Profile feeding and cutting device

A cutting device and feeding technology, which is applied in the direction of grinding feed movement, grinding machine parts, grinding workpiece support, etc., can solve problems such as low work efficiency, complicated operation, and failure to meet production requirements, and achieve convenient The effect of accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

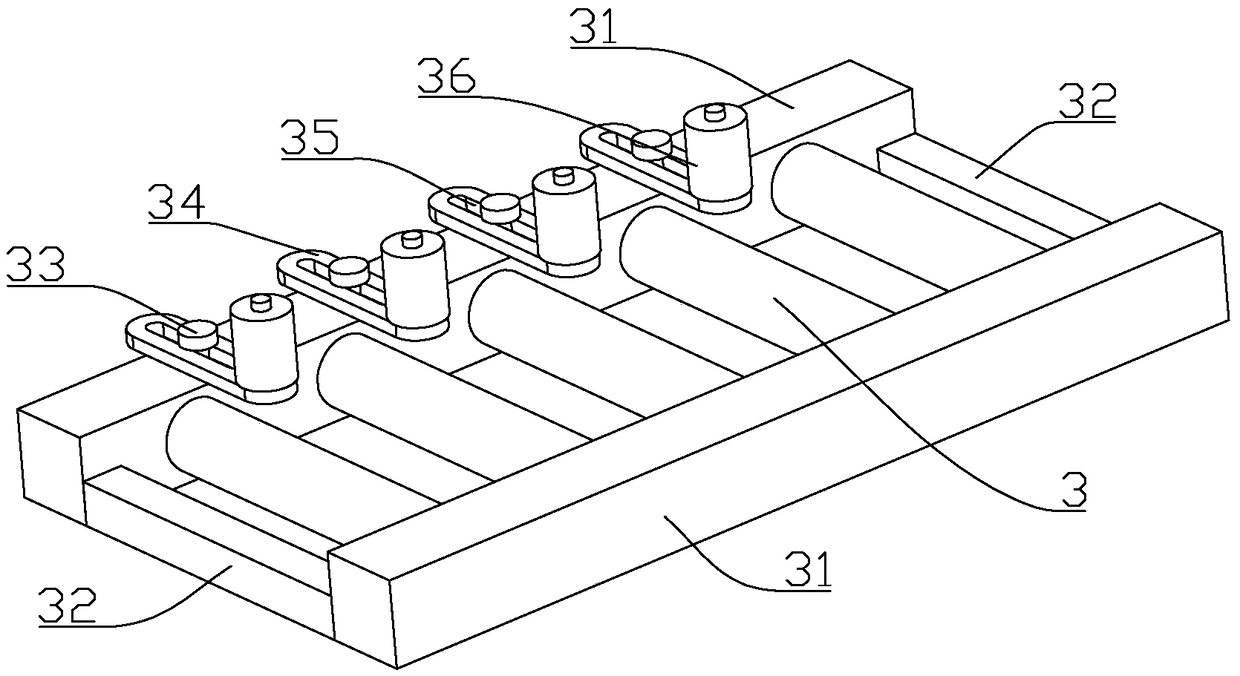

[0014] Such as figure 1 , 2 As shown, a feed cutting device for profiles includes a feed frame A and a cutting table B that are sequentially connected front and back, and the feed frame A includes a pair of symmetrically arranged side feed brackets 31, and connects two The feeding connecting rod 32 of the side feeding bracket 31, a plurality of rollers 3 are installed between the two side feeding brackets 31, and a row of bolt holes are provided on the top of the side feeding bracket 31 on the front side , the fastening bolts 33 are matched in the bolt holes, an adjusting piece 34 is arranged between the fastening bolts 33 and the side feed bracket 31, and a strip shaped Through holes 35, the fastening bolts 33 pass through the elongated through holes 35 to fix the adjusting piece 34 on the side feeding bracket 31, and a roller 36 is installed on the top of the inner end of the adjusting piece 34.

[0015] The outside of the roller 3 is covered with an anti-skid layer.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com