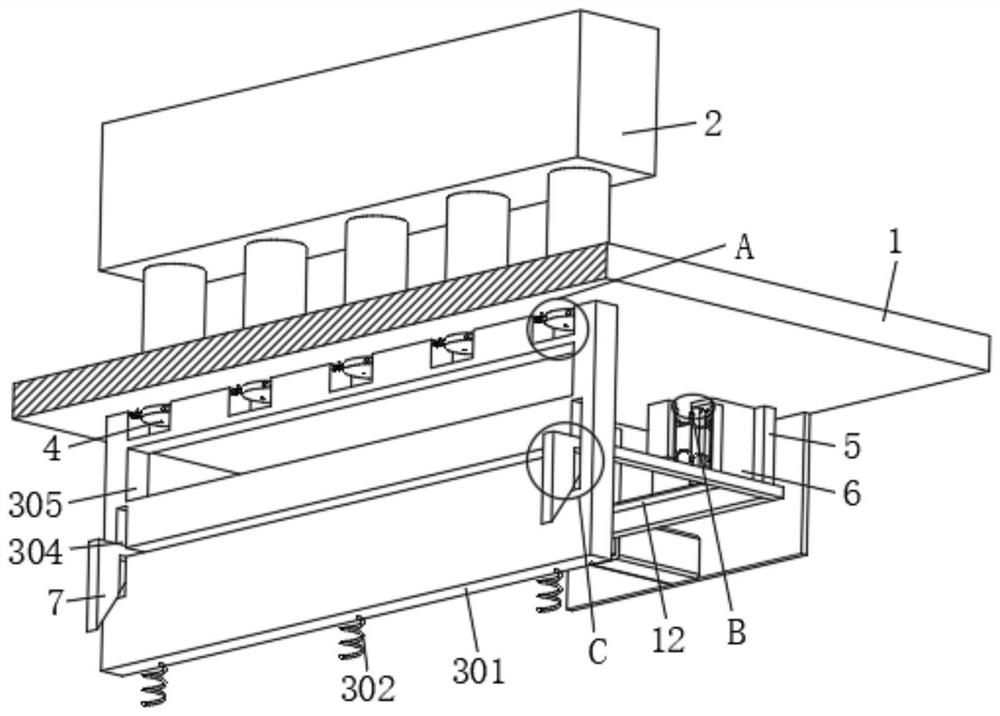

[0033] see Figure 1 to Figure 7 , the embodiment of the present invention provides a kind of organic light-emitting diode production and recycling equipment, which is mainly suitable for the cutting process of light-emitting diodes. The base 301 and the wedge-shaped groove 304 opened on the surface of the base 301, the surface of the base 301 is rotatably installed with several limit assemblies 4 for supporting the light-emitting diodes, the limit assembly 4 includes a receiving tray 403, and the receiving tray 403 in this embodiment The setting is circular, and the surface of the workbench 1 is provided with several round holes corresponding to the material receiving tray 403. The inside of the material receiving tray 403 is slidably installed with a sliding assembly 9, and the surface of the workbench 1 is fixedly installed with a feeding mechanism 2. Because the light-emitting diode is delivered to the corresponding limit component 4 through the round hole with the pin fac...

Embodiment 2

[0039] see Figure 1 to Figure 9 , on the basis of Embodiment 1, a first spring 302 is fixedly installed between the bottom of the base 301 and the surface of the workbench 1, and under the action of the first spring 302, the base 301 always has a tendency to move upward; the base 301 There are several square holes 303 for placing several limiting components 4 through the surface, and an avoidance hole 305 is also formed through the surface of the base 301. The avoidance hole 305 is divided into two parts, and one part corresponds to the cutting mechanism 12 to form an avoidance. The other part is located below the square hole 303, which avoids the processed pins of the light-emitting diodes in the later stage when blanking.

[0040] The receiving tray 403 is divided into two symmetrical and identical semicircles, and each semicircle is provided with a guide hole 404 concave toward the center. Keeping parallel with the base 301, the guide hole 404 is designed in a funnel shap...

Embodiment 3

[0046] see Figure 1 to Figure 10 , on the basis of the second embodiment, the surface of the partition plate 5 and the top of the cutting mechanism 12 are fixedly installed with several mobile assemblies 6 corresponding to the positions of several receiving trays 403 one-to-one, which are used to realize the cutting process. LED protection.

[0047] The moving assembly 6 includes a wedge block 602 and a housing 601 fixedly connected to the partition 5, the wedge block 602 is fixedly connected to the inner wall of the housing 601 through a second spring 603, side plates 604 are slidably installed on both sides of the housing 601, The opposite sides of the two side plates 604 and both sides of the wedge block 602 are provided with corresponding inclined surfaces. When the wedge block 602 is in contact with the two side plates 604 at the same time, pressing the side plates 604 through the inclined surfaces can make the two side plates 604 is relatively far away. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com