Instrument for accurate cutting of crystal round examples and method of use thereof

A tool and wafer technology, applied in the field of cutting tools for wafer sample test strips, can solve the problems of high price, complicated operation and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

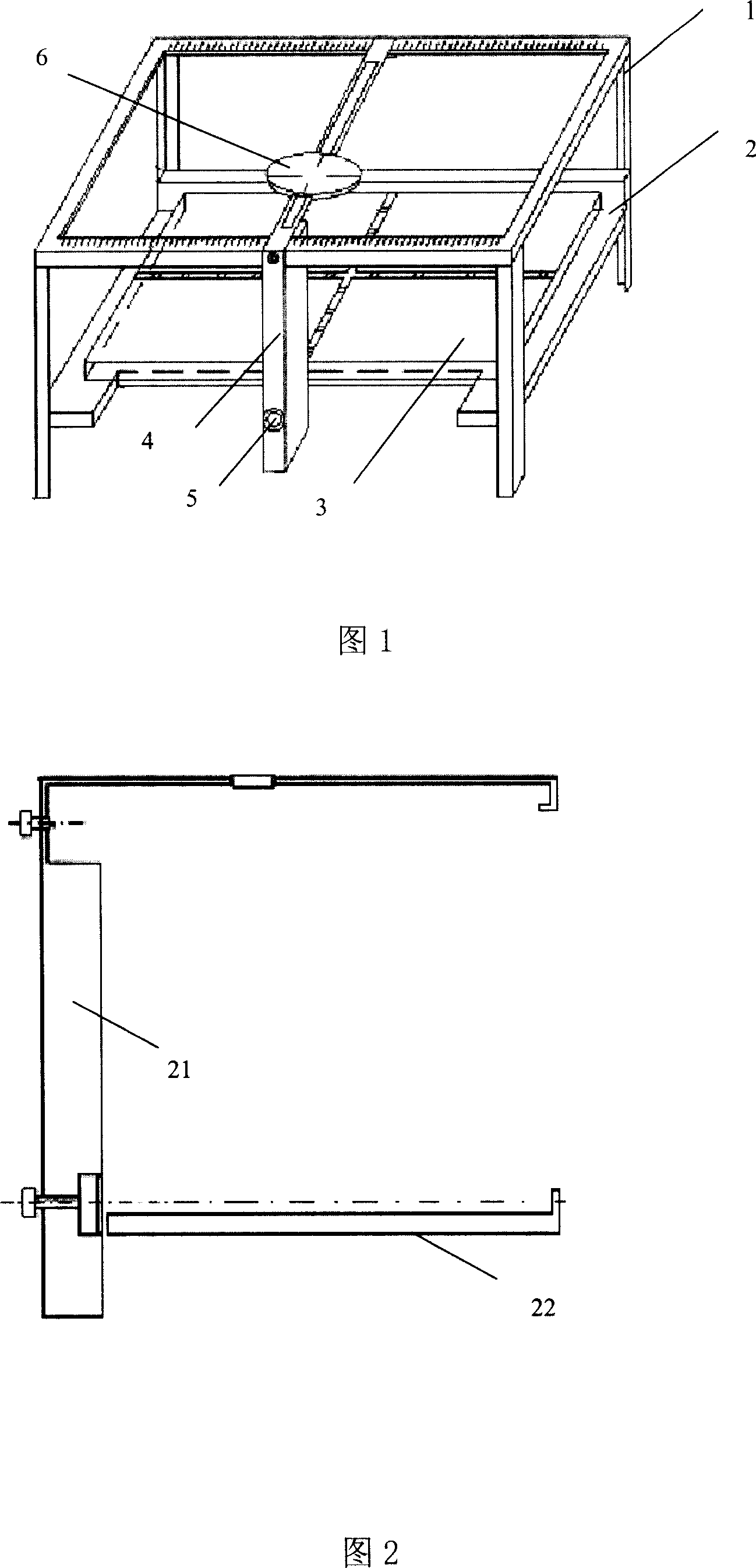

[0030] This embodiment includes a device frame, a magnifying glass and its support, a sample stage, a tool frame, and a tool, as shown in FIG. 1 .

[0031] The device frame is divided into two layers, the upper layer is a square frame, and a pair of opposite sides in the frame are engraved with scales, which can be inserted into the upper inner recess of the tool frame as a guide rail when the tool frame moves.

[0032] The four corners of the square frame are respectively connected with four legs of the shelf. A sample stage is connected to the leg at a fixed distance from the upper magnifying glass. The distance should ensure that the distance from the upper surface of the sample stage to the upper magnifying glass is the focal length plus the thickness of the wafer.

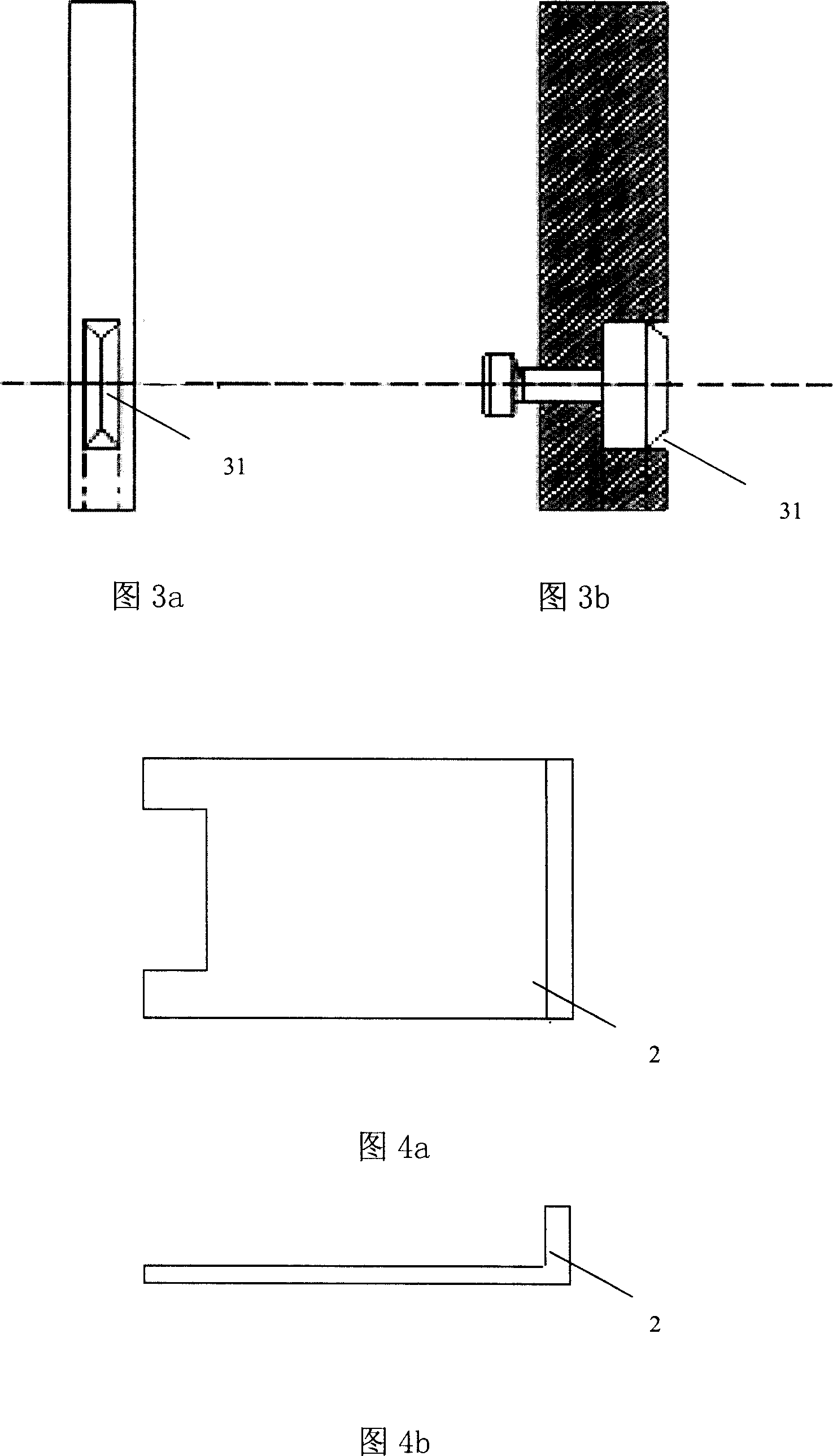

[0033] The top view of the sample stage is shown in Fig. 4a. One side is folded up, and a rectangle is cut in the middle of the other side to prevent the knife from cutting the sample table when entering.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com