Multi-rolled gear shaft cutting machine

A grinding wheel cutting machine, cutting machine technology, applied in the direction of grinding workpiece brackets, grinding machines, metal processing equipment, etc., can solve the problems of waste of manpower and material resources, poor positioning, cutting errors, etc., to achieve convenient and accurate cutting, improve work efficiency, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

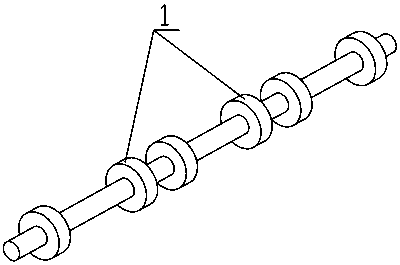

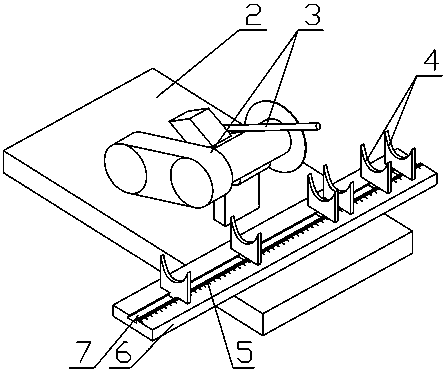

[0010] see figure 1 , figure 2 , the present invention is a multi-rolling gear shaft cutting machine, which has a base 2, on which a grinding wheel cutting machine 3 is arranged, and a horizontal supporting plate 6 is arranged directly below the cutting wheel of the grinding wheel cutting machine, and the horizontal supporting plate A guide rail groove 7 is arranged horizontally on the upper side. The cross section of the guide rail groove is a trapezoidal structure placed in the forward direction. The bottoms of the boards are all slidably connected with the guide rail grooves.

[0011] When the device of the present invention is in use, since a horizontal support plate is provided, and an arc-shaped shelf and a scale line are arranged on the horizontal support plate, when cutting, only the gear plate 1 of the multi-rolled gear shaft blank to be cut is clamped. On the curved shelf, then adjust the distance of the curved shelf according to the distance to be cut through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com