Sectional material cutting device

A cutting device and profile technology, applied in the direction of grinding feed movement, grinding workpiece support, grinding machine, etc., can solve the problems of low work efficiency, inability to meet production requirements, complicated operation, etc., to facilitate accurate cutting and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

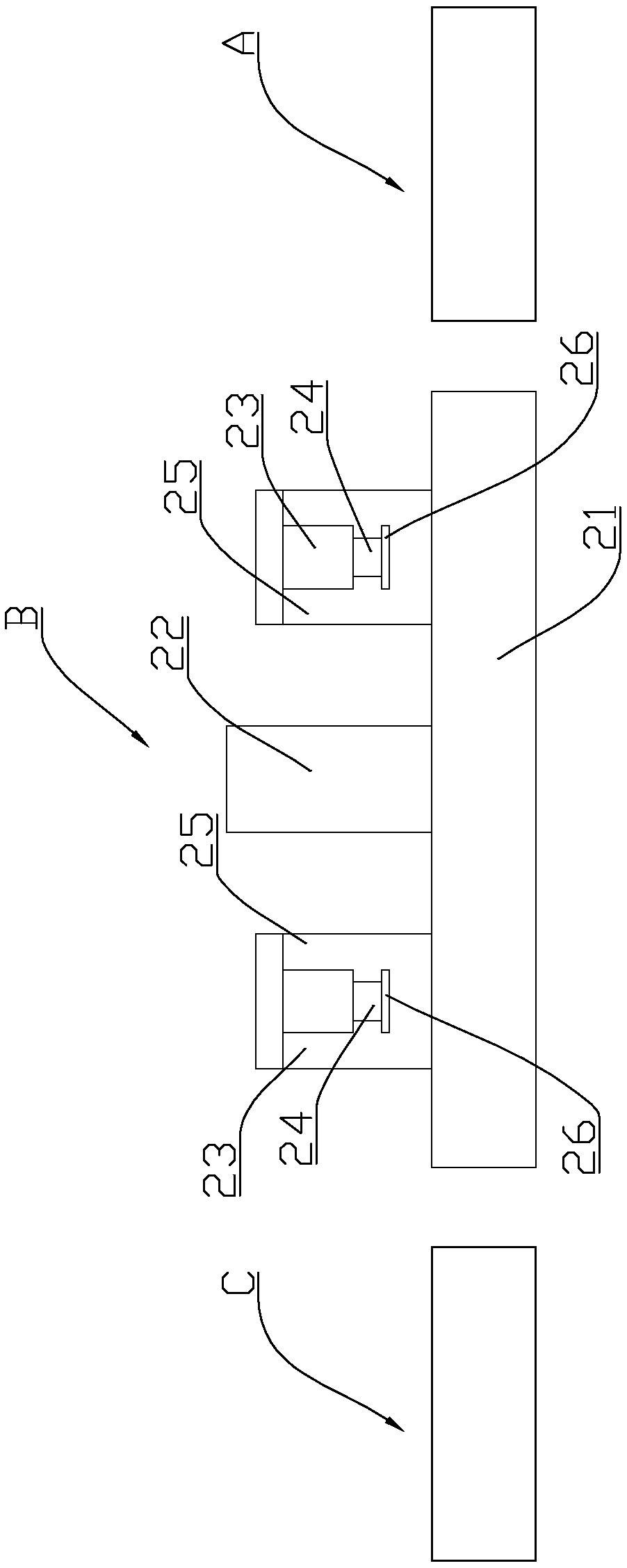

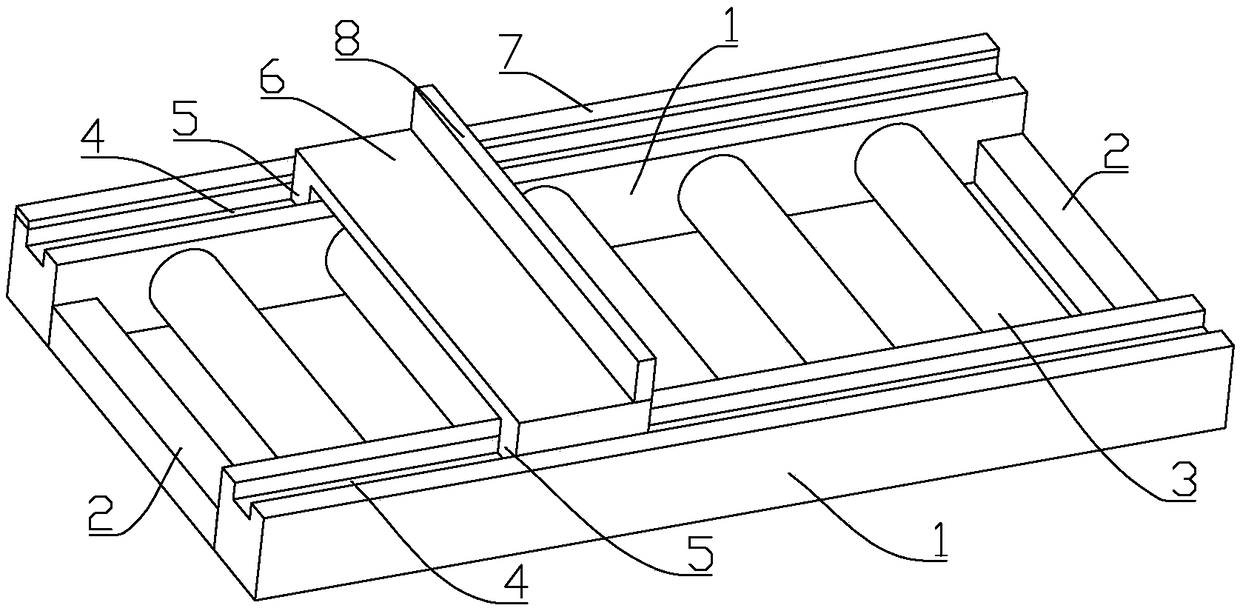

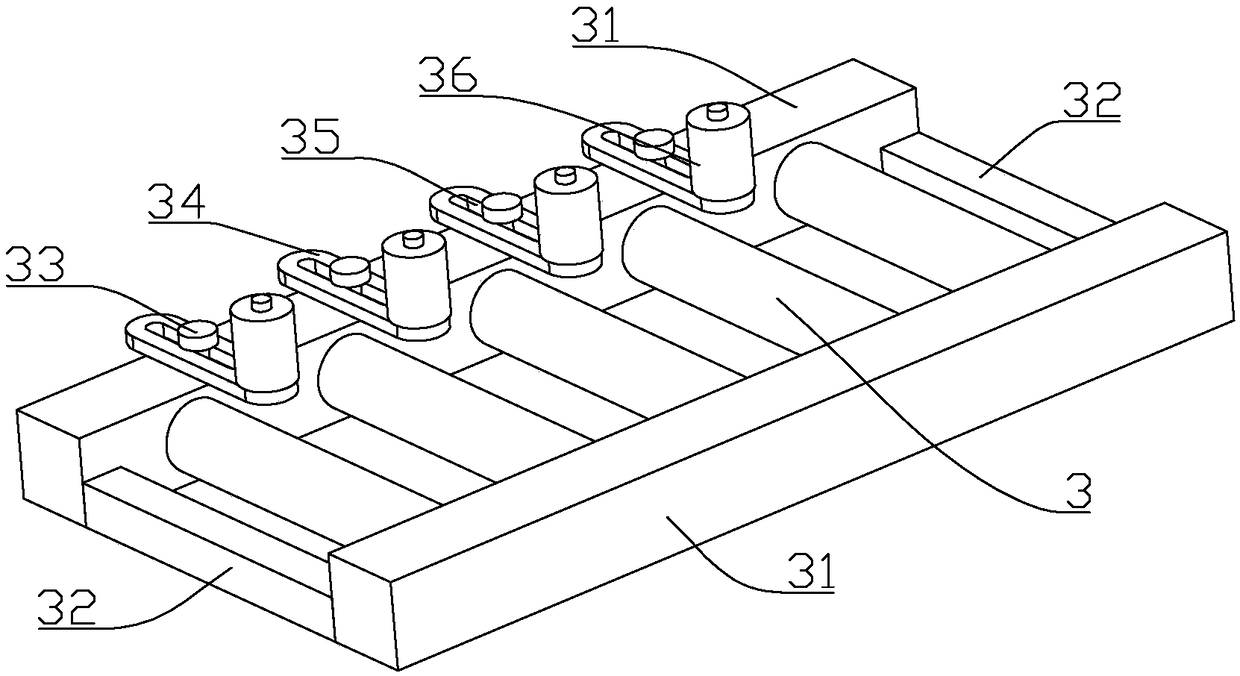

[0016] Such as figure 1 , 2 . As shown in 3, a profile cutting device includes a feed frame A, a cutting table B, and a discharge frame C that are sequentially connected front and back, and the discharge frame C includes a pair of symmetrically arranged side discharge brackets 1 , and the discharge connecting rod 2 connecting the two side discharge supports 1, a plurality of rollers 3 are installed between the two side discharge supports 1, and the tops of the two side discharge supports 1 A chute 4 is provided respectively, and a slide table 6 is arranged on the top of the roller 3, and a pair of slide blocks 5 matching the chute 4 are fixed on both sides of the bottom of the slide table 6. A baffle plate 8 is fixed on the right side of the top, a scale 7 is fixed on the top of any one of the side discharge supports 1, and the cutting table B includes a cutting platform 21, and an emery wheel cutting machine installed on the cutting platform 21 22. The cutting platform 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com