Patents

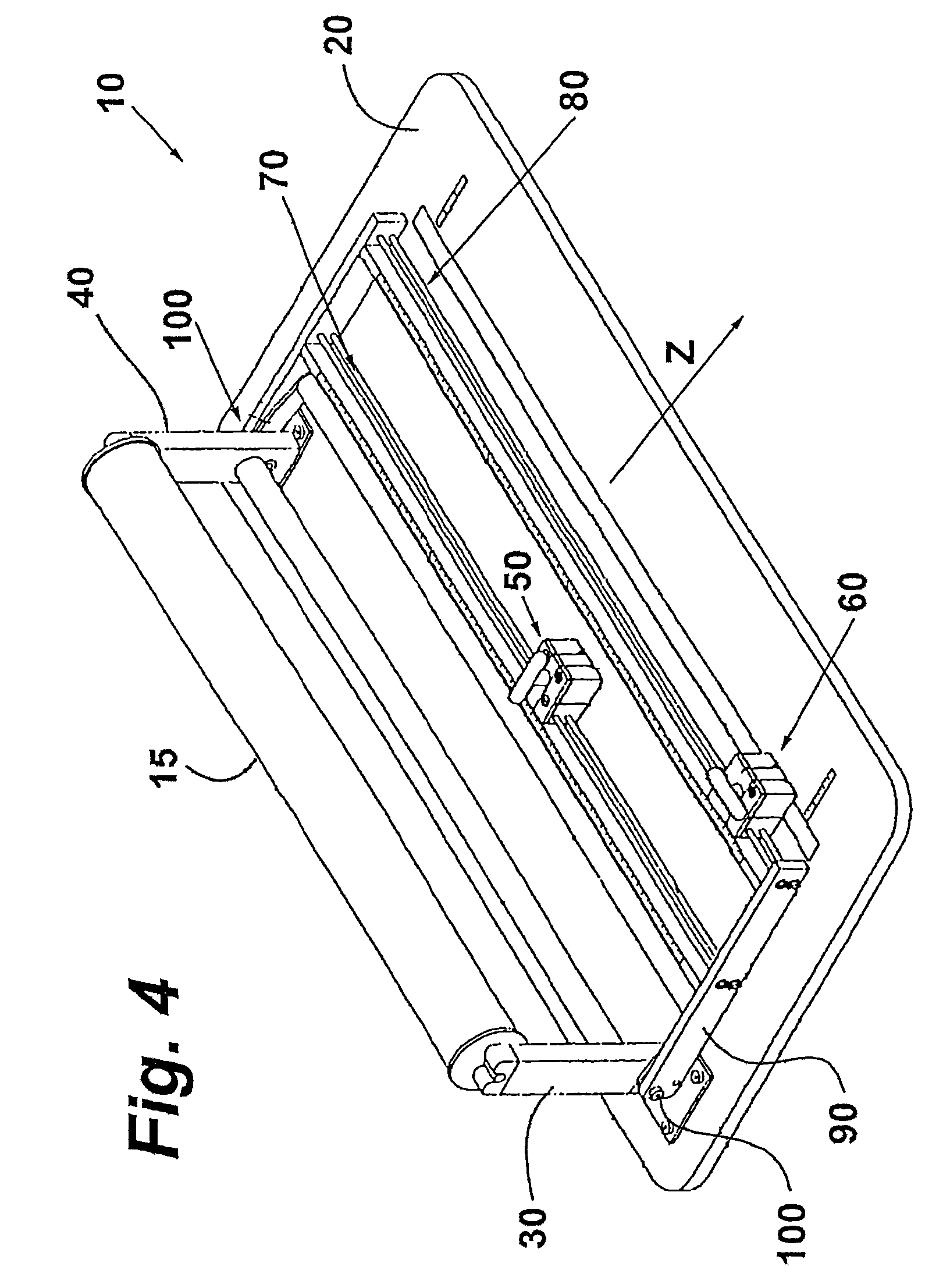

Literature

39results about How to "For accurate cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

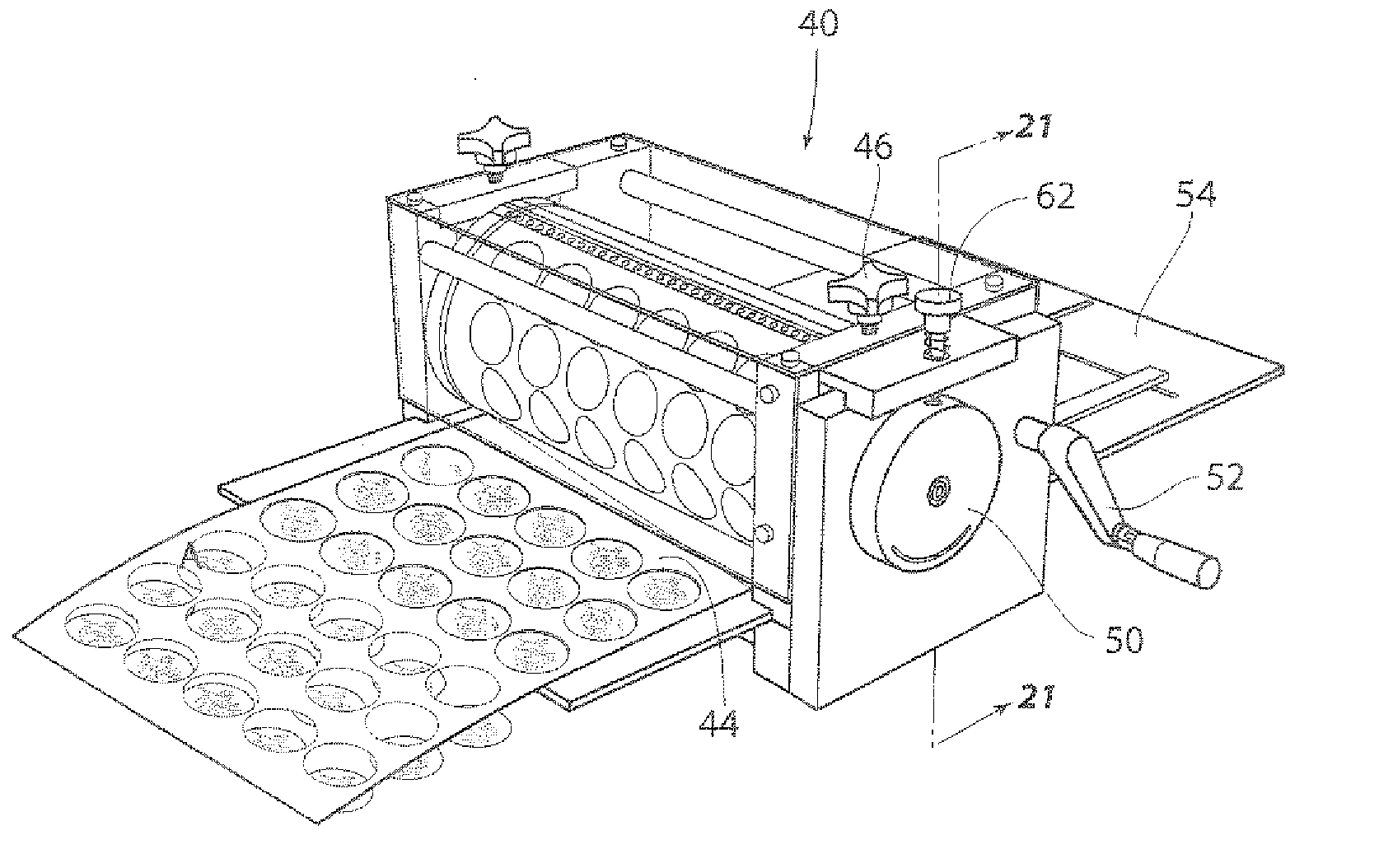

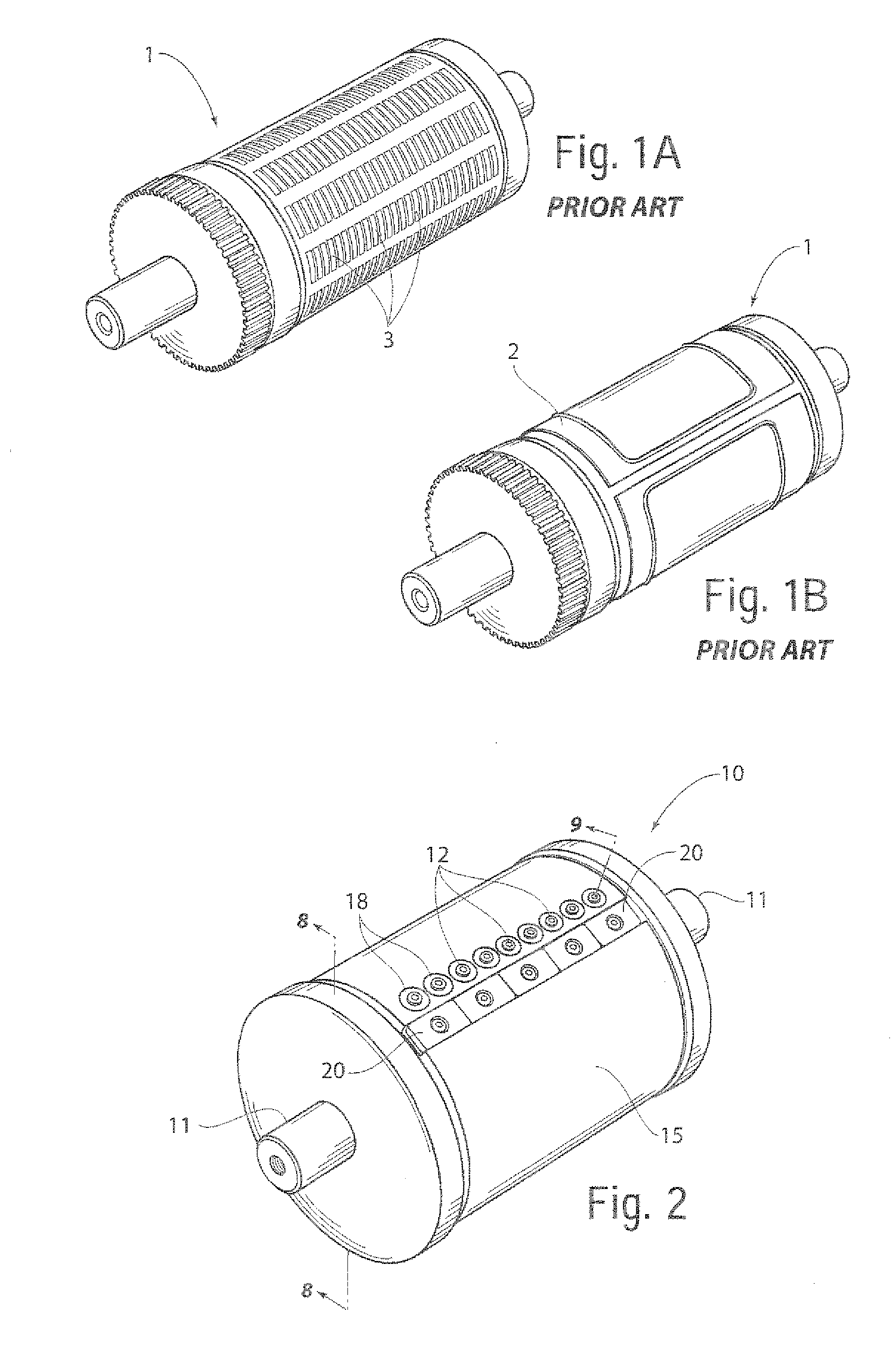

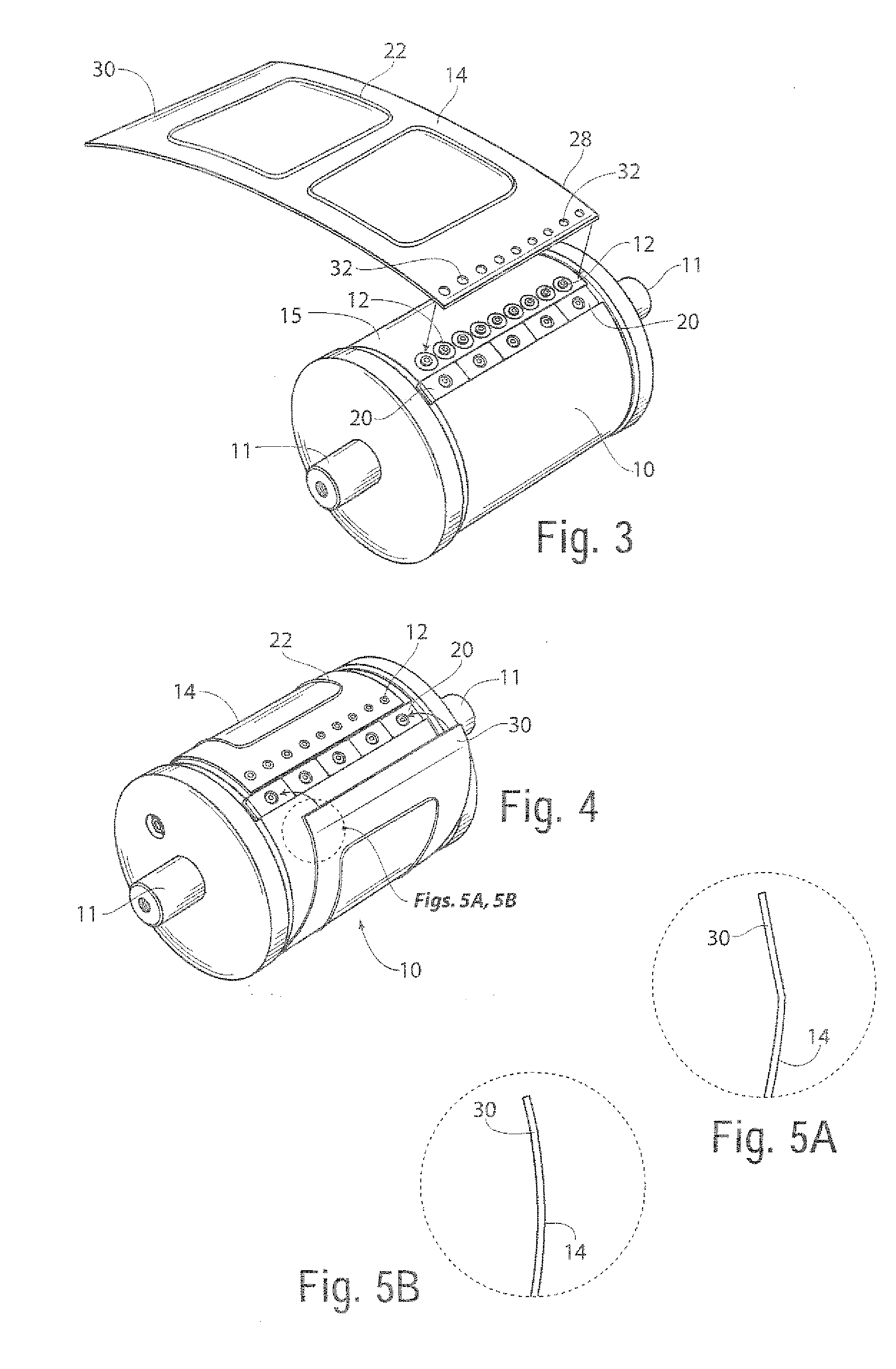

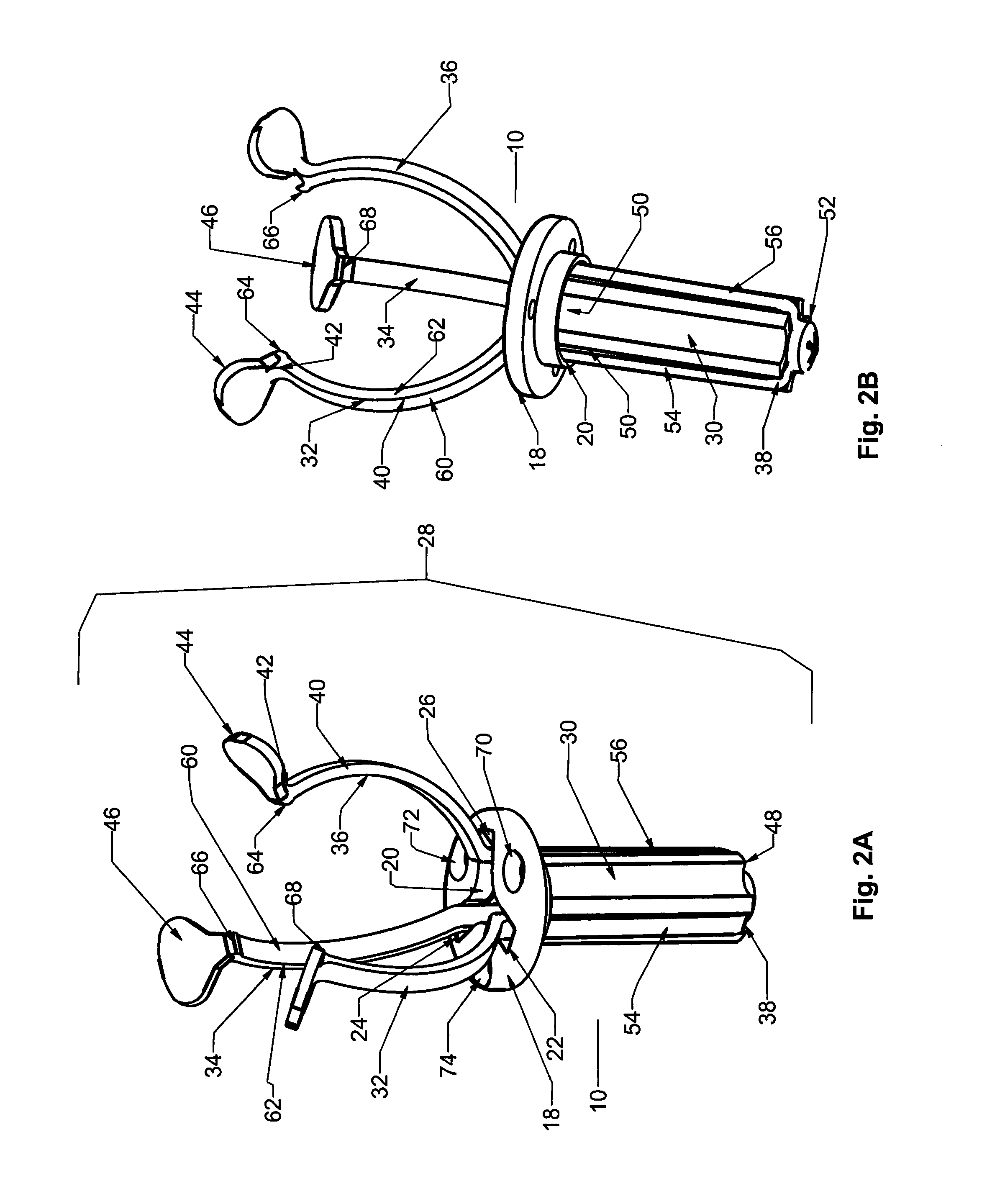

Flexible die retaining system and method

InactiveUS20140260851A1For accurate cuttingStock shearing machinesMetal working apparatusEngineeringDie cutting

A method and apparatus for producing shaped articles from a web material is disclosed. The apparatus generally includes a rotary cylinder adapted to receive a flexible cutting die, and an anvil roller operating in cooperating rotational movement with the rotary cylinder. The cylinder includes attachment mechanisms that are adapted to be received by apertures in the flexible cutting die to thereby secure the cutting die to the cylinder. The apparatus die cuts web material into predetermined shapes.

Owner:BEAUDRY WALLACE J

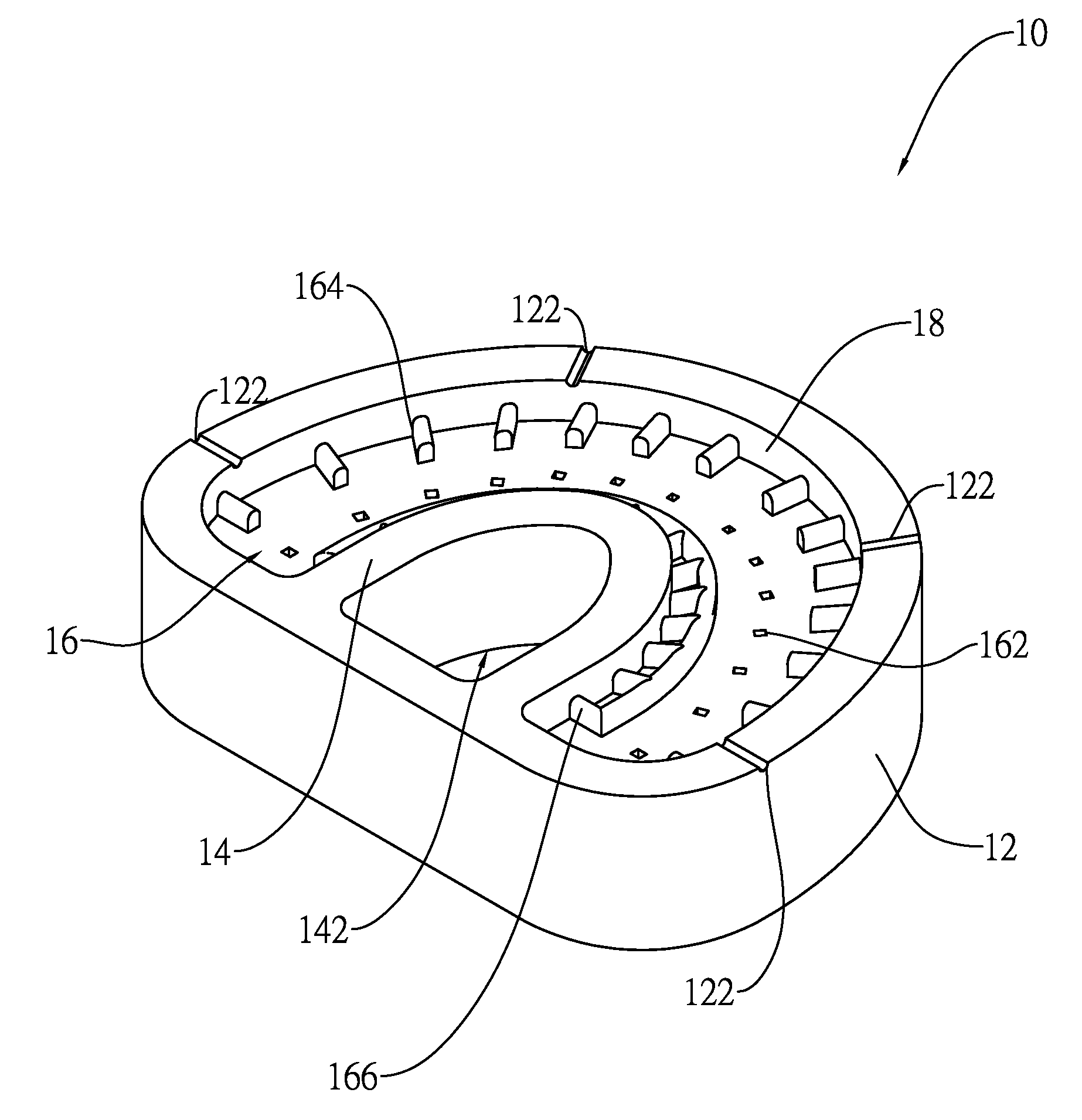

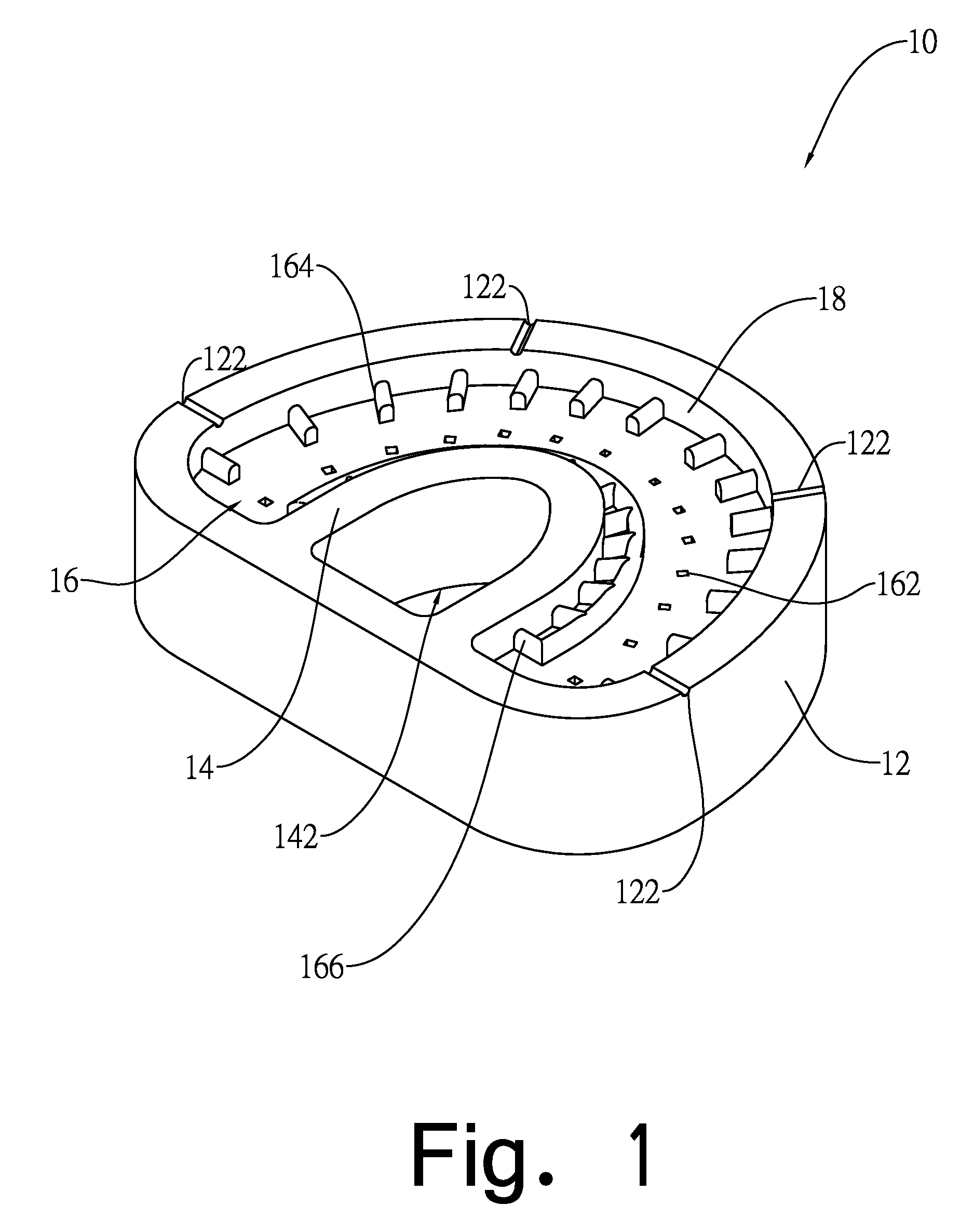

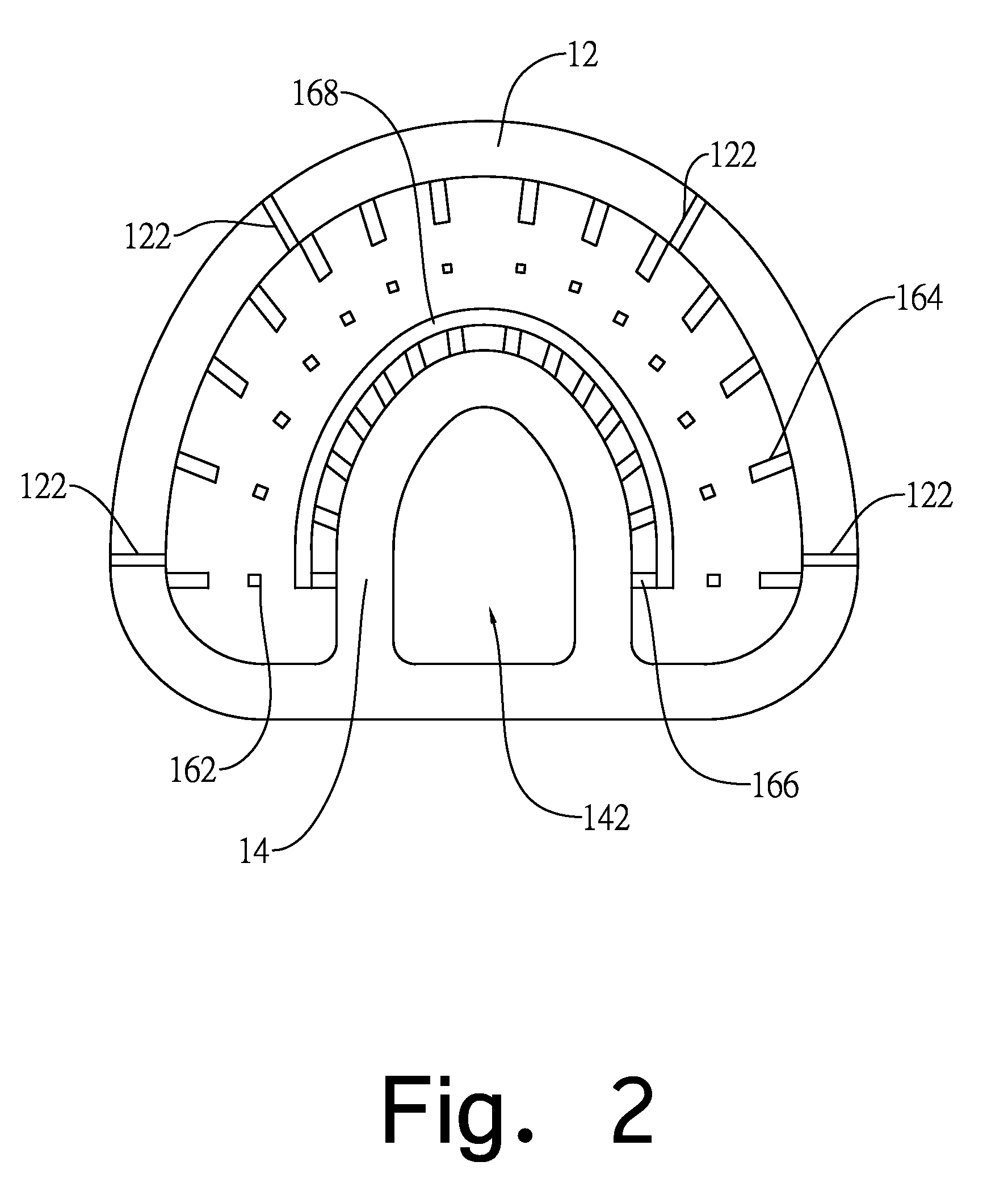

Plaster dental cast gum plate molding mold

InactiveUS20090208895A1Consume moreIncrease the amount of deformationImpression capsPlaster CastsDental cast

A plaster dental cast gum plate molding mold for molding a plaster dental cast gum plate having pins is disclosed. The body of the mold is made of an elastic material, having a cavity surrounded by a smoothly arched inner wall, a smoothly arched outer wall and a bottom wall, a plurality of insertion holes cut through the bottom wall for the insertion of a respective pin, and a plurality of alignment pegs respectively perpendicularly extending from the smoothly arched outer wall and suspending in the cavity so that the molded plaster cast gum plate has dents corresponding to the alignment pegs for quick recognition of the locations of the pins after positioning of the plaster cast gum plate on a base plate and bonding of a dental cast to the flat top surface of the plaster cast gum plate for enabling the dentist to cut one individual tooth model accurately.

Owner:SONG YOUNG INT

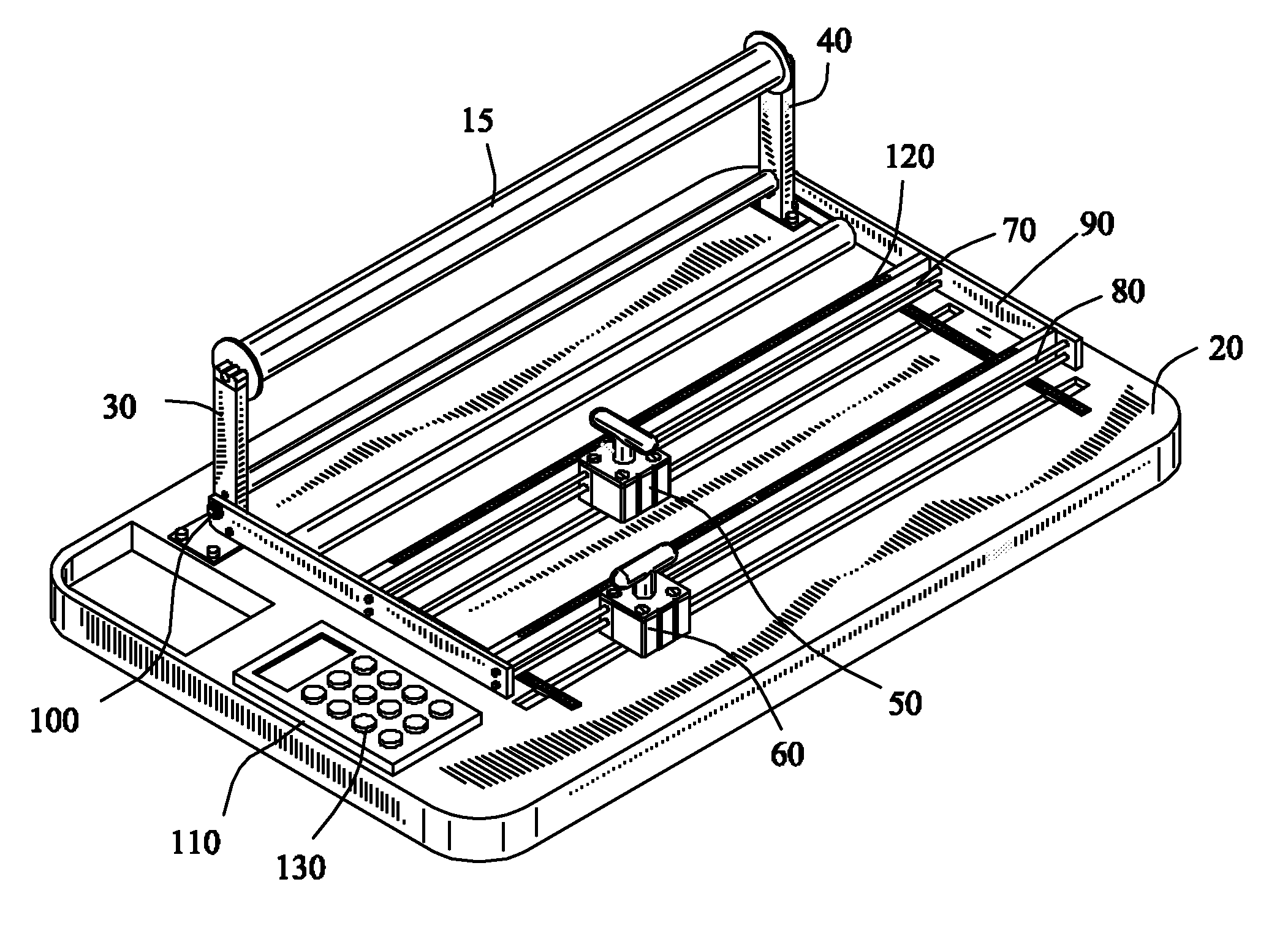

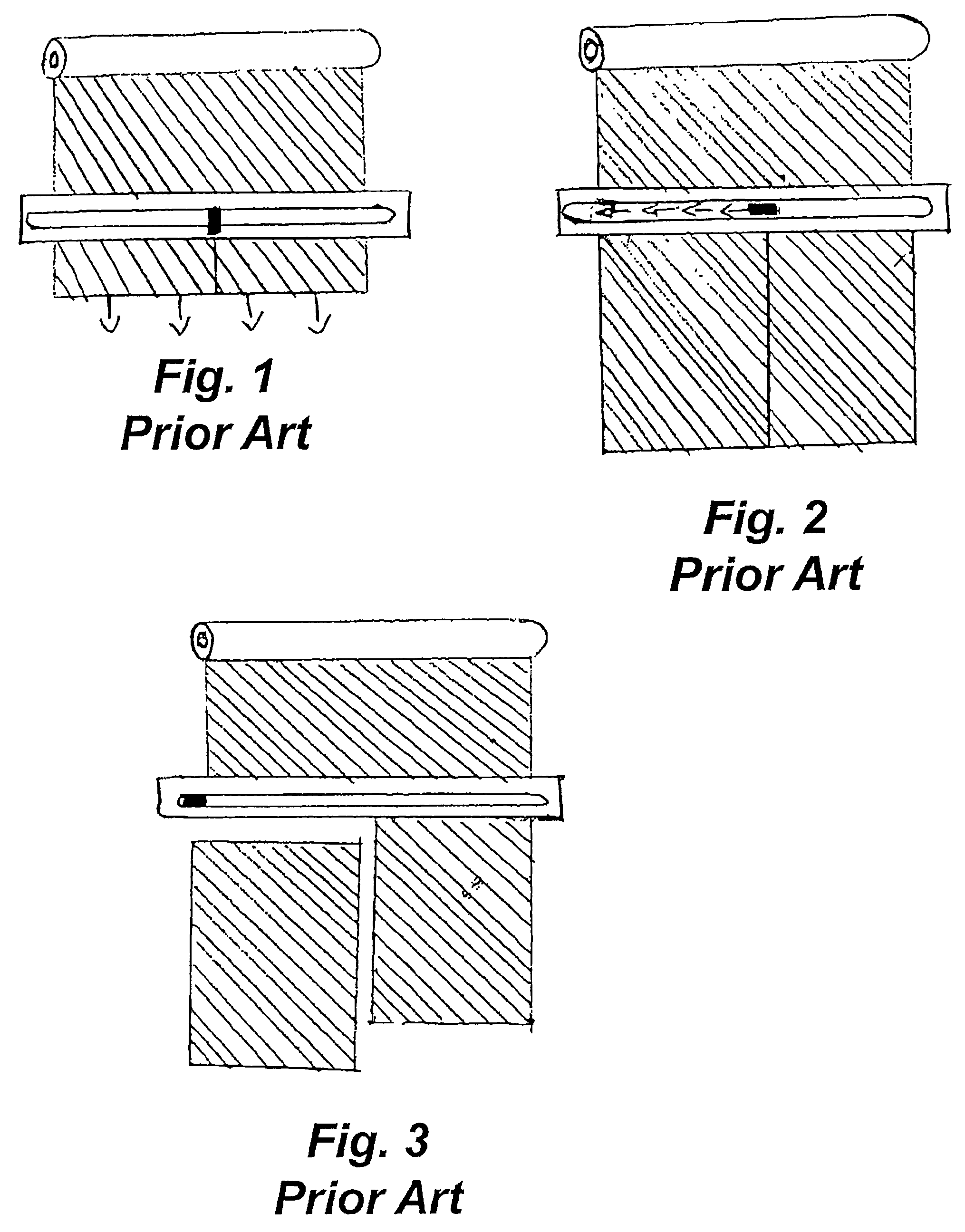

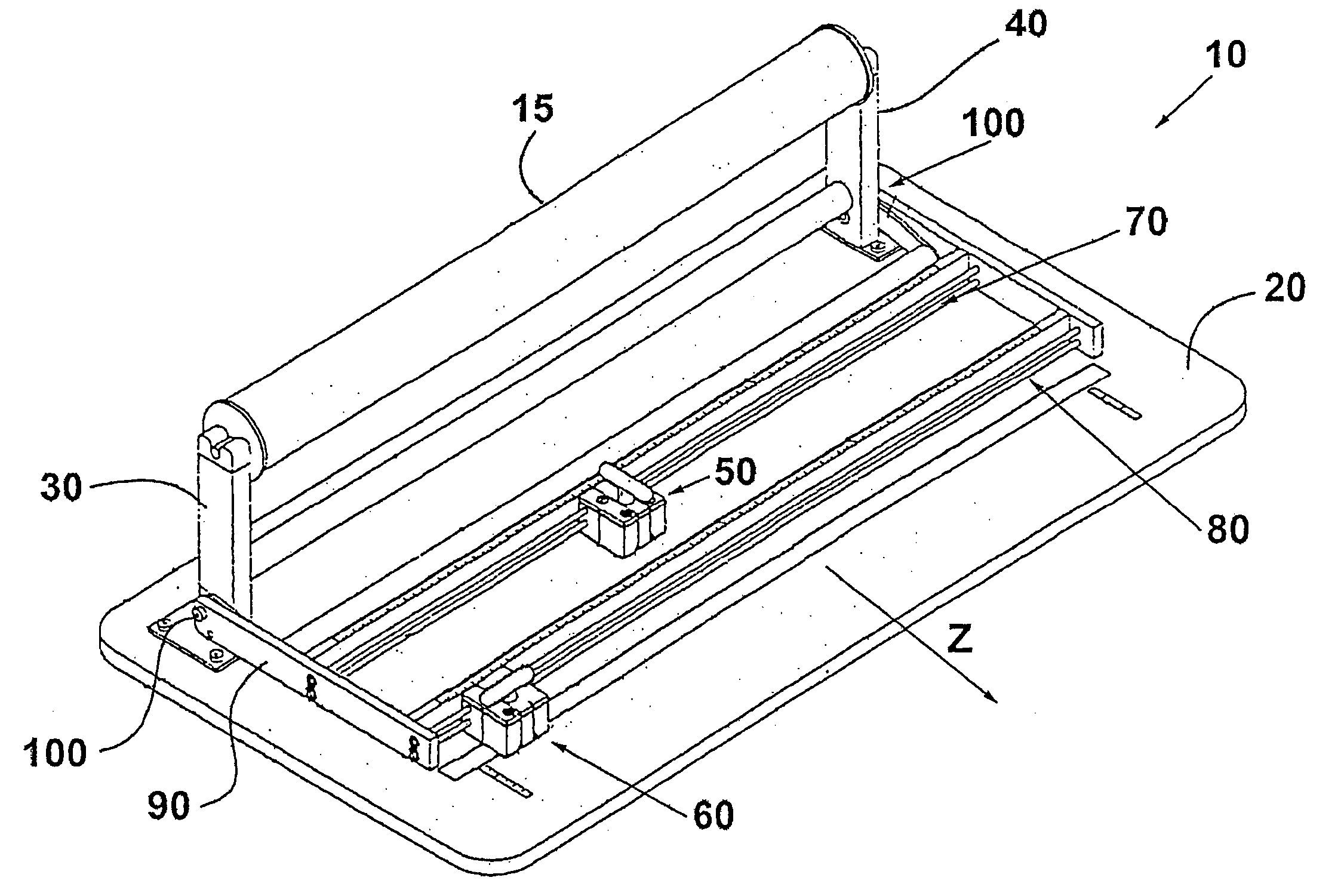

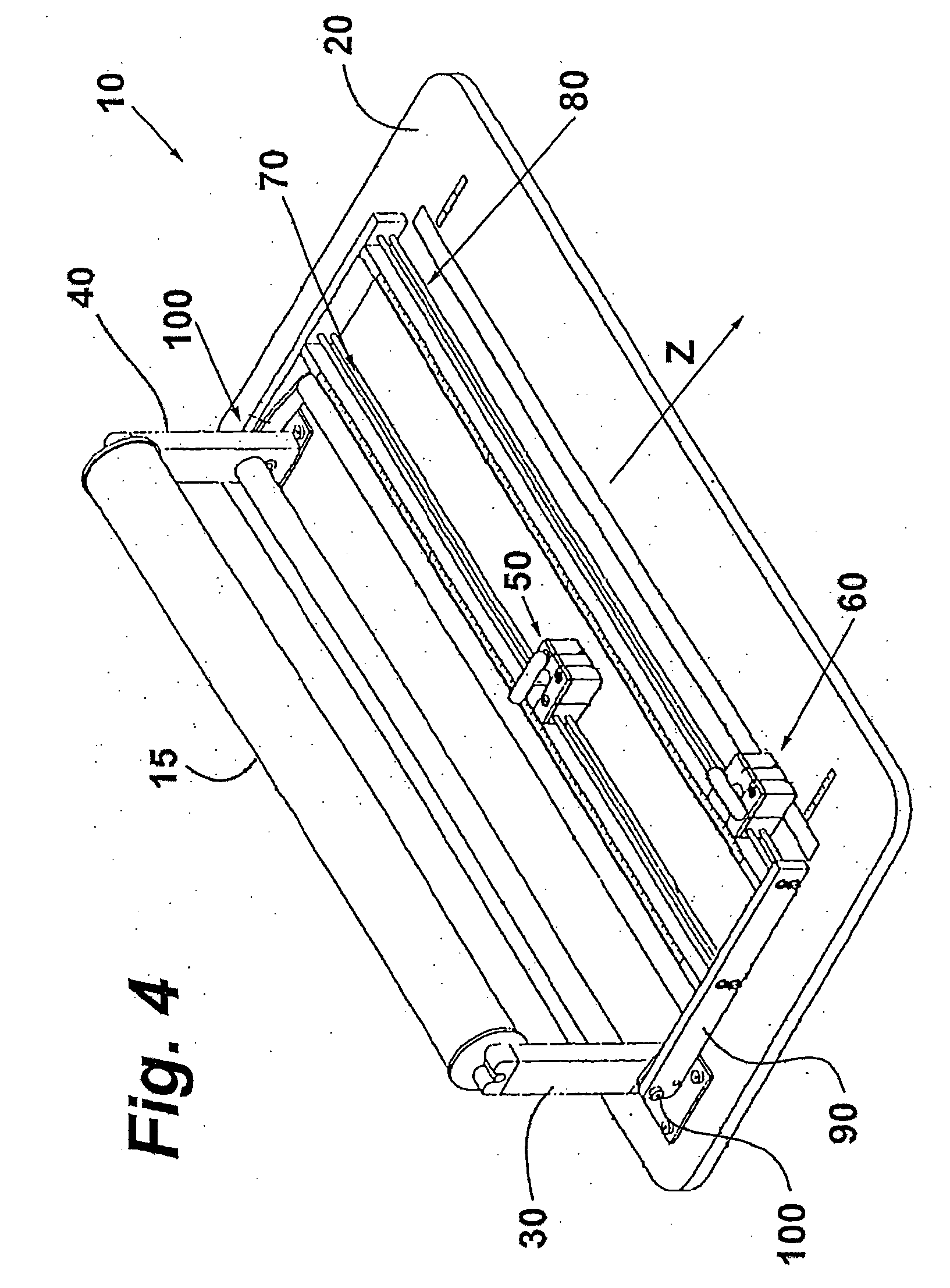

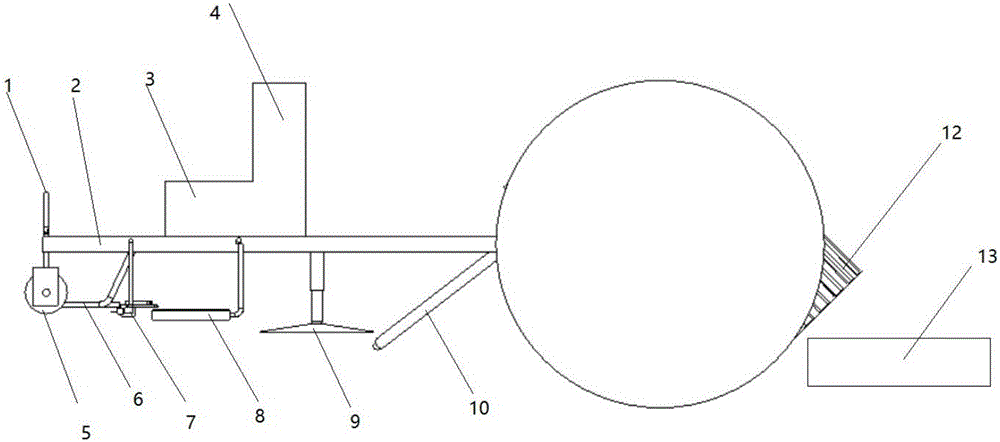

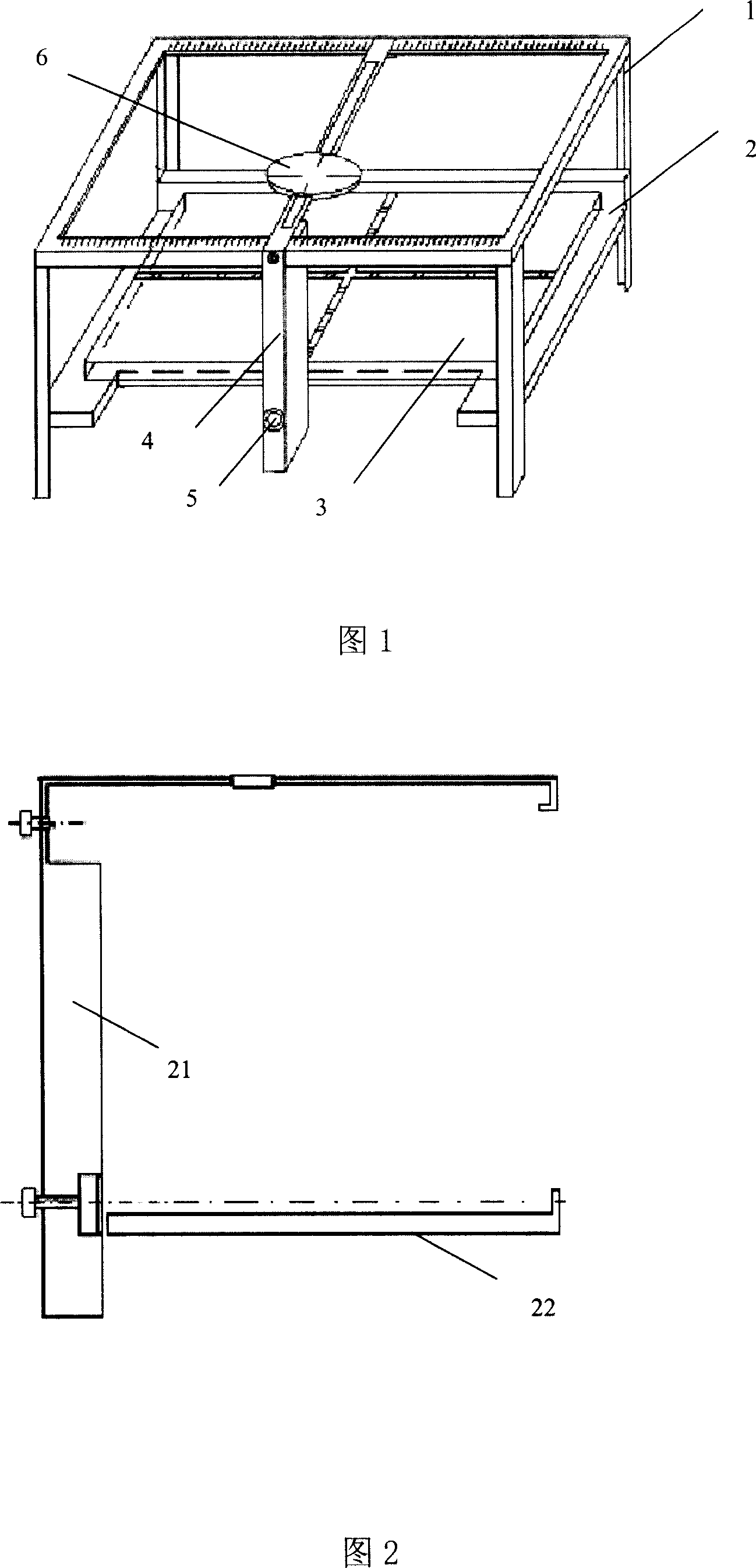

Rolled media cutting device

InactiveUS7726222B2For accurate cuttingAccurate placementShearing machinesMetal working apparatusEngineeringComputing systems

A cutting device comprises a support to hold a roll of rolled media, a surface upon which the media is unrolled, and first and second cutting guides, each oriented substantially perpendicular to the media's unrolling path and supporting first and second cutters. The first cutter is movably supported by the first cutting guide and is capable of cutting the rolled media substantially parallel to the unrolling path. The second cutter is movably supported by the second cutting guide and is capable of cutting the rolled media substantially perpendicular to the unrolling path. The cutting device further includes a computing system to calculate the amount of rolled media to be dispensed and how best to cut the rolled media.

Owner:ENDRESEN KARA

Rolled media cutting device

InactiveUS20080302225A1For accurate cuttingAccurate placementShearing machinesMetal working apparatusEngineeringComputing systems

A cutting device comprises a support to hold a roll of rolled media, a surface upon which the media is unrolled, and first and second cutting guides, each oriented substantially perpendicular to the media's unrolling path and supporting first and second cutters. The first cutter is movably supported by the first cutting guide and is capable of cutting the rolled media substantially parallel to the unrolling path. The second cutter is movably supported by the second cutting guide and is capable of cutting the rolled media substantially perpendicular to the unrolling path. The cutting device further comprises means for releasably securing the first cutter at a desired width position along the first cutting guide. The cutting device further includes a computing system to calculate the amount of rolled media to be dispensed and how best to cut the rolled media.

Owner:ENDRESEN KARA

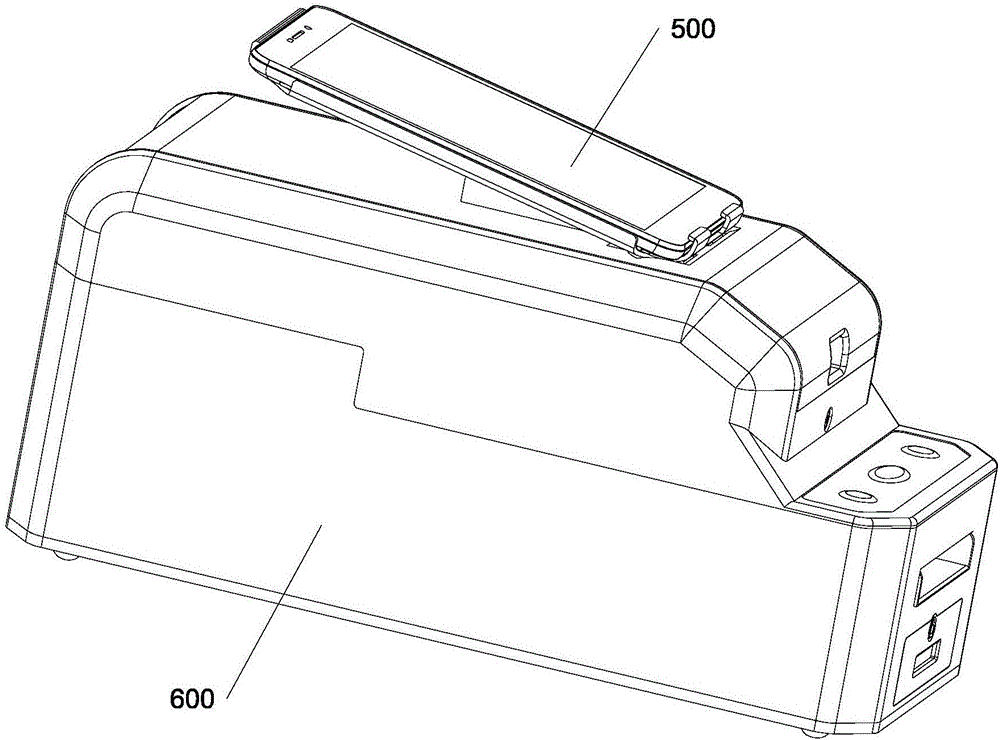

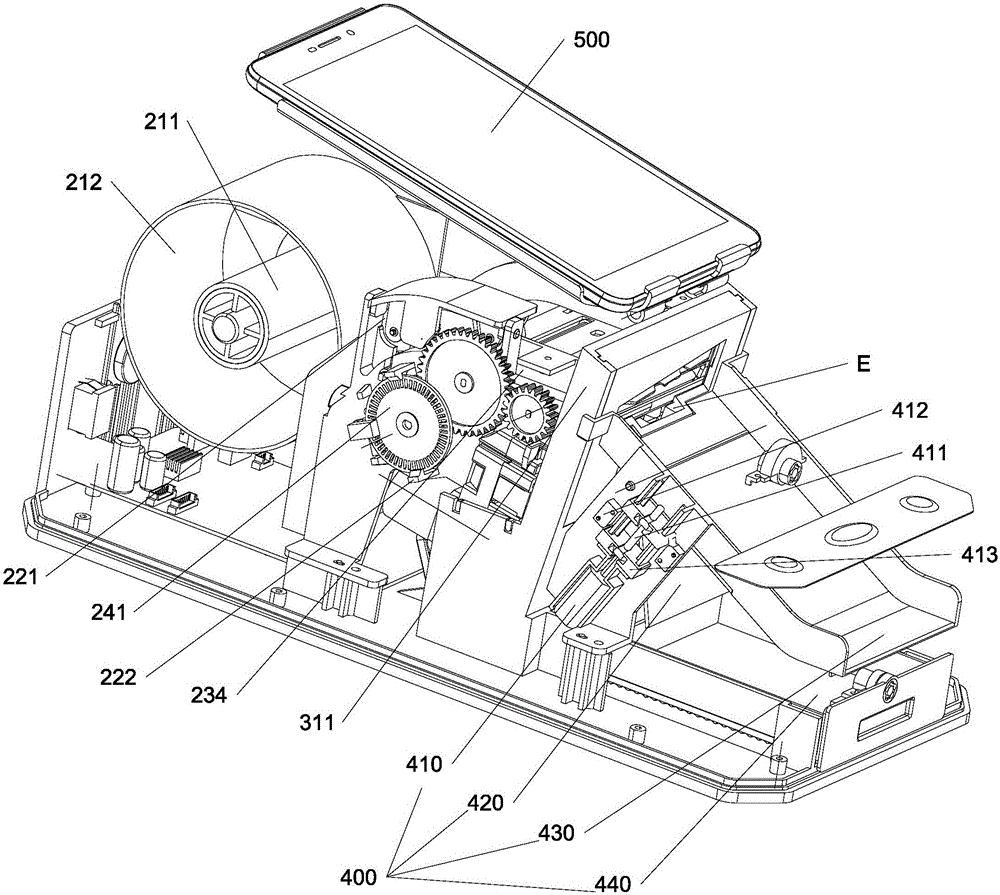

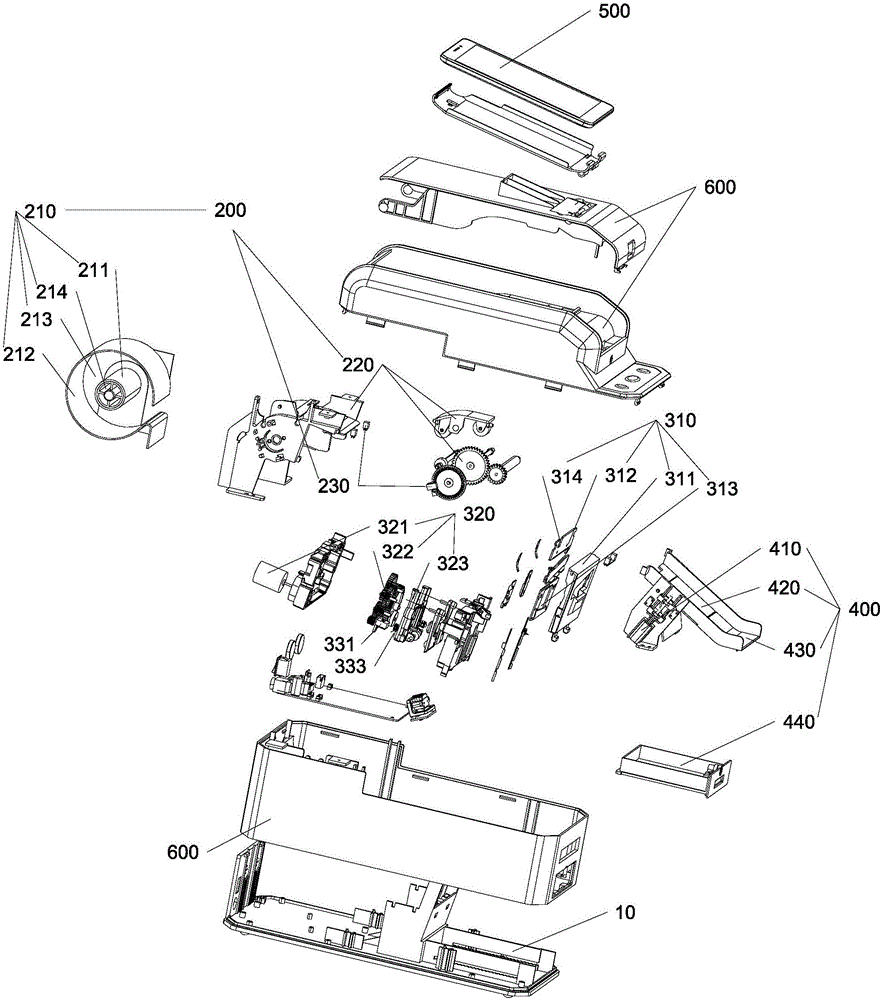

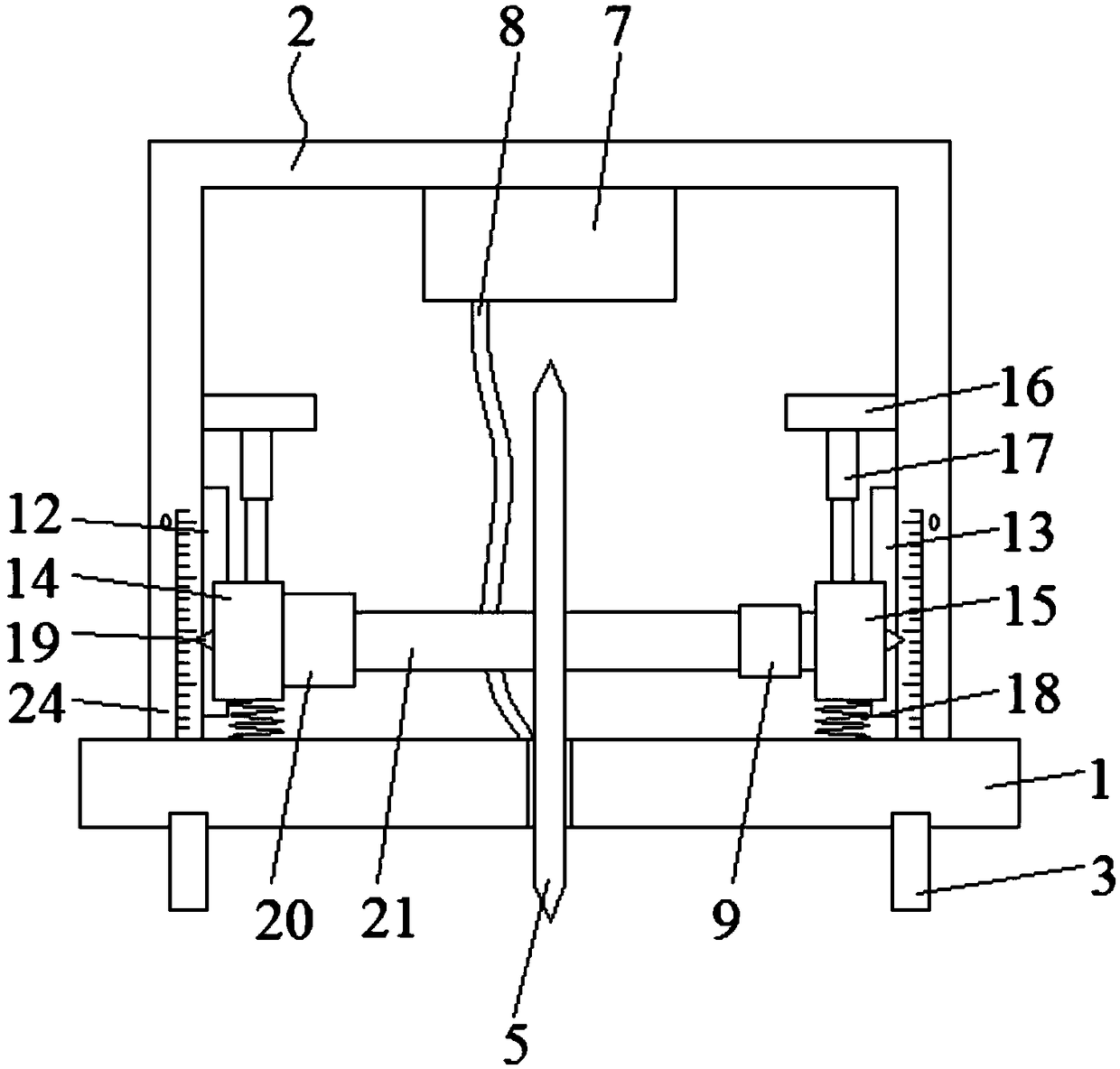

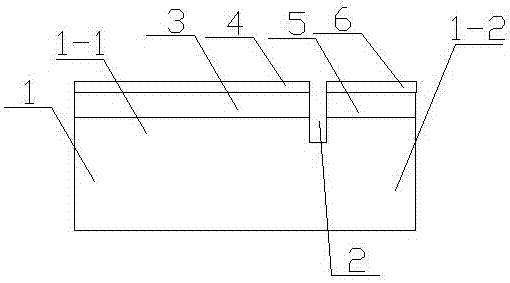

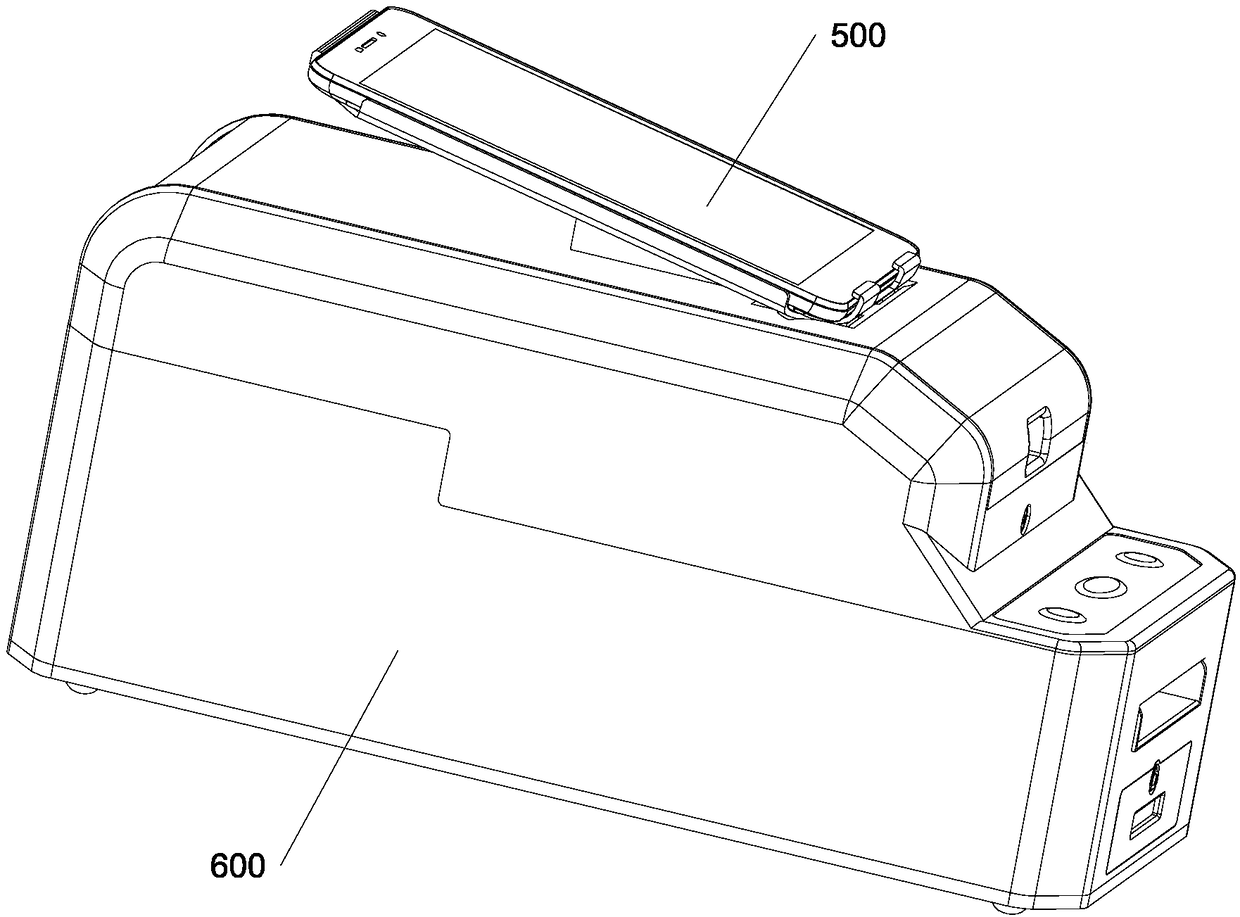

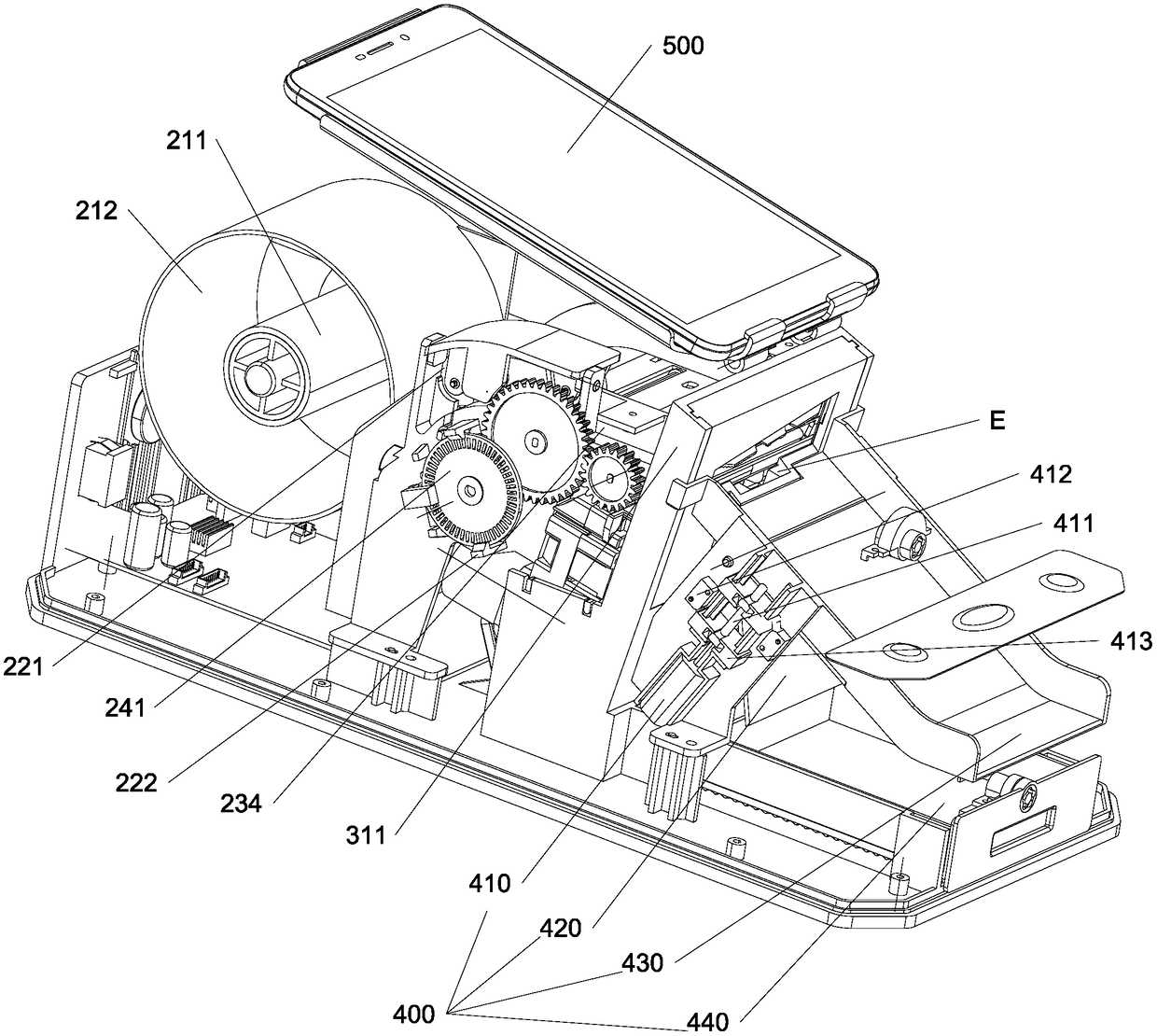

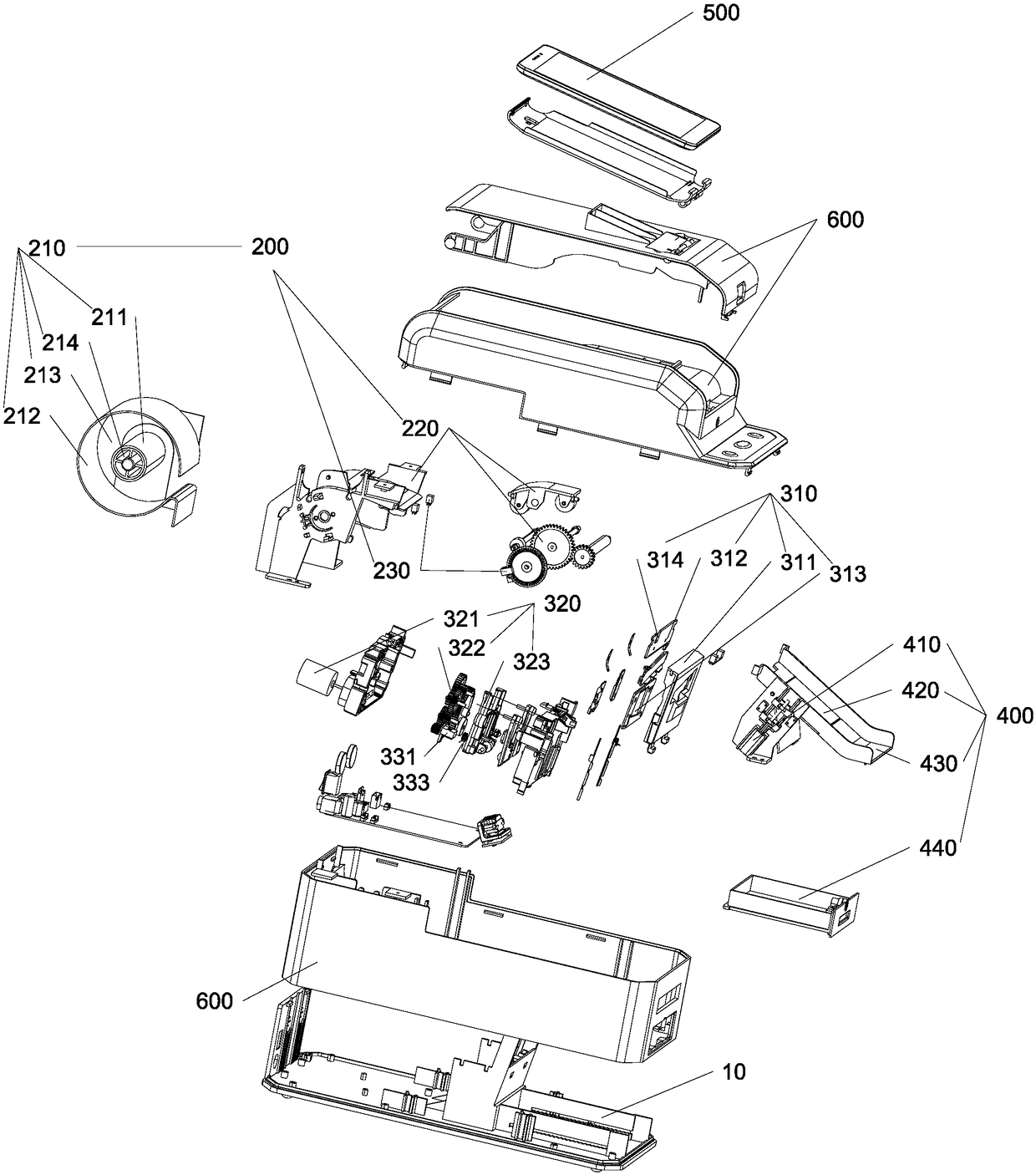

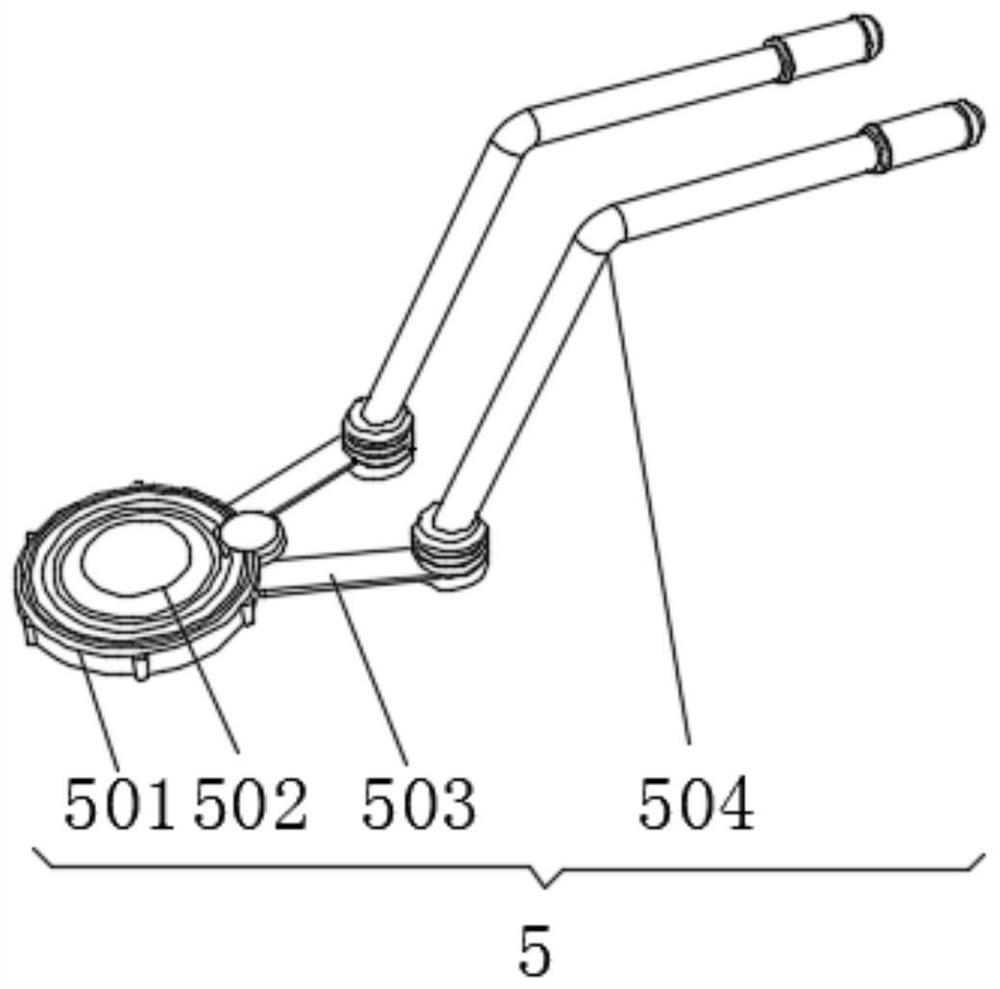

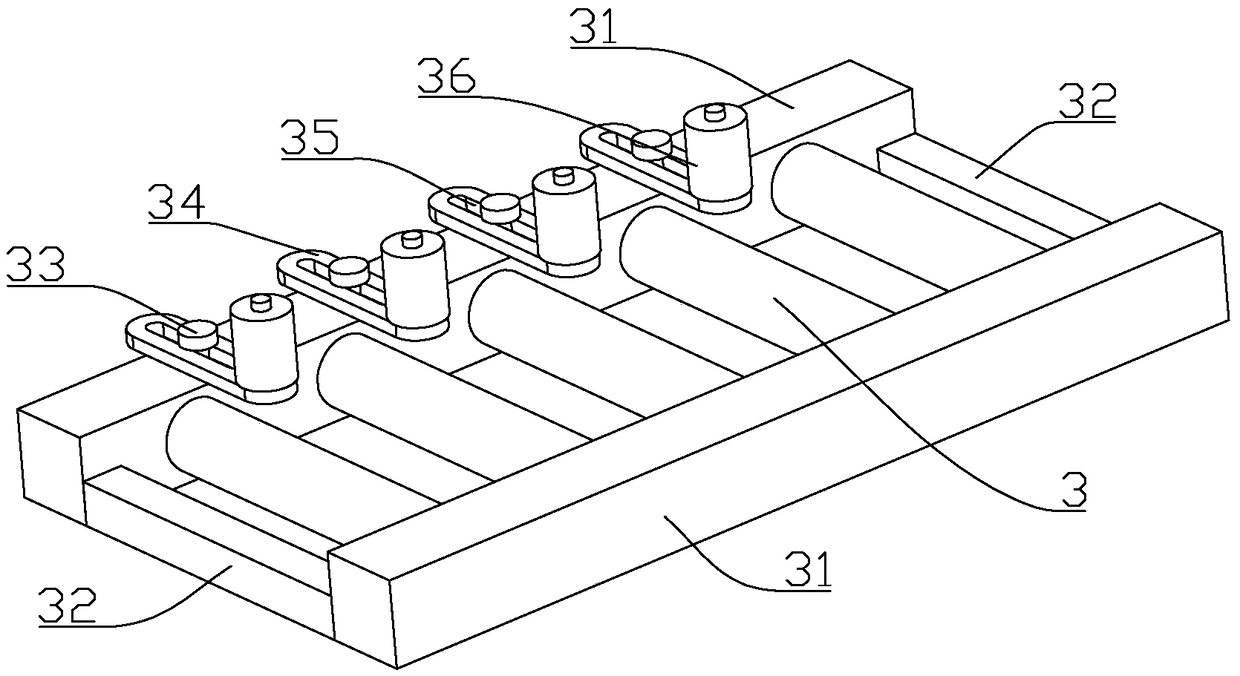

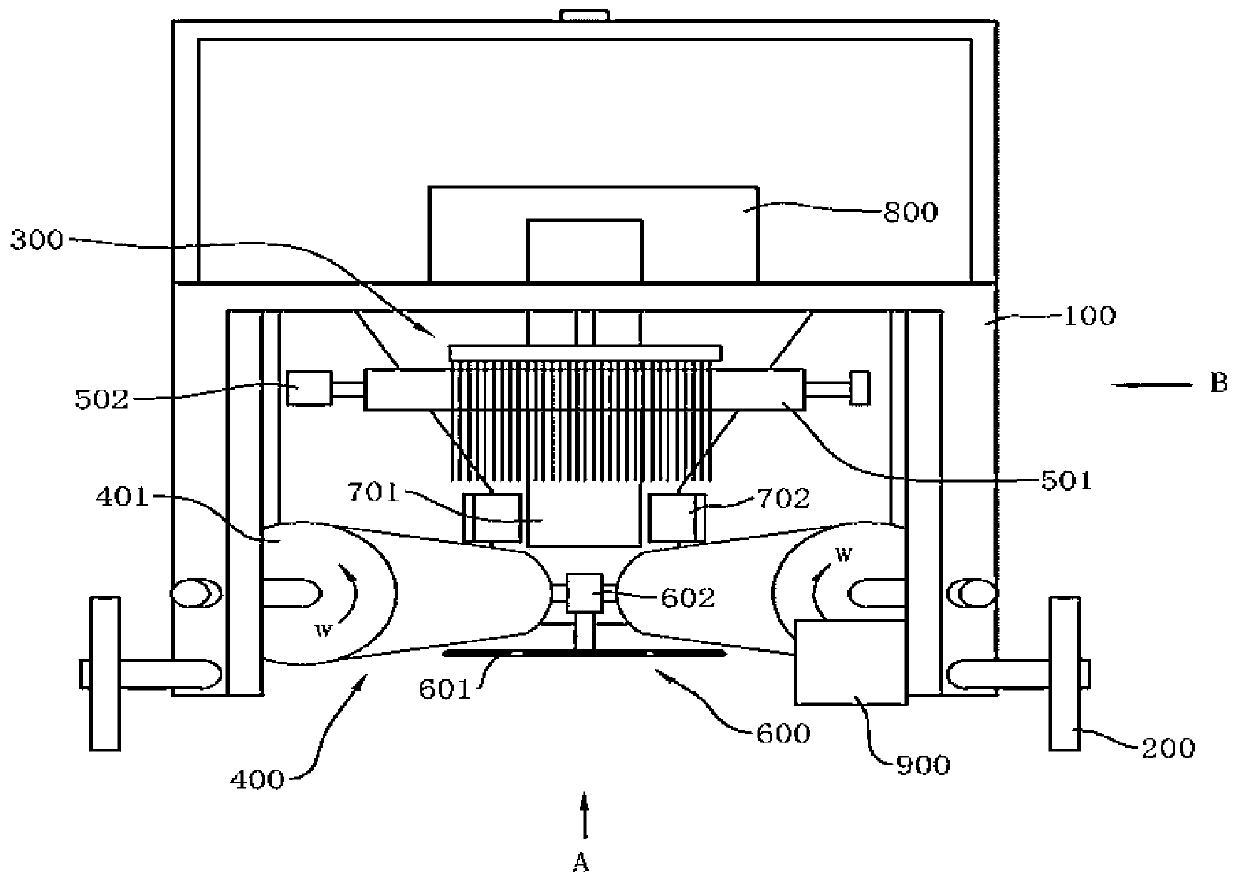

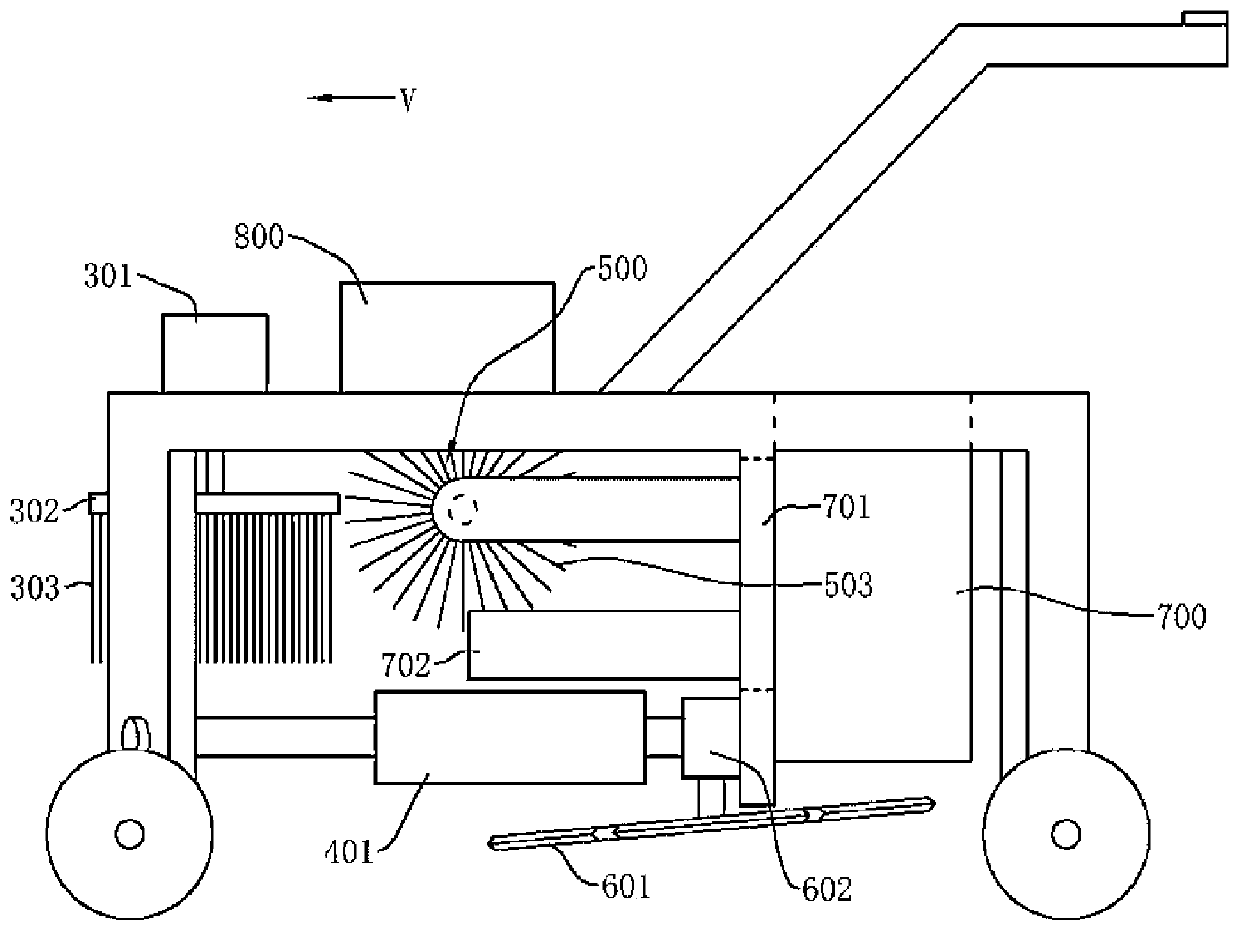

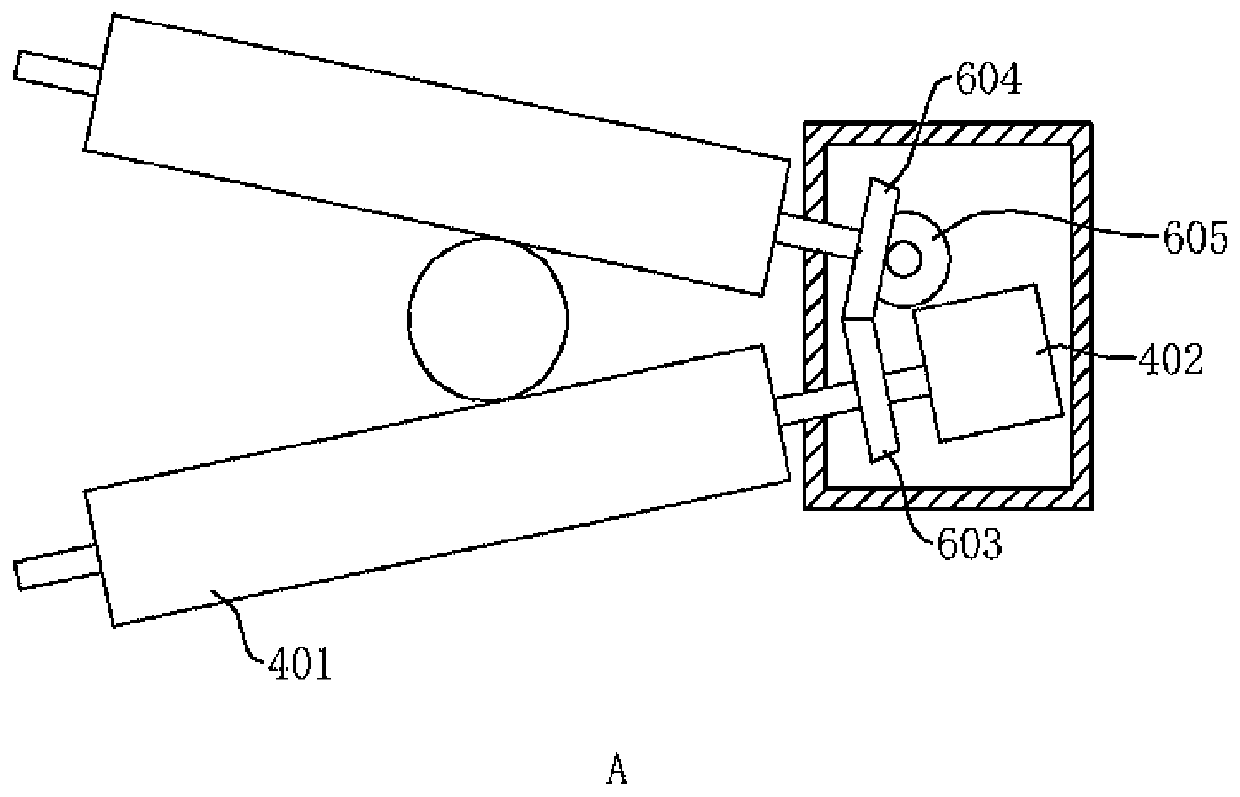

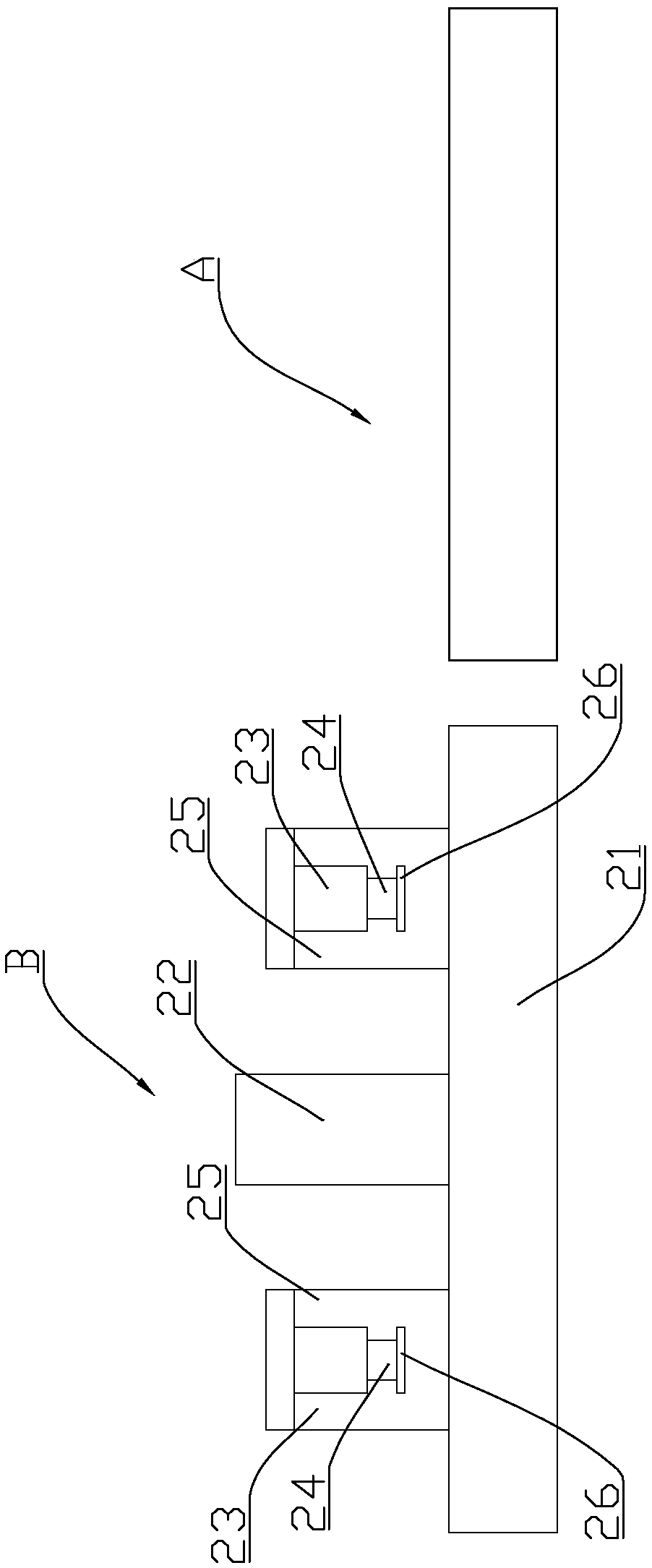

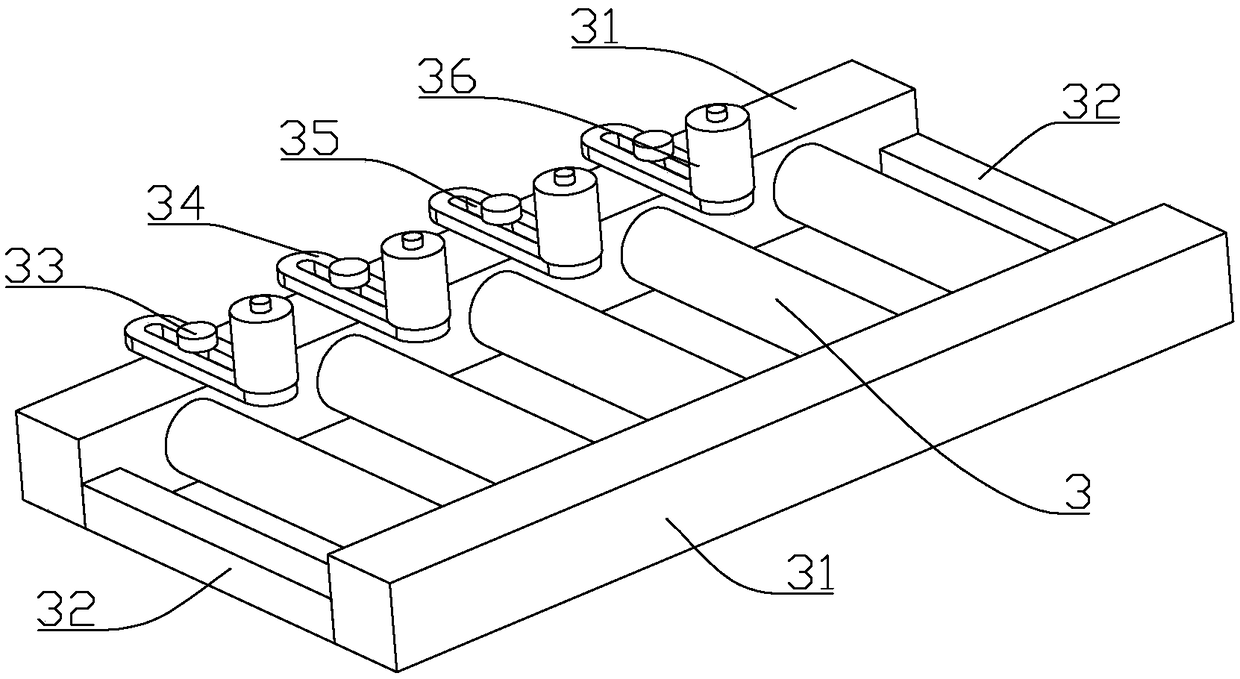

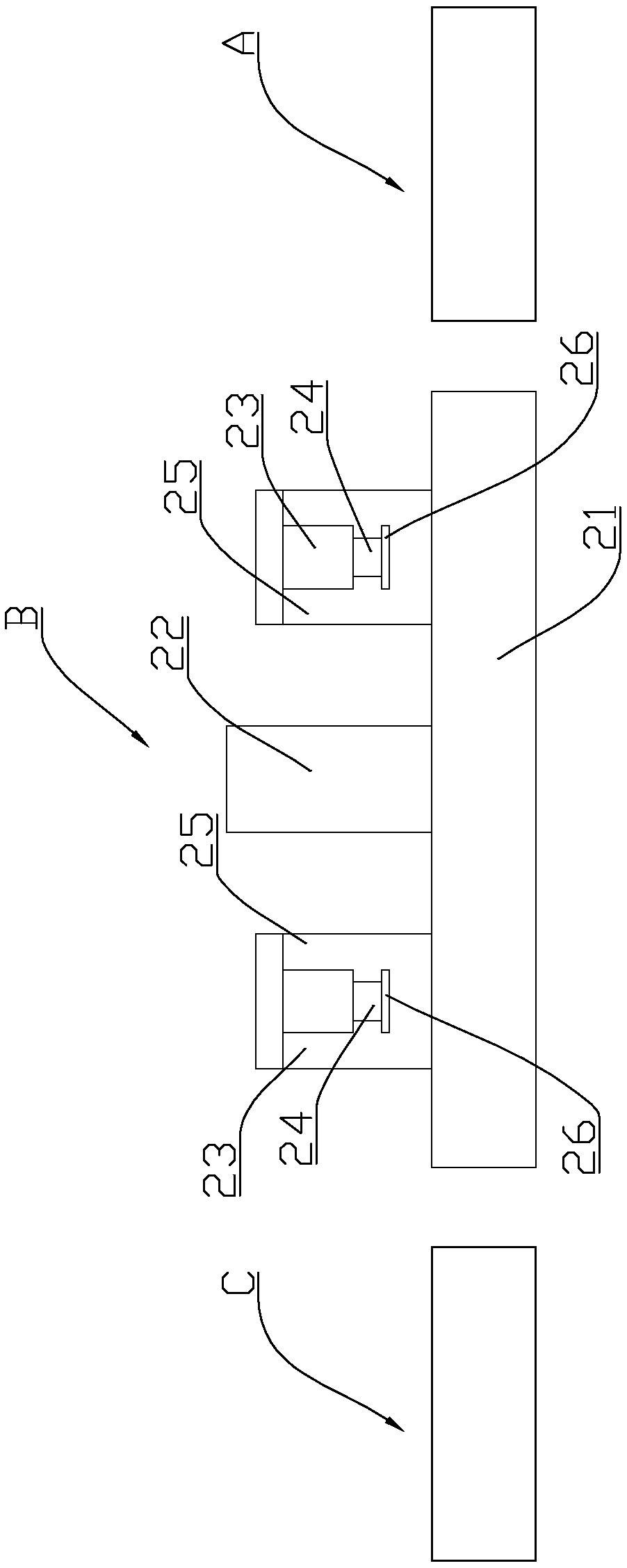

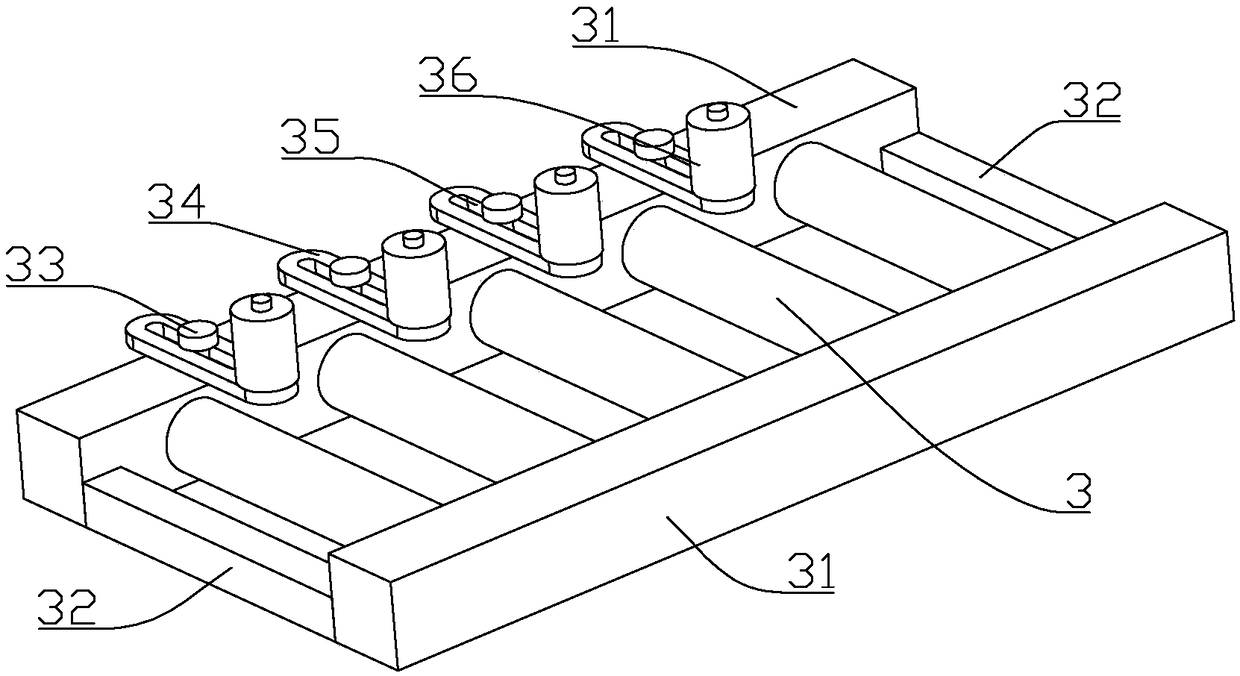

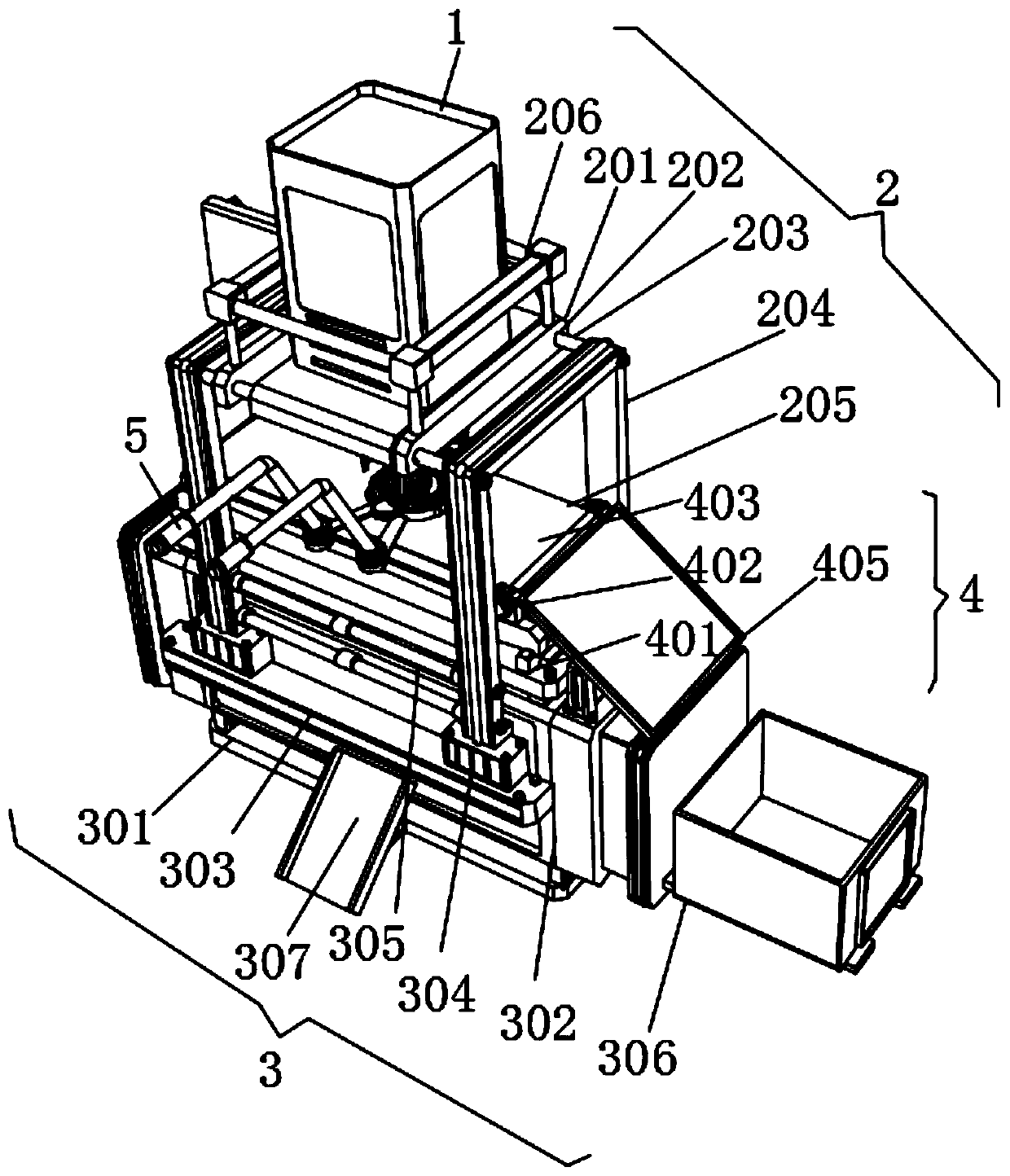

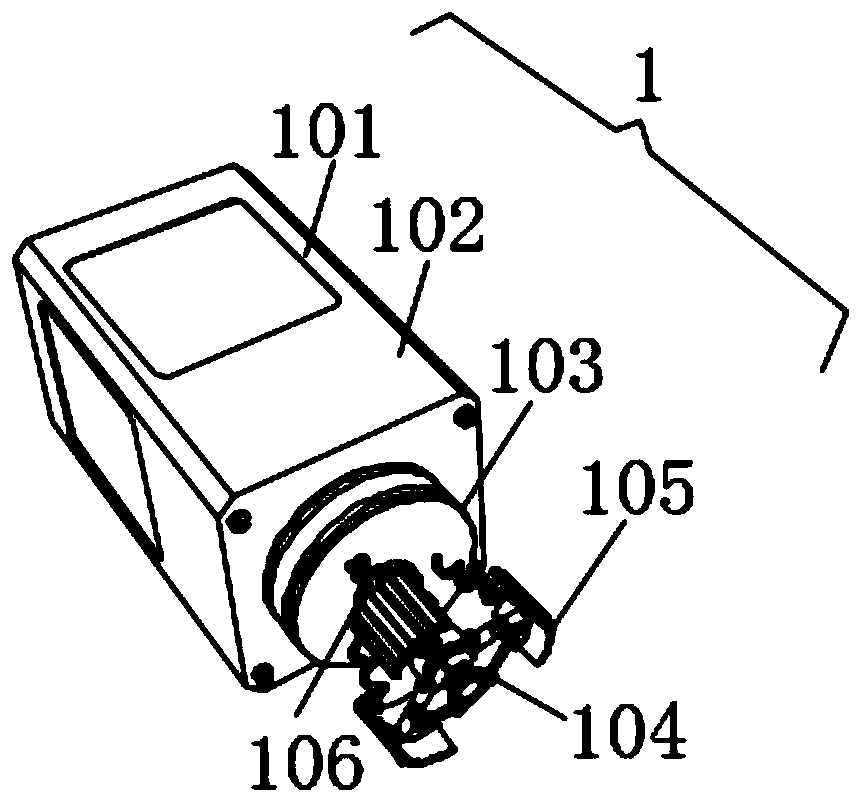

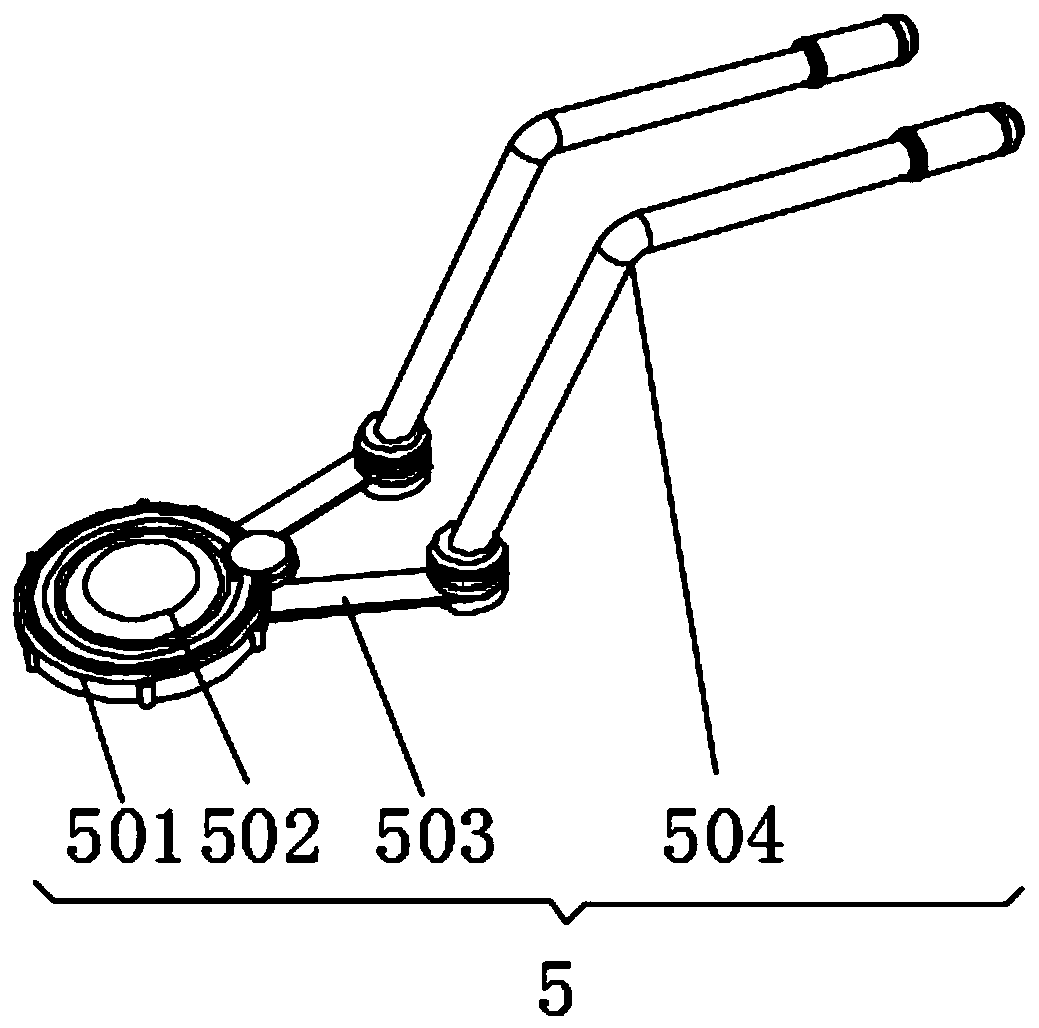

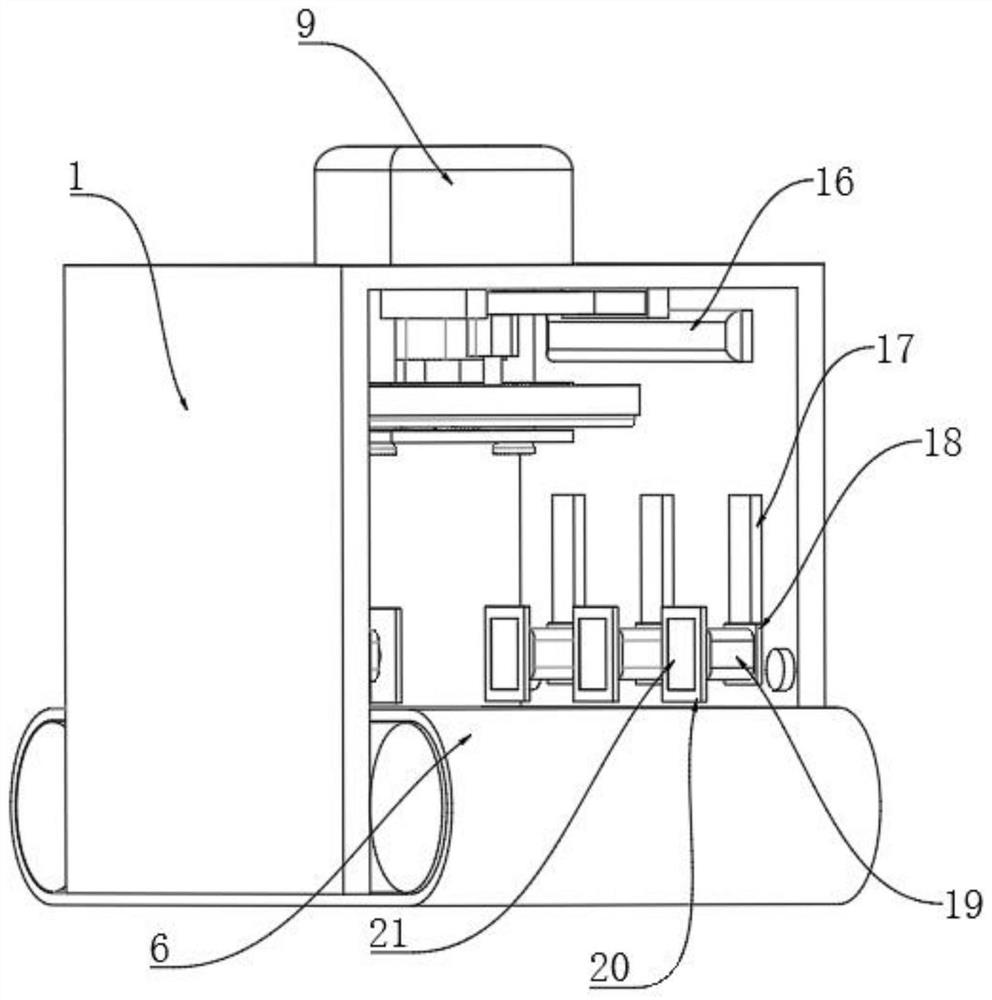

Intelligent medicine taking reminding device for winding-type continuous medicine bags

ActiveCN106205072AFor precise cuttingFor accurate cuttingTransmission systemsControl devices for conveyorsEquipment stateEmergency medicine

The invention discloses an intelligent medicine taking reminding device for winding-type continuous medicine bags. The winding-type continuous medicine bags are provided with serial numbers, a reading device for recognizing the serial numbers is connected with a wireless communication module, the wireless communication module is connected with a microprocessor, and each medicine bag is provided with a black label; a medicine bag conveying mechanism comprises a rotational conveying device, a translational conveying device, a distance measuring device and a medicine bag in-place device; a medicine bag cutting mechanism comprises a blade assembly, a blade driving device and a blade in-place detection device; a medicine bag shunting mechanism comprise a turnover device and a medicine bag shunting baffle; the microprocessor is further connected with a medicine fetching alarm. When it is up to the set medicine taking time, the device can automatically output one medicine bag, cut off the medicine bag automatically or according to an instruction of a patient and remind the patient to use medicine on time; the device also can remotely receive medicine using setting and monitor and report information such as the on-time medicine using condition of the patient and the equipment state through a sensor and the communication module and then reporting the information to a remote cloud or a server.

Owner:XIAMEN ZAYATA TECH INC

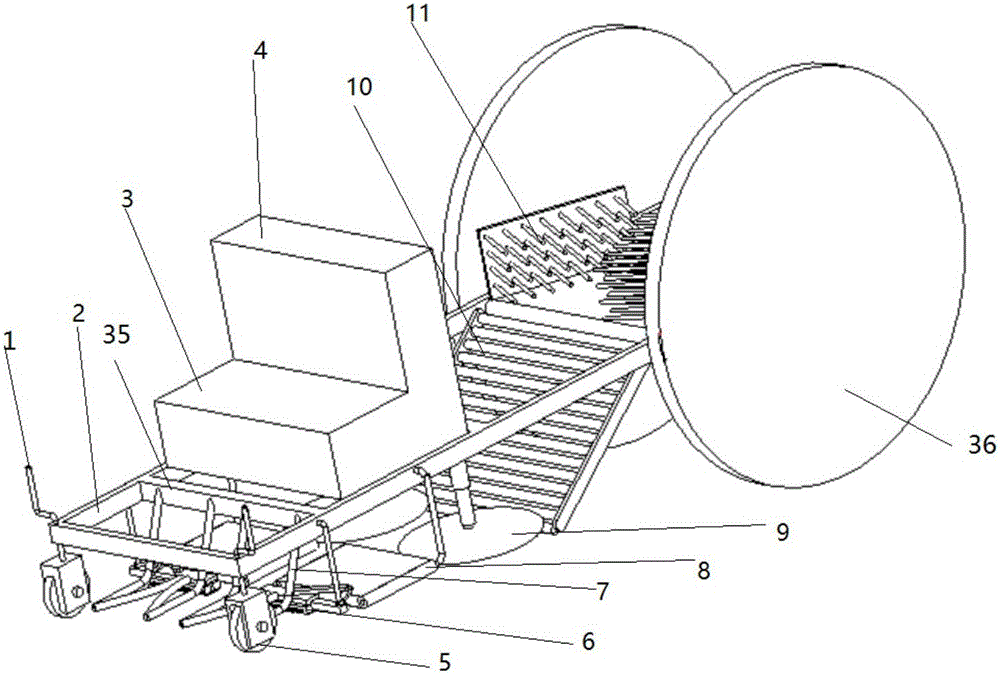

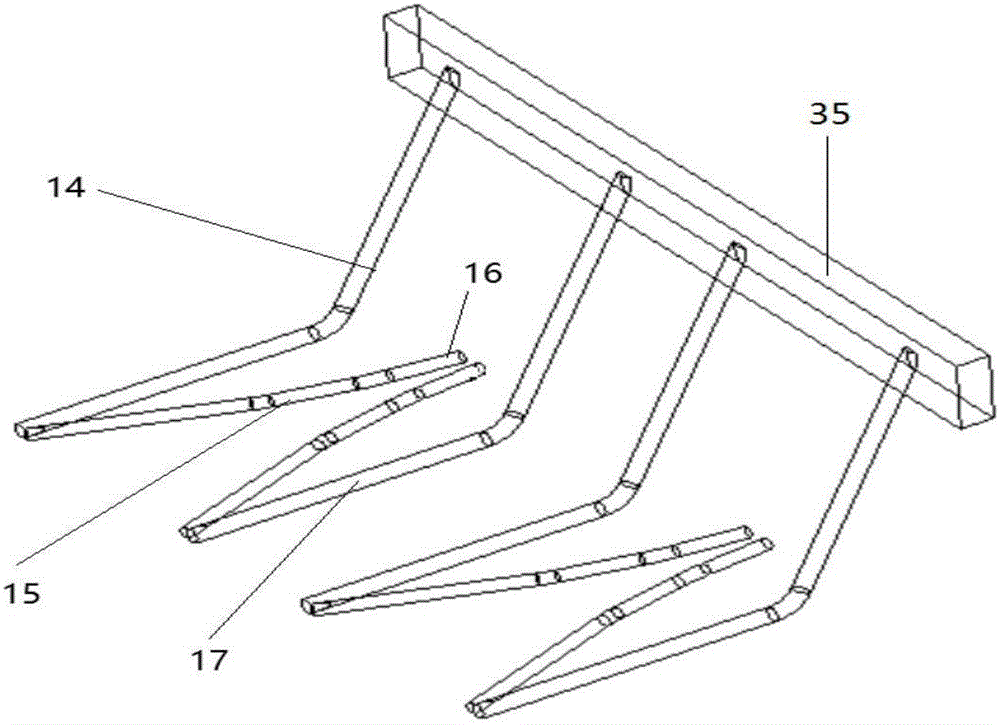

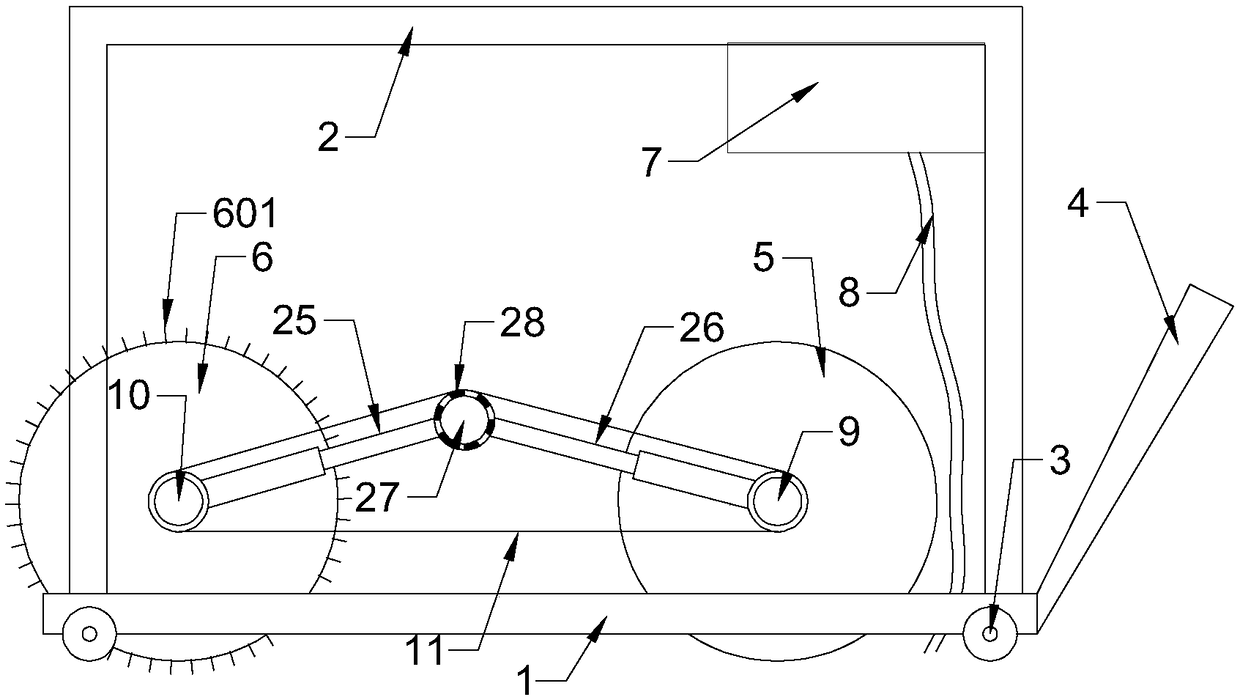

Full-automatic efficient machine for soil cleaning and garlic digging

InactiveCN106538134ANo cloggingGood soil cleaning effectLiftersTopping machinesAgricultural engineeringAgricultural machinery

The invention provides a full-automatic efficient machine for soil cleaning and garlic digging and relates to the technical field of agriculture machinery. The machine provided by the invention comprises a rack and a cab disposed on the upper surface of the rack, wherein a power system is disposed on the cab; depth limiting wheels are disposed on two sides of one end of the rack, and vehicle wheels are disposed on two sides of the other end; and a stem cutting device and a soil digging and root cutting device are disposed on the lower part of the rack. Along a travelling direction of the machine, the stem cutting device is located in front of the soil digging and root cutting device; garlic heads are dug by the soil digging and root cutting device and then conveyed to a conveying and separation device disposed on the lower part of the rack; and then, the garlic heads are successively conveyed to a soil crushing brush and a roller soil cleaning device, wherein the soil crushing brush and the roller soil cleaning device are disposed on the lower part of the rack. The machine for the garlic digging provided by the invention has the advantages that the harvested garlic heads do not need to be manually processed, so labor efficiency is increased; and the harvesting rate is high, and the thorough soil cleaning is conducted to products. The machine for the garlic digging provided by the invention is applicable to various types of soil.

Owner:ANHUI AGRICULTURAL UNIVERSITY

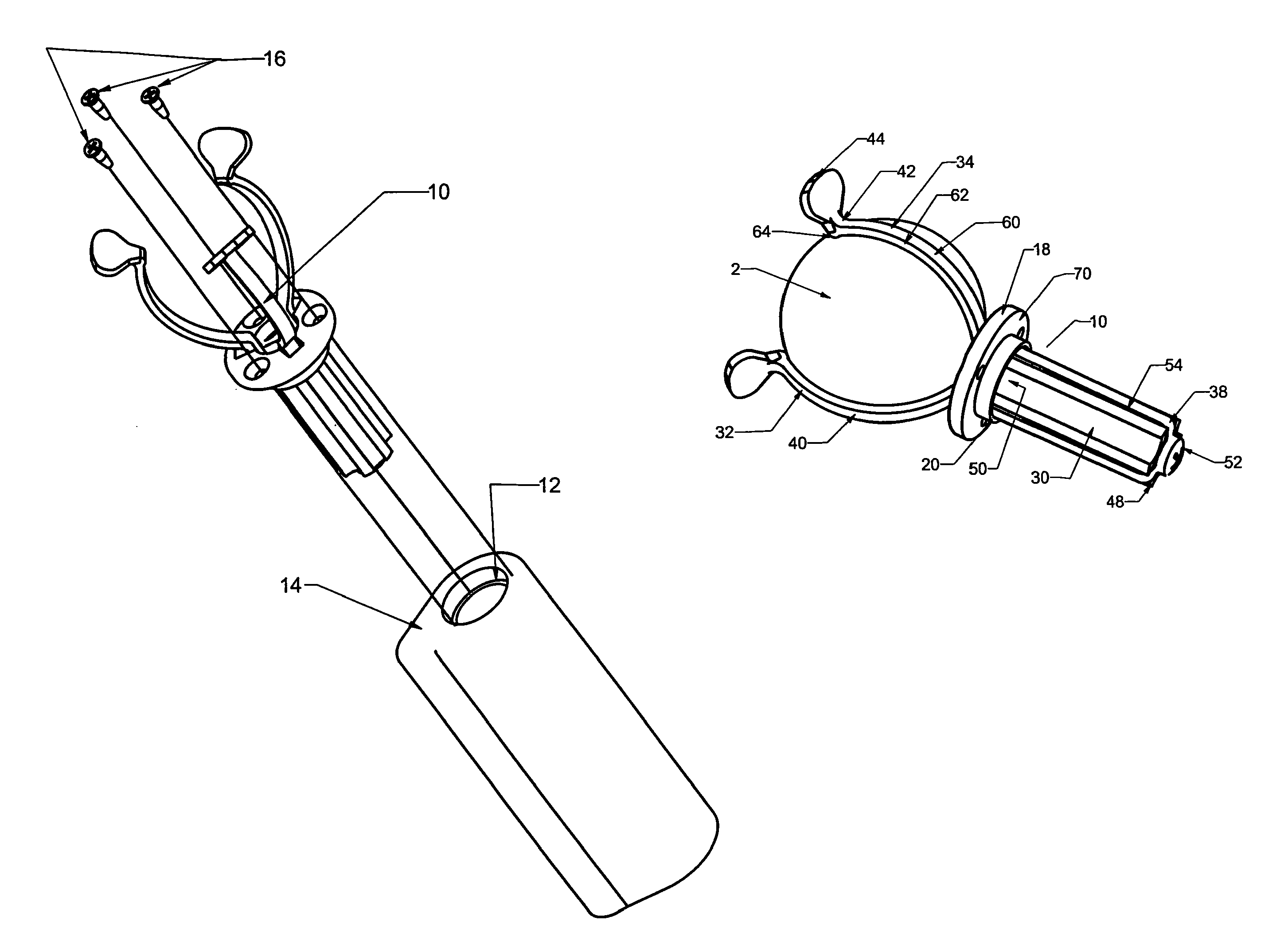

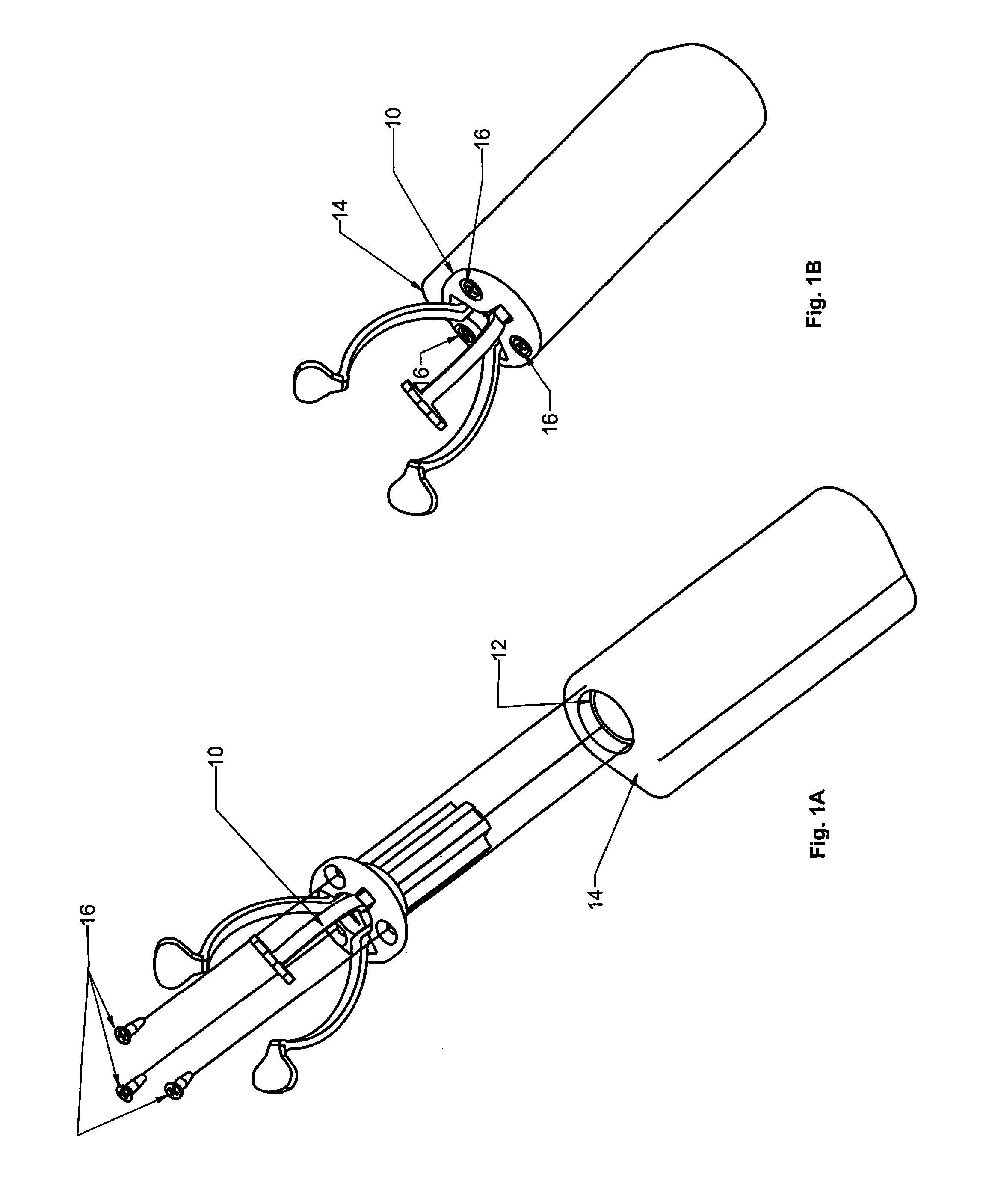

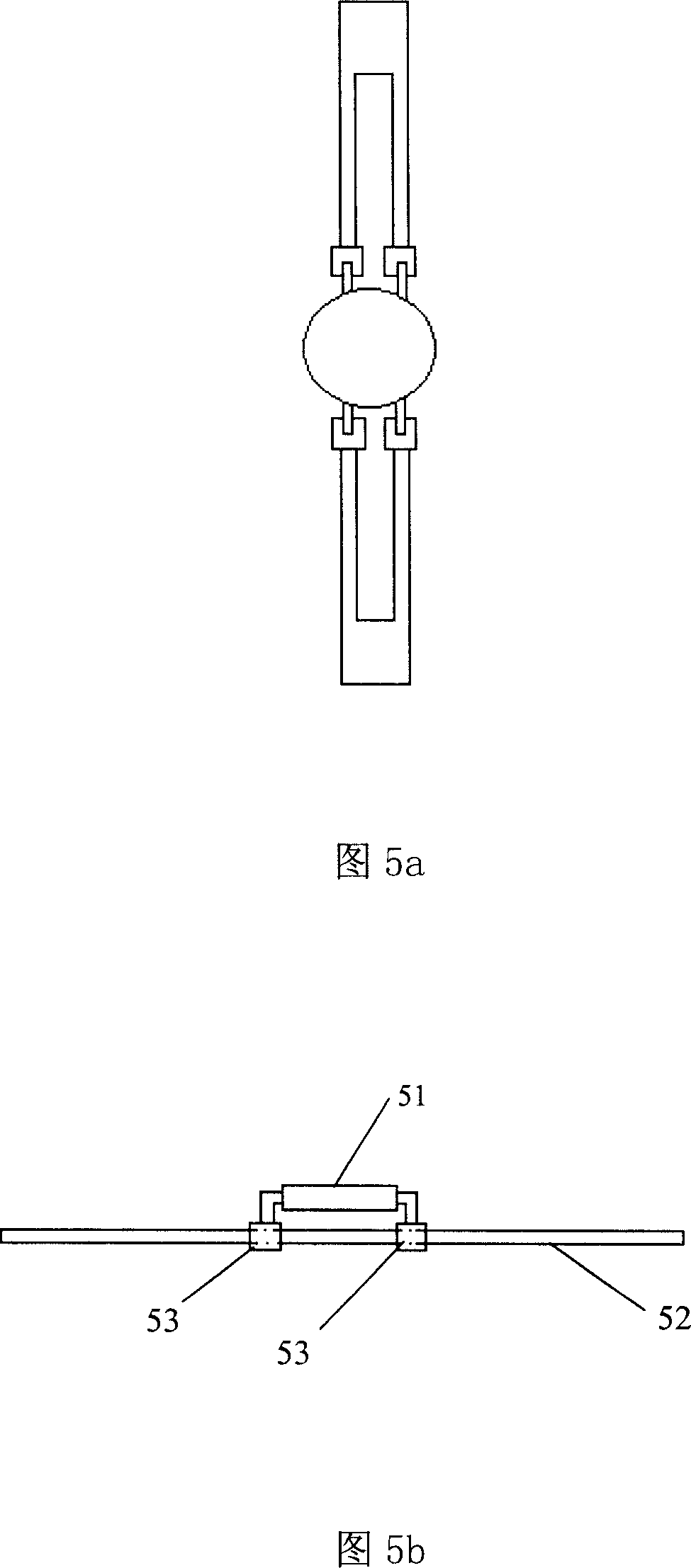

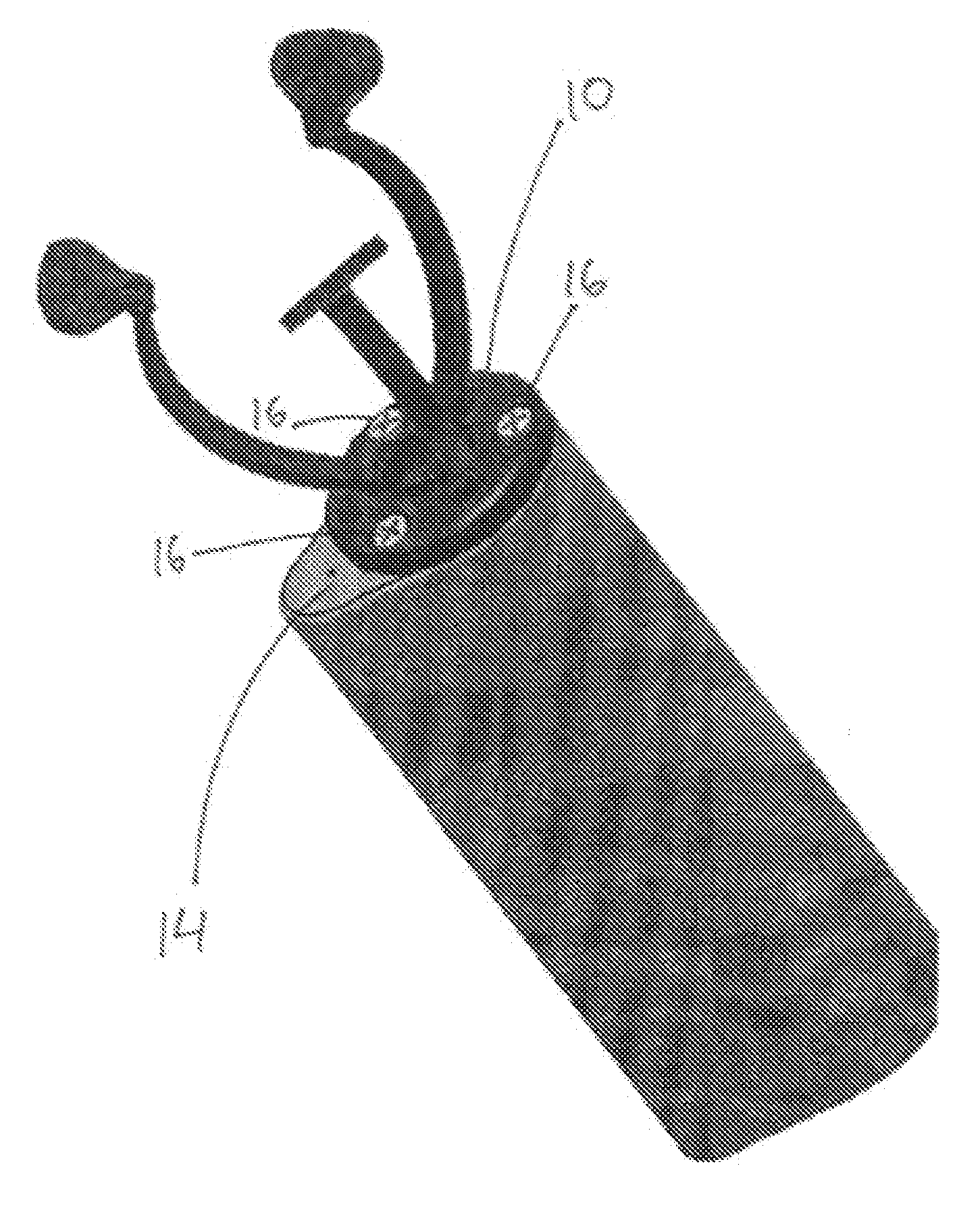

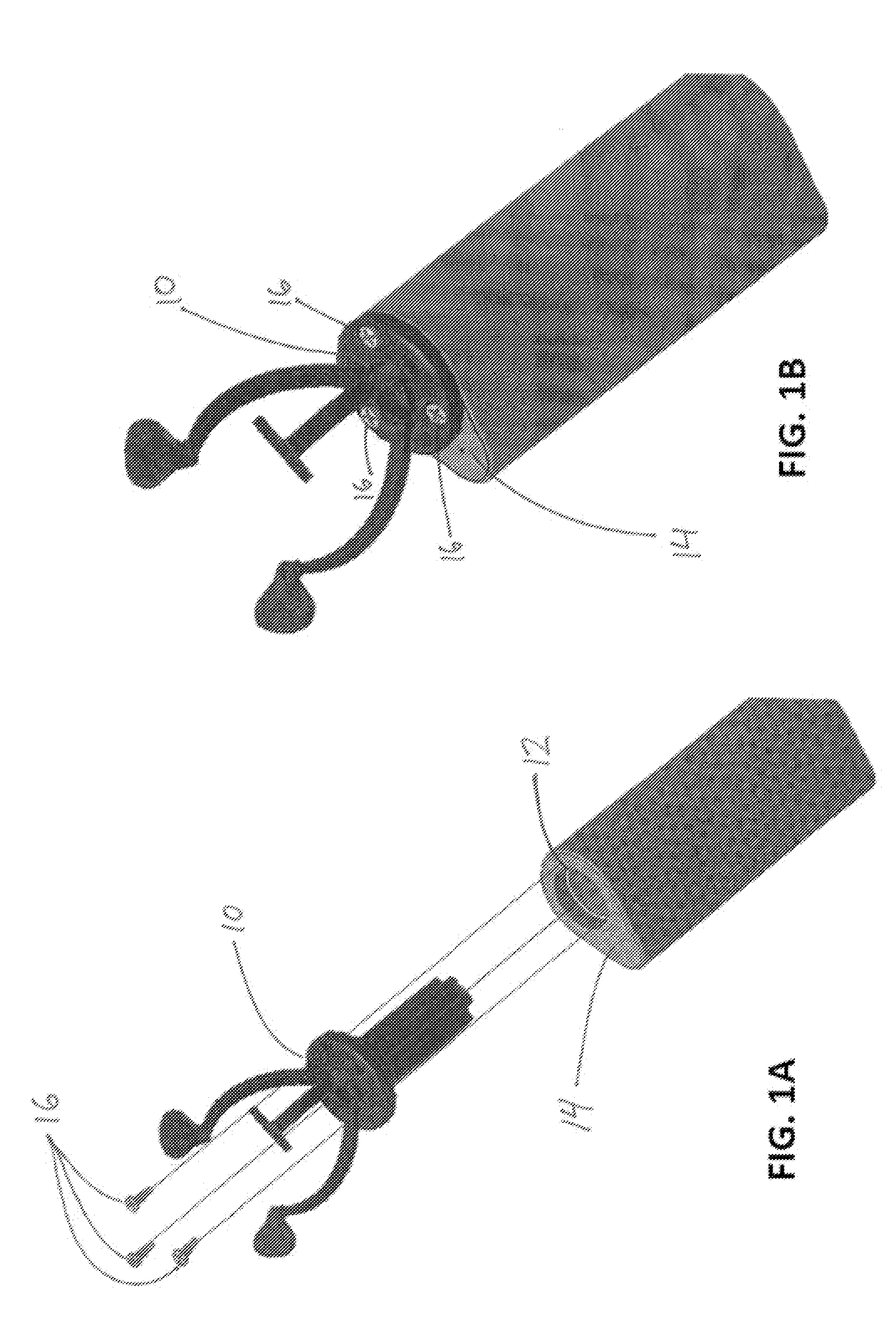

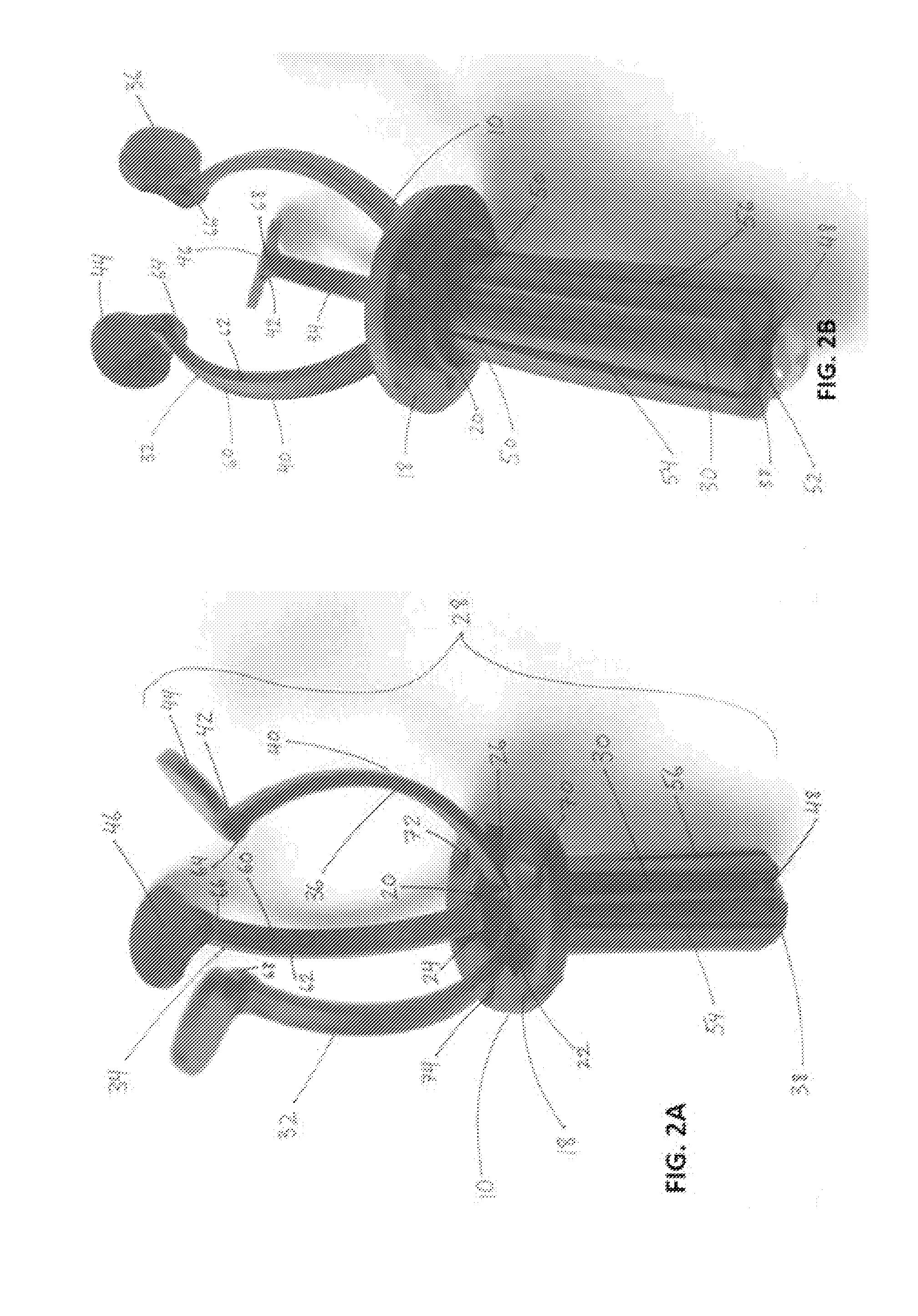

Golf ball grabber

InactiveUS9089741B2Function increaseEasy and reliable spreadingBall sportsSpace saving gamesArcuate shapeCam

A golf ball-grabbing device including a cap affixable at the longitudinal extremity of the grip of a putter shaft and having a single central opening therethrough with finger-receiving guide notches therearound, and a movable grabber assembly having (a) a base member shaped to be movably retained within the shaft below the cap and (b) at least three non-destructibly resiliently-deformable resiliently-deformable strip-like fingers each having a proximal end secured to the base member, an arcuate ball-grabbing portion, and a distal end terminating in a camming member having a substantially-planar ball-engagable face, each finger slidably engaged within one of the notches. The movable grabber assembly is slidable with respect to the cap between a non-use position in which the arcuate portions of the fingers are contained only by the shaft and a use position in which the arcuate portions of the fingers are deployed outside the shaft and above the cap.

Owner:KALUZA BERNHARD +1

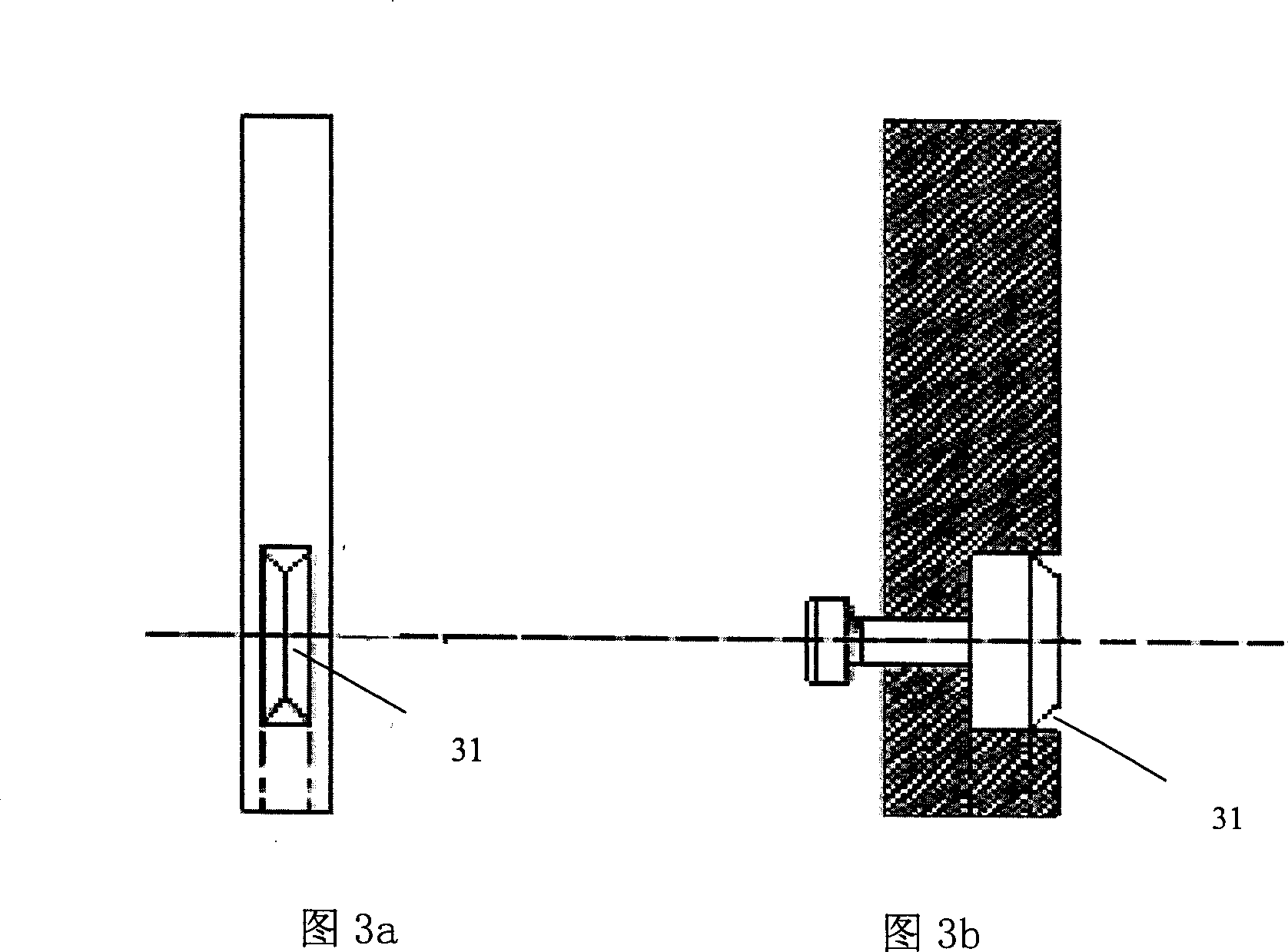

Instrument for accurate cutting of crystal round examples and method of use thereof

InactiveCN101112776APrecise positioningFor accurate cuttingFine working devicesComputer engineeringCrystal

Aiming at simply and reliably implementing the precise cutting to the wafer sample testing belt, the invention relates to a cutting tool cutting the wafer sample testing belt and the application method. The cutting tool includes a device frame, a magnifier, a sample table, a cutter rest and a cutter; wherein, the cutter is arranged in the cutter rest, the magnifier and the frame of the magnifier are arranged on the cutter rest, and the sample table is also arranged on the cutter rest.

Owner:SEMICON MFG INT (SHANGHAI) CORP

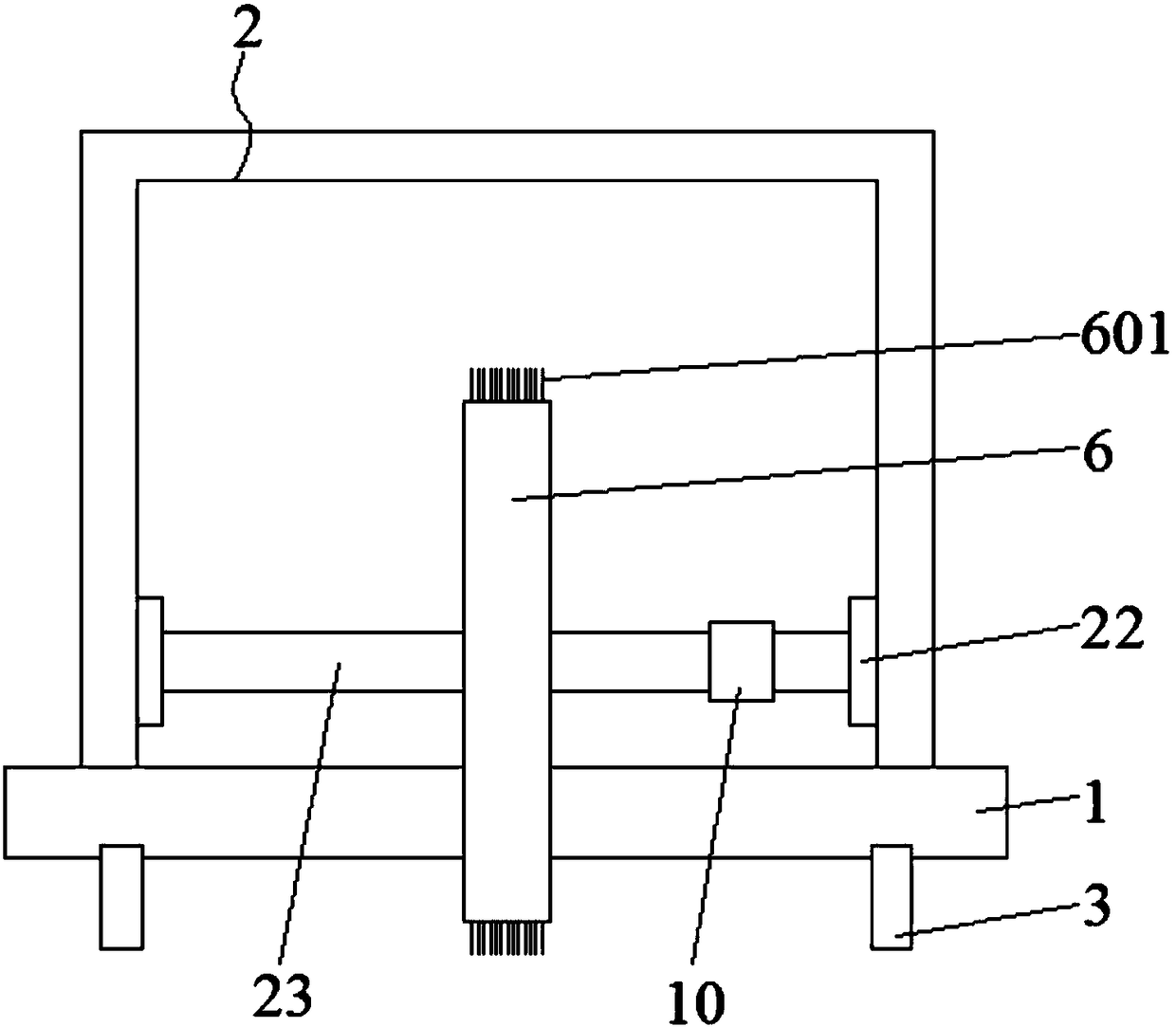

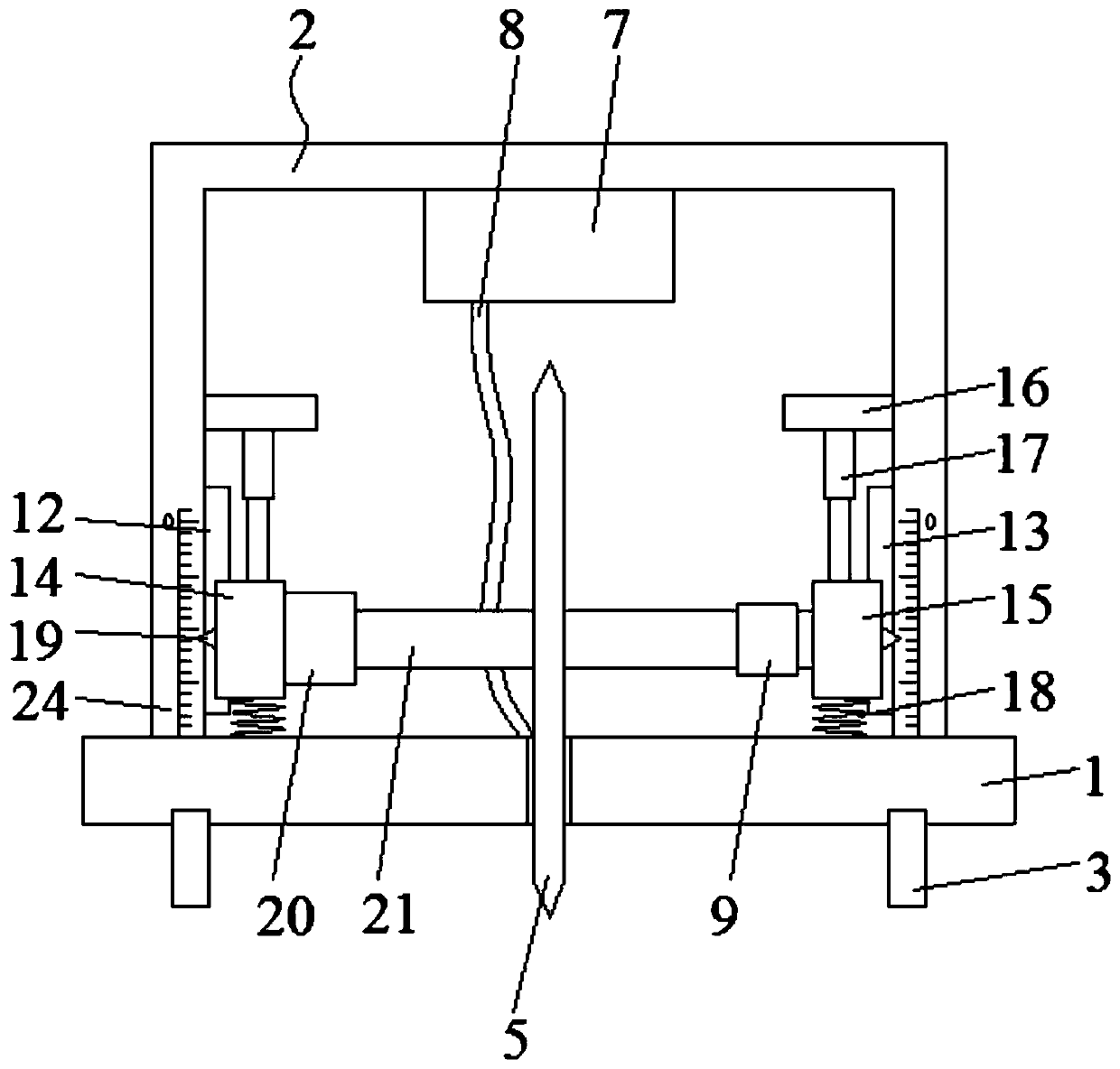

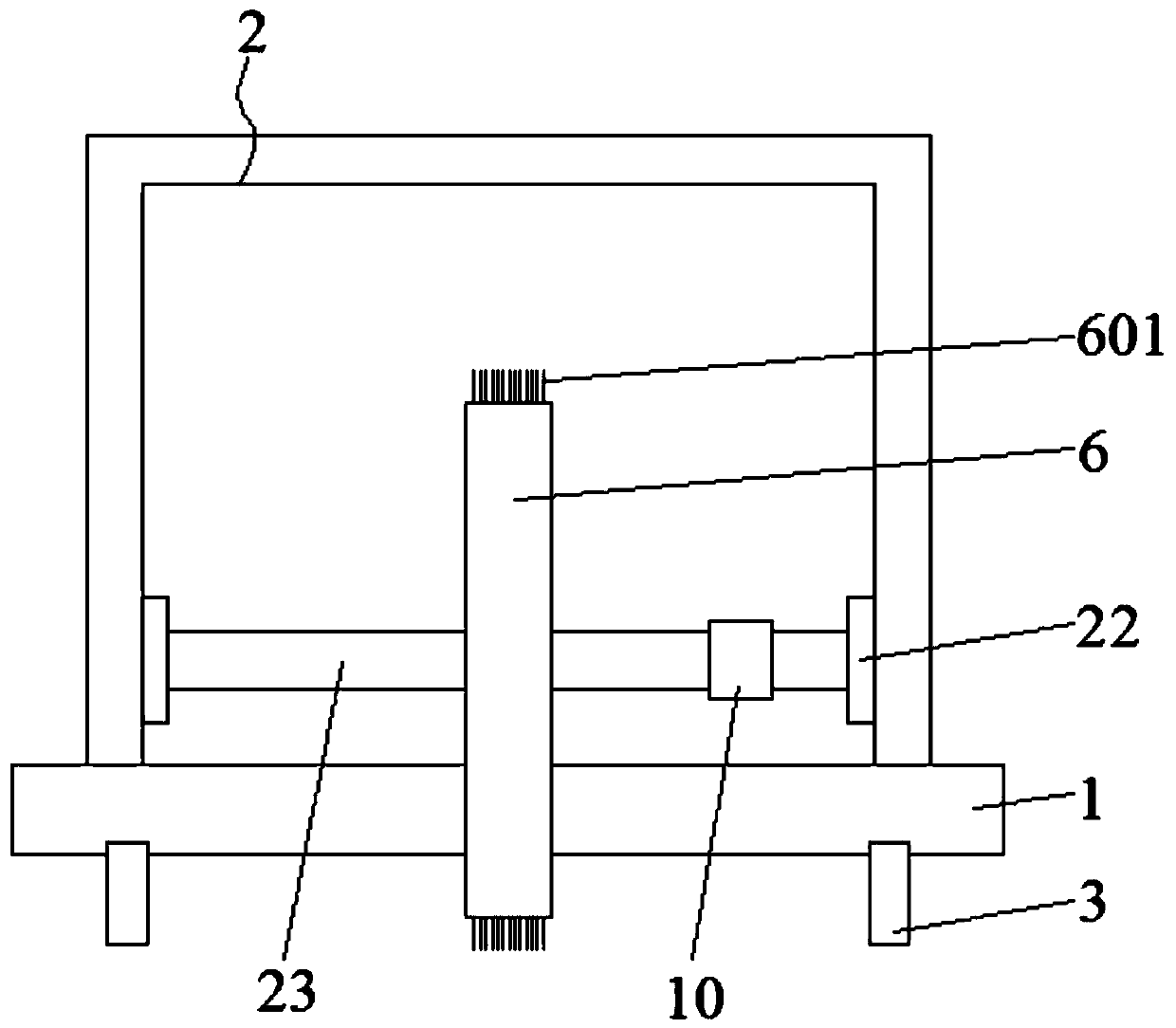

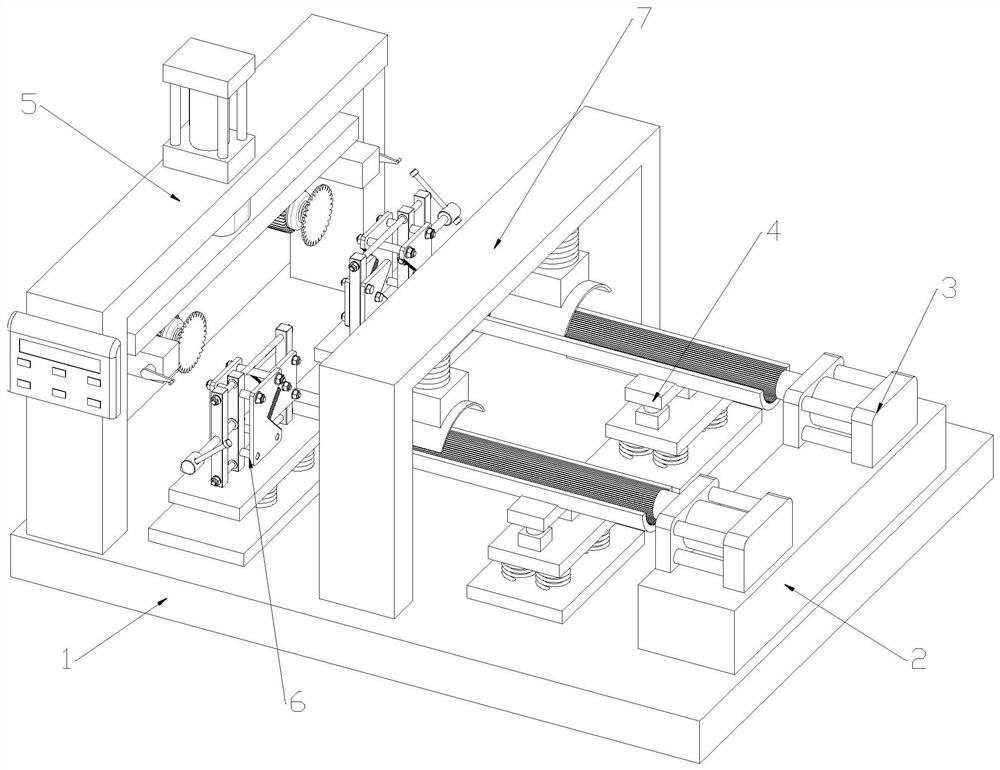

Cutting device for expansion joint of bridge

ActiveCN108265610AQuality assuranceFor accurate cuttingBridge erection/assemblyRoads maintainenceBridge deckEngineering

The invention relates to the technical field of bridge construction, in particular to a cutting device for an expansion joint of a bridge. The cutting device for the expansion joint of the bridge comprises a base and a machine frame. A first sliding rail and a second sliding rail are correspondingly arranged on the inner wall of the front half part of the machine frame, the first sliding rail andthe second sliding rail are correspondingly provided with a first sliding block and a second sliding block, a motor is installed on the first sliding block, a first rotating shaft is arranged on the motor, and a circular parting tool and a first belt pulley are arranged on the first rotating shaft in a sleeving mode. Bearing seats are arranged on the inner wall of the rear half part of the machineframe, a second rotating shaft is connected between the bearing seats, and a cleaning cylinder and a second belt pulley are arranged on the second rotating shaft in a sleeving mode. A vacuum cleaneris arranged on the upper side of the machine frame. The cleaning cylinder cleans up dust on a bridge deck to-be-cut, so that the circular parting tool can cut accurately, and the quality of cutting ofthe expansion joint is guaranteed; the dust produced by the cutting can be recovered in the vacuum cleaner, so that the pollution degree to the environment is effectively reduced; and the cutting depth of the circular parting tool can be quickly adjusted by an extensible rod and the sliding blocks.

Owner:河北省高速公路石黄管理处

Golf Ball Grabber

InactiveUS20120208652A1Function increaseEasy and reliable spreadingBall sportsSpace saving gamesPhysical medicine and rehabilitationEngineering

A golf ball-grabbing device including a cap affixable at the longitudinal extremity of the grip of a putter shaft and having a single central opening therethrough with finger-receiving guide notches therearound, and a movable grabber assembly having (a) a base member shaped to be movably retained within the shaft below the cap and (b) at least three non-destructibly resiliently-deformable resiliently-deformable strip-like fingers each having a proximal end secured to the base member, an arcuate ball-grabbing portion, and a distal end terminating in a camming member having a substantially-planar ball-engagable face, each finger slidably engaged within one of the notches. The movable grabber assembly is slidable with respect to the cap between a non-use position in which the arcuate portions of the fingers are contained only by the shaft and a use position in which the arcuate portions of the fingers are deployed outside the shaft and above the cap.

Owner:KALUZA BERNHARD +1

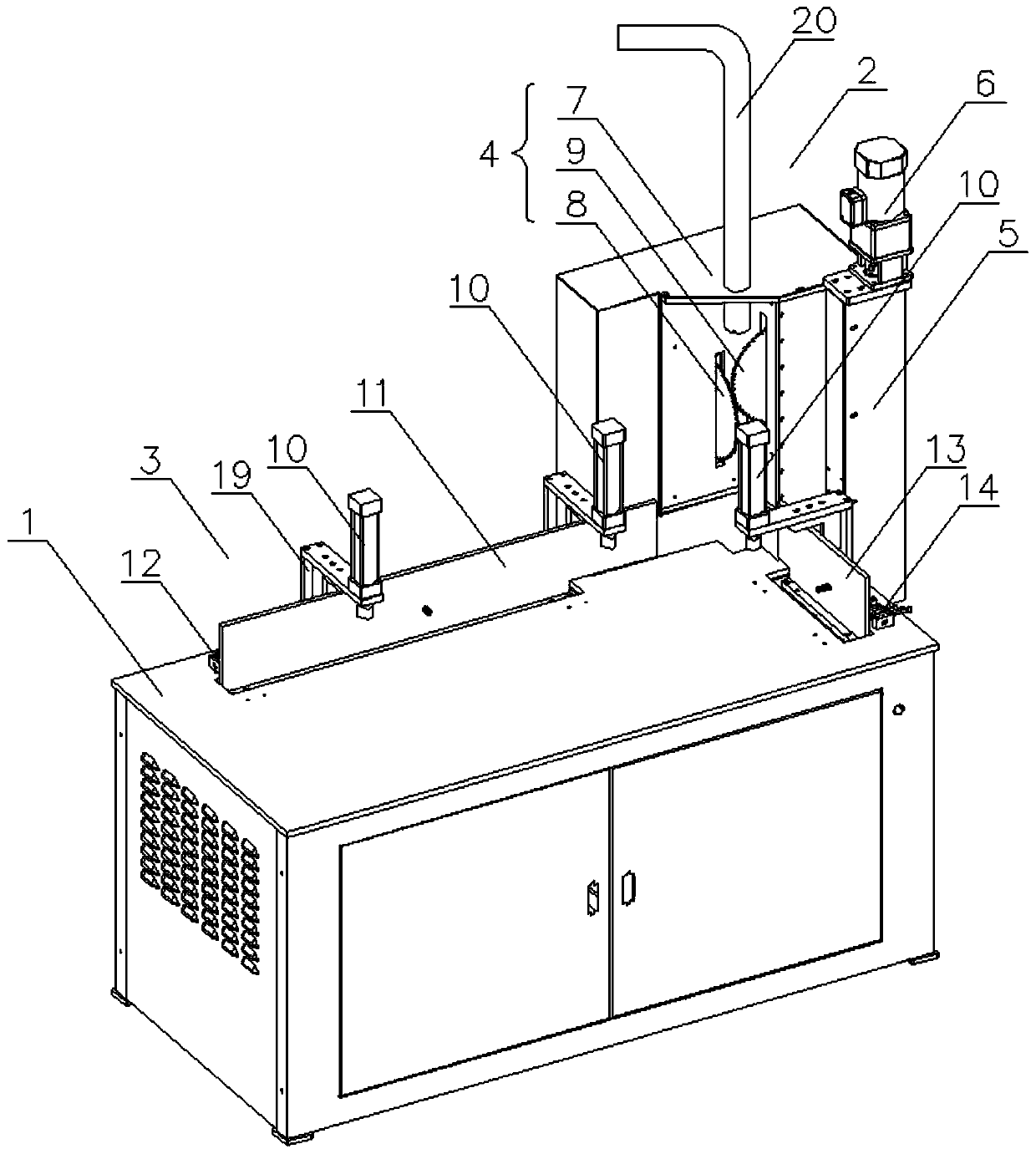

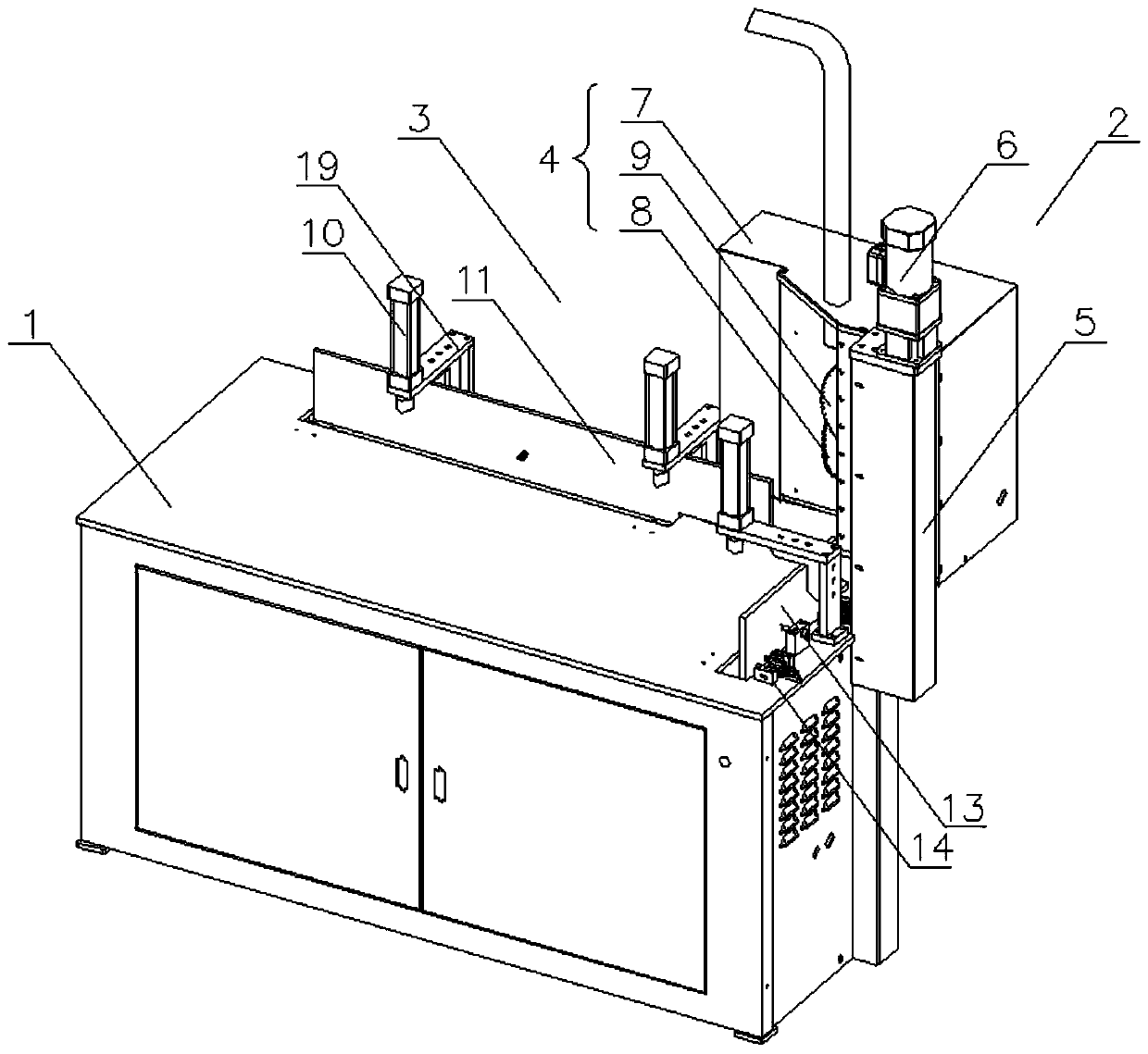

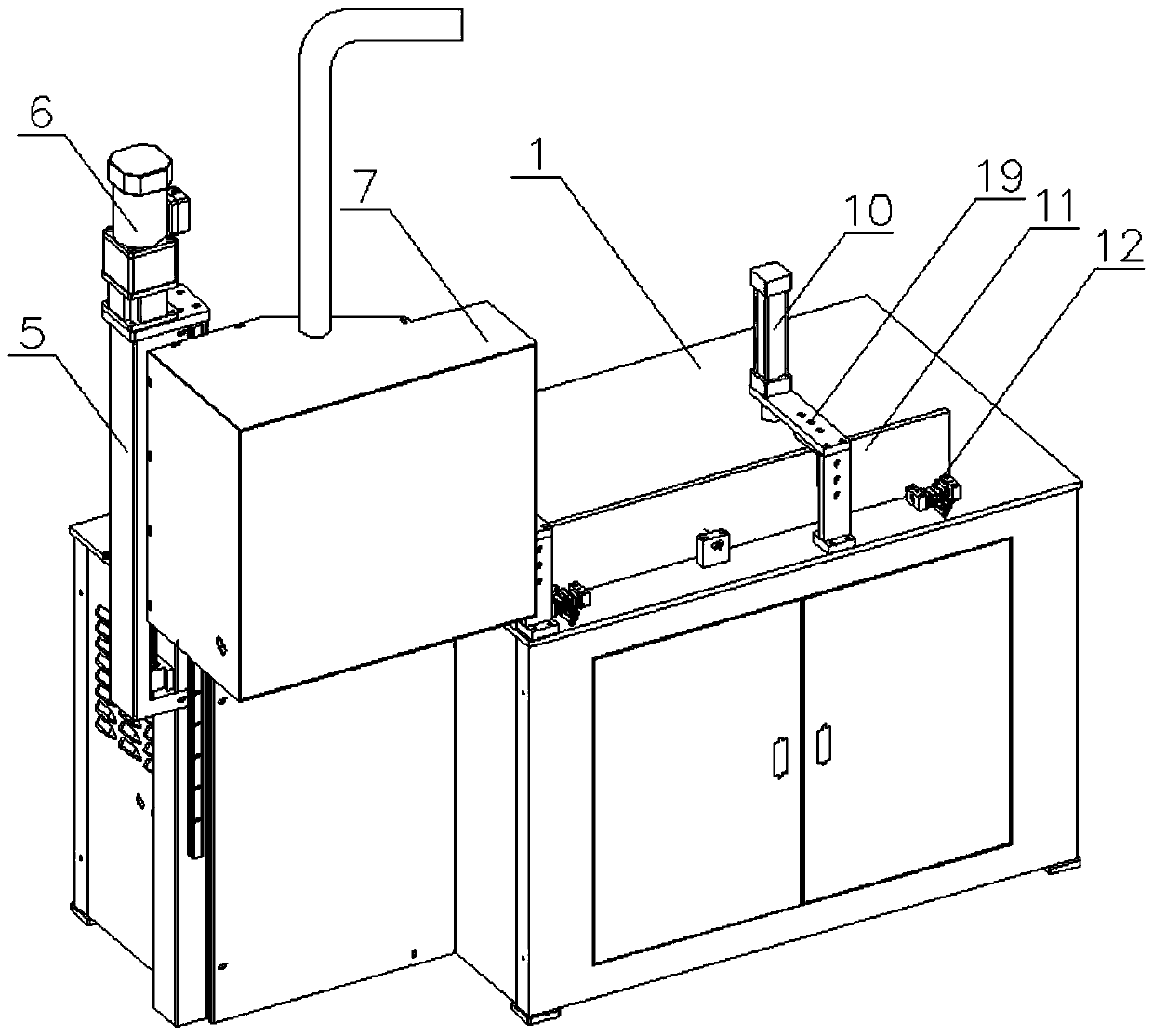

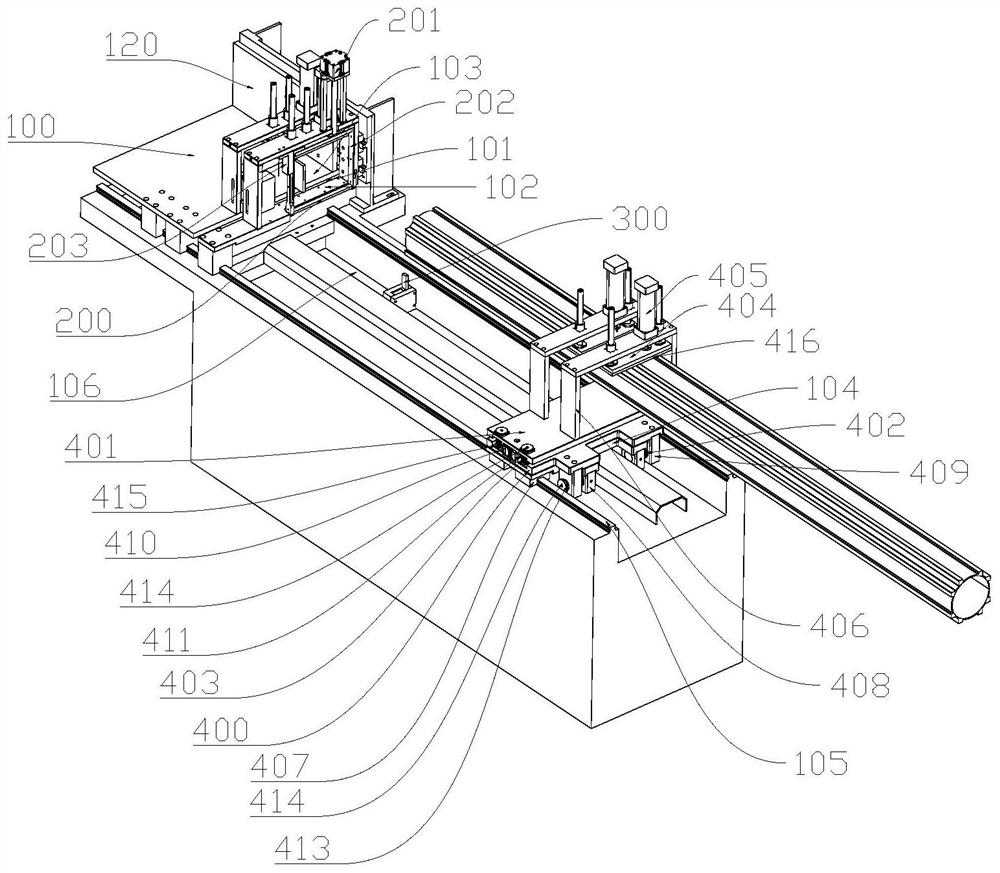

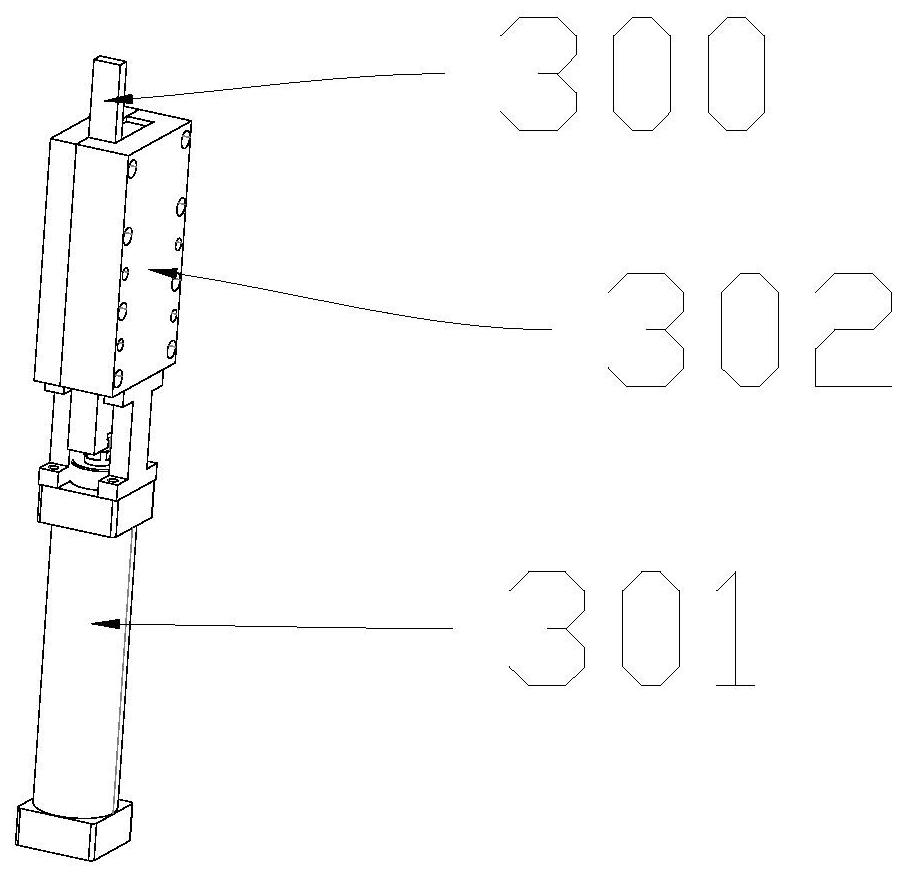

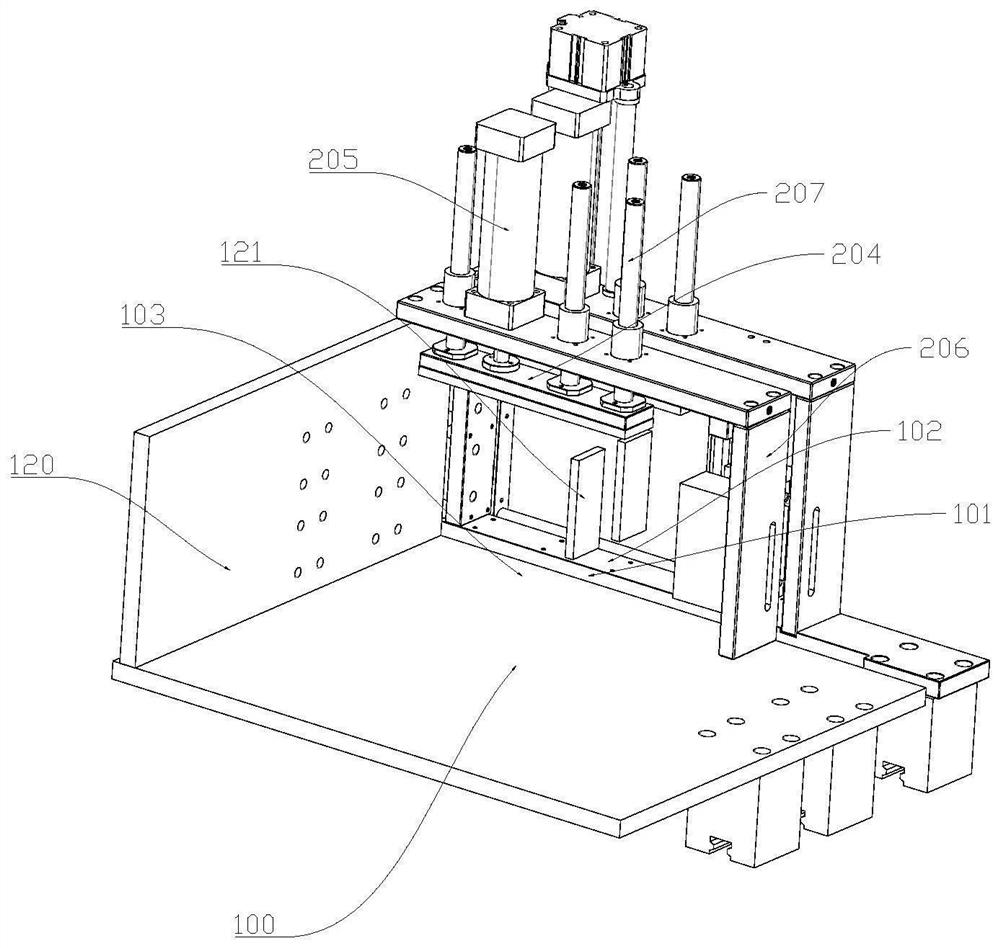

Full-automatic right-angle cutting device

PendingCN110270715AGuaranteed cutting accuracyImprove cutting efficiencyMetal sawing devicesMechanical engineeringEngineering

The invention relates to a full-automatic right-angle cutting device. The full-automatic right-angle cutting device comprises a workbench, a cutting assembly and a positioning assembly; the cutting assembly comprises a cutting module capable of achieving vertical lifting; the positioning assembly is used for positioning a to-be-cut workpiece to the workbench and enabling one corner of the to-be-cut workpiece to be located under the cutting assembly; and the cutting module is used for cutting the corners of the to-be-cut workpiece when the cutting module moves downwards, and then a right-angle cutting opening is formed in each corner of the to-be-cut workpiece. According to the full-automatic right-angle cutting device, the to-be-cut workpiece is positioned on the workbench through the positioning assembly, one corner of the to-be-cut workpiece is located under the cutting assembly, and then the cutting precision is guaranteed; the corners of the to-be-cut workpiece are cut at a time when the cutting module in the cutting assembly moves downwards, the right-angle cutting openings are formed in the corners of the to-be-cut workpiece, and no portion needs to be cut at twice; and in addition, multiple pieces of to-be-cut workpieces stacked together can be cut each time, therefore, the cutting efficiency is greatly improved, automatic cutting is achieved, and the manual labor intensity is reduced.

Owner:武汉汉沙斯德自动化设备有限公司

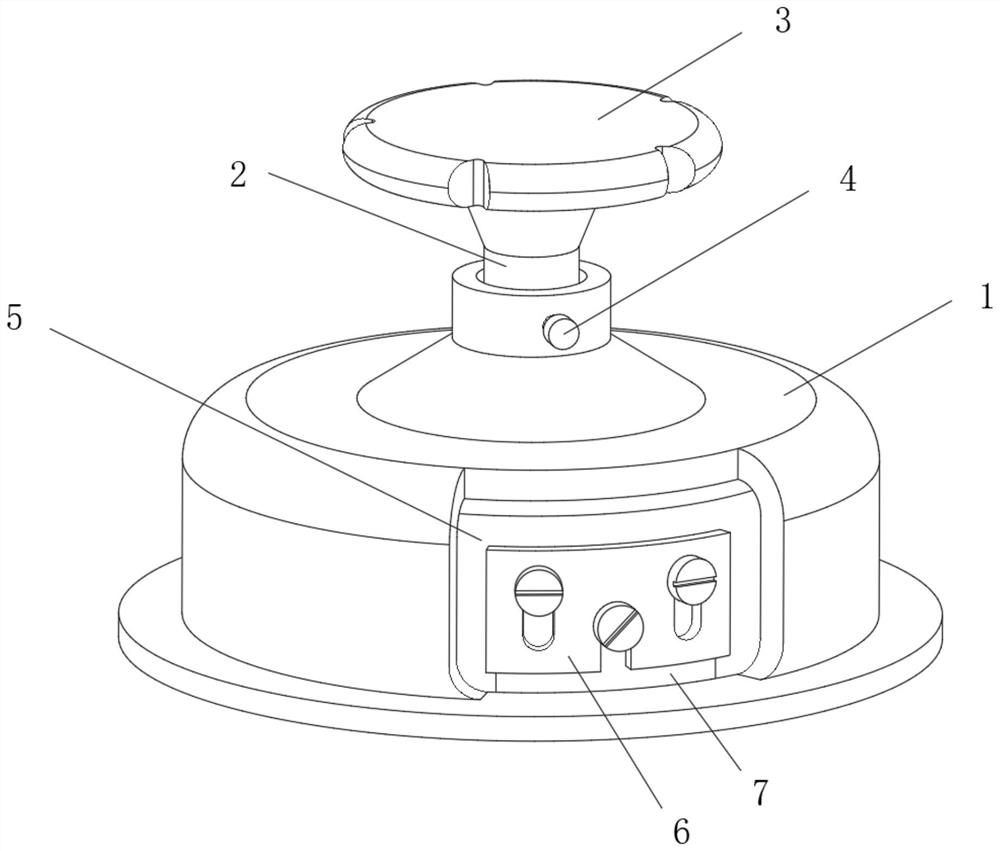

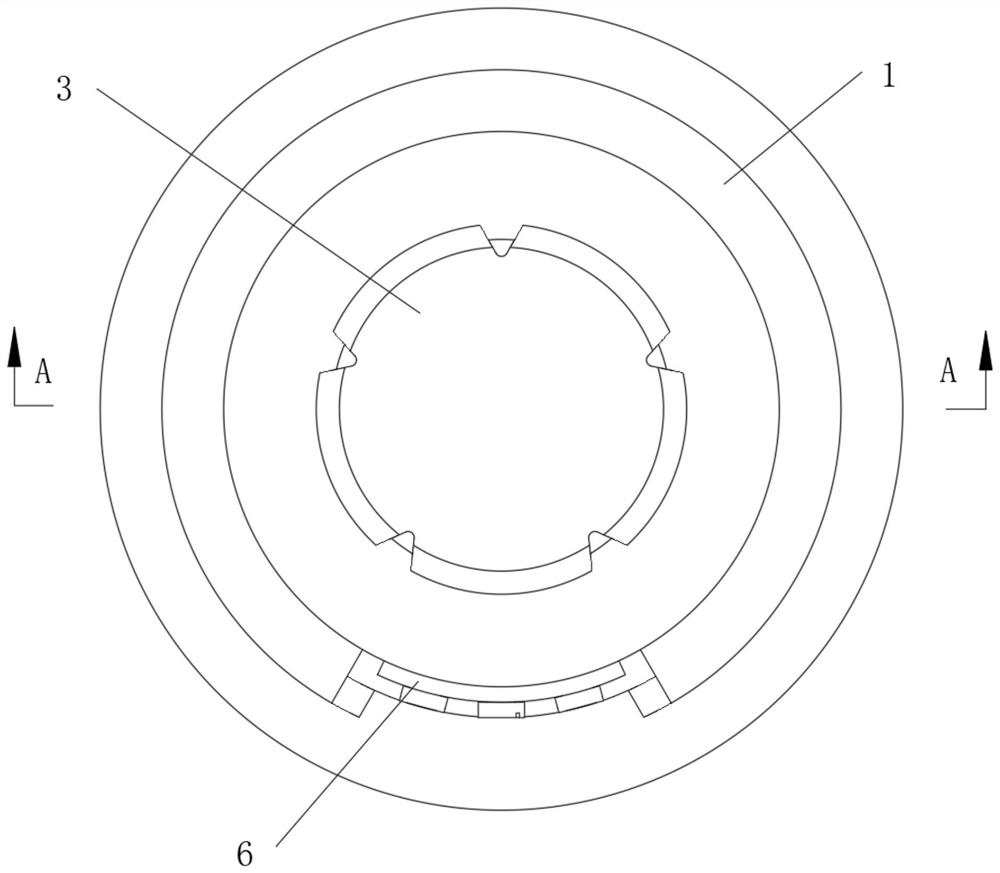

Disc sampler for cloth detection

Owner:陈兴元

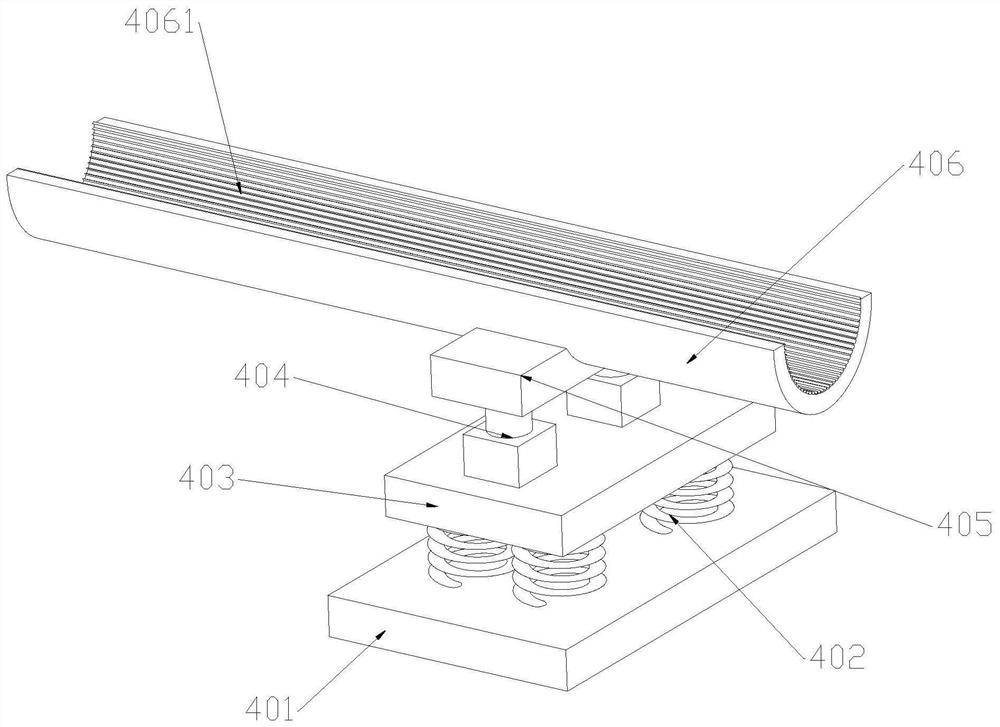

Pipeline cutting-fixing device

InactiveCN107498341AImprove adsorption capacityImprove abilitiesWork holdersLarge fixed membersScrew threadIndustrial engineering

The invention discloses a pipe cutting and fixing device, which comprises a cutting table, and a cutting groove is arranged on the cutting table, and the cutting groove divides the cutting table into a first fixing table and a second fixing table; the first fixing table is provided with a second fixing table. A semicircular pipe groove, the hinge on the first semicircular pipe groove is connected with a first pressing member; the second fixed platform is provided with a second semicircular pipe groove, and the hinge on the second semicircular pipe groove A second pressing piece is connected; one end of the first pressing piece is hingedly connected to the notch of the first semicircular pipe groove, and the other end is screwed and fixed to the first fixing table; one end of the second pressing piece is connected to the The notch of the second semicircular pipe groove is hingedly connected, and the other end is threaded and fixed to the second fixing table. The invention has a reasonable and simple structure, is easy to manufacture and is convenient to use, facilitates people to fix the pipe during cutting, and improves labor production efficiency.

Owner:YANGZHOU HUAGONG CEMENT MACHINERY MFG CO LTD

Cutting equipment for long rod or long pipe machining

ActiveCN113275932AAvoid scratchesFor accurate cuttingWork clamping meansMetal working apparatusStructural engineeringMachining

The invention discloses cutting equipment for long rod or long pipe machining. The cutting equipment comprises a cutting table, a cutting wheel and a feeding device; a feeding opening is formed in the cutting table; the feeding device comprises a sliding rail and a moving table; the sliding rail is connected with a feeding position; the moving table is driven by a driving mechanism to move; a clamping device is arranged on the moving table; a side baffle is arranged on one side of the cutting table; a plurality of side clamping plates are arranged on the other side of the cutting device; the side clamping plates are driven by side air cylinders to move towards the side baffle; and the cutting device further comprises an anti-friction structure, a first section positioning structure and an automatic correcting structure. The cutting equipment is very suitable for fixed-length cutting of long rods or long pipes; materials can be effectively prevented from being scratched in the feeding process, and the situation that a cutting face is deformed due to deformation of the materials can be prevented; manual measurement and positioning are not needed during first-section cutting; and accurate cutting and machining of long-rod or long-pipe materials are greatly facilitated.

Owner:浙江郑林机械股份有限公司

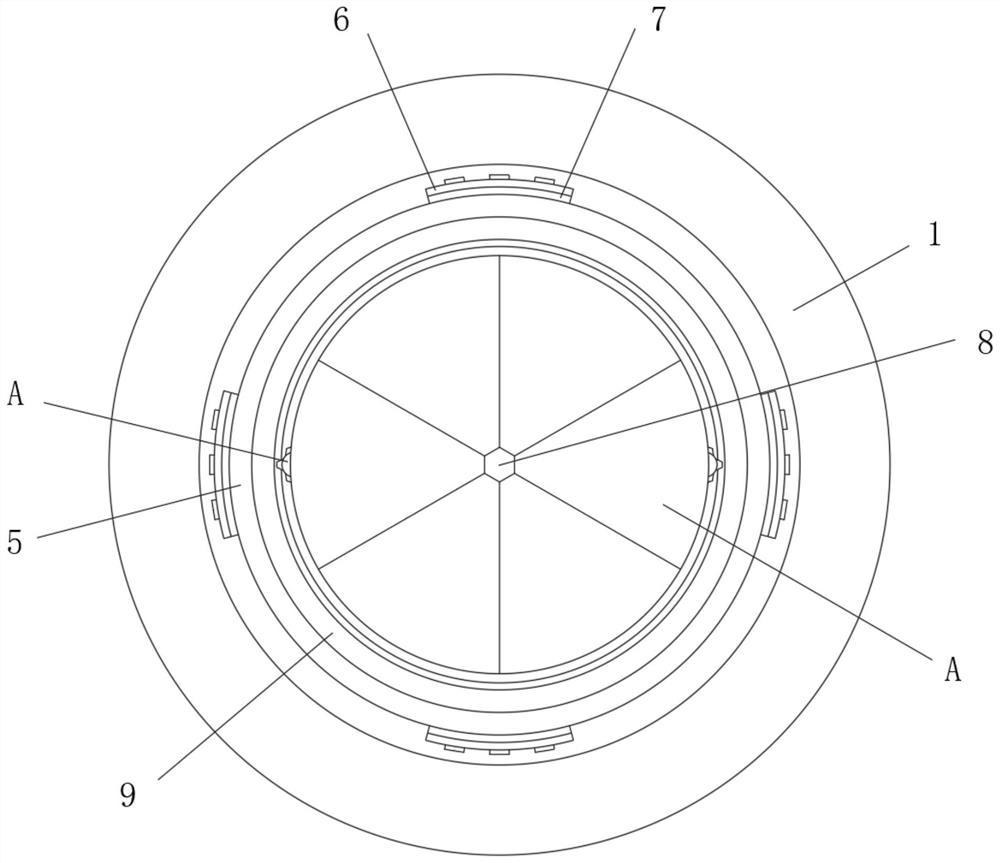

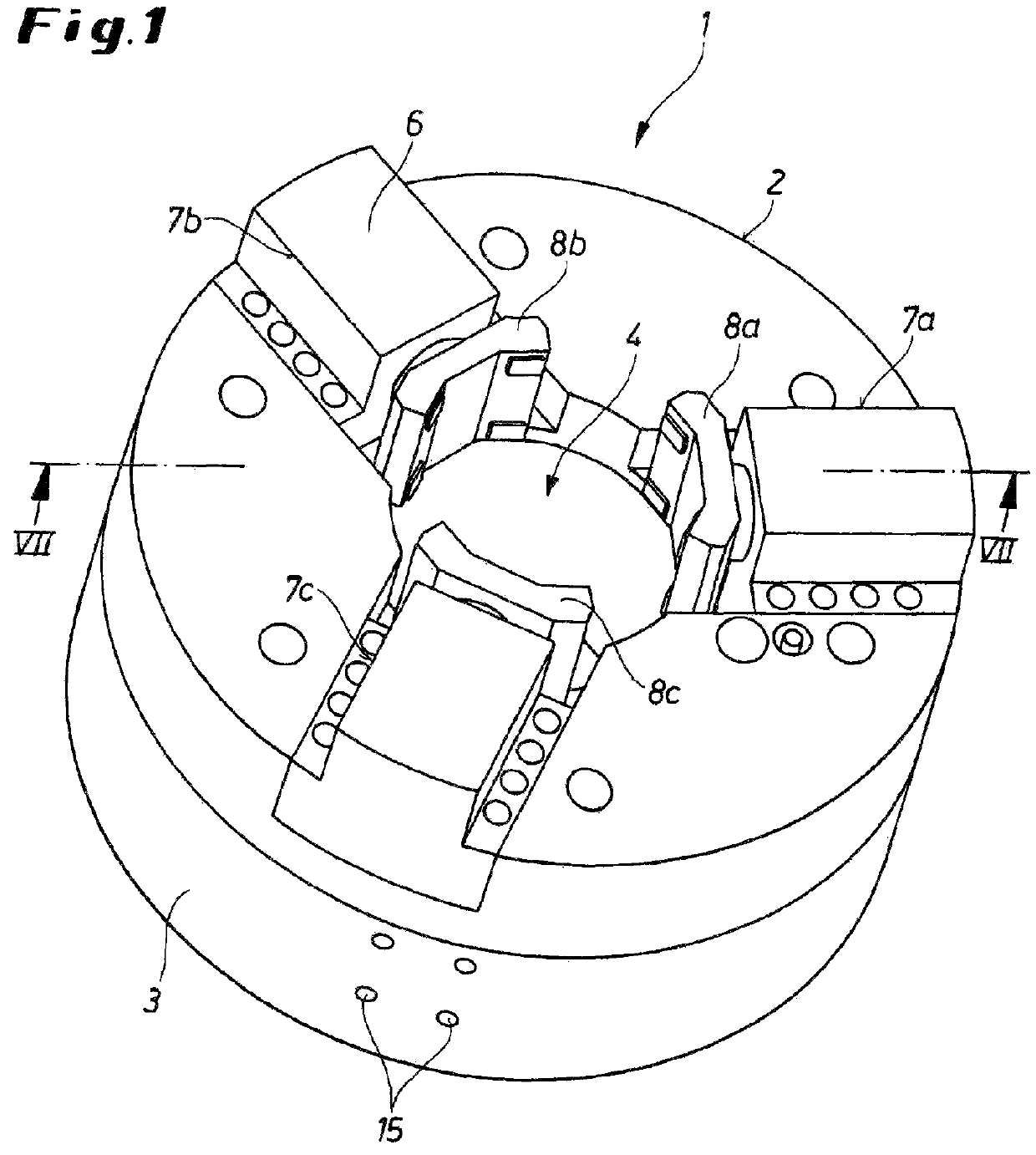

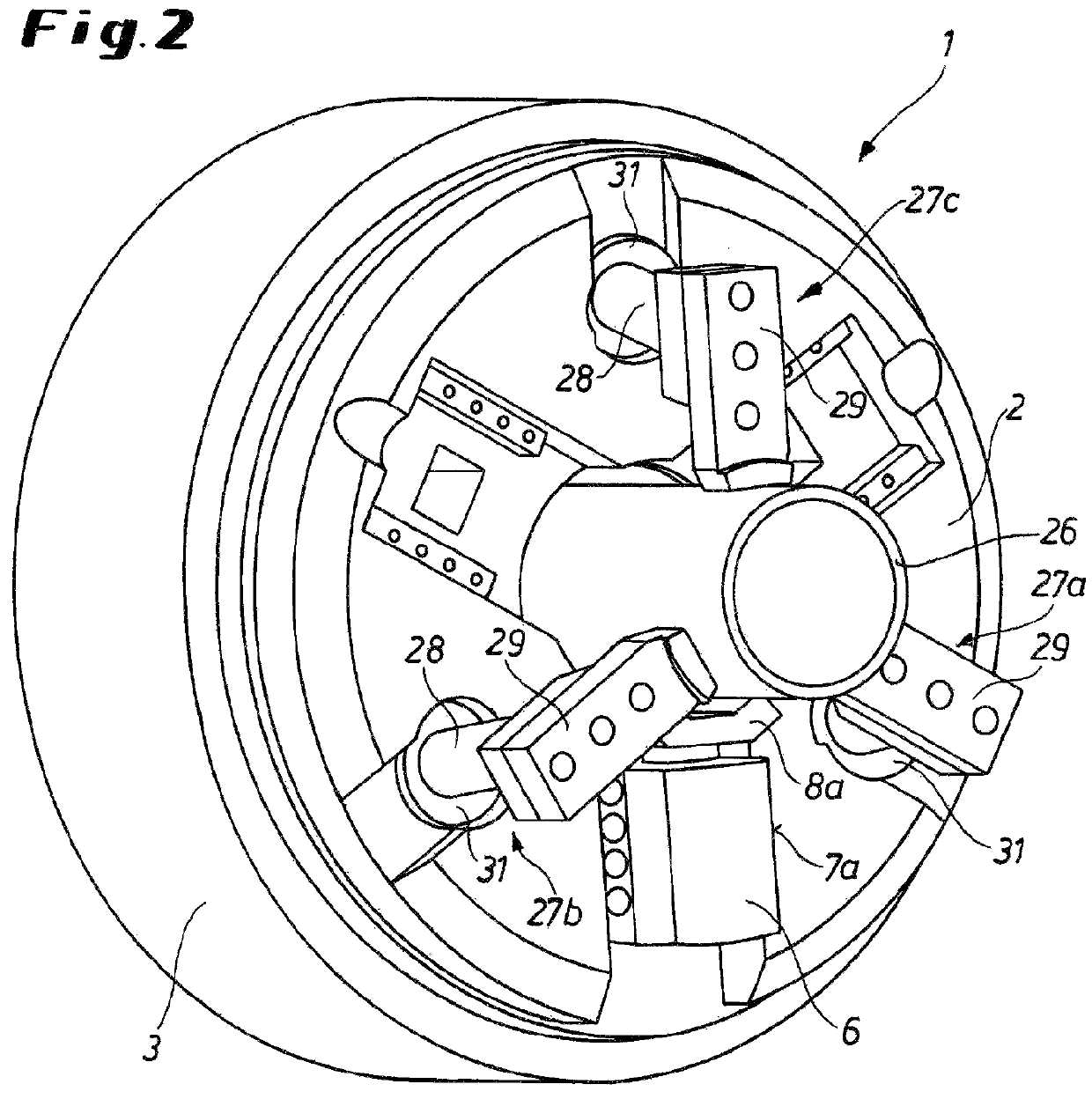

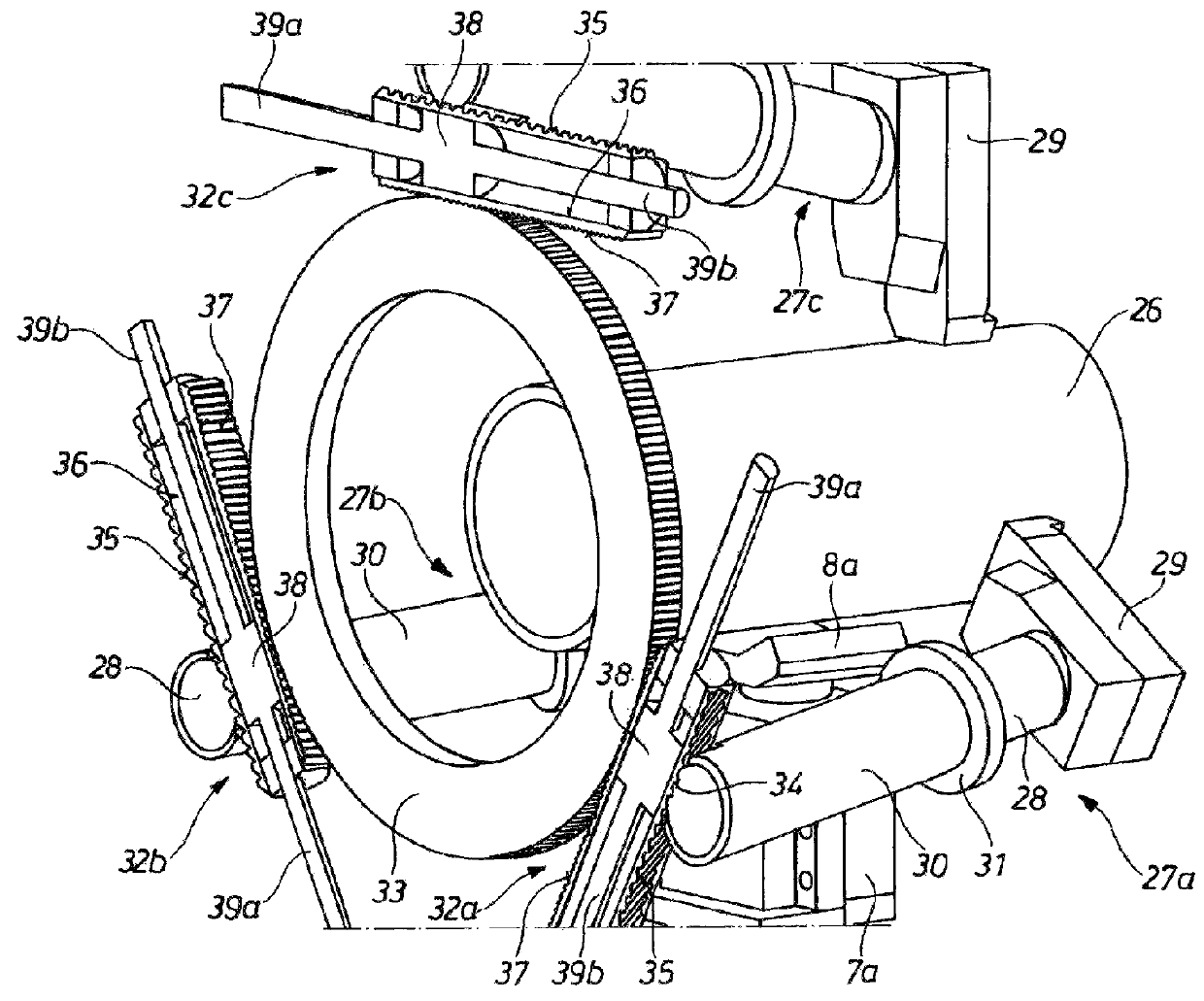

Chuck for apparatus for machining a tubular rotating workpiece

ActiveUS9381576B2Improve operating characteristicsFor accurate cuttingSleeve/socket jointsChucksRotational axisMachine tool

The invention relates to a chuck (1) for a machine tool for machining a tubular workpiece (26) which rotates about a rotational axis that coincides with the center of the chuck, comprising at least two chucking slides (7a, b, c) that are designed to be positionable radially with respect to the rotational axis in order to release and chuck the workpiece, are arranged on the end side of and in a manner distributed uniformly around the circumference of a chuck head plate, and bear chucking jaws (8a, b, c). Such a chuck is intended to be created with improved operating characteristics and extension to all chucking functions. To this end, for the external central chucking of a tube (26), there are provided centring slides (27a, b, c) which can be disengaged from the chuck head plate with a forward inclination towards the end of the tube to be machined and center the tube by means of chucking claws (29) which are arranged at the front, free end of centring slide rods (28), said centring slides (27a, b, c) engaging via a toothed rod section (34) into a toothing (35) of a drive means assigned to each centring slide, and meshing for their part, on a toothing side (37) parallel to the side with the toothing, with a central toothed wheel (33) arranged concentrically with the rotational axis, wherein the central toothed wheel (33) synchronizes the movements of all the centring slides (27a, b, c).

Owner:SMS MEER

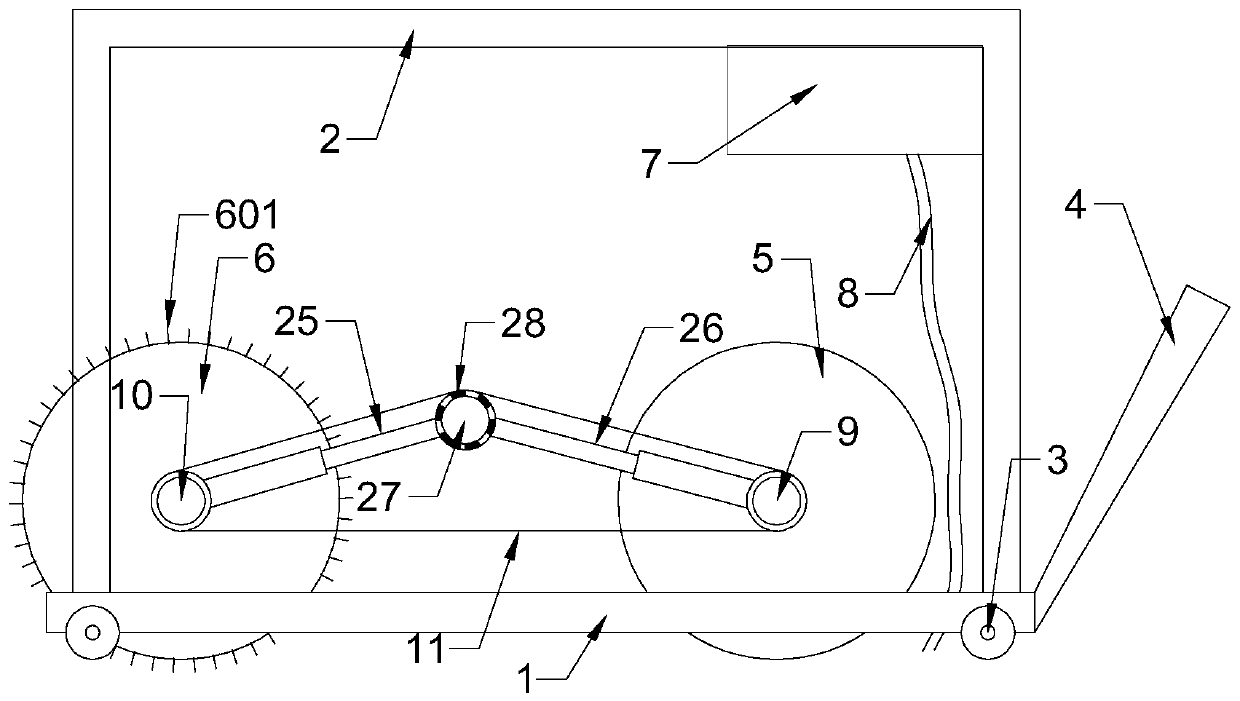

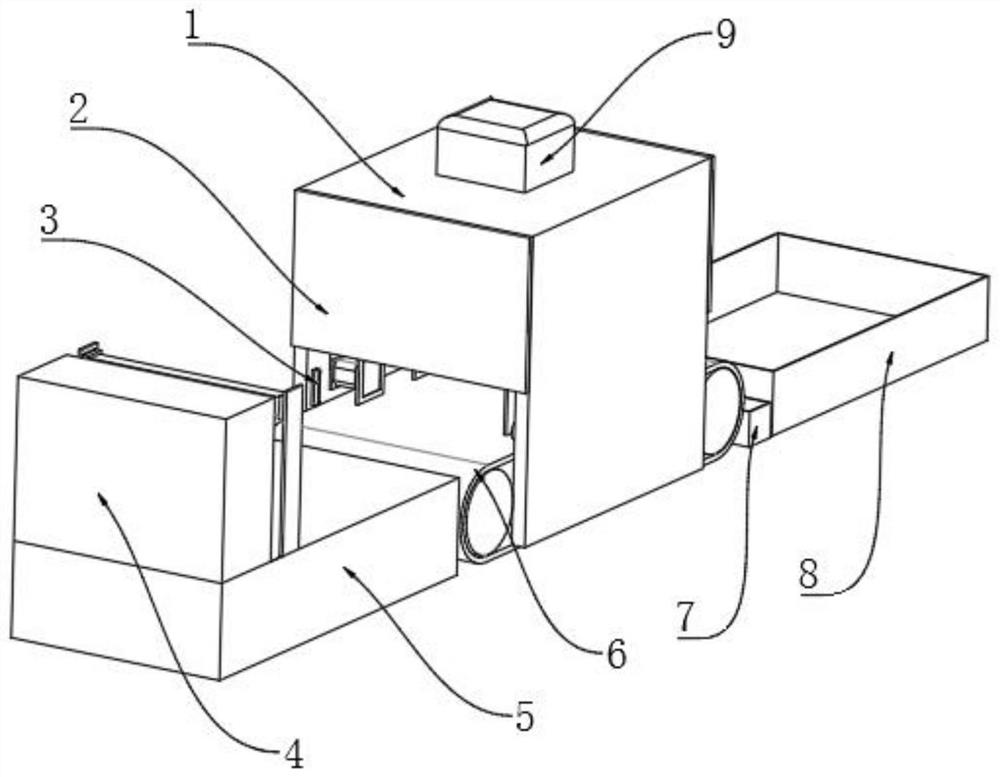

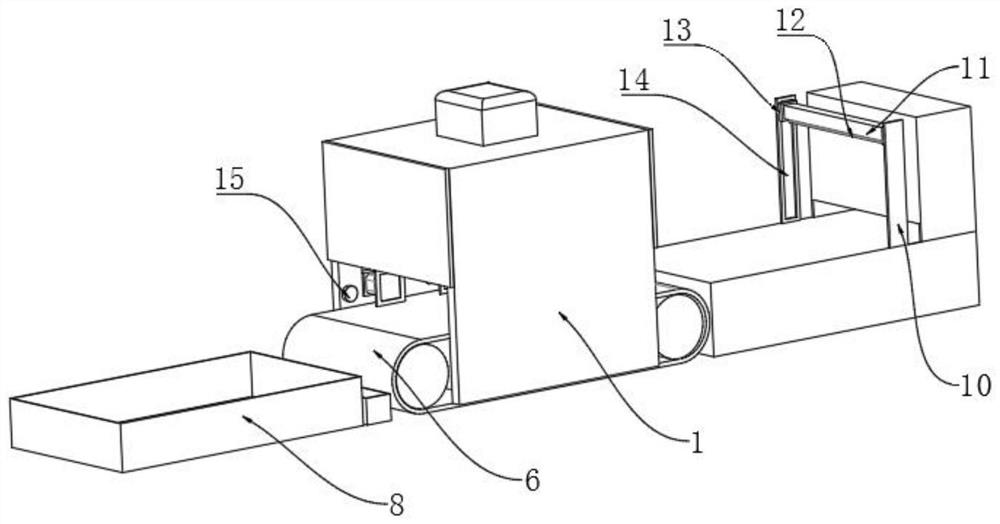

A plasma cutting machine

ActiveCN105750719BImprove securityAvoid natural saggingPlasma welding apparatusGear wheelElectric machinery

Owner:闫喜庆

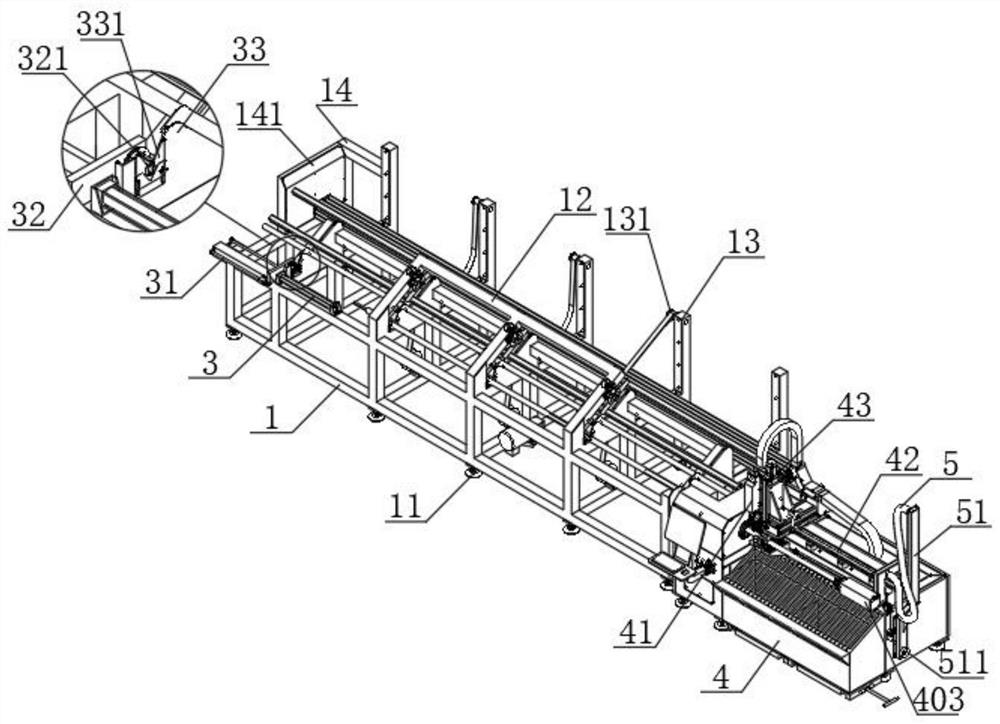

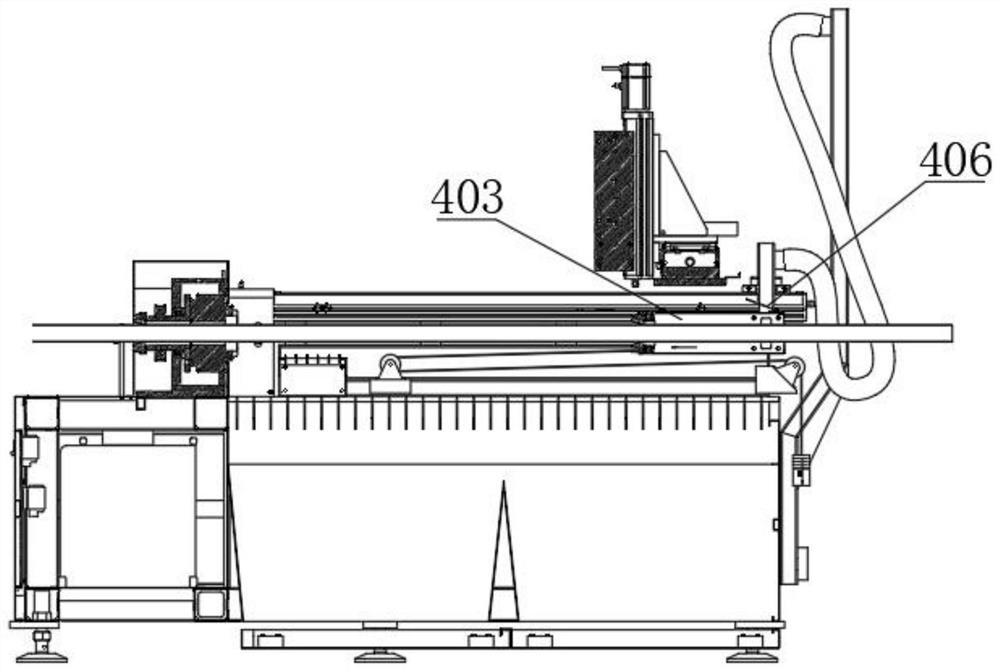

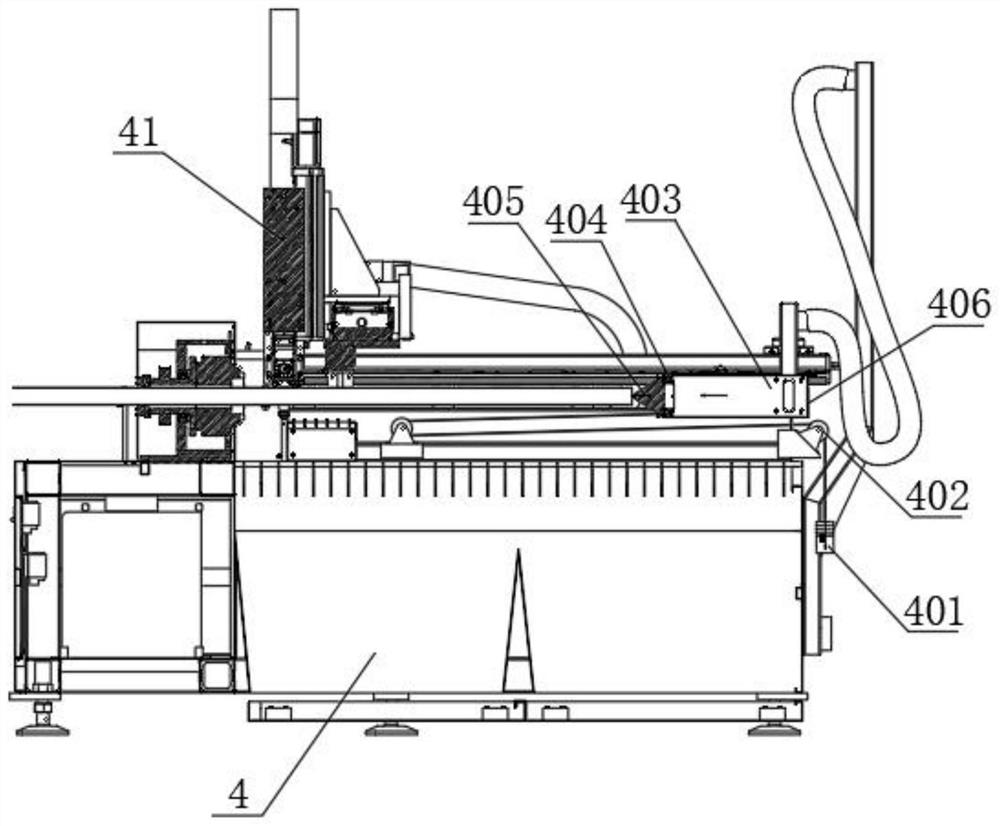

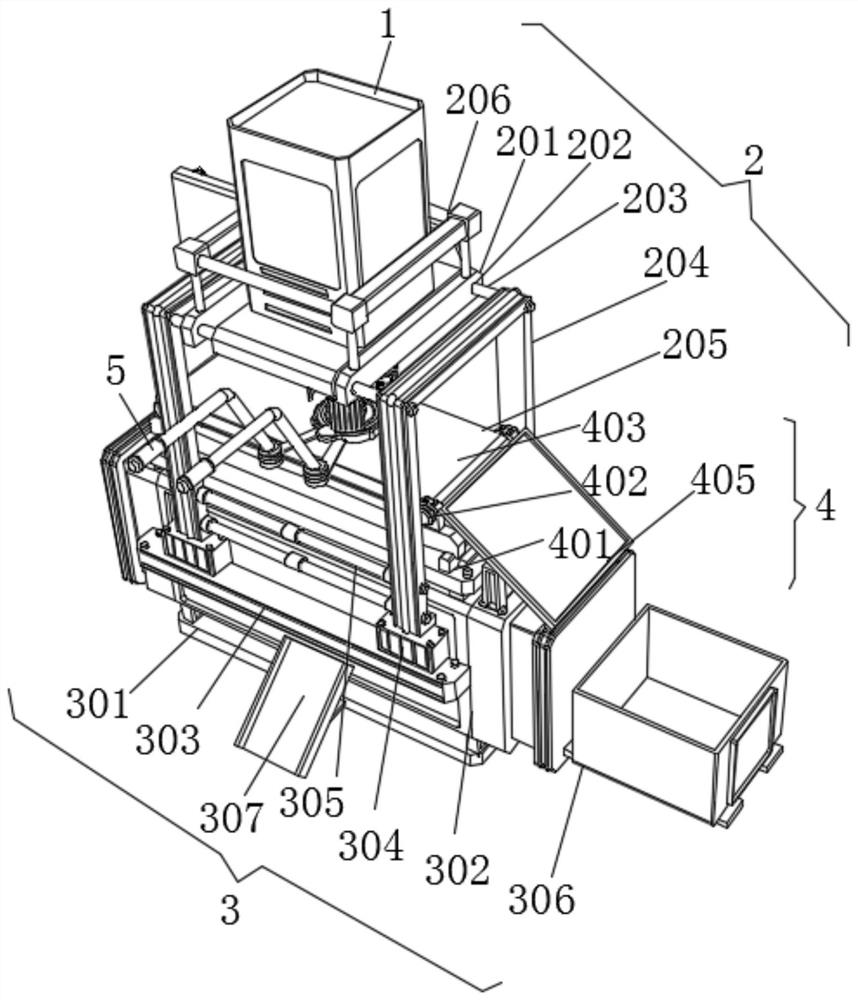

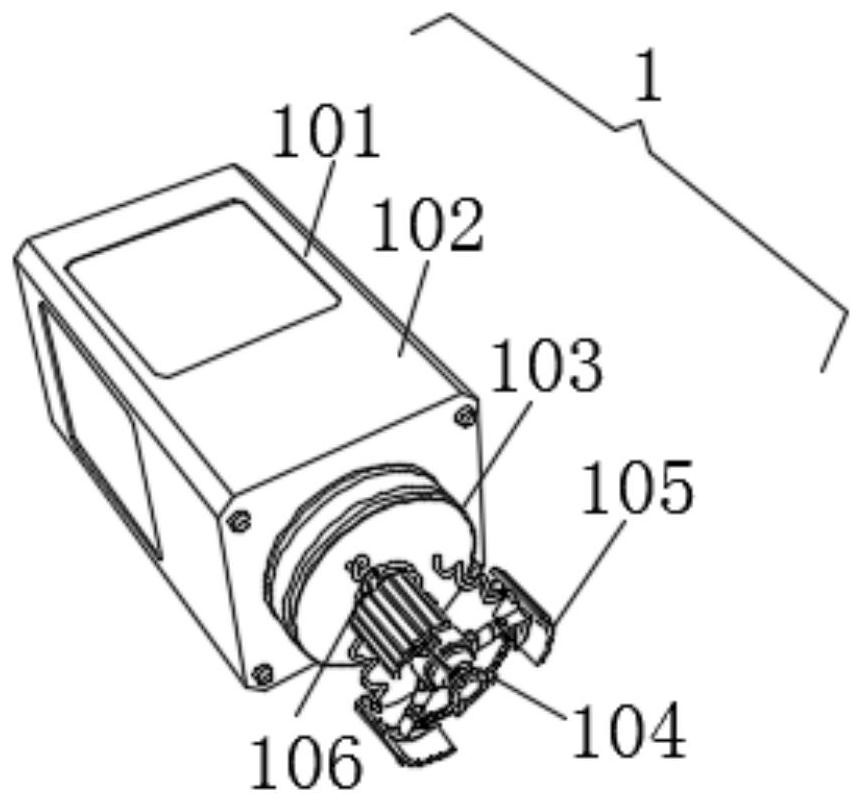

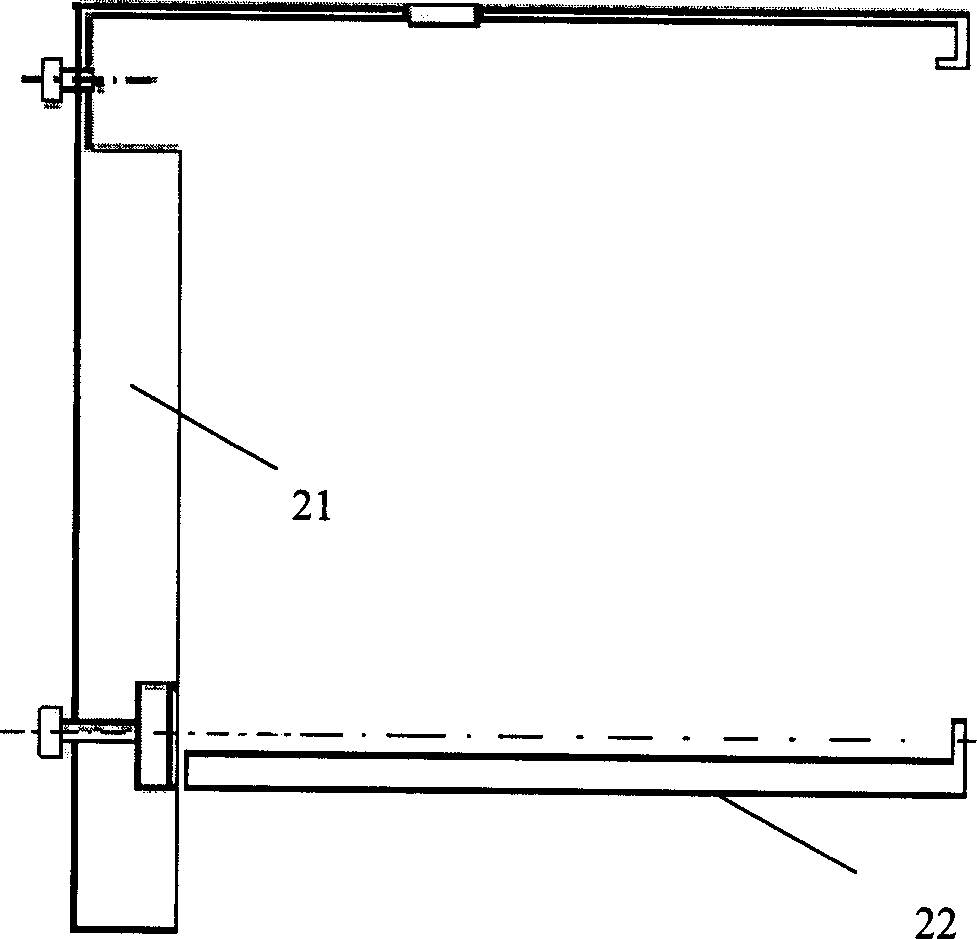

An intelligent reminder device for taking medicine with a continuous medicine bag on a roll

ActiveCN106205072BFor precise cuttingFor accurate cuttingTransmission systemsControl devices for conveyorsUse medicationDevice status

A smart medicament administration reminder device for tape-on-reel continuous medicament packs (700). Serial numbers are provided on the tape-on-reel continuous medicament packs (700). A reading device for recognizing the serial numbers is connected to a wireless communication module (34). The wireless communication module (34) is connected to a microprocessor (20). Also, a black mark (710) is provided on each medicament pack (700). A medicament pack delivery mechanism (200) comprises a rotating delivery apparatus (210), a translating delivery apparatus (220), a ranging apparatus (240), and a medicament pack positioning apparatus (230). A medicament pack severing mechanism (300) comprises a blade component (310), a blade driving apparatus (320), and a blade positioning detection apparatus (330). A medicament pack diverting mechanism (400) comprises a flipping apparats (410) and a medicament pack diversion baffle (420). The microprocessor (20) also is connected to a medicament retrieval alarm. The apparatus automatically outputs one medicament pack (700) at a set time for medicament administration, severs the medicament pack (700) either automatically or on the basis of an instruction of a patient, and is capable of reminding the patient to take a medicament on time.

Owner:XIAMEN ZAYATA TECH INC

A bridge expansion joint cutting device

ActiveCN108265610BQuality assuranceFor accurate cuttingBridge erection/assemblyRoads maintainencePillow block bearingBridge deck

The invention relates to the technical field of bridge construction, in particular to a cutting device for an expansion joint of a bridge. The cutting device for the expansion joint of the bridge comprises a base and a machine frame. A first sliding rail and a second sliding rail are correspondingly arranged on the inner wall of the front half part of the machine frame, the first sliding rail andthe second sliding rail are correspondingly provided with a first sliding block and a second sliding block, a motor is installed on the first sliding block, a first rotating shaft is arranged on the motor, and a circular parting tool and a first belt pulley are arranged on the first rotating shaft in a sleeving mode. Bearing seats are arranged on the inner wall of the rear half part of the machineframe, a second rotating shaft is connected between the bearing seats, and a cleaning cylinder and a second belt pulley are arranged on the second rotating shaft in a sleeving mode. A vacuum cleaneris arranged on the upper side of the machine frame. The cleaning cylinder cleans up dust on a bridge deck to-be-cut, so that the circular parting tool can cut accurately, and the quality of cutting ofthe expansion joint is guaranteed; the dust produced by the cutting can be recovered in the vacuum cleaner, so that the pollution degree to the environment is effectively reduced; and the cutting depth of the circular parting tool can be quickly adjusted by an extensible rod and the sliding blocks.

Owner:河北省高速公路石黄管理处

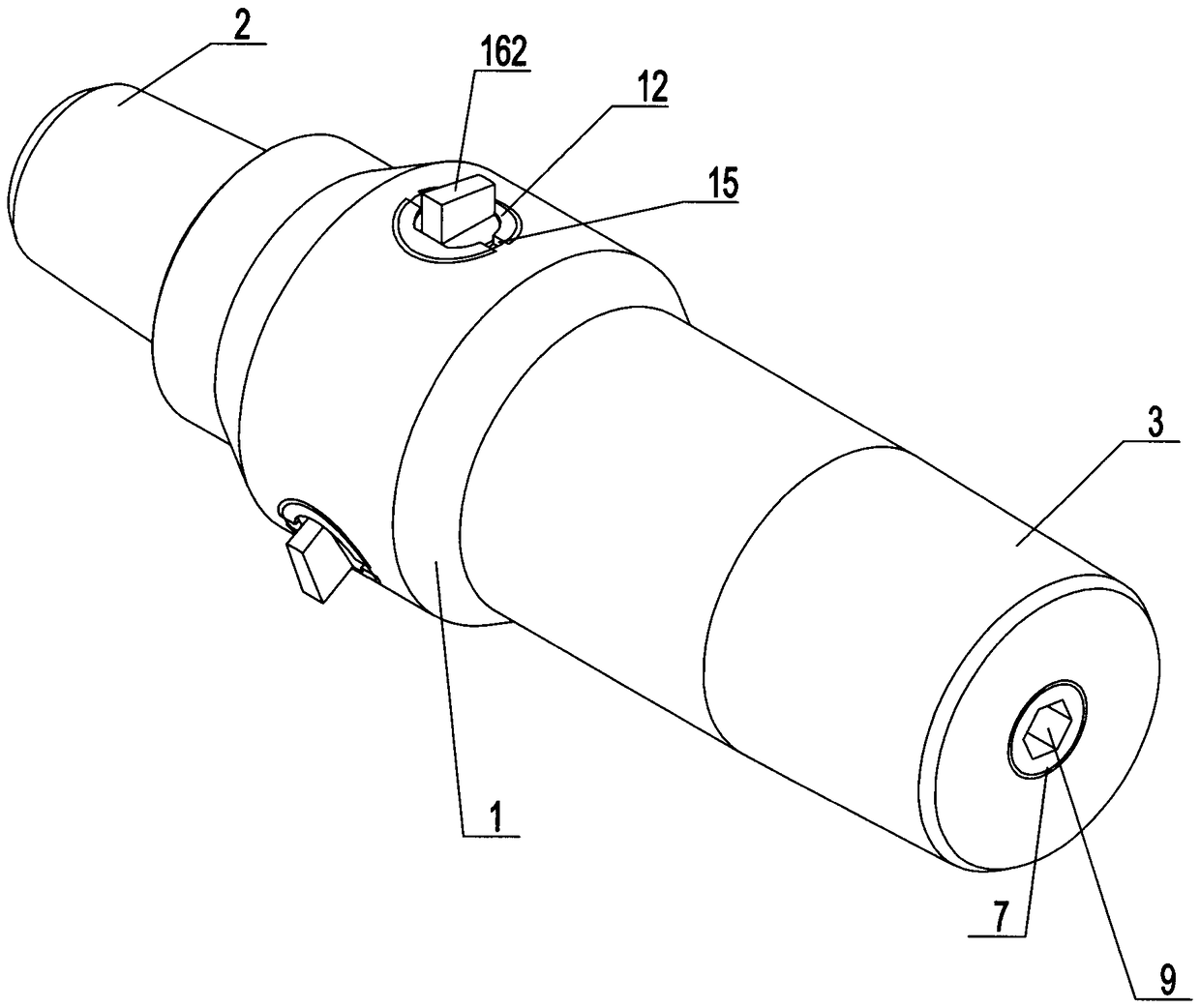

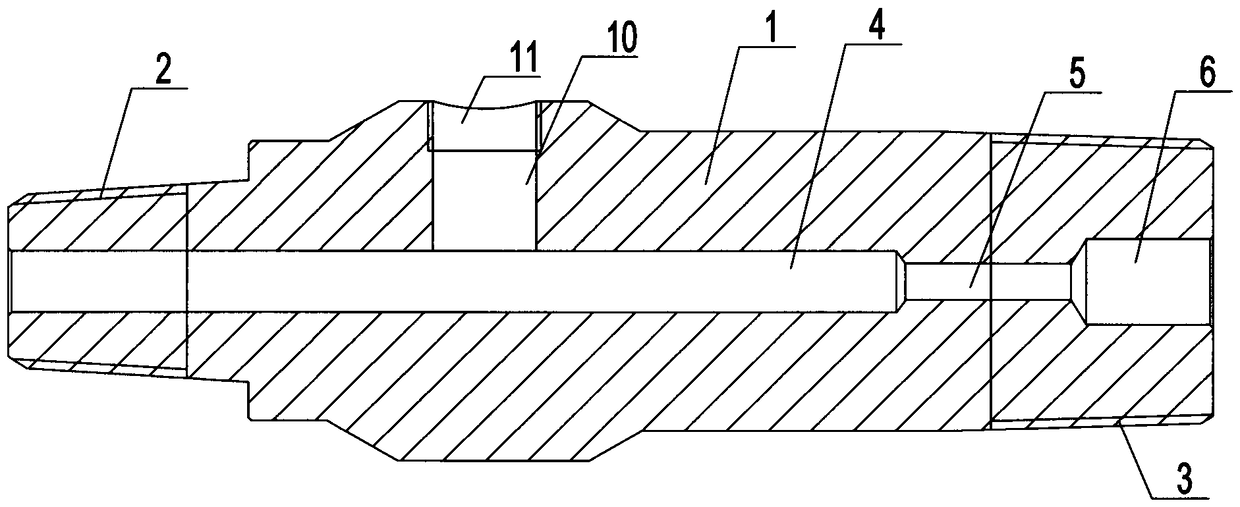

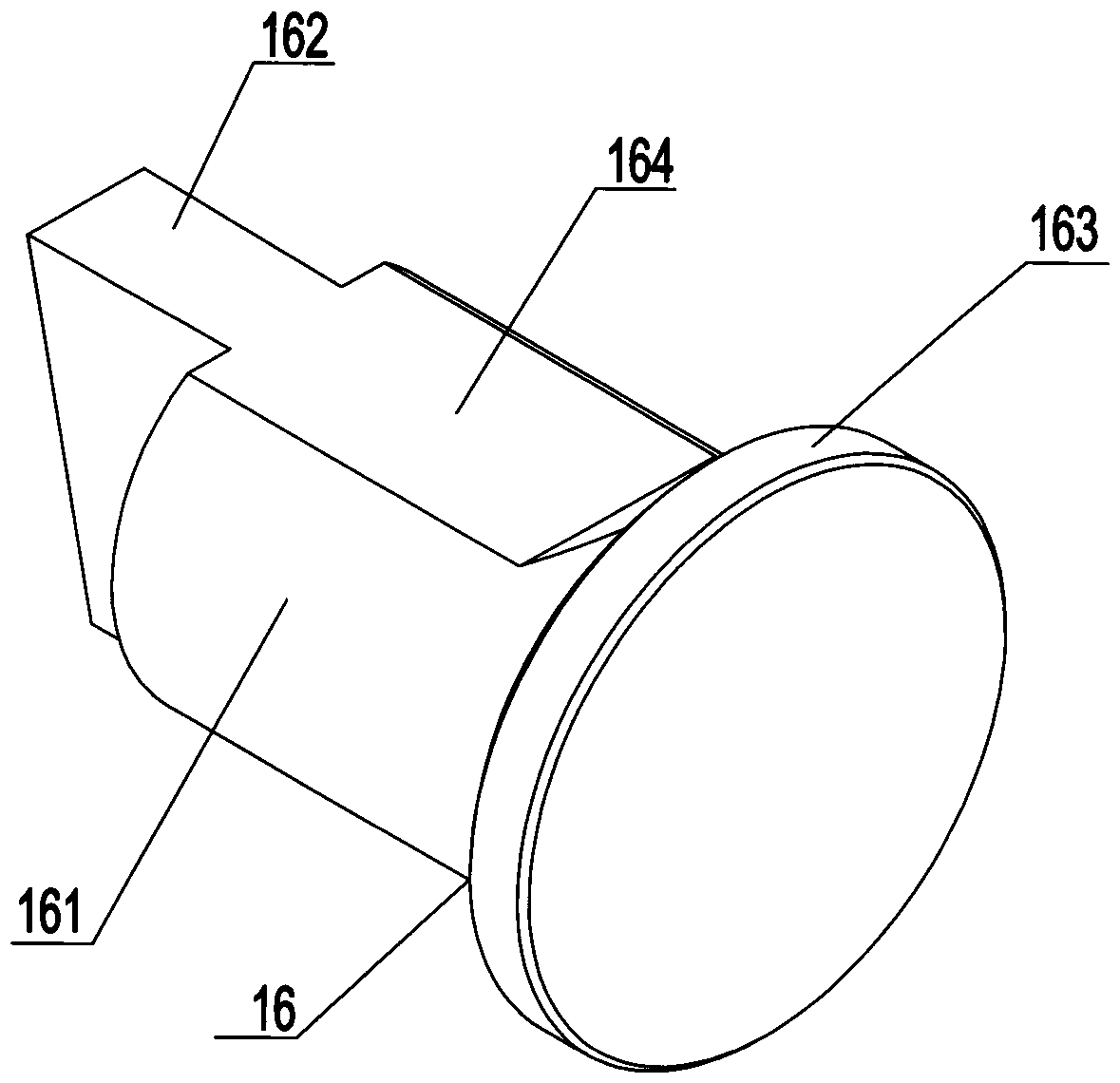

Hydraulic oil pipe inner cutter

ActiveCN105257232BFor accurate cuttingEasy and accurate pressure adjustmentBorehole/well accessoriesEngineeringScrew thread

Owner:YANCHENG DONGRONG PETROLEUM MACHINERY CO LTD

Simple pipe cutting machine

PendingCN113927354AFor accurate cuttingRealize automatic feeding processTube shearing machinesMetal working apparatusIndustrial engineeringSupport plane

The invention discloses a simple pipe cutting machine. The simple pipe cutting machine comprises a feeding supporting frame, a feeding mechanism is arranged on one side of the interior of the feeding supporting frame, a conveying mechanism is arranged in one end of the feeding supporting frame, a cutting mechanism is arranged at one end of the feeding supporting frame, and a limiting mechanism and a dust collection mechanism are arranged on the cutting mechanism. The simple pipe cutting machine has the characteristics of being reasonable in structure and convenient to use, through mutual cooperation between the arranged feeding mechanism and the arranged conveying mechanism, automatic feeding of to-be-cut pipes can be achieved, and then the pipe cutting efficiency can be improved; through mutual cooperation between the arranged cutting mechanism and the arranged limiting mechanism, pipe cutting is more convenient and accurate; and through the arrangement of the dust collection mechanism, chippings generated during pipe cutting can be effectively cleaned away.

Owner:GUANGZHOU HANMA AUTOMATION CONTROL EQUIP CO LTD

An ultrasonic cutting mechanism for ear loops and nose wires for full-servo masks

ActiveCN111452118BEasy to cutTo achieve the purpose of ultrasonic cuttingGarment suspendersMetal working apparatusUltrasonic vibrationHigh intensity

The invention provides an ultrasonic cutting mechanism for ear hooks and nose wires for a full-servo mask, which belongs to the field of mask processing and includes an ultrasonic cutting mechanism. The bottom of the ultrasonic cutting mechanism is fixedly supported by a cutter supporting mechanism. The transportation mechanism is fixedly installed at each corner, and the traction mechanism is fixedly installed in the middle of the bottom end of the ultrasonic cutting mechanism. The present invention uses the ultrasonic cutting mechanism, body, ultrasonic generator and ultrasonic horn to facilitate High-intensity ultrasonic cutting energy is generated at the place, and the energy is converted into high-frequency ultrasonic vibration by the transducer, so as to be transmitted to the ultrasonic horn, and then transmitted to the ultrasonic cutter by the ultrasonic horn. The high-frequency vibration generated by the ultrasonic cutter can achieve the purpose of ultrasonic cutting when the ear hooks and nose wires to be cut touch.

Owner:广州龙越自动化设备有限公司

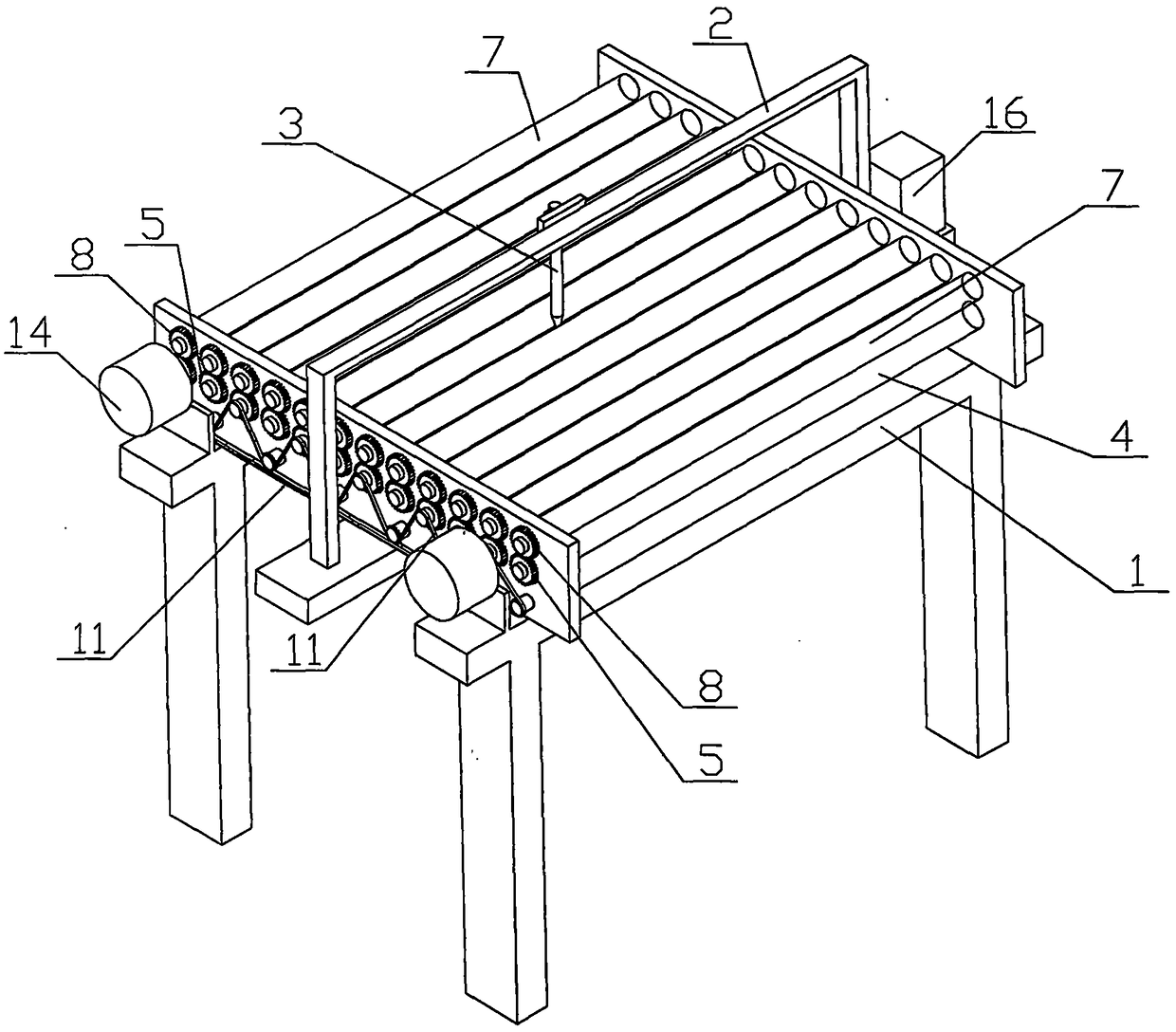

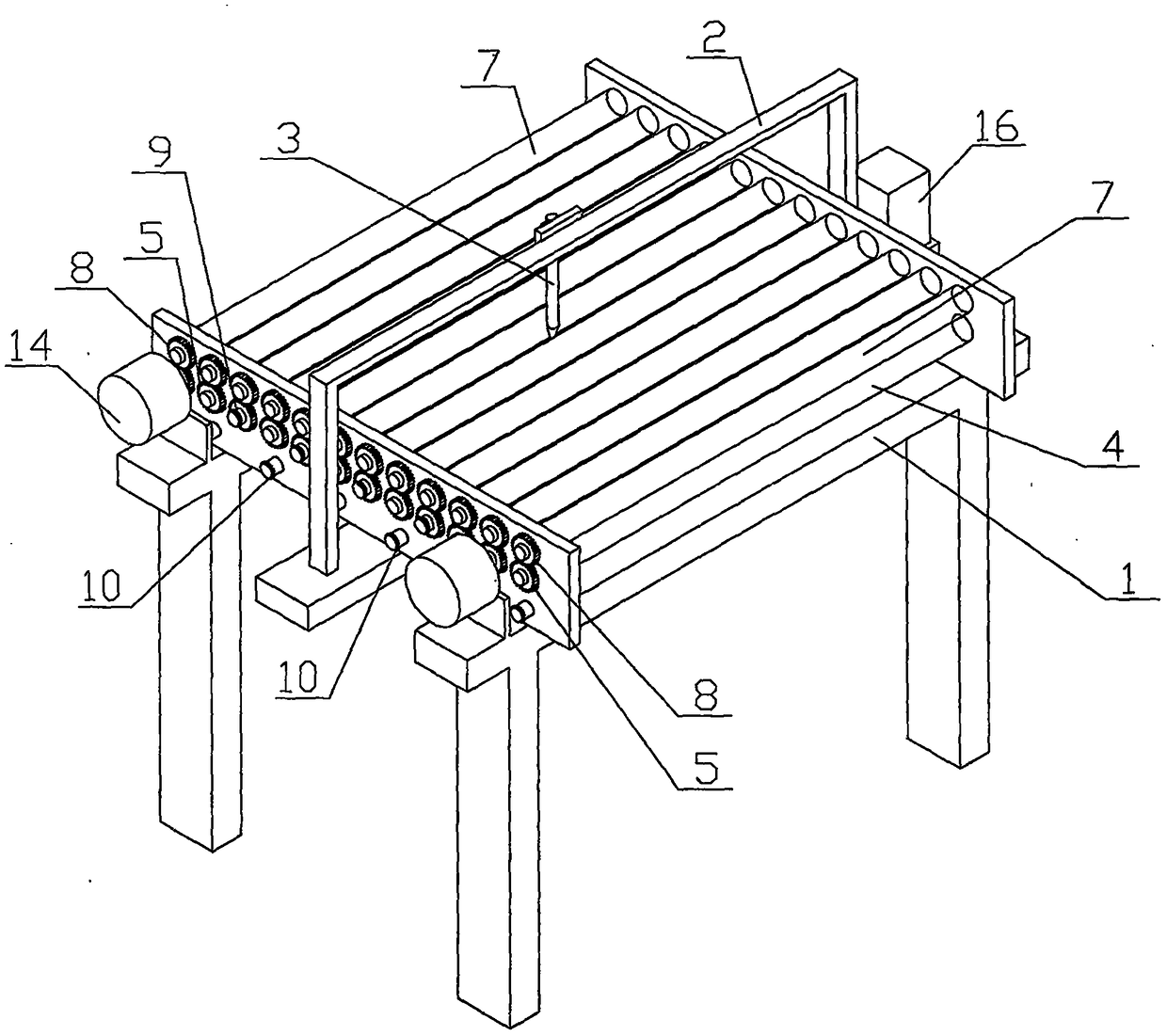

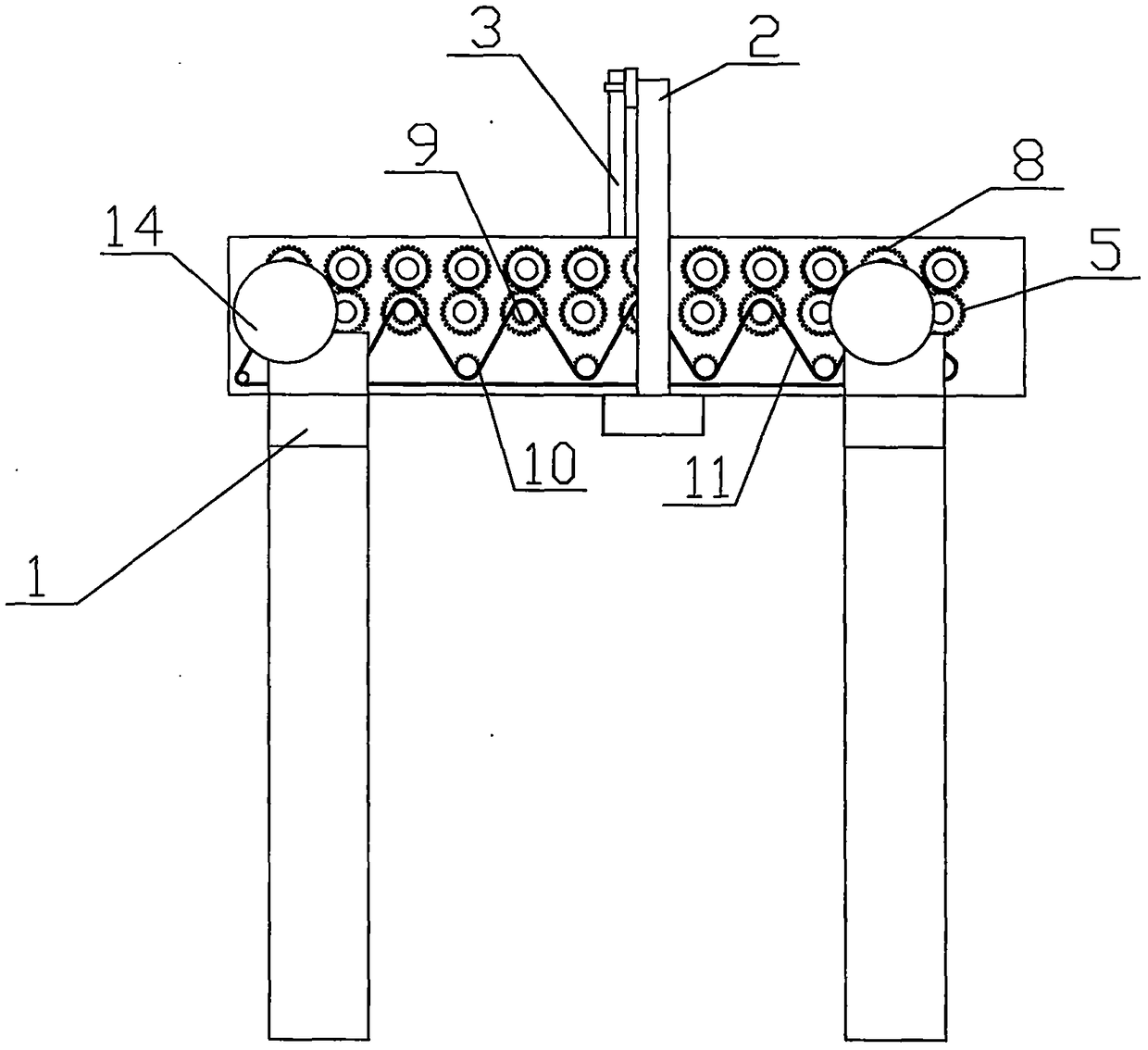

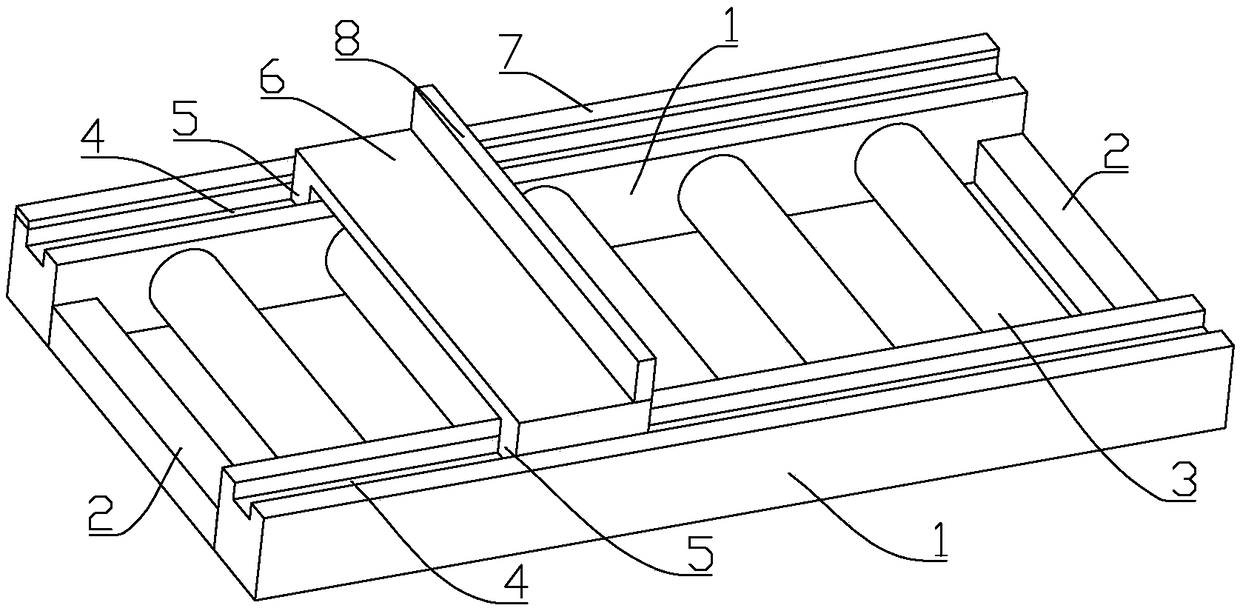

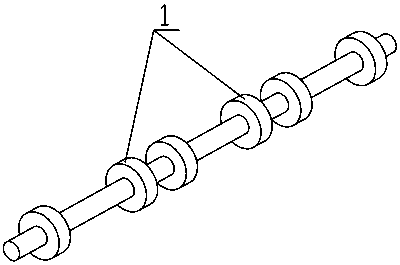

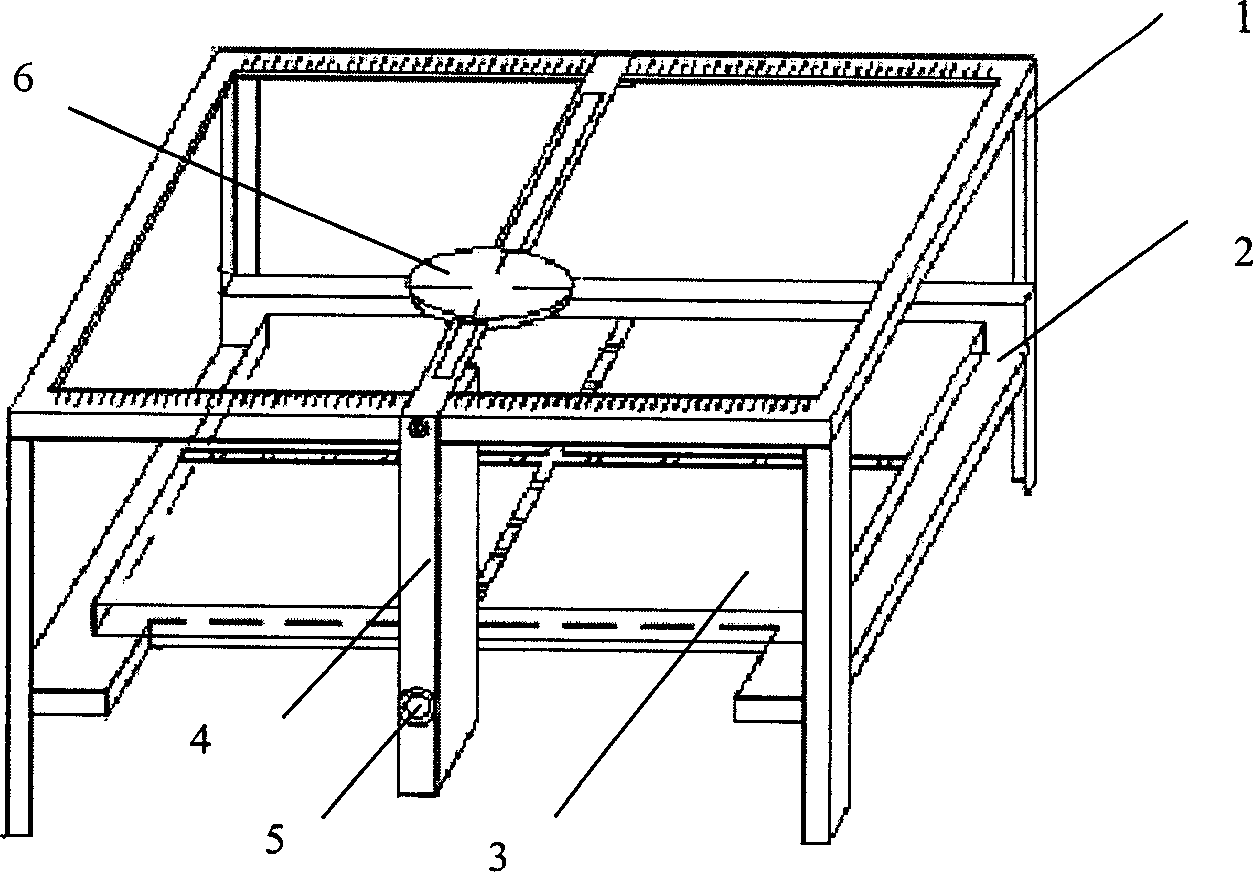

Profile feeding and cutting device

InactiveCN109079640AEasy to feedFor accurate cuttingGrinding machinesGrinding feedersMechanical engineeringEngineering

The invention discloses a profile feeding and cutting device which comprises a feeding rack and a cutting platform which are connected in sequence front and back, wherein the feeding rack comprises apair of side feeding brackets which are symmetrically arranged, and a feeding connecting rod for connecting the two side feeding brackets; a plurality of rollers are mounted between the two side feeding brackets; a row of bolt holes are formed in the top of a front side feeding bracket; fastening bolts are arranged in match inside the bolts; adjusting pieces are arranged between the fastening bolts and the side feeding brackets; long-strip shaped through holes are formed in the adjusting pieces; the fastening bolts penetrate through the long-strip shaped through holes to fix the adjusting pieces on the side feeding brackets; rollers are mounted at the tops of the inner ends of the adjusting pieces. Due to adoption of the feeding racks at the front end of a cutting platform, profiles can beconveniently fed into the cutting platform behind, in addition, the profiles can be positioned in a direction perpendicular to the profiles, profiles of different widths can be adjusted, and later accurate cutting can be facilitated.

Owner:浙江柏仕顿装饰科技有限公司

Self-propelled mustard tumorous stem harvester

The invention discloses a self-propelled mustard tumorous stem harvester, which comprises a frame, a leaf removing device, a pulling-up device and a cutting device. The leaf removing device, the pulling-up device and the cutting device are mounted on the frame. The leaf removing device comprises a leaf brushing conical hood, and after moving to a position of coverage of a whole mustard plant, theleaf brushing conical hood rotates to collide with mustard leaves so as to remove the mustard leaves by brushing. The pulling-up device comprises a clamping and lifting portion with a large front endopening and a small rear end opening, and the mustard enters from the front end of the clamping and lifting portion and is gradually clamped and lifted and finally cut off by the cutting device afterlifting. By the self-propelled mustard tumorous stem harvester, tumorous stems of the mustard planted in mountain land can be harvested efficiently, damages of the mustard tumorous stems are reduced,labor intensity of workers is relieved, and operating efficiency is improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Novel profile cutting and feeding device

InactiveCN109048618AReduce shockAvoid damageGrinding machinesGrinding feedersEngineeringMechanical engineering

The invention discloses a novel profile cutting and feeding device. The novel profile cutting and feeding device comprises a feeding frame and a cutting table which are arranged in a front and rear mode in sequence. The cutting table performs good pressing on a profile by a cylinder pressing device to facilitate the cutting of the profile by an abrasive wheel cutting machine, and the feeding frameis arranged at the front end of a profile cutting device, so that the profile is conveniently fed into the cutting table at the rear part. Moreover, the profile can be positioned in the direction ofa vertical profile, and profiles with different widths can be adjusted to facilitate subsequent accurate cutting.

Owner:浙江柏仕顿装饰科技有限公司

Sectional material cutting device

InactiveCN108908060AEasy to cutEasy to compressGrinding machinesGrinding feedersEngineeringMechanical engineering

The invention discloses a sectional material cutting device. The sectional material cutting device comprises a feeding rack, a cutting table and a discharging rack. The feeding rack, the cutting tableand the discharging rack are connected in sequence from front to rear. According to the sectional material cutting device, the cutting table carries out very good pressing on a sectional material through an air cylinder pressing device so that an abrasive wheel cutting machine can be conveniently used for cutting the sectional material; because the discharging rack is arranged at the rear end ofthe cutting table to facilitate discharging of the sectional material, and carries out accurate measurement on cutting length, the cutting accuracy of the sectional material is greatly improved; and because the feeding rack is arranged at the front end of the cutting table, the sectional material can be conveniently sent into the cutting table behind, and can be positioned in the direction perpendicular to the sectional material, adjustment is carried out according to sectional materials of different widths, and follow-up accurate cutting is facilitated.

Owner:浙江柏仕顿装饰科技有限公司

Ultrasonic cut-off mechanism of ear ribbons and nose bridge bars of full-server masks

ActiveCN111452118AEasy to cutTo achieve the purpose of ultrasonic cuttingGarment suspendersMetal working apparatusEngineeringUltrasonic vibration

The invention provides an ultrasonic cut-off mechanism of ear ribbons and nose bridge bars of full-server masks, and belongs to the field of mask processing. The mechanism comprises an ultrasonic cutting mechanism, a cutter supporting mechanism is fixedly supported at the bottom of the ultrasonic cutting mechanism, transport mechanisms are fixedly mounted at the four corners of the bottom of the cutter supporting mechanism, and a traction mechanism is fixedly arranged in the middle of the bottom end of the ultrasonic cutting mechanism. The ultrasonic cutting mechanism, a machine body, an ultrasonic generator and an ultrasonic amplitude-change pole are arranged, so that high-intensity ultrasonic cutting energy is conveniently generated at the cutting end, and the energy is converted into high-frequency ultrasonic vibration under the action of a transducer so as to be transmitted to the ultrasonic amplitude-change pole; and then the high-frequency ultrasonic vibration is transmitted to an ultrasonic cutter through the ultrasonic amplitude-change pole, and due to the high-frequency vibration generated at the ultrasonic cutter, when the to-be-cut ear ribbons make contact with the nosebridge bars, the ultrasonic cutting aim is achieved.

Owner:广州龙越自动化设备有限公司

Profile forming device with shearing function

PendingCN113172113AAvoid destructionFor accurate cuttingShearing machinesShearing machine accessoriesTransmission beltBolt connection

The invention discloses a profile forming device with a shearing function, and relates to the technical field of profile shearing. The problem that in the production process of profiles, shearing is not smooth is solved. The device specifically comprises a box body, and the inner wall of one side of the box body is fixedly connected with a conveying belt. Fixed electric sliding rails which are uniformly distributed are machined on the inner walls of the two sides of the box body. Fixed electric sliding blocks are slidably connected to the inner walls of one sides of the fixed electric sliding rails. The outer walls of one sides of the fixed electric sliding blocks are connected with fixed electric push rods through bolts. The outer walls of one sides of output shafts of the fixed electric push rods are fixedly connected with fixed plates through screws. By arranging the conveying belt, the fixed electric sliding blocks, the fixed electric push rods, the fixed electric sliding rails and the fixed plates, an aluminum profile is lifted by the fixed electric sliding blocks, follow-up accurate cutting of the aluminum profile is facilitated, the aluminum profile is smooth at a notch, the quality of the aluminum profile is improved, the conveying belt can be prevented from being damaged because the aluminum profile is cut after being lifted, and the device practicability is improved.

Owner:肖述虎

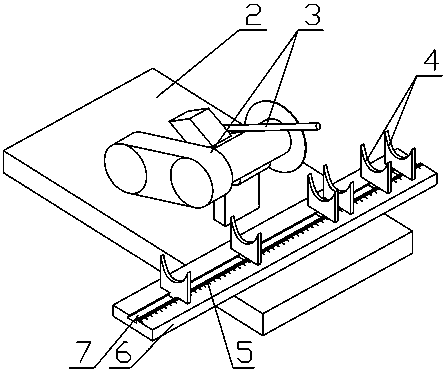

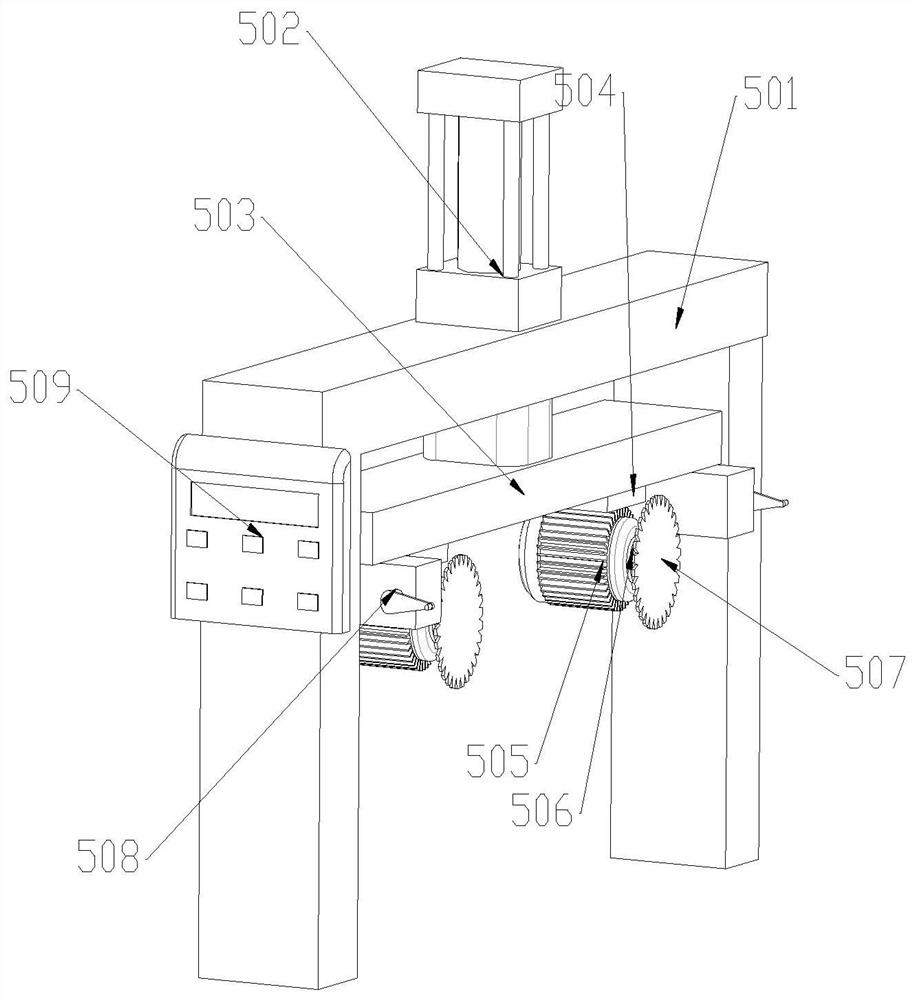

Multi-rolled gear shaft cutting machine

InactiveCN108237463ASimple structureAccurate card positioningGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention provides a multi-rolled gear shaft cutting machine. The multi-rolled gear shaft cutting machine is provided with a base, a grinding wheel cutting machine is arranged on the base, a transverse supporting plate is arranged below the front part of a cutting wheel of the grinding wheel cutting machine, a guide rail groove is transversely formed in the transverse supporting plate, the cross section of the guide rail groove is of a trapezoid structure which is arranged in the forward direction, a scale line is arranged at the edge of the guide rail groove, a plurality of arc-shaped shelves are clamped in the guide rail groove side by side, and the bottom of each arc-shaped shelf is connected with the guide rail groove in a sliding mode. The multi-rolled gear shaft cutting machine is simple in structure, accurate in clamping and positioning, and low in manufacturing cost, conveniently and accurately cuts, greatly improves the working efficiency of a one-rolled-into-six gear shaft in a workshop, and has good practical application value.

Owner:武汉重冶集团大冶重型装备有限公司

Dustproof solid-wall pipe directional cutting device and using method thereof

PendingCN112692895AReduce the problem of easy shakingHigh precisionMetal working apparatusClassical mechanicsStructural engineering

The invention belongs to the technical field of solid-wall pipe cutting and discloses a dustproof solid-wall pipe directional cutting device and a using method thereof. The device comprises a bottom plate, wherein a mounting table is arranged on the bottom plate, two first electric control air cylinders are symmetrically arranged on the mounting table, supporting mechanisms are arranged at the front ends of the first electric control air cylinders, clamping mechanisms are arranged at the front ends of the supporting mechanisms, a cutting mechanism is arranged at the front ends of the clamping mechanisms, a pressing mechanism is arranged between the supporting mechanisms and the clamping mechanisms, the supporting mechanisms, the clamping mechanisms, the cutting mechanism and the pressing mechanism are all fixed to the bottom plate, and the supporting mechanisms, the clamping mechanisms, the cutting mechanism and the pressing mechanism are all located on the same horizontal line. According to the device, by means of an arranged measuring mechanism, a solid-wall pipe can be directly cut according to a required cutting length, the cutting precision is improved, meanwhile, through mutual cooperation of a second clamping plate and a first clamping plate on an adjustable assembly, solid-wall pipes of different thicknesses can be cut at the same time, cutting is facilitated, and meanwhile the cutting efficiency is improved.

Owner:安徽康桥管业有限公司

Instrument for accurate cutting of crystal round examples and method of use thereof

InactiveCN101112776BPrecise positioningFor accurate cuttingFine working devicesComputer engineeringCrystal

Aiming at simply and reliably implementing the precise cutting to the wafer sample testing belt, the invention relates to a cutting tool cutting the wafer sample testing belt and the application method. The cutting tool includes a device frame, a magnifier, a sample table, a cutter rest and a cutter; wherein, the cutter is arranged in the cutter rest, the magnifier and the frame of the magnifier are arranged on the cutter rest, and the sample table is also arranged on the cutter rest.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com