A processing tool for metal sealing gasket

A metal sealing gasket and tooling technology, which is applied in metal processing, metal processing equipment, forming tools, etc., can solve the problems of deviation or slipping off the workbench, high labor intensity of workers, and poor safety, so as to improve sealing performance and facilitate processing work, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

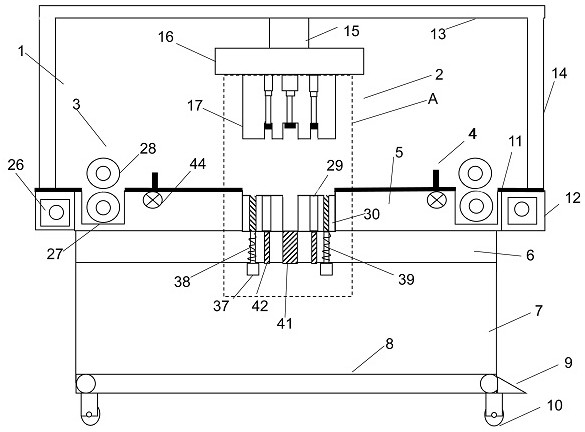

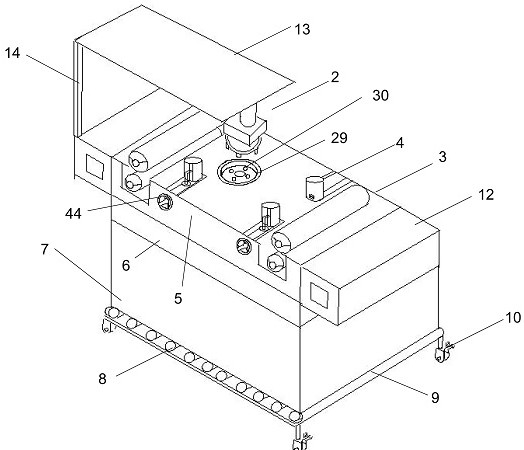

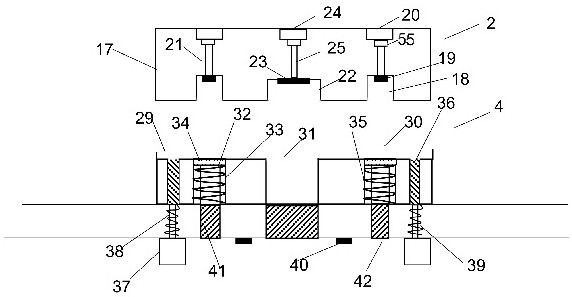

[0043] A processing tool for a metal sealing gasket, including a stamping cavity 1, a mold cavity 5, a receiving box 6, a worktable 11, a stamping mechanism 2, a feeding mechanism 3 and a clamping mechanism 4, and the worktable 11 is provided with a stamping cavity 1. The punching cavity 1 is composed of a top plate 13 and four brackets 14 located on the worktable 11. The punching mechanism 2 is located on the top plate 13. The bottom surface of the worktable 11 is connected to the mold cavity 5. The left and right sides of the mold cavity 5 are provided with control boxes. 12. There is a mold groove 29 in the mold cavity 5 and the upper part of the mold groove 29 is not covered by the worktable 11. The worktable 11 and in the mold cavity 5 are also provided with a feeding mechanism 3 and a clamping mechanism 4. The lower part of the mold cavity 5 is: The receiving box 6 is connected to the waste box 7. The waste box 7 is provided with a conveyor belt 8. The interface between t...

Embodiment 2

[0045]A processing tool for a metal sealing gasket, including a stamping cavity 1, a mold cavity 5, a receiving box 6, a worktable 11, a stamping mechanism 2, a feeding mechanism 3 and a clamping mechanism 4, and the worktable 11 is provided with a stamping cavity 1. The punching cavity 1 is composed of a top plate 13 and four brackets 14 located on the worktable 11. The punching mechanism 2 is located on the top plate 13. The bottom surface of the worktable 11 is connected to the mold cavity 5. The left and right sides of the mold cavity 5 are provided with control boxes. 12. There is a mold groove 29 in the mold cavity 5 and the upper part of the mold groove 29 is not covered by the worktable 11. The worktable 11 and in the mold cavity 5 are also provided with a feeding mechanism 3 and a clamping mechanism 4. The lower part of the mold cavity 5 is: The receiving box 6 is connected to the waste box 7. The waste box 7 is provided with a conveyor belt 8. The interface between th...

Embodiment 3

[0048] A processing tool for a metal sealing gasket, including a stamping cavity 1, a mold cavity 5, a receiving box 6, a worktable 11, a stamping mechanism 2, a feeding mechanism 3 and a clamping mechanism 4, and the worktable 11 is provided with a stamping cavity 1. The punching cavity 1 is composed of a top plate 13 and four brackets 14 located on the worktable 11. The punching mechanism 2 is located on the top plate 13. The bottom surface of the worktable 11 is connected to the mold cavity 5. The left and right sides of the mold cavity 5 are provided with control boxes. 12. There is a mold groove 29 in the mold cavity 5 and the upper part of the mold groove 29 is not covered by the worktable 11. The worktable 11 and in the mold cavity 5 are also provided with a feeding mechanism 3 and a clamping mechanism 4. The lower part of the mold cavity 5 is: The receiving box 6 is connected to the waste box 7. The waste box 7 is provided with a conveyor belt 8. The interface between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com