An ultrasonic cutting mechanism for ear loops and nose wires for full-servo masks

A cutting mechanism and ultrasonic technology are applied in the direction of pulling clothes, clothing, clothing, etc., which can solve the problems of inconvenient ear-hook and nose line cutting processing, inability to improve the stability of the cutting process, and inconvenience in assembly-line cutting production, etc. Achieve the effect of fast cutting and transfer, smooth incision and accurate edge trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

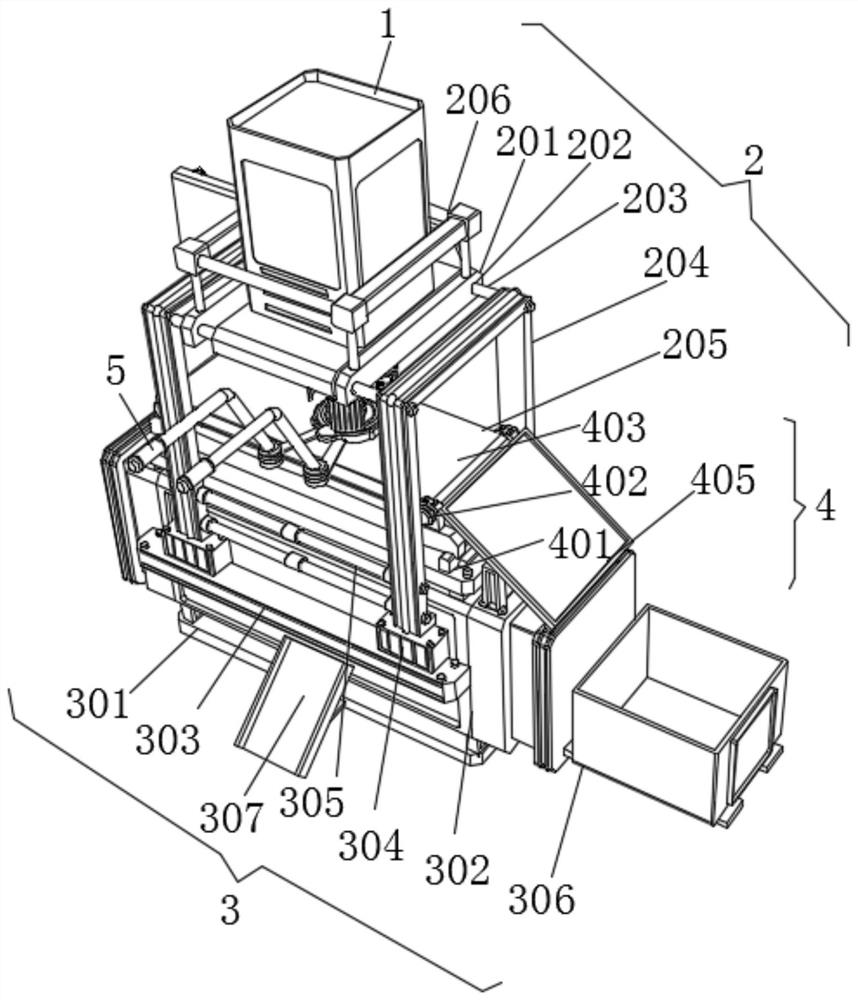

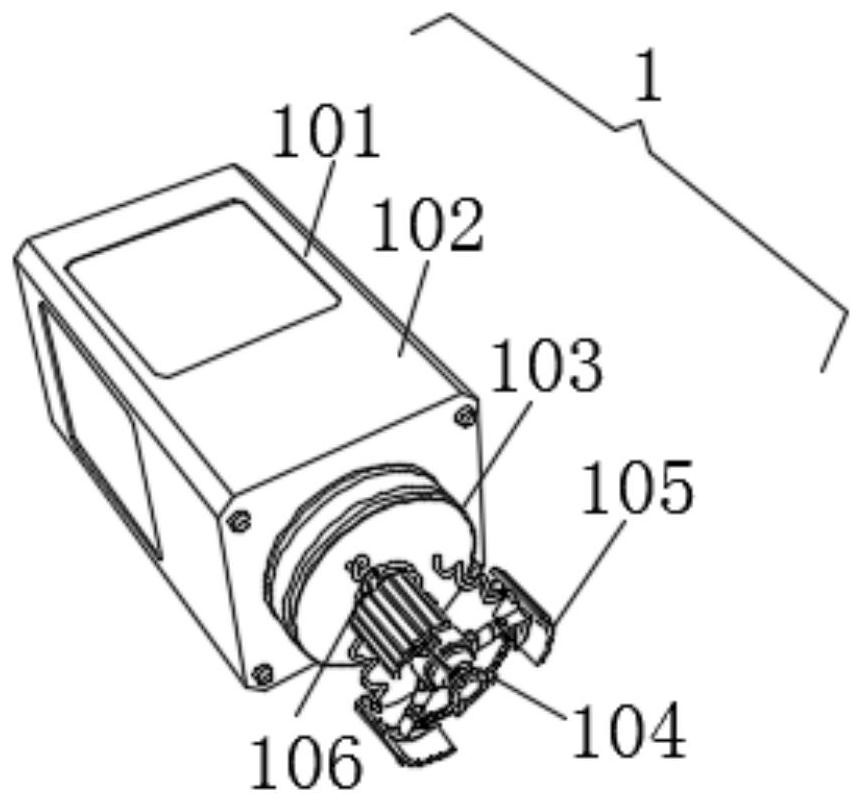

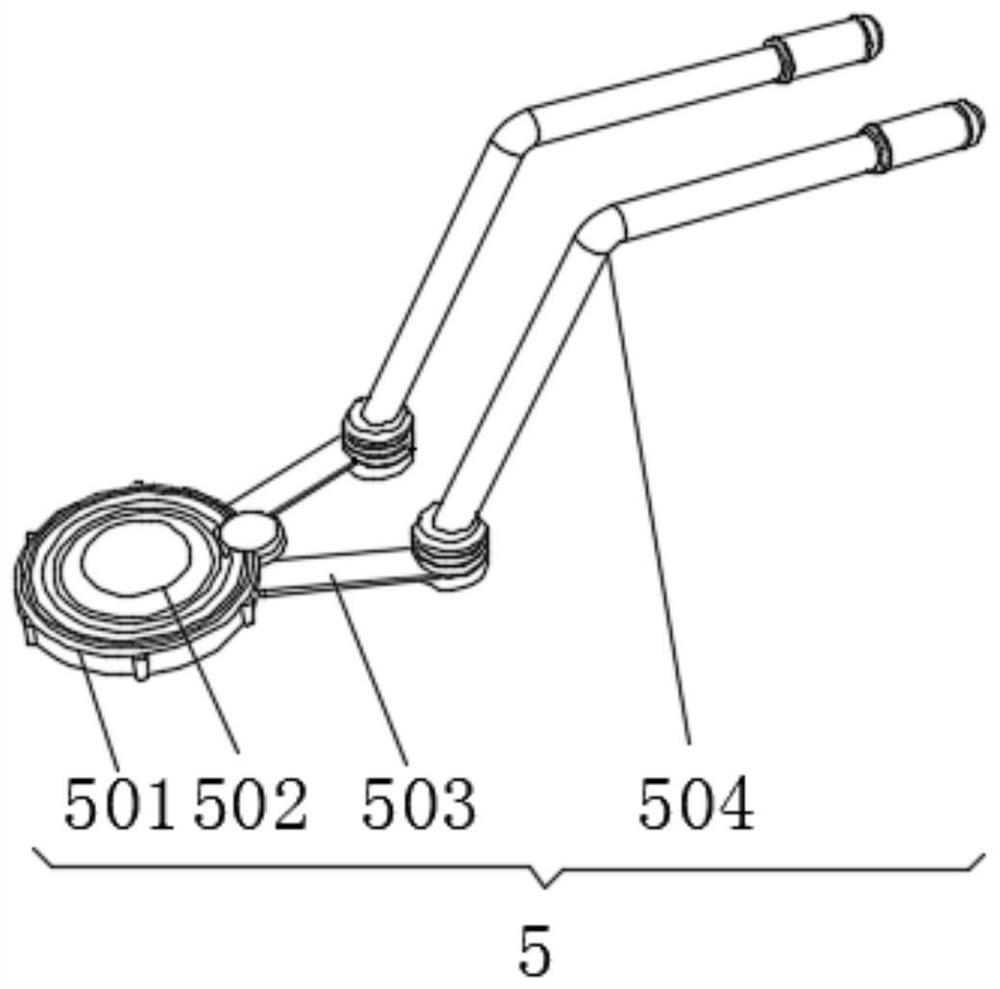

[0026] see Figure 1-6 , the present invention provides the following technical solutions: including an ultrasonic cutting mechanism 1, the bottom of the ultrasonic cutting mechanism 1 is fixedly supported with a cutter support mechanism 2, and the bottom four corners of the cutter support mechanism 2 are fixedly installed with a transport mechanism 4, A traction mechanism 5 is fixed in the middle of the bottom end of the ultrasonic cutting mechanism 1. The ultrasonic cutting mechanism 1, the body 101, the ultrasonic generator 102 and the ultrasonic horn 103 are provided to facilitate the generation of high-strength ultrasonic cutting at the cutting end. The energy is converted into high-frequency ultrasonic vibration under the action of the transducer, so as to be transmitted to the ultrasonic horn 103, and then transmitted by the ultrasonic horn 103 to the ultrasonic cutter, and then generated at the ultrasonic cutter. high frequency vibration.

[0027] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com