Chain type automatic transfer printing device

A chain-type, pad printing technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problem of the inability to realize the fully automated process of feeding fixtures, the lack of controllability and stability of the overall process, and the impact on the working efficiency of pad printing machines and other problems, to achieve the effect of solving waste of manpower and material resources, high operation stability, and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

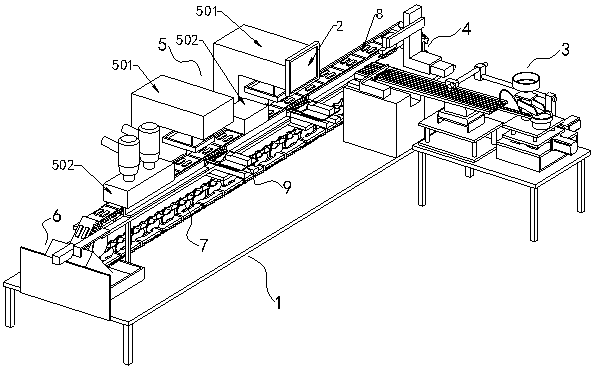

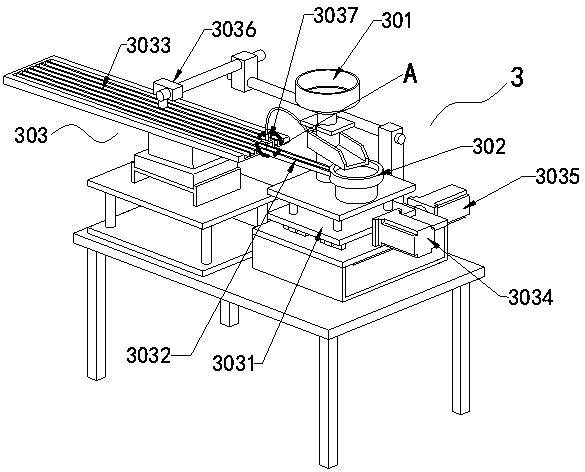

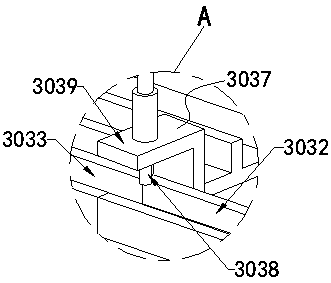

[0023] Specific Example 1: See Figure 1 to Figure 6 , in an embodiment of the present invention, a chain-type automatic pad printing equipment includes a frame 1, a PLC controller 2, a feeding unit 3, a loading unit 4, a pad printing unit 5, a reciprocating sprocket conveying device 7 and a feeding unit Unit 6; the feeding unit 3 and the loading unit 4 are on one side of the frame 1, the pad printing unit 5 is in the middle of the frame 1, and the unloading unit 6 is arranged on the frame The other side of 1; the feeding unit 3 is on the right side of the feeding unit 4, and the feeding unit 3 includes a blanking cylinder 301, a vibrating plate 302 and a multi-track vibrating feeding device 303, and the vibrating plate 302 is set Below the blanking cylinder 301, the multi-track vibrating feeding device 33 is arranged at the discharge port of the vibrating plate 302;

[0024] The reciprocating sprocket conveying device 7 includes a chain 702 and a sprocket 701, the sprocket 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com