Patents

Literature

113results about How to "Solve the waste of manpower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

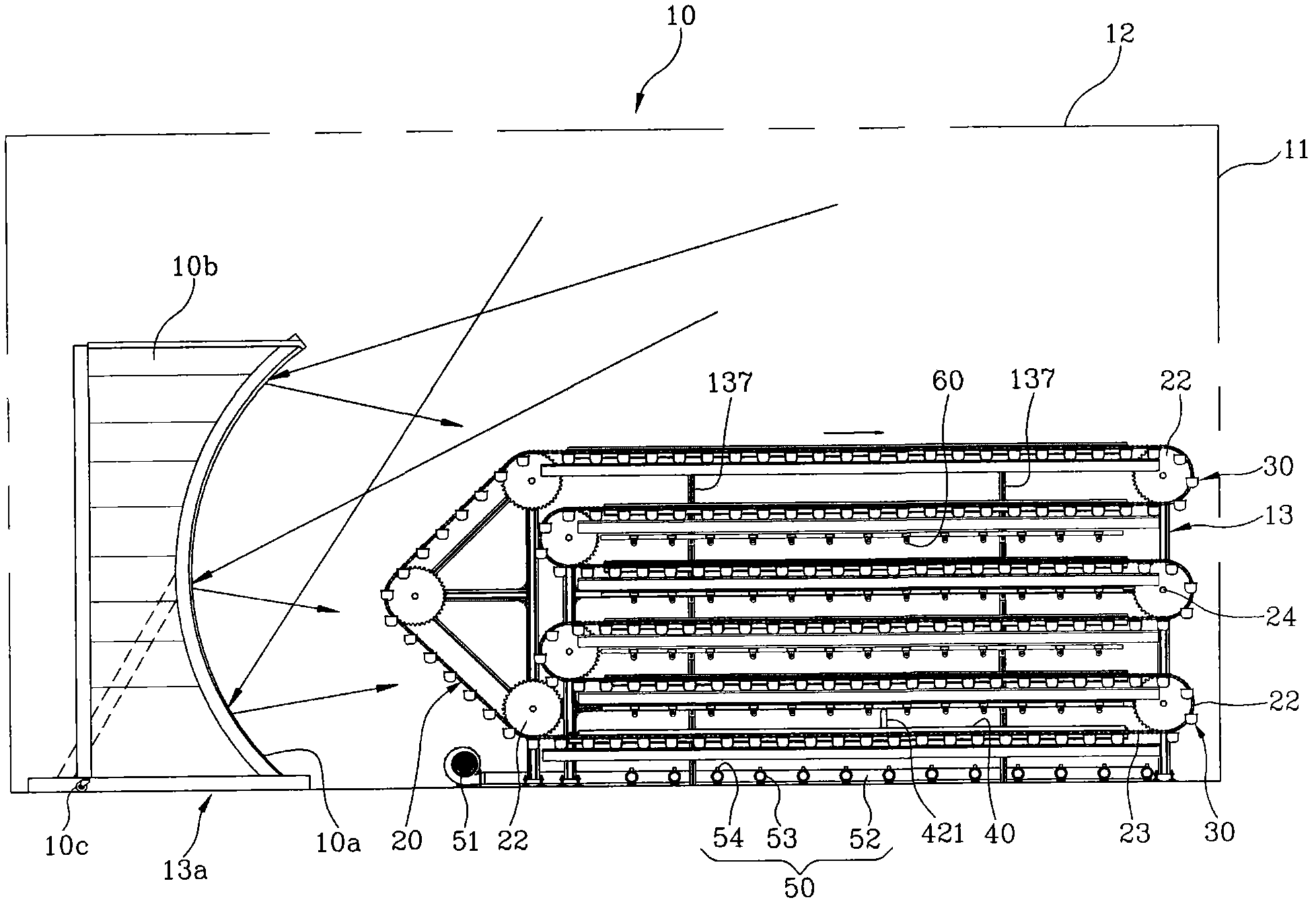

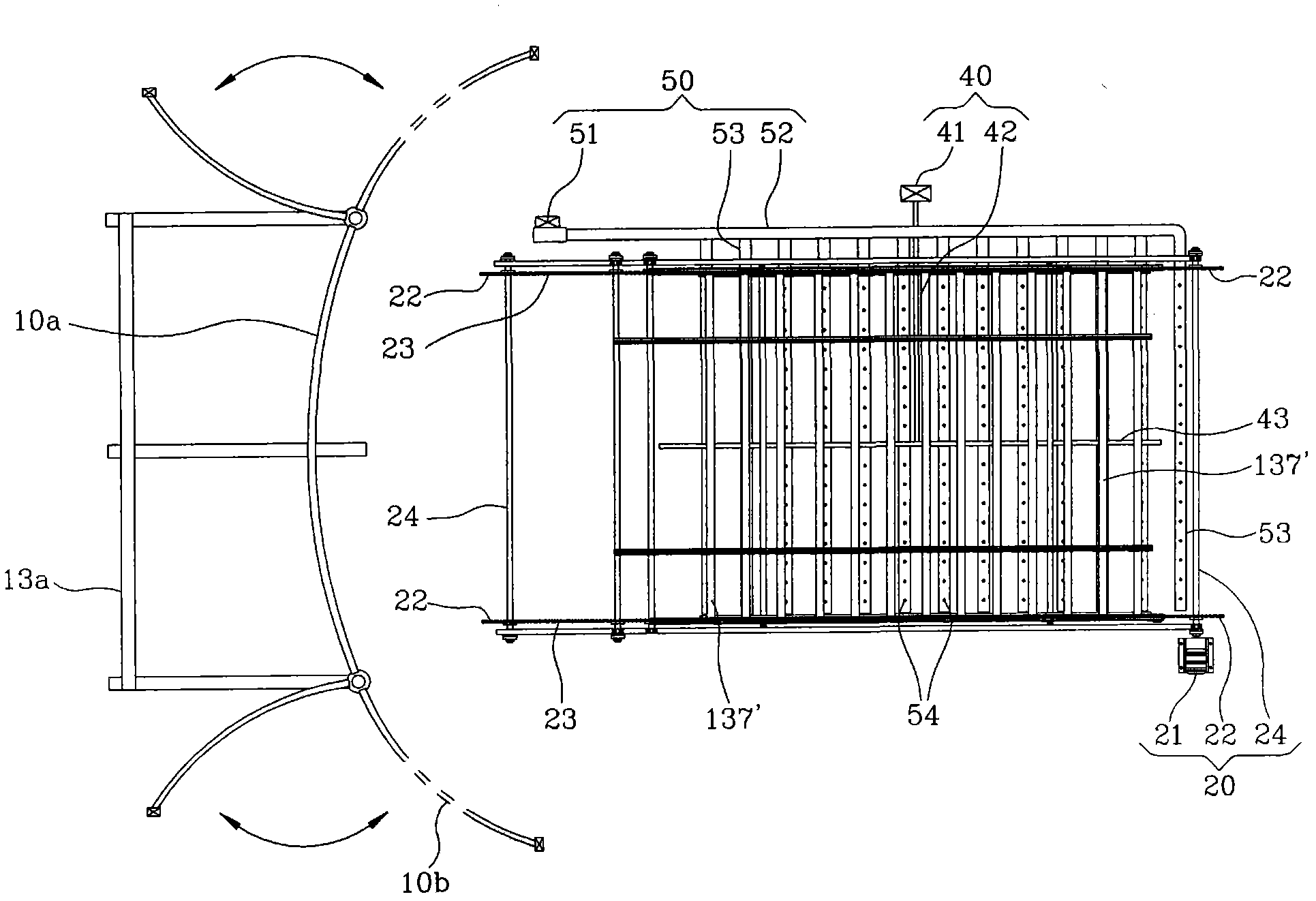

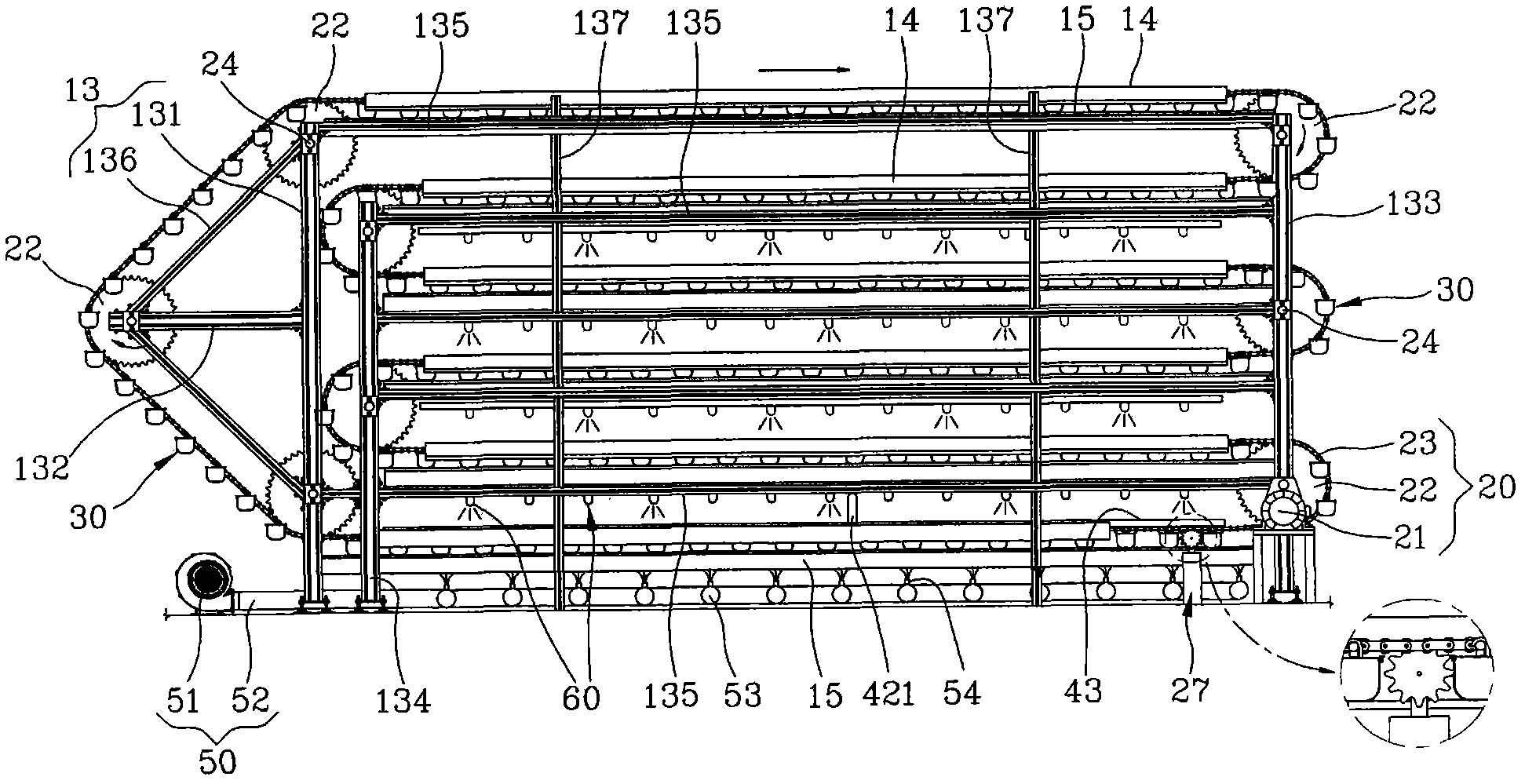

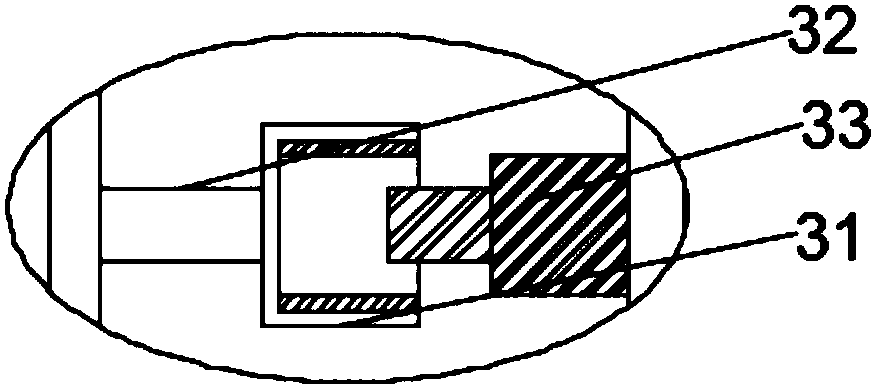

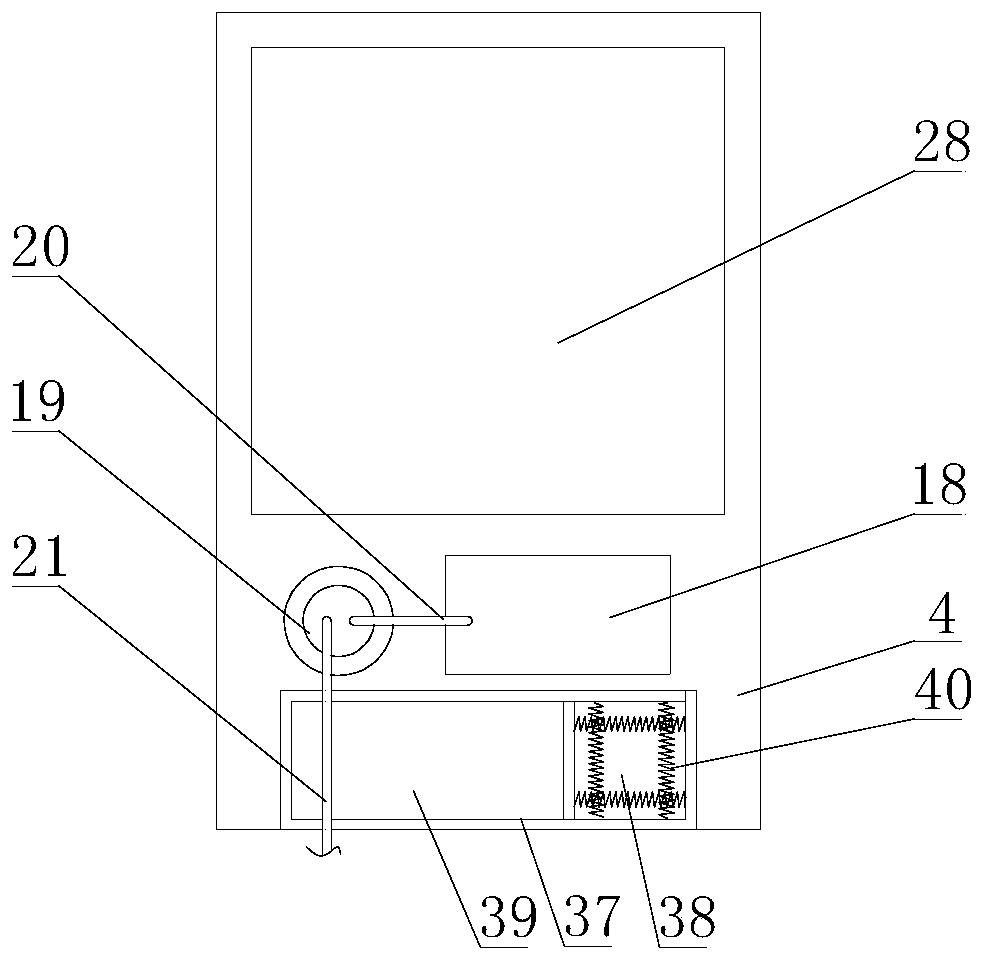

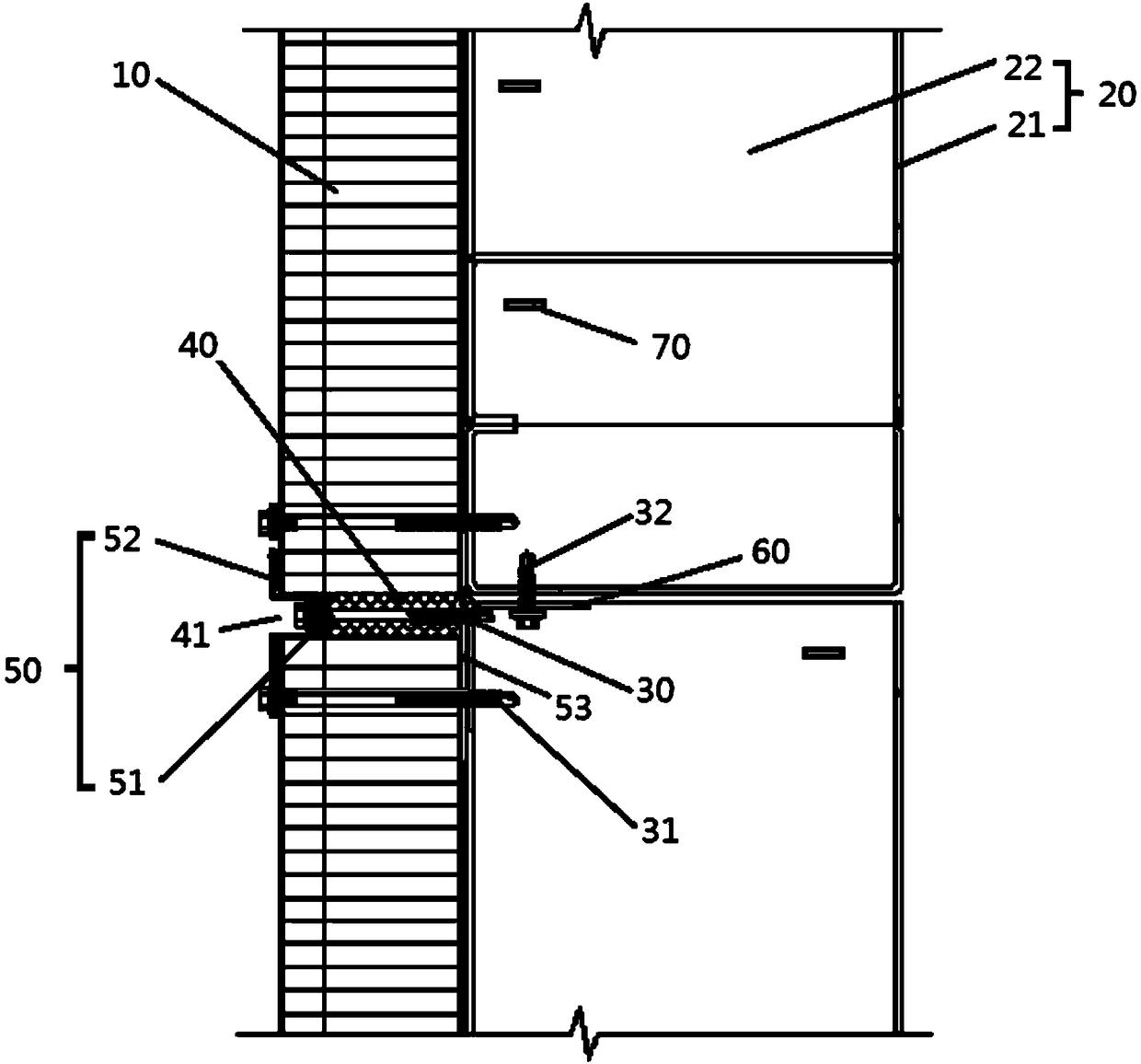

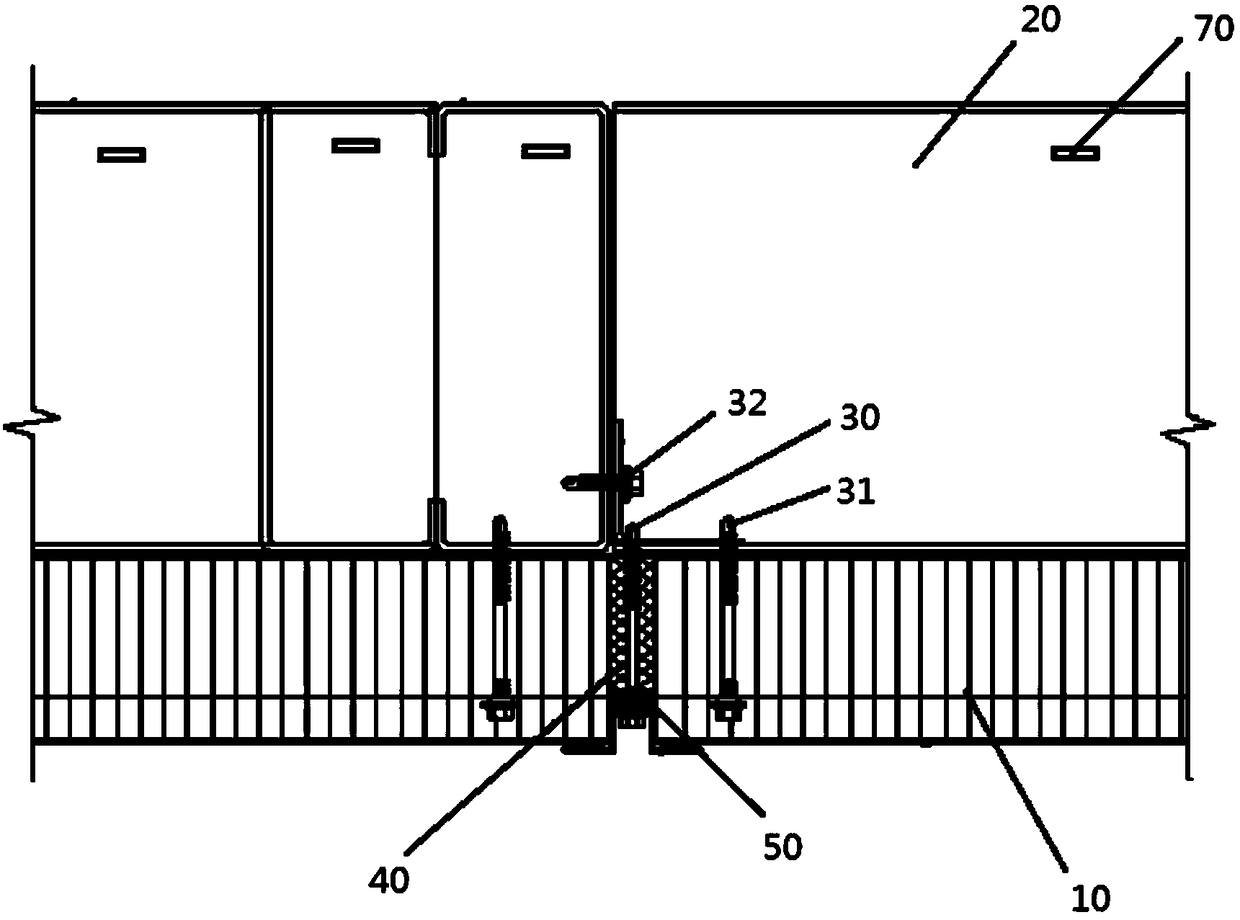

Plant cultivation system

ActiveCN102640679AUniform receptionContinuous growth characteristicsAgriculture gas emission reductionGreenhouse cultivationAgricultural scienceAgricultural engineering

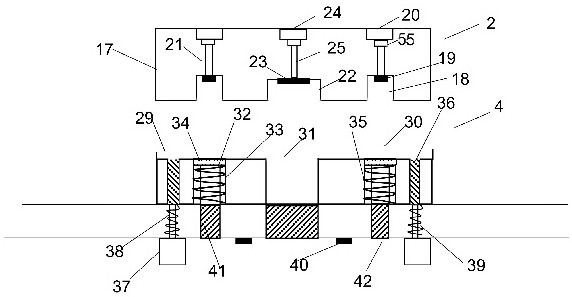

Disclosed is a plant cultivation system, including: a circulatory system (20) including a plurality of axes (24) installed in a corresponding portion of a frame (13); a plurality of chain gears (22) axis-installed on the plurality of axes (24) respectively; a gear motor (21) connected and installed onto any axis of the plurality of axes (24); a plurality of cultivating pot members (30) including a can body (31) having an opening in an upper surface, and a hook plate (32), fixed to left and right ends of the upper surface of the can body; a medicinal fluid supplier (40) for providing the medicinal fluid to the plurality of cultivating pot members (30); and an air blower (50), installed in a cultivation room (10), for providing the filtered external air to an interior or for circulating the inner air. According to the technical scheme, the plant cultivation system, the can enable the productivity per unit area to be greatly increased in any natural environments or at any places.

Owner:GREEN PLUS CO LTD +1

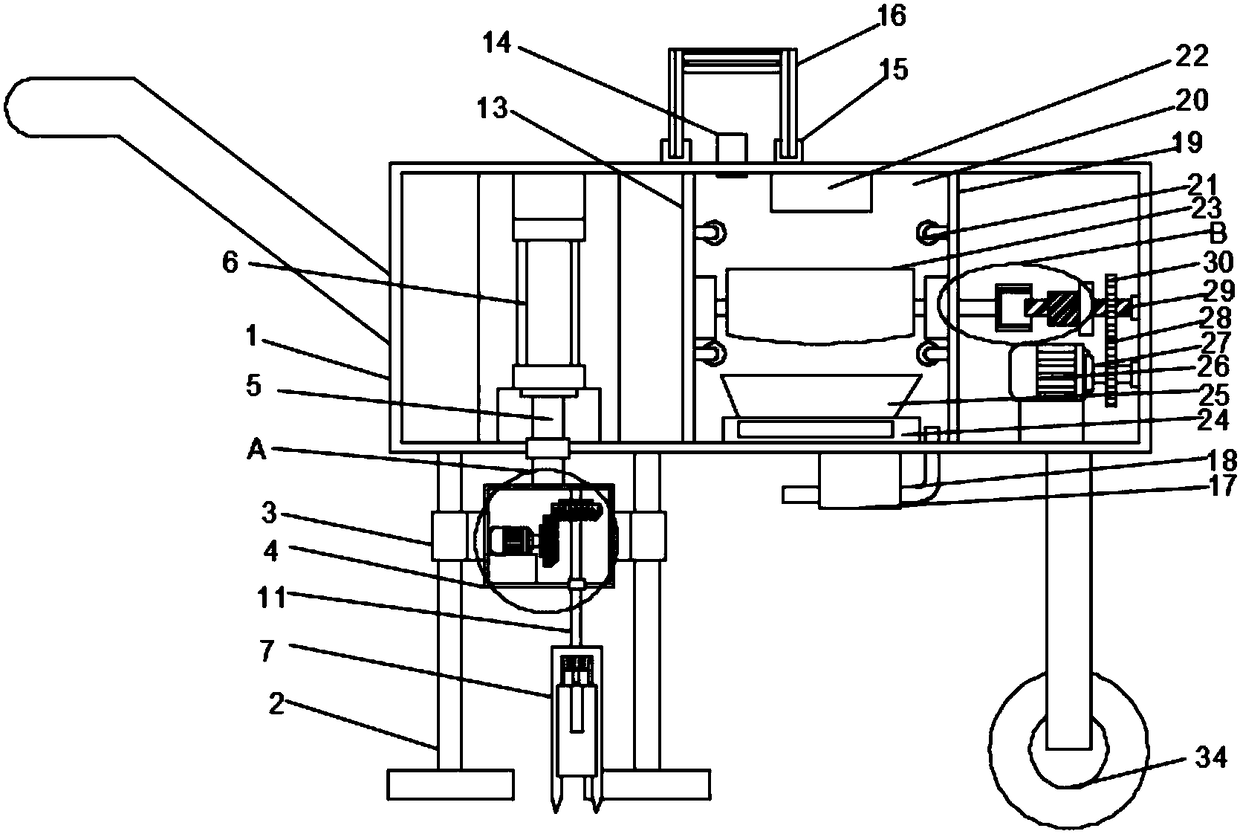

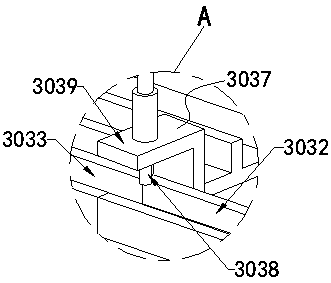

Sampling processing device for soil detection

InactiveCN108225820ASolve the inconvenience of carryingEasy to carryWithdrawing sample devicesPreparing sample for investigationElectric machineryEngineering

The invention discloses a sampling processing device for soil detection. The sampling processing device comprises a control cabinet, movable rods are fixedly connected to one side of the bottom part of the control cabinet, two movable rods are symmetrically arranged, a slider is connected to the upper end of the external wall of each movable rod in a sliding way, a first tank body is fixedly connected to the inner sides of the external walls of the sliders, a telescopic rod is fixedly connected to the top part of the first tank body, one end, far from the first tank body, of the telescopic rodpenetrates through the control cabinet and extends into the inner part of the control cabinet, an air cylinder is fixedly connected to one end, located in the inner part of the control cabinet, of the telescopic rod, a first motor is fixedly connected to the bottom part of the inner wall of the first tank body, and one side of the first motor is rotatably connected with a first rotating shaft through an output shaft. The sampling processing device relates to the technical field of environment detection. The sampling processing device solves the problems that a sampling device for soil detection is inconvenient to carry, the soil sampling efficiency is low, the manual labor is wasted, and a soil sample is easily interfered by people and is easily contaminated.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

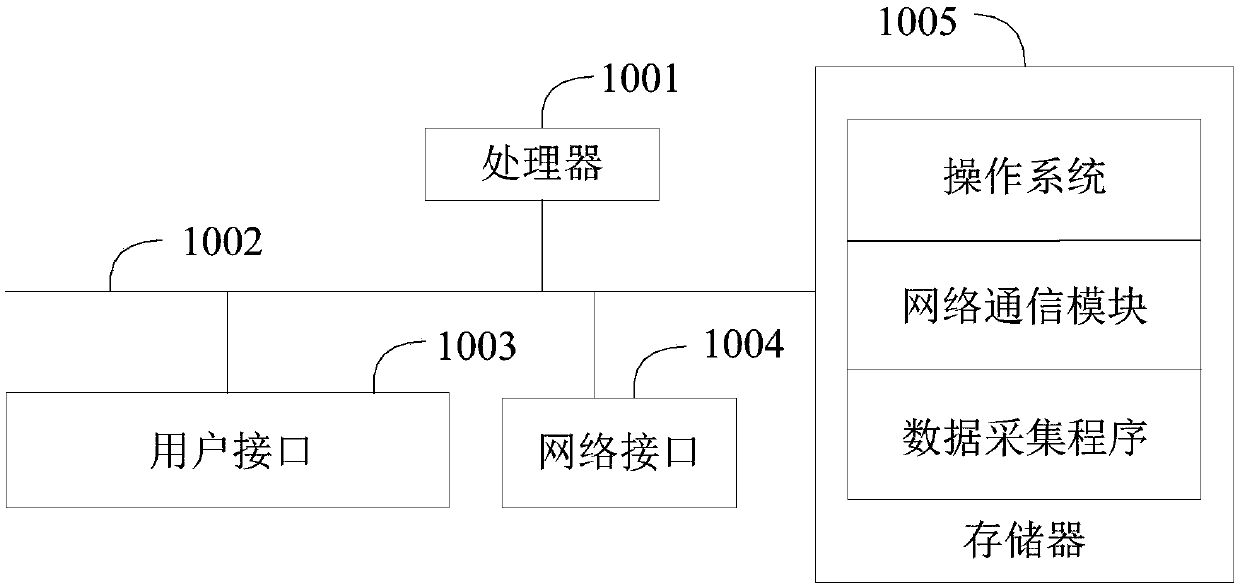

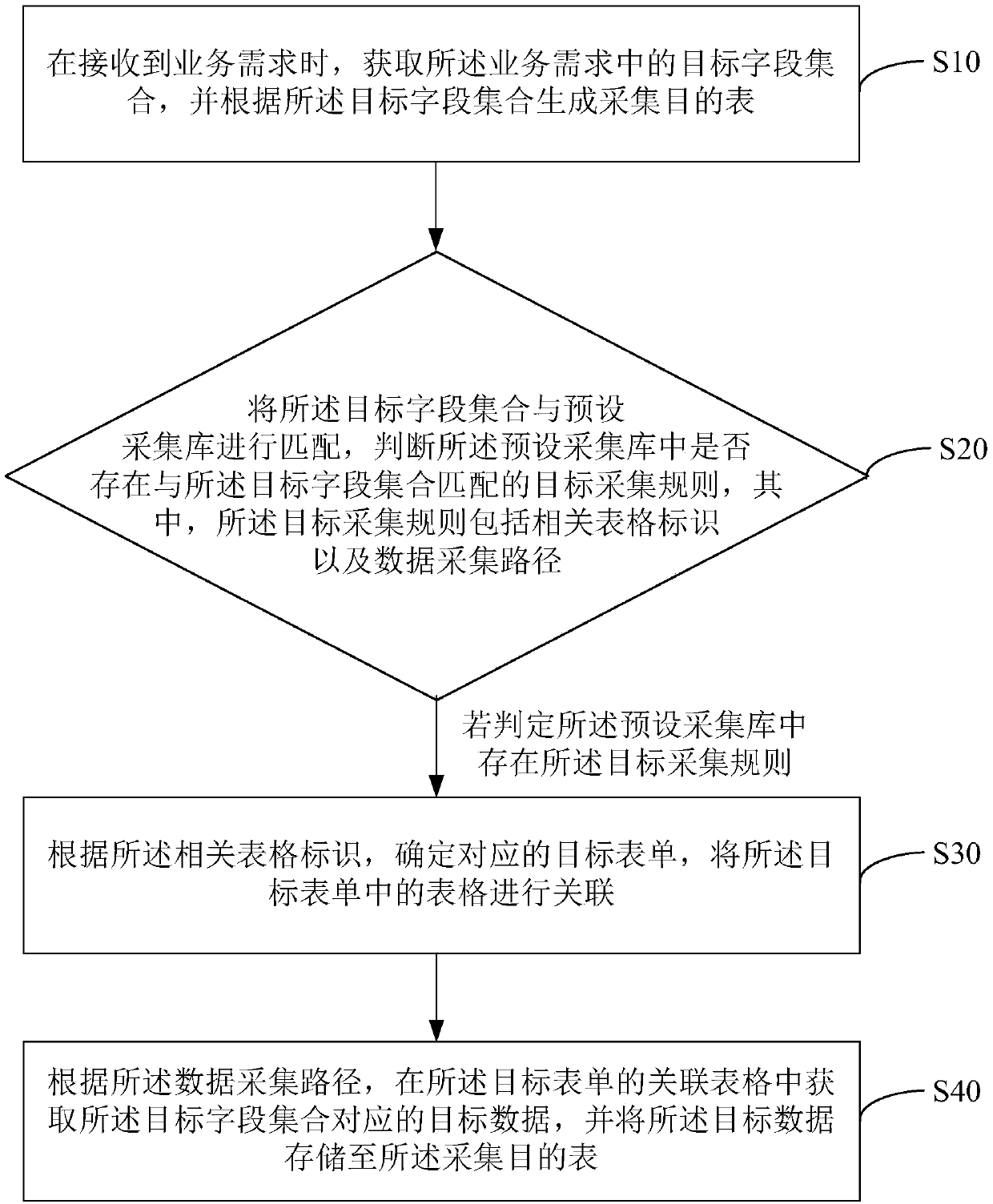

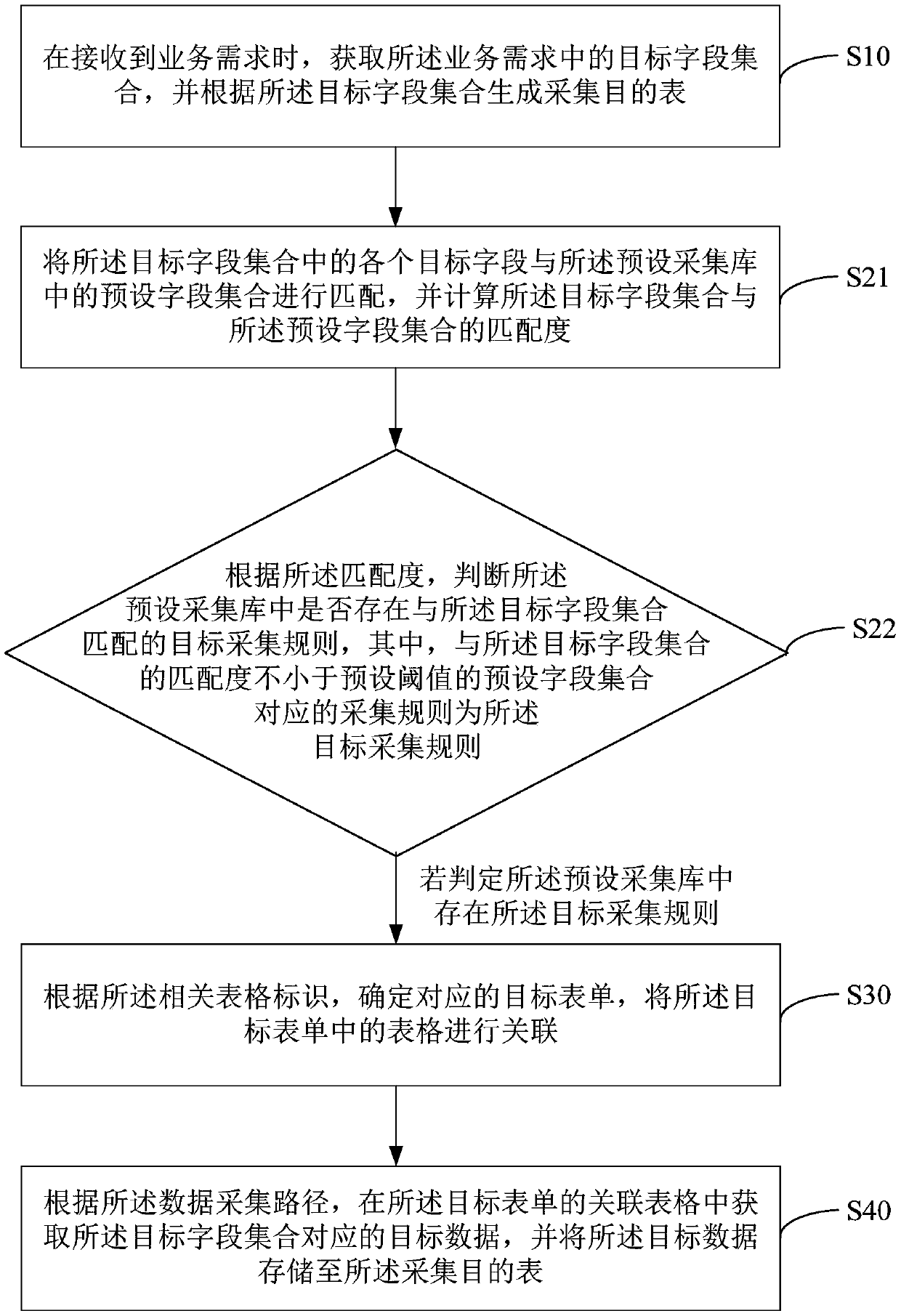

Data acquisition method, device and equipment and storage medium

ActiveCN110019486ARealize automatic collectionSolve the waste of manpowerDatabase management systemsSpecial data processing applicationsData acquisitionDatabase

The invention provides a data acquisition method, device and equipment and a computer readable storage medium, and the method comprises the steps of obtaining a target field set in a service demand when the service demand is received, and generating an acquisition target table; matching the target field set with a preset collection library, and judging whether a target collection rule matched withthe target field set exists or not, the target collection rule comprising a related table identifier and a data collection path; if the target collection rule exists, determining a corresponding target form according to the related form identifier, and associating forms in the target form; and according to a data acquisition path, obtaining the target data corresponding to the target field set from an association table, and storing the target data to the acquisition target table. According to the invention, the automatic collection of the target data is realized, the manpower is saved, and the collection efficiency is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

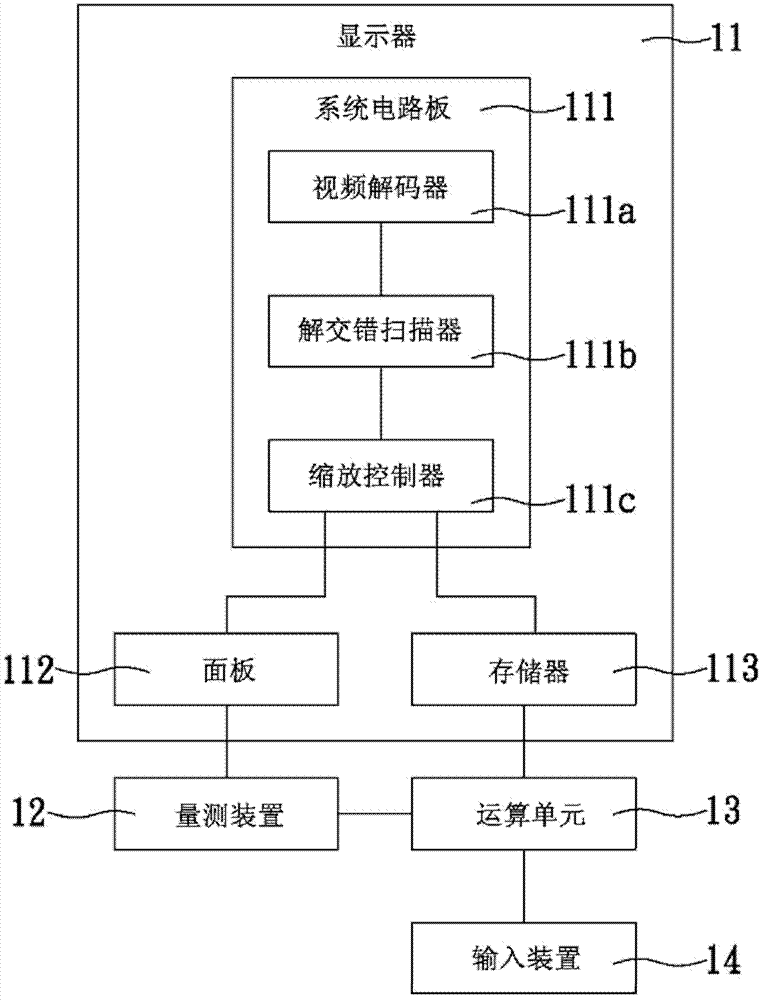

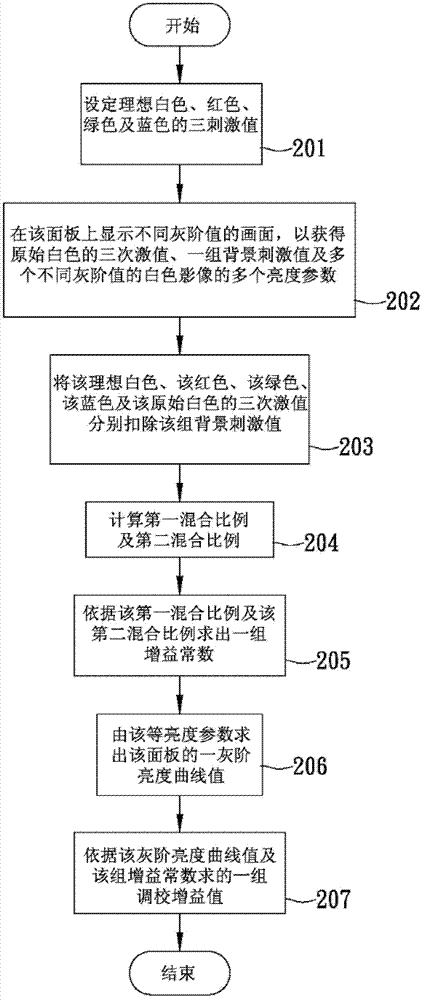

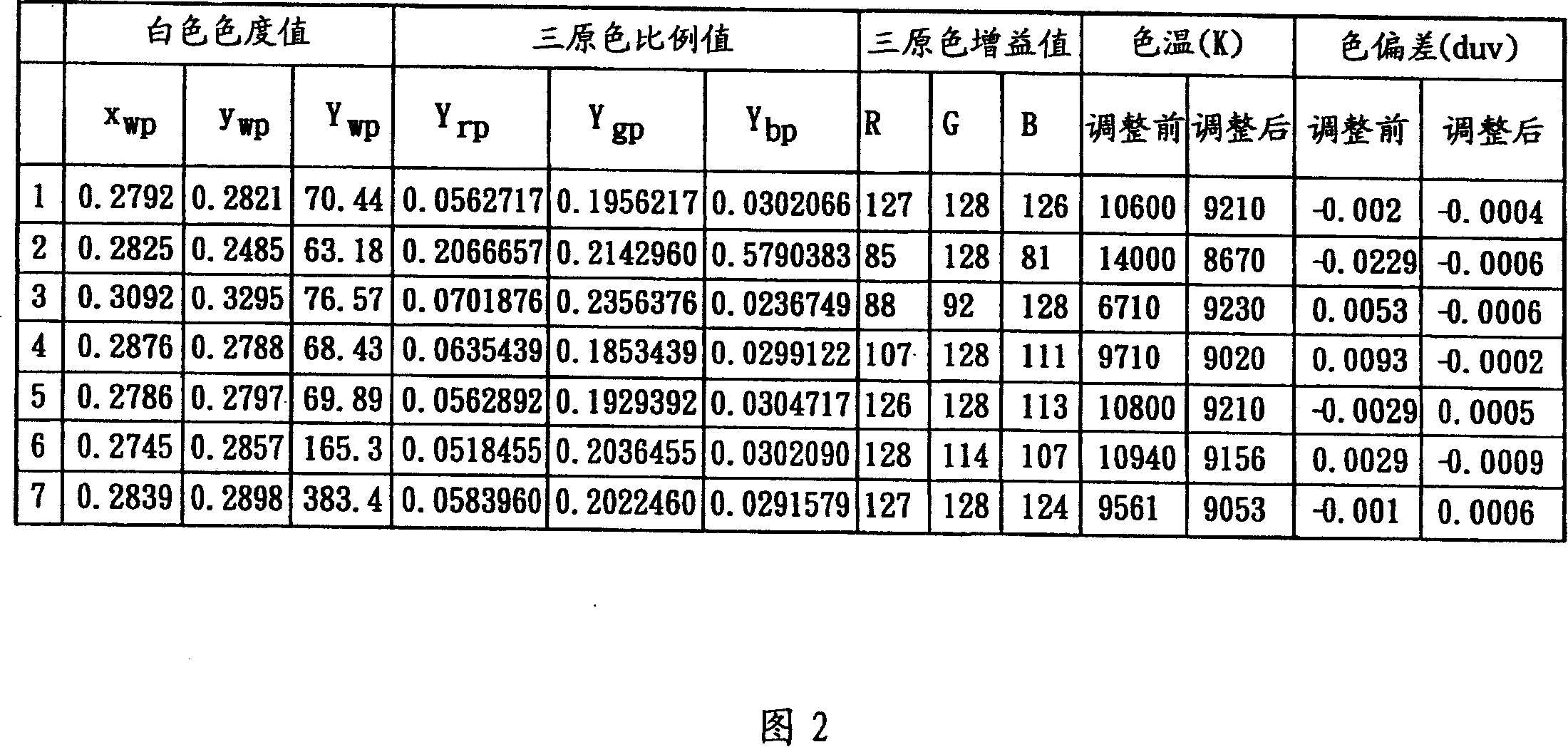

Method for improving monochromatic white balance adjustment and calibration precision on basis of white color brightness parameters

InactiveCN103366709AImprove consistencyResolution timeColor signal processing circuitsCathode-ray tube indicatorsOptical propertyDisplay device

The invention discloses a method which is characterized in that a gray scale white balance yield value is calculated by importing white color luminance parameters of a display device panel according to display device panel white color optical properties, and therefore gray scale white balance adjustment and calibration precision of the display device panel can be improved. The method is applied to a display device. The display device employing the method can effectively solve the problem that time and manpower are wasted due to conventional hand-operated gray scale white balance adjustment and calibration, and consistency displayed by frames of the display device can be improved because the white color brightness parameters of the display device are corrected.

Owner:MARKETECH INT

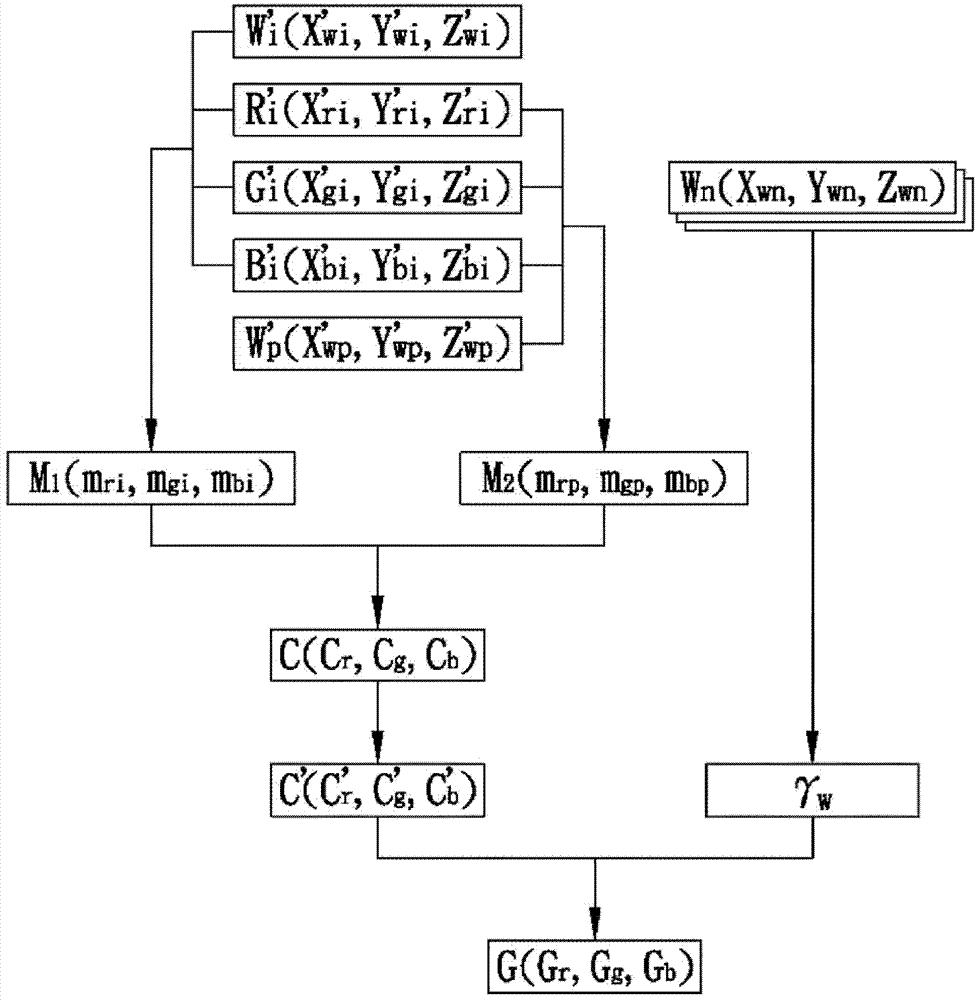

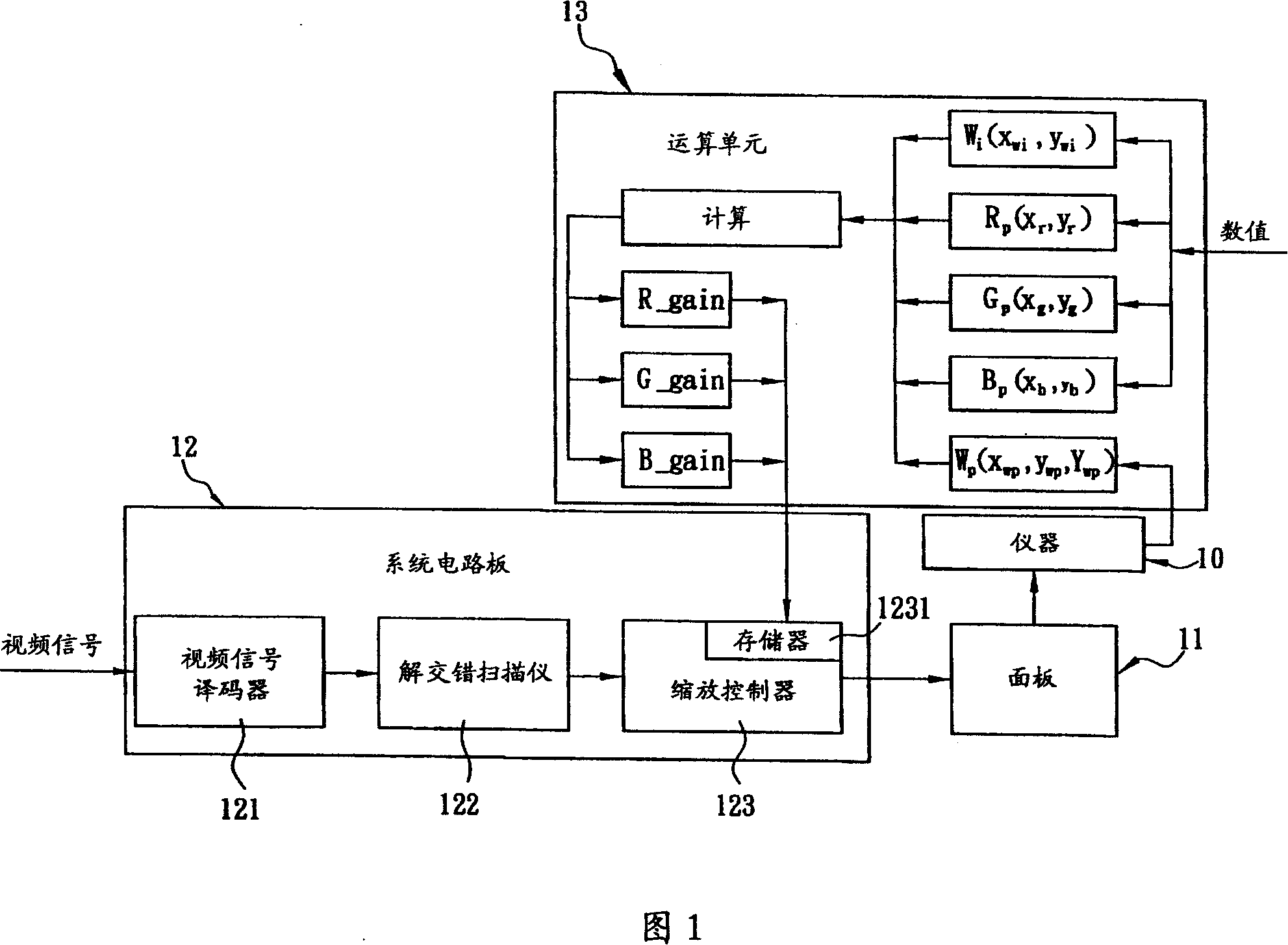

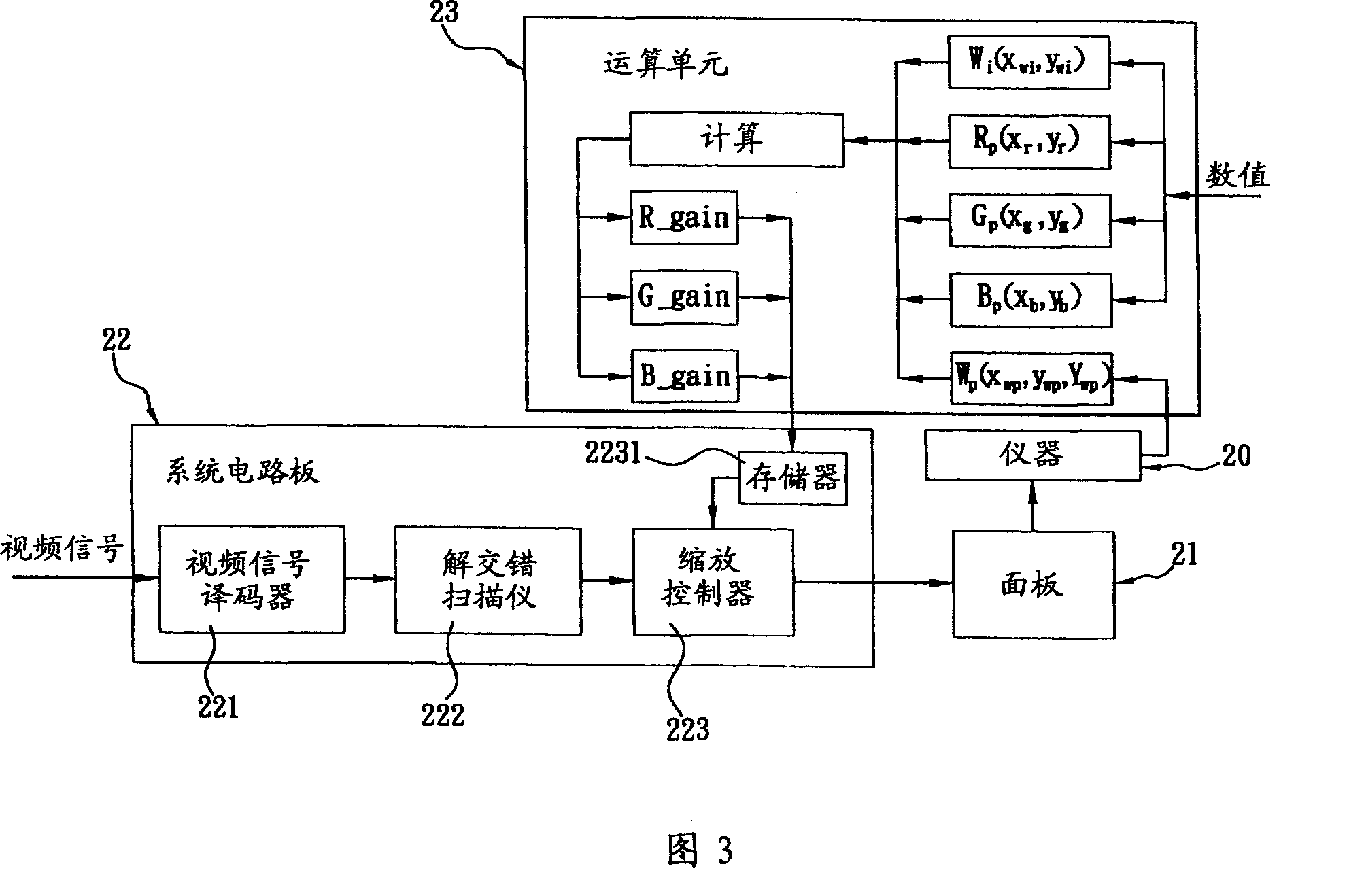

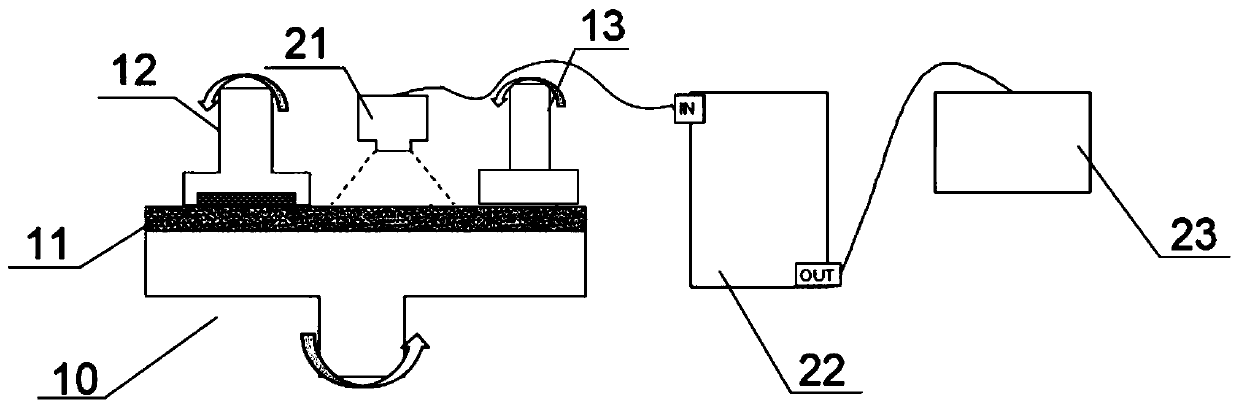

Method and system for automatic measuring and regulating gray level white balance of display apparatus

InactiveCN101155320AImprove coloring performanceResolution timeColor signal processing circuitsTelevision systemsGray levelDisplay device

The present invention provides a method for measuring and adjusting gray-step white balance of display automatically, that is to measure the white chroma coordinates and brightness of a display using an apparatus, and selecting the chroma coordinates of the three primary colors of red, green, blue in the known chroma space, to calculate the required mixing proportion of composing the white of the display by red, green, blue, according to Grassman's Low of Color Mixture; at the same time, to calculate the required mixing proportion of composing ideal white from the red, green, blue under some objective color temperature; to compare the two mixing proportion, and to take one proportion as one group plus value of the three primary colors of red, green, blue of the display to solve the problem of wasting time as well as manpower by the traditional adjusting gray-step white balance, and avoiding the artificial error due to adjusting manually.

Owner:MARKETECH INT

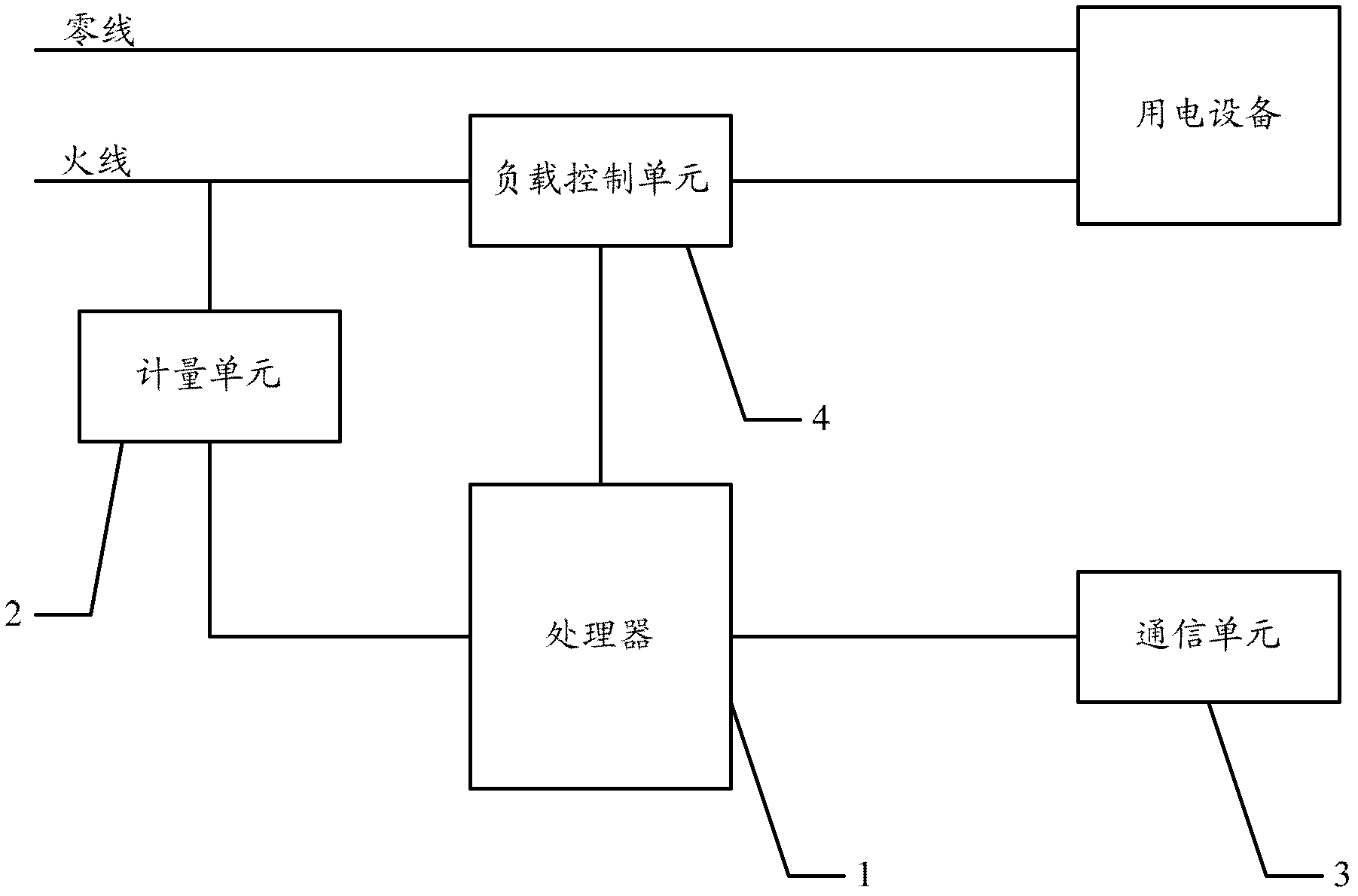

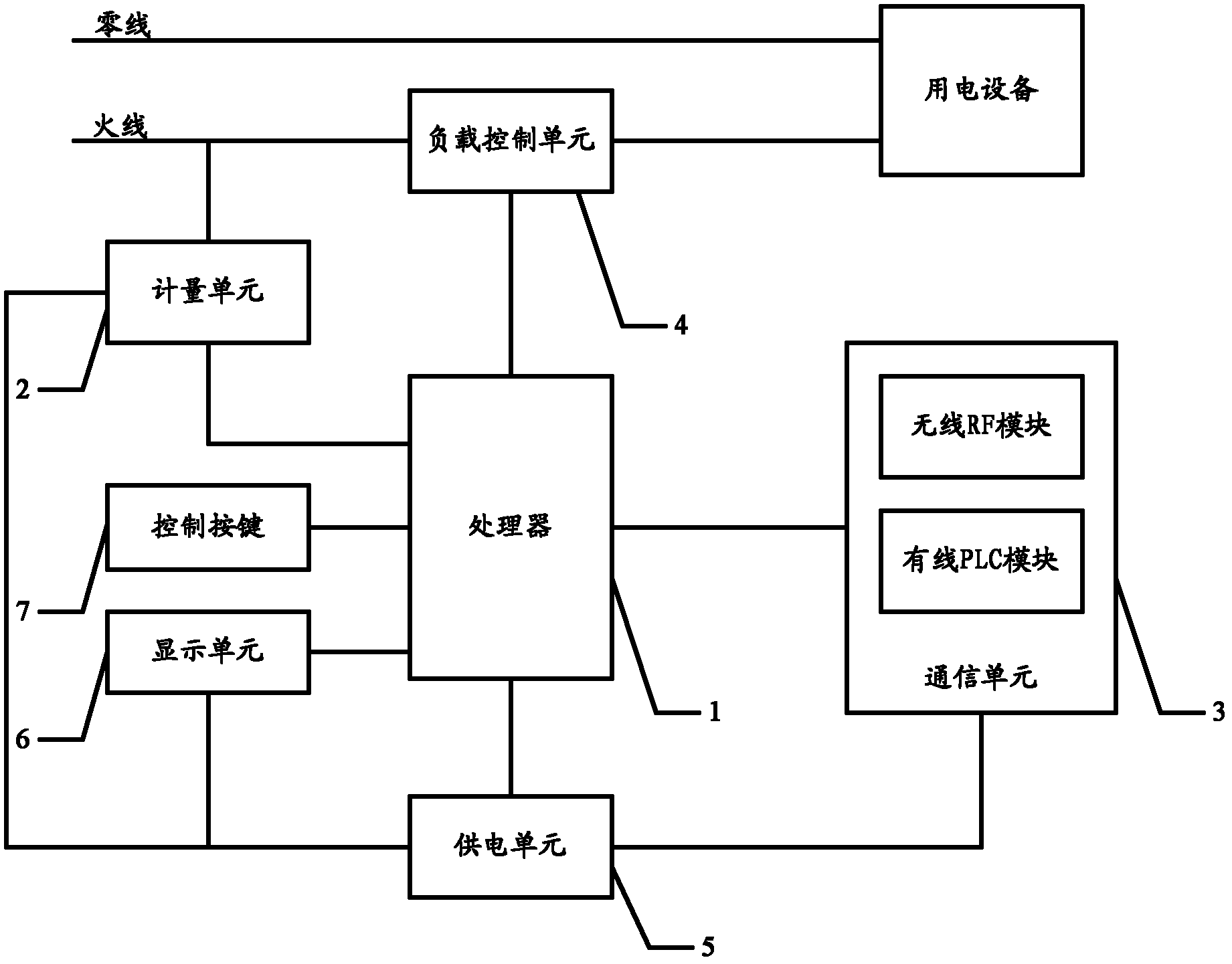

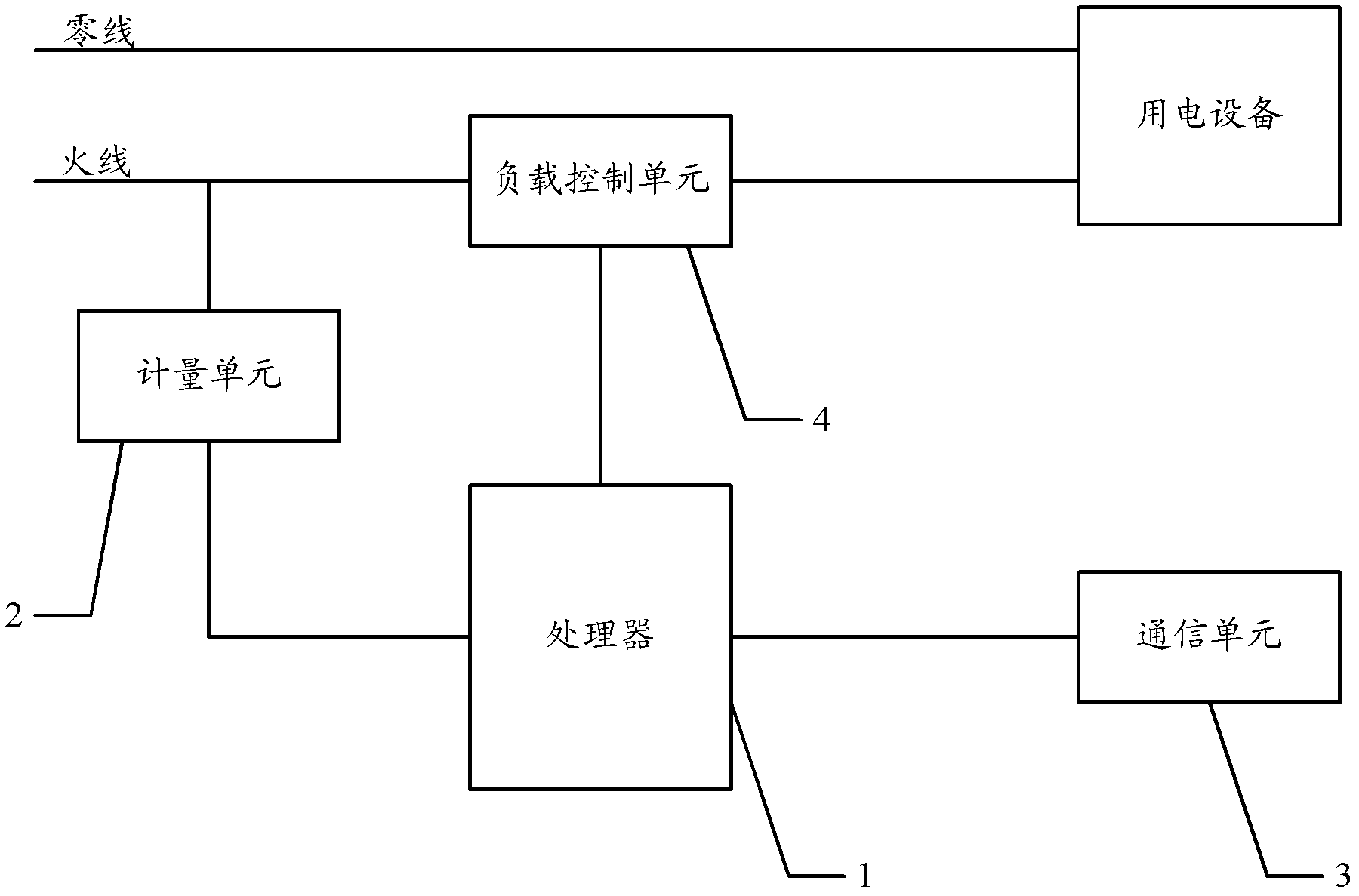

Intelligent socket

InactiveCN102496816AEasy to controlSolve the waste of manpowerCoupling device detailsProgramme control in sequence/logic controllersCommunication unitRemote control

The embodiment of the invention discloses an intelligent socket, comprising a socket body, a metering unit, a communication unit, a processor and a load control unit, wherein the metering unit is used for acquiring power consumption information of power consumption equipment plugged on the intelligent socket; the load control unit is used for actuating corresponding connection-disconnection operation according to a control signal output by the processor; and the communication unit is connected with the processor and is used for transmitting the power consumption information output by the processor to a control end and simultaneously transmitting control information output by the control end to the processor. In the intelligent socket disclosed by the invention, real-time acquisition of the power consumption information at a user side can be realized by the metering unit, and the power consumption information is uploaded by the communication unit; and the intelligent socket not only can carry out remote control on the power consumption equipment according to the control information of the power consumption equipment from the control end, but also can carry out direct control on the power consumption equipment according to the power consumption information acquired by the metering unit, so that on one hand, multiple control for the power consumption equipment is realized, and on the other hand, the power consumption safety is enhanced.

Owner:STATE GRID CORP OF CHINA +2

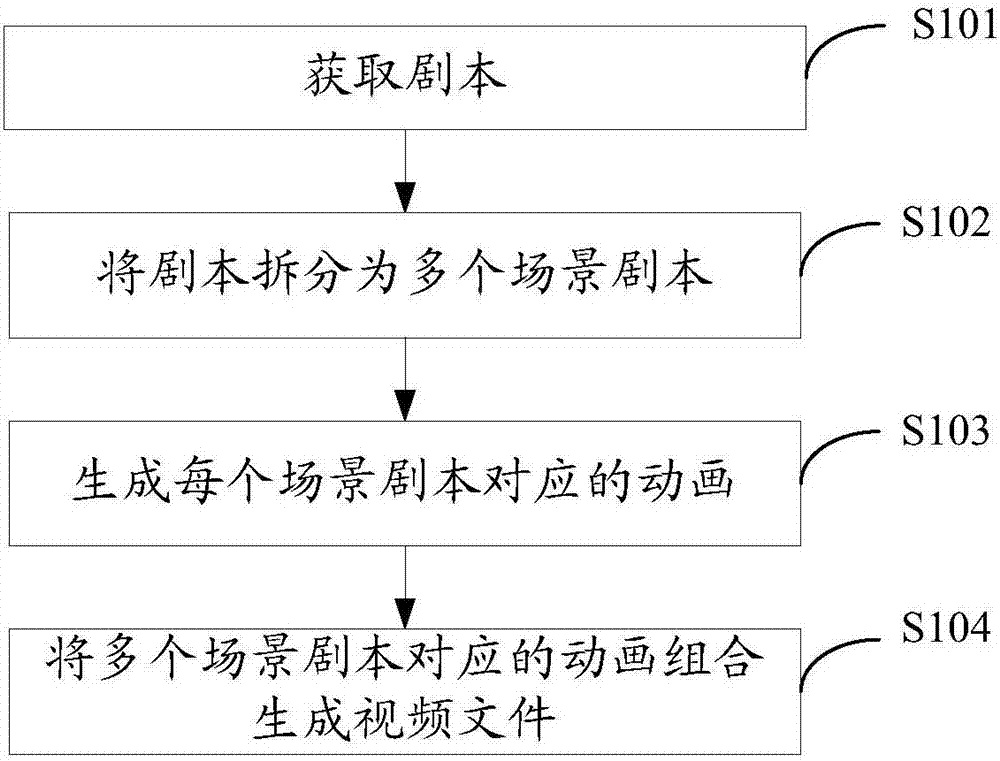

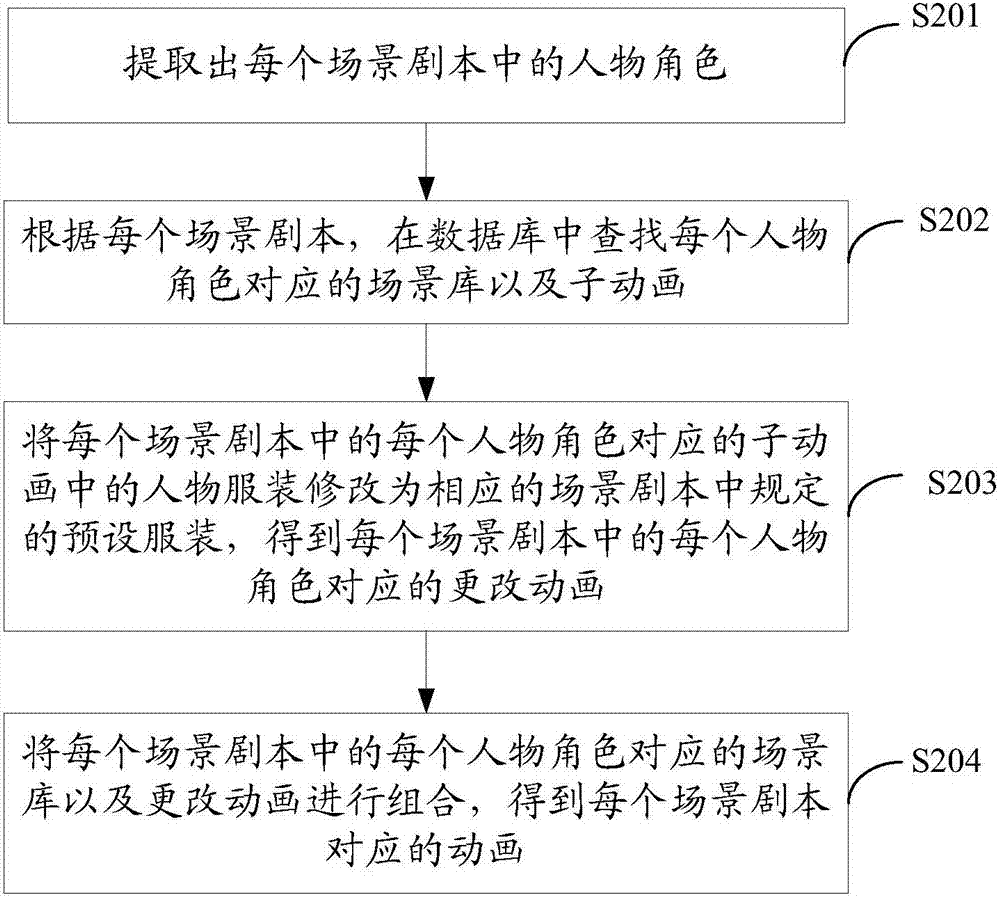

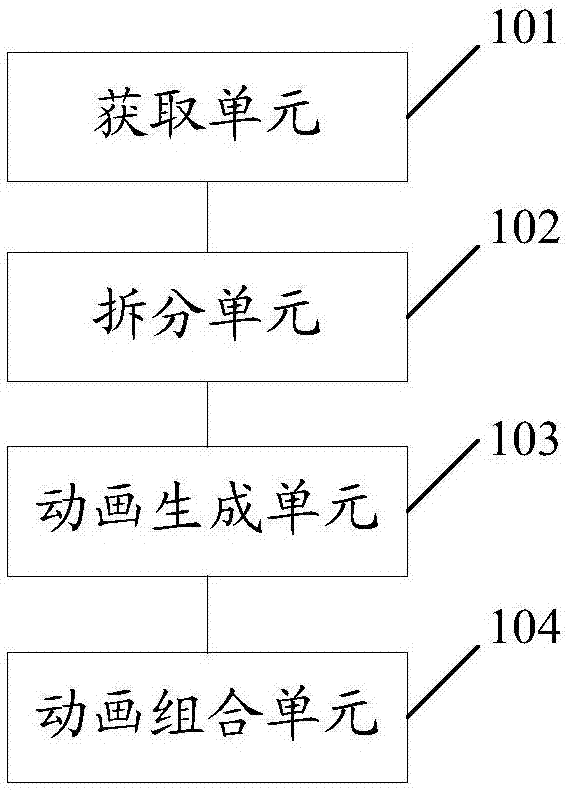

Method and device for making video

The invention provides a method and a device for making a video. After a script is acquired, the script is split to multiple scene scripts, an animation corresponding to each scene script is generated, and the animations corresponding to the multiple scene scripts are combined to generate a video file. The video file can be generated automatically, manual recording is not needed, and the problems that when a movie is made in the prior art, a video recording device needs to be adopted to acquire the sound and the action of an actor according to the script, editing work needs to be carried out layer, and thus, manual waste is further caused can be solved.

Owner:福建中金在线信息科技有限公司

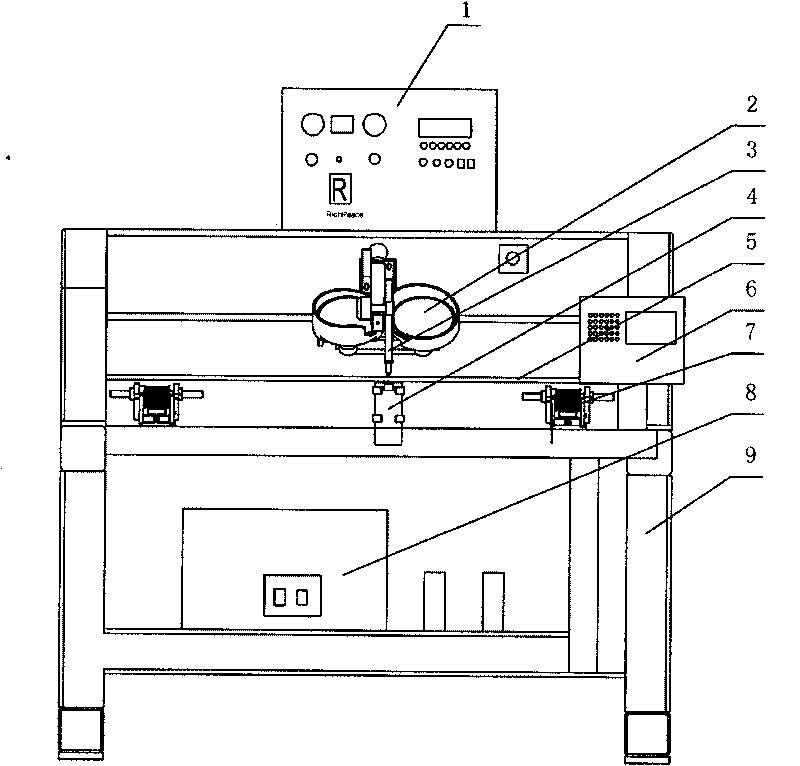

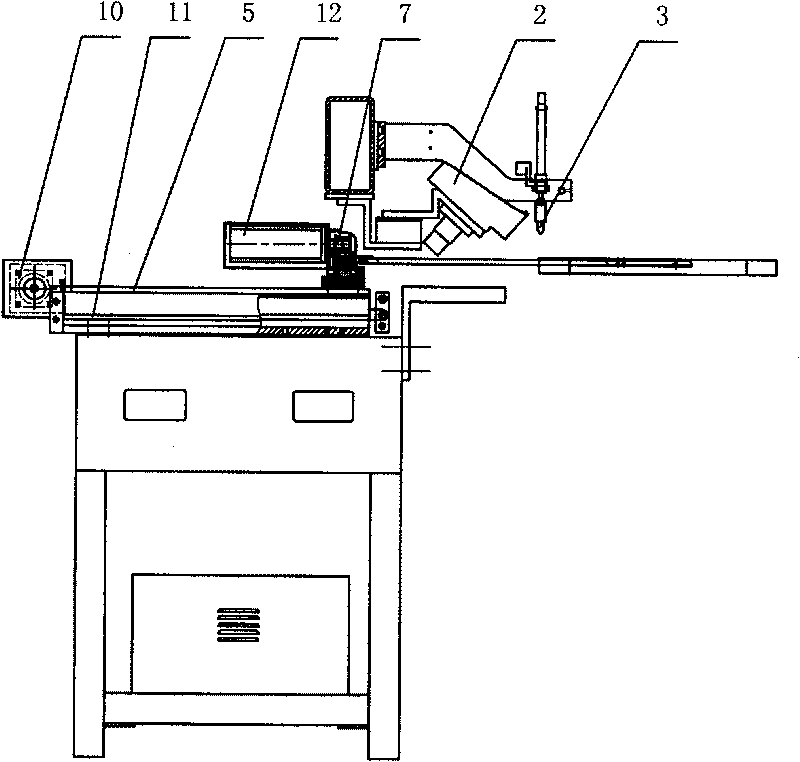

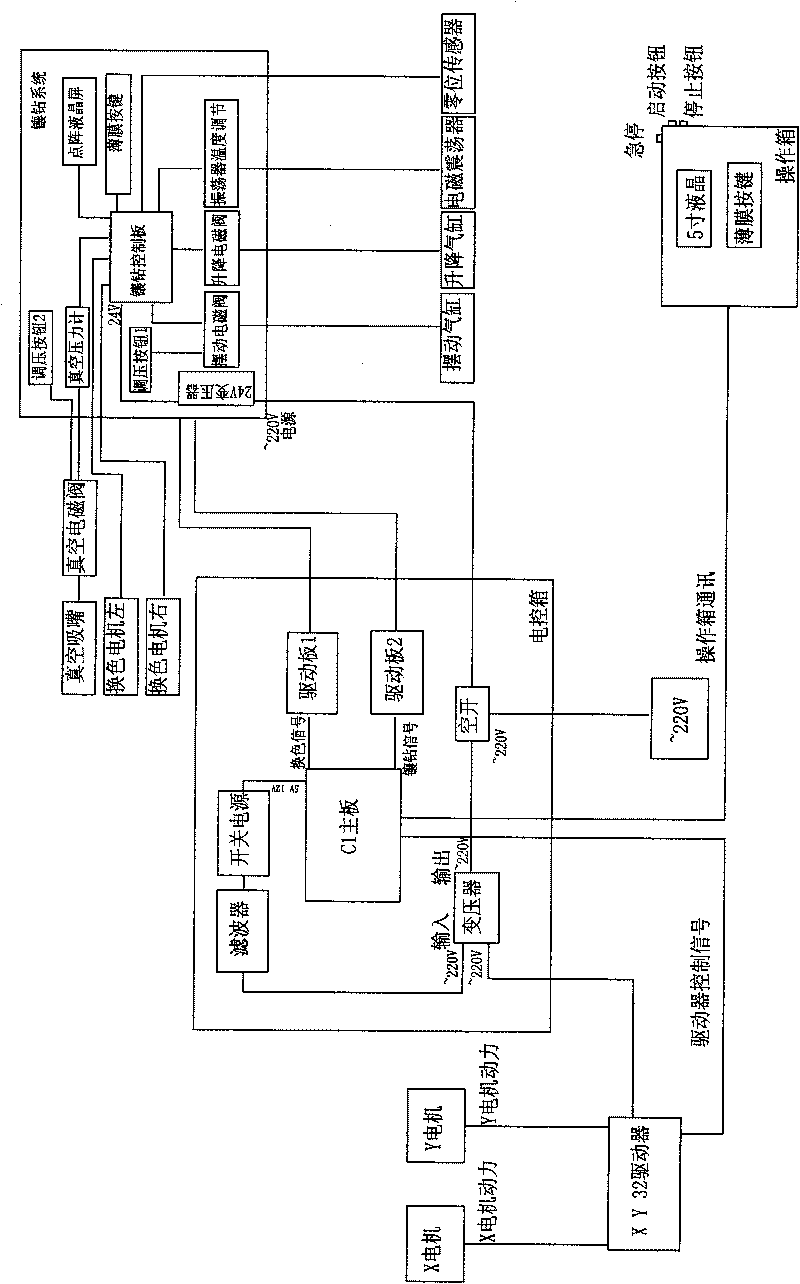

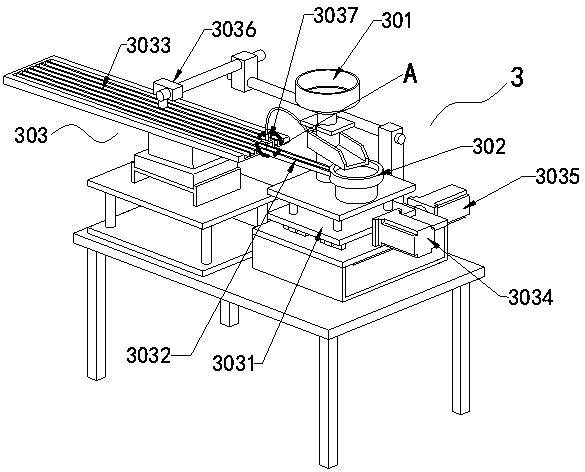

Full-automatic drill inlaying machine

InactiveCN101760907ARealize automatic diamond setting functionSolve the waste of manpowerAutomatic machinesAuxillary devicesMotor driveElectric machinery

The invention relates to a full-automatic drill inlaying machine which comprises an embroidery machine frame, a drill inlaying machine head vacuum gun, a bead feeding disc, a cloth feeding mechanism and a cloth to be drill-inlaid. The drill inlaying machine head vacuum gun carries out drill inlaying in an embroidery frame along with the movement of the cloth feeding mechanism; an electromagnetic vibrator is fixedly arranged on the machine frame and under the cloth corresponding to the right lower part of a vacuum gun suction nozzle; an electric cabinet which is arranged in the machine frame controls a Y-direction motor and an X-direction motor on the machine frame by a built-out driver; the Y-direction motor and the X-direction motor drive respective linear guide rails, the embroidery frame is arranged at the front ends of the linear guide rails, the electric cabinet is connected with an operation box on the machine frame, and a display box on the machine frame displays the running condition of the drill inlaying work. The characteristics of the full-automatic drill inlaying machine are as follows: the integral structure is simple, and the design is scientific as well as reasonable; as manual labor is replaced by the full-automatic drill inlaying machine, the production efficiency is increased, the processing of pyrographs is convenient, the inlaying of various patterns can be carried out only by inputting the patterns through a software, and large quantities of funds are saved; moreover, the drill inlaying quality and level are ensured.

Owner:上工富怡智能制造(天津)有限公司

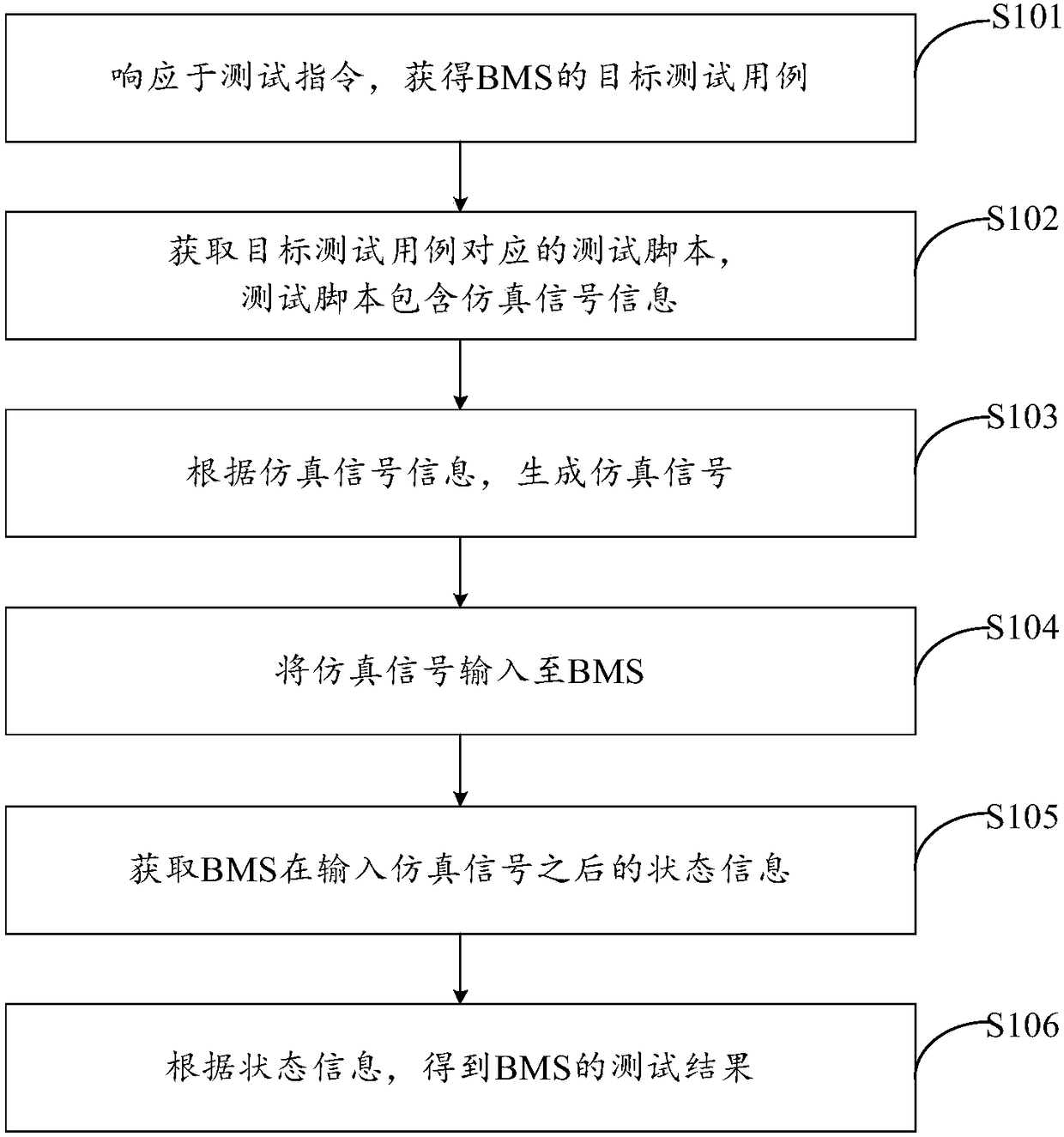

Battery management unit test method and system

ActiveCN108802511AAvoid less accurateReduce adverse effectsElectrical testingManagement unitTest script

The embodiment of the invention provides a battery management unit test method and system; the test method comprises the following steps: responding to a test command, obtaining a target test case ofa battery management system BMS, obtaining a test script corresponding to the target test case, wherein the test script contains simulation signal information; forming a simulation signal according tothe simulation signal information; outputting the simulation signal to the BMS, obtaining state information of the BMS after the simulation signal is inputted; obtaining the BMS test result accordingto the state information. The test method and system can solve the problems that an existing method enables test personnel to manually simulate the simulation signal, thus causing manpower wastes andlow testing efficiency.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

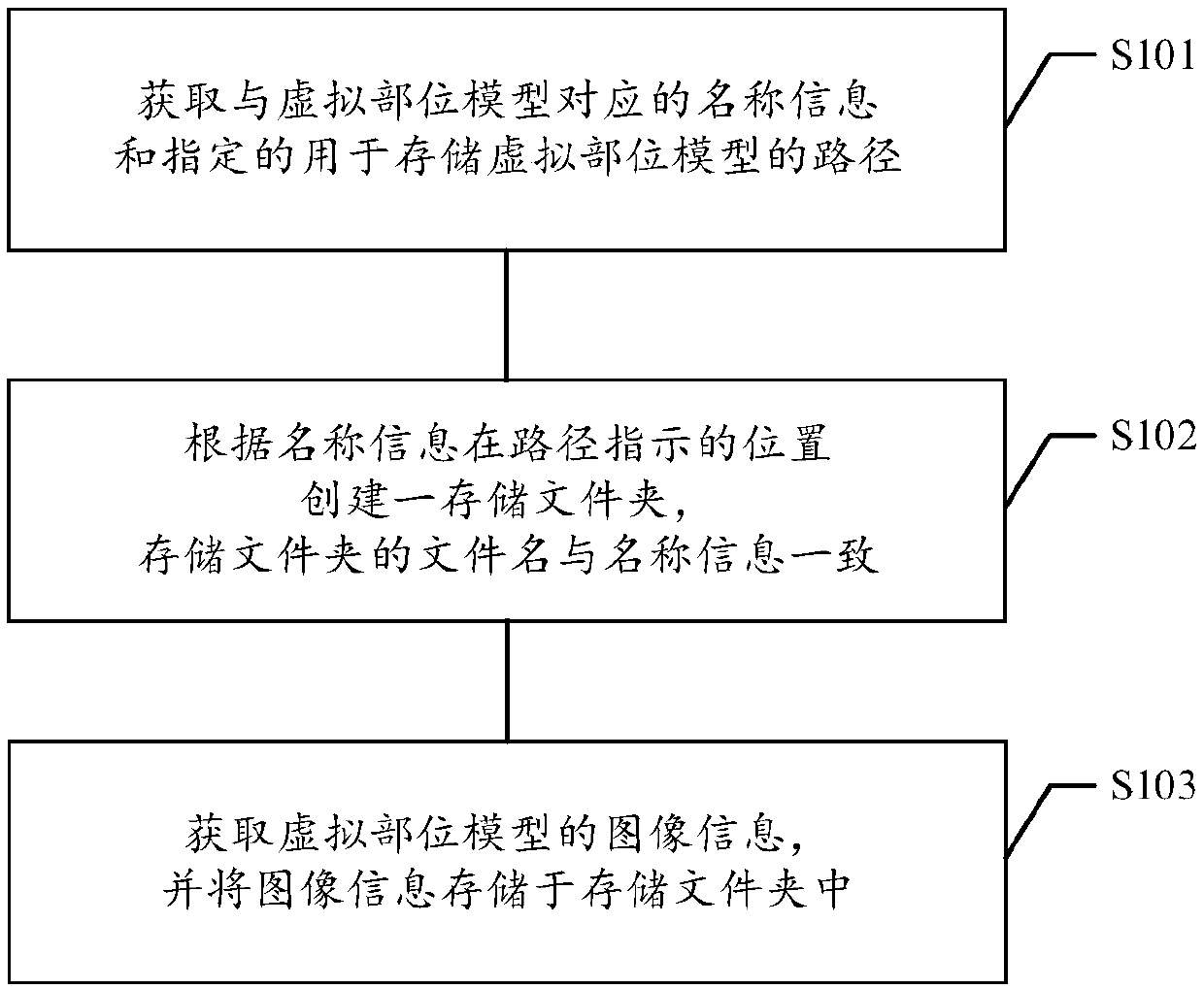

Game role fashion output method and device and electronic equipment

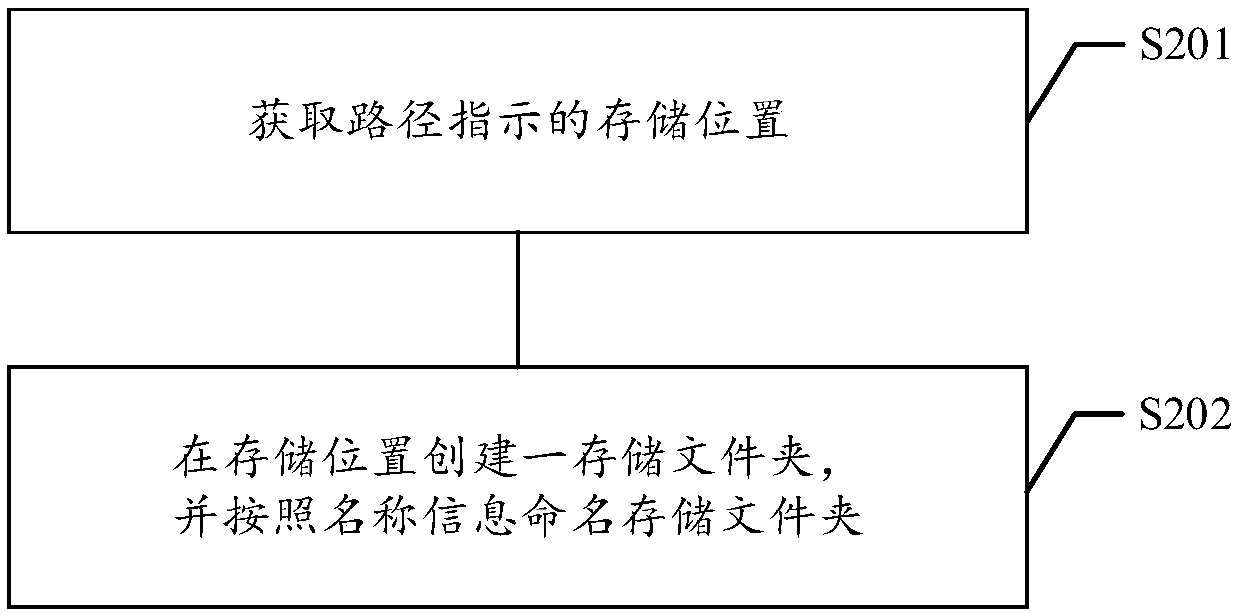

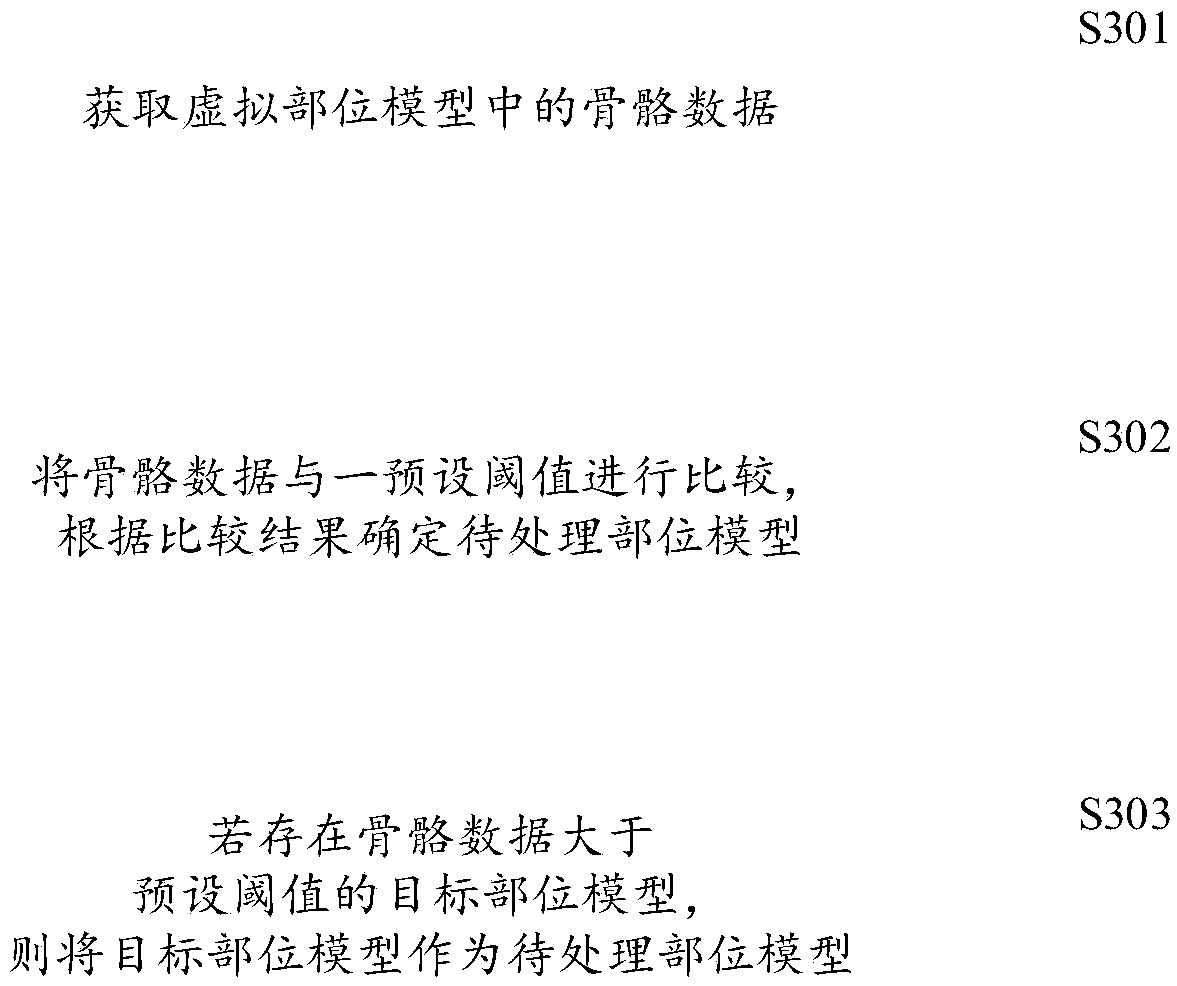

ActiveCN109558383AImprove detection error problemSolve the waste of manpowerFile/folder operationsSimulationSoftware engineering

The invention belongs to the technical field of games, and relates to a game role fashion output method and device, a computer readable storage medium and electronic equipment. The method comprises the following steps: obtaining name information corresponding to a virtual part model and a specified path for storing the virtual part model; creating a storage folder at a storage position indicated by the path according to the name information, wherein the file name of the storage folder is consistent with the name information; and acquiring image information of the virtual part model, and storing the image information in a storage folder. On one hand, automatic fashion output process of the game role is achieved, and the problem that manpower and time are wasted is solved; and on the other hand, the skeleton data of the virtual part model is adjusted to meet the target skeleton data, so that a large amount of mechanical and complicated operation is simplified, the problem of detection errors caused by skeleton missed selection is improved, and the problem of low efficiency caused by repeated output flow is solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

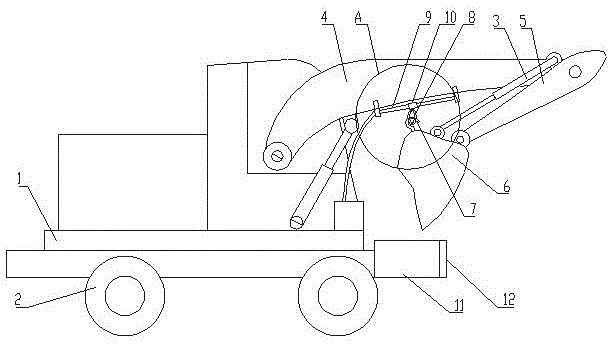

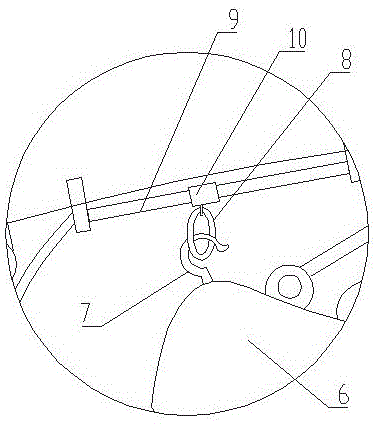

Excavator

The invention discloses an excavator. The excavator comprises a working device, an upper portion rotary table and a walking mechanism, wherein the working device comprises a bucket and a crane boom component, and the crane boom component is mainly composed of an oil cylinder system, a movable arm and a bucket rod hinged to the front end of the movable arm; the bucket is installed at the end portion of the bucket rod. The excavator is characterized in that a lifting hook is arranged at the back of the bucket, and a lifting ring is arranged on the movable arm; and the bucket rod is controlled to swing toward the movable arm through the oil cylinder system, and meanwhile the back of the bucket is controlled to overturn toward the movable arm to enable the lifting hook to be hung on the lifting ring. The excavator can achieve the aim that the disassembly and carrying of the bucket and the installation of a quartering hammer can be completed without manpower, and the technical problem that manpower and time are wasted due to the replacement of the bucket and the quartering hammer of an existing excavator is solved.

Owner:CHONGQING RADIO & TV UNIV +1

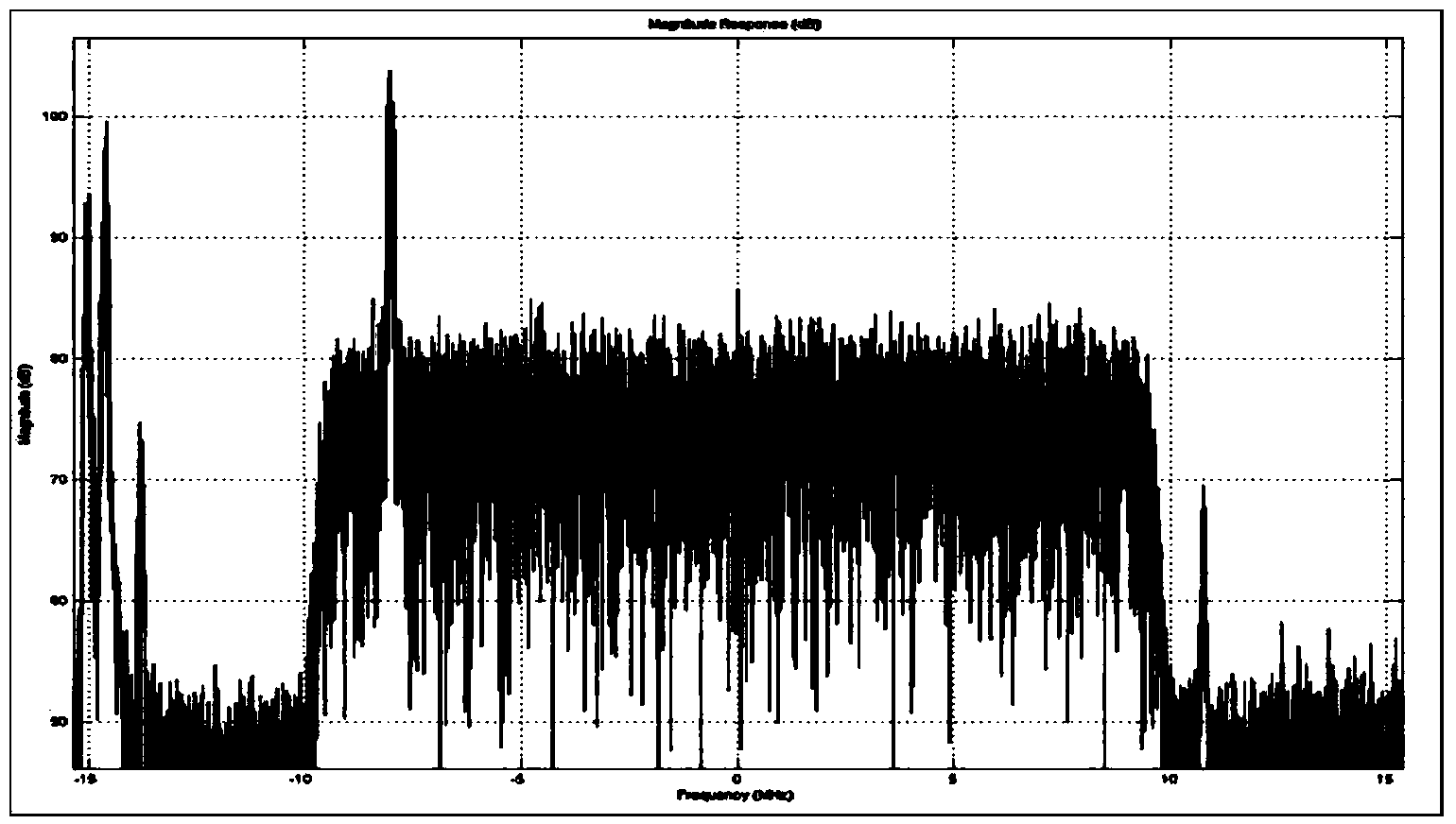

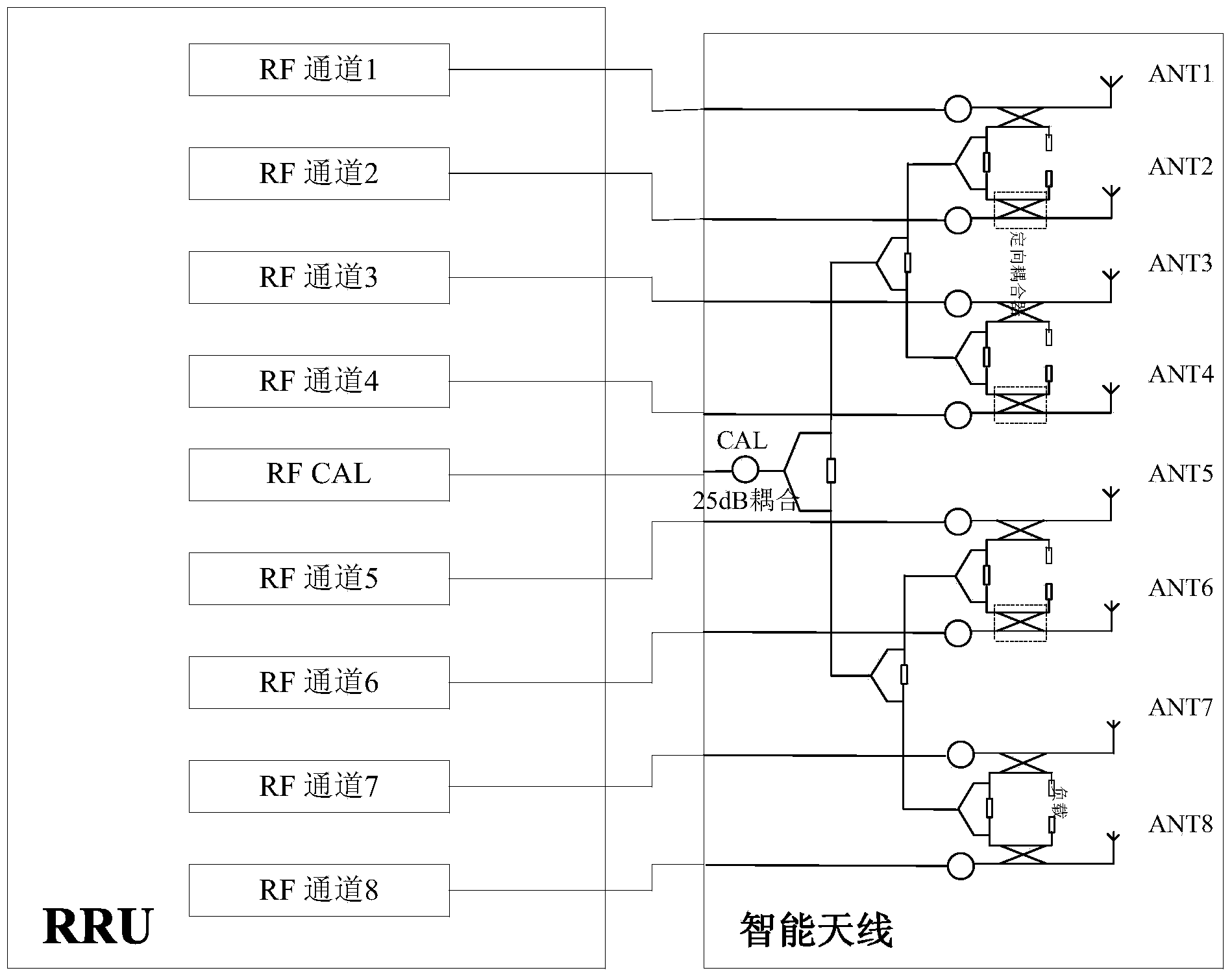

Interference detection method and device of multi-antenna TDD system

ActiveCN103532601AEasy to detectEliminate blockingSpatial transmit diversityTransmission monitoringSmart antennaRadio frequency signal

The invention provides an interference detection method of a multi-antenna TDD (Time Division Duplex) system, which comprises the following steps of inputting a radio-frequency signal received by an intelligent antenna into a calibration channel in a remote radio module, processing the radio-frequency signal with the calibration channel, obtaining a processing result of the radio-frequency signal, and determining a corresponding parameter of the radio-frequency signal according to the processing result. The invention further provides an interference detection device of the multi-antenna TDD system. The interference detection method and the device of the multi-antenna TDD system can realize convenient and quick detection of radio frequency interference from the outside, so that blocking removal of a receiving end is facilitated, external interference removal by a network optimization mode is facilitated, the problems of manpower waste and low efficiency in an interference detection means in the prior art are solved, and the support is provided for subsequent network optimization.

Owner:DATANG MOBILE COMM EQUIP CO LTD

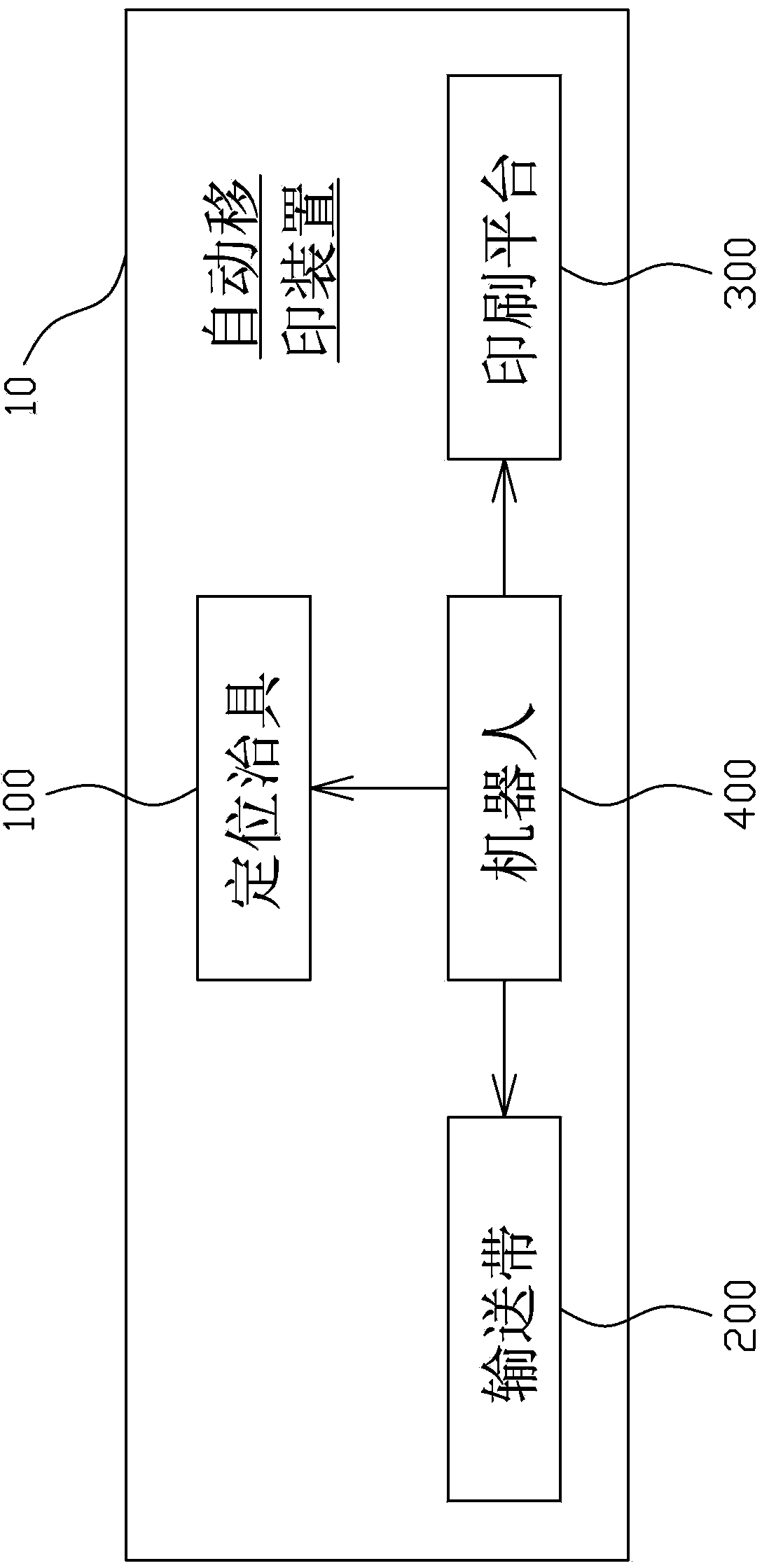

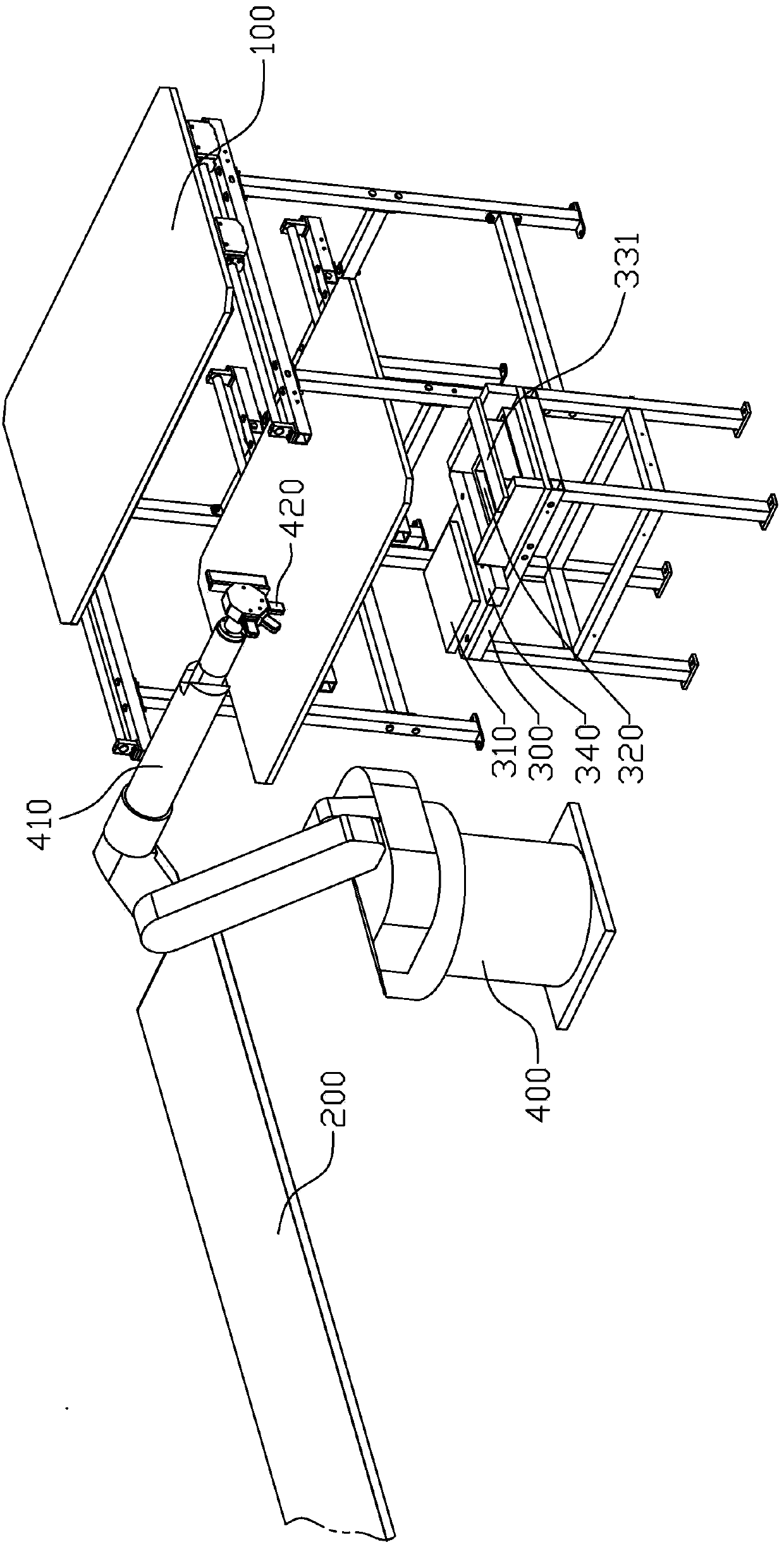

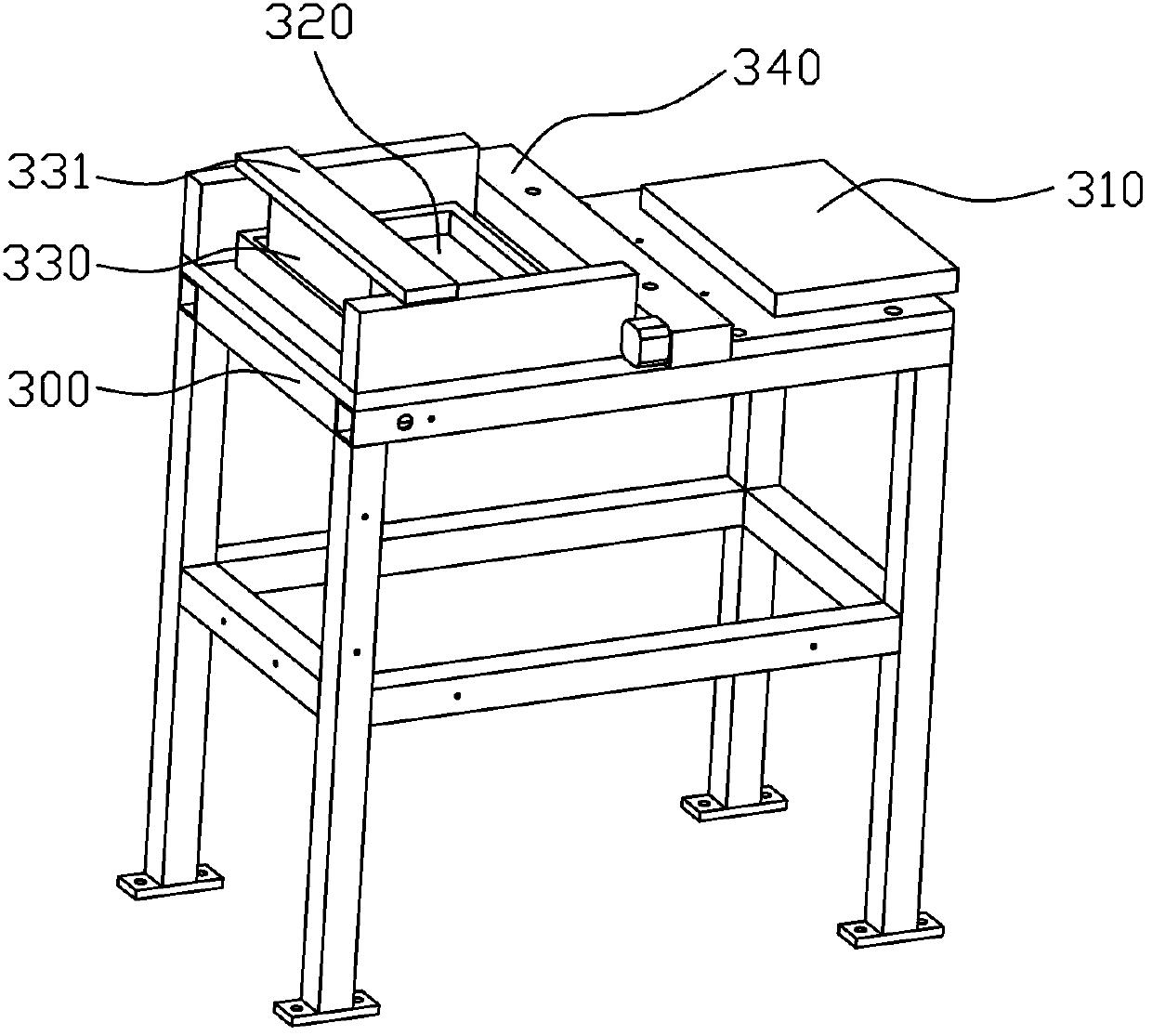

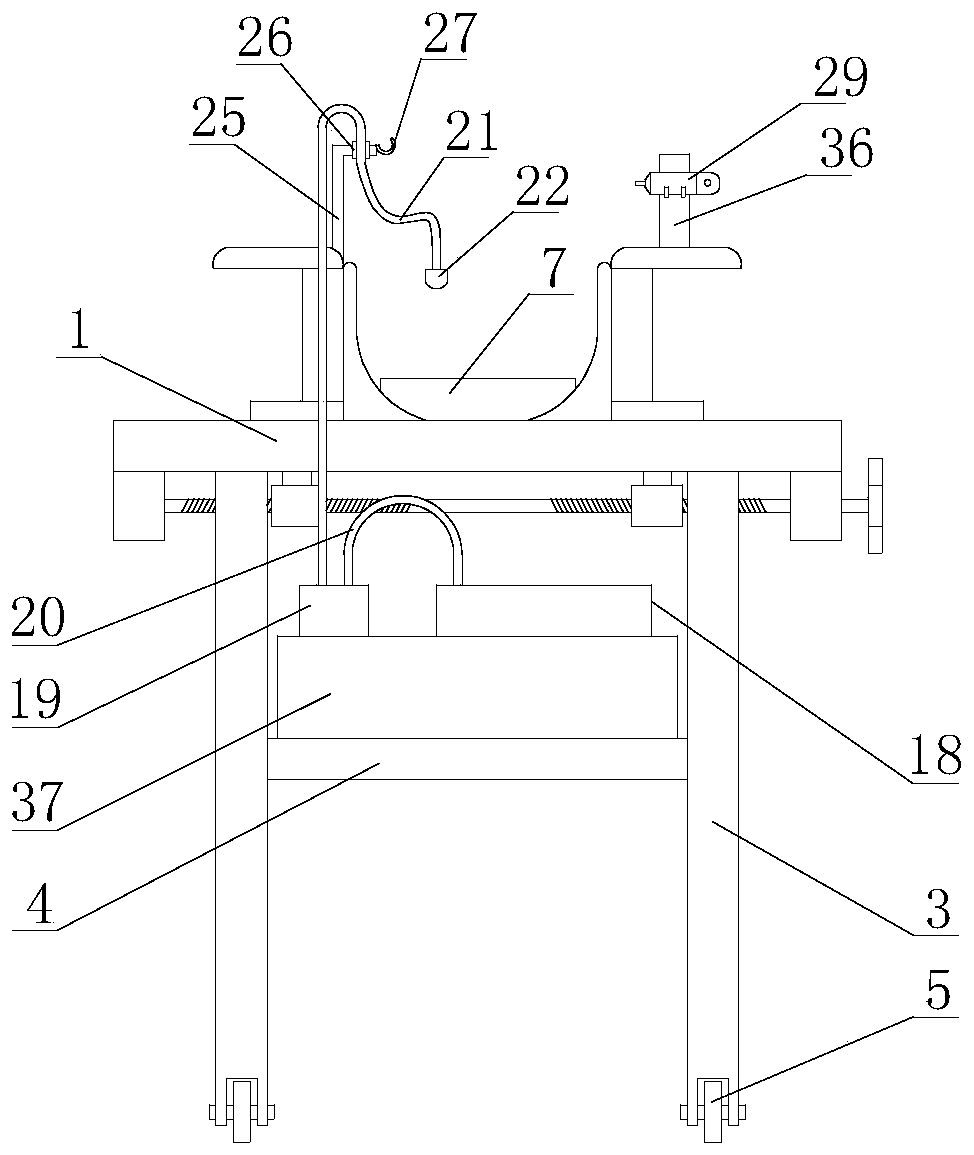

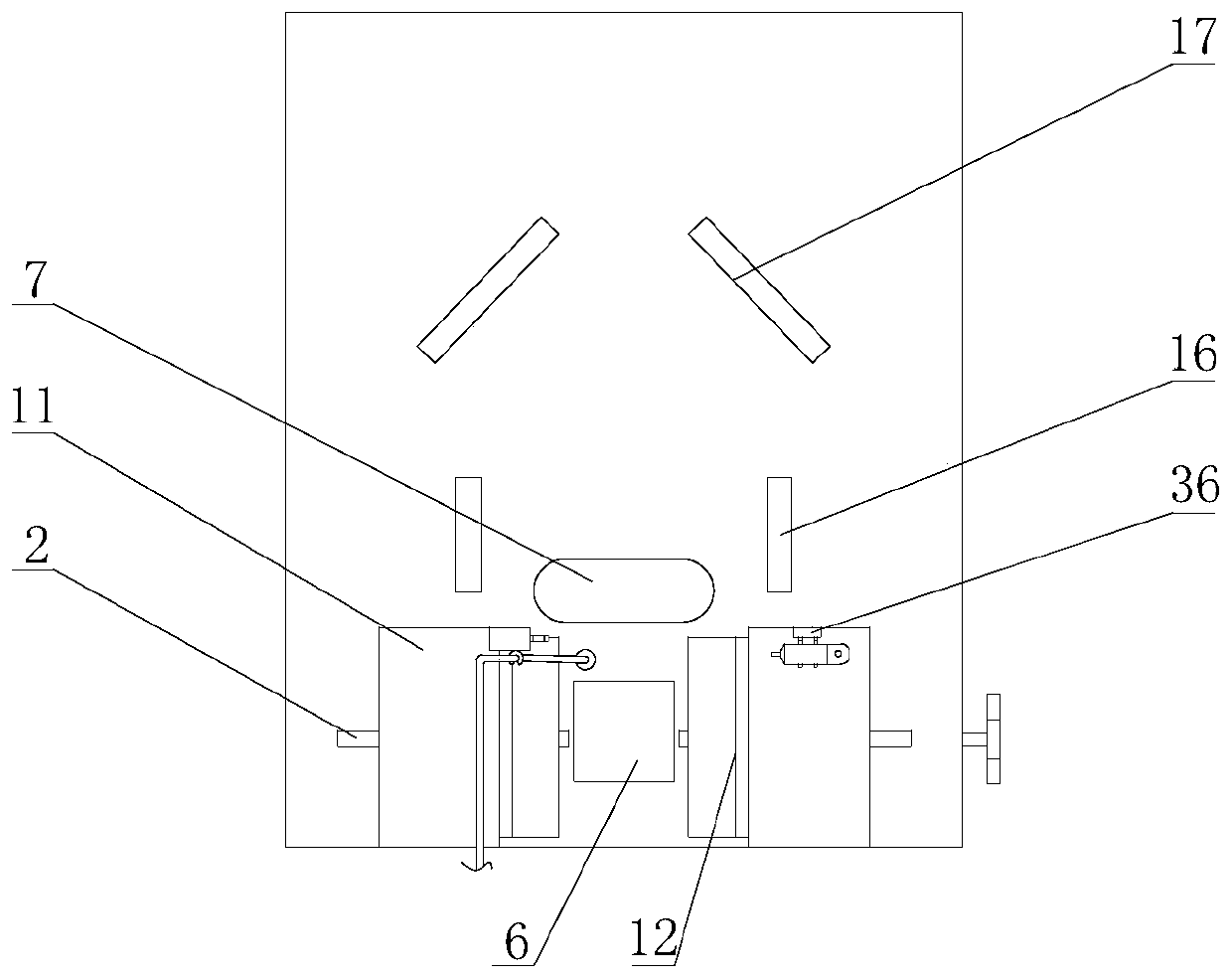

Automatic transfer printing device

An automatic transfer printing device comprises a positioning jig, a conveying belt, a printing platform and a robot. The printing platform is provided with a printing jig, an etching plate and a scraper. According to the automatic transfer printing device, due to the fact that the robot is respectively matched with the positioning jig, the printing platform and the conveying belt, a product can be fast printed, the continuity of product printing is guaranteed, production efficiency is improved, only one person is needed to place the product to the positioning jig and monitor the robot, the problem of wasting of manpower and material resources is solved, and cost is reduced.

Owner:SUZHOU MITAC PRECISION TECH

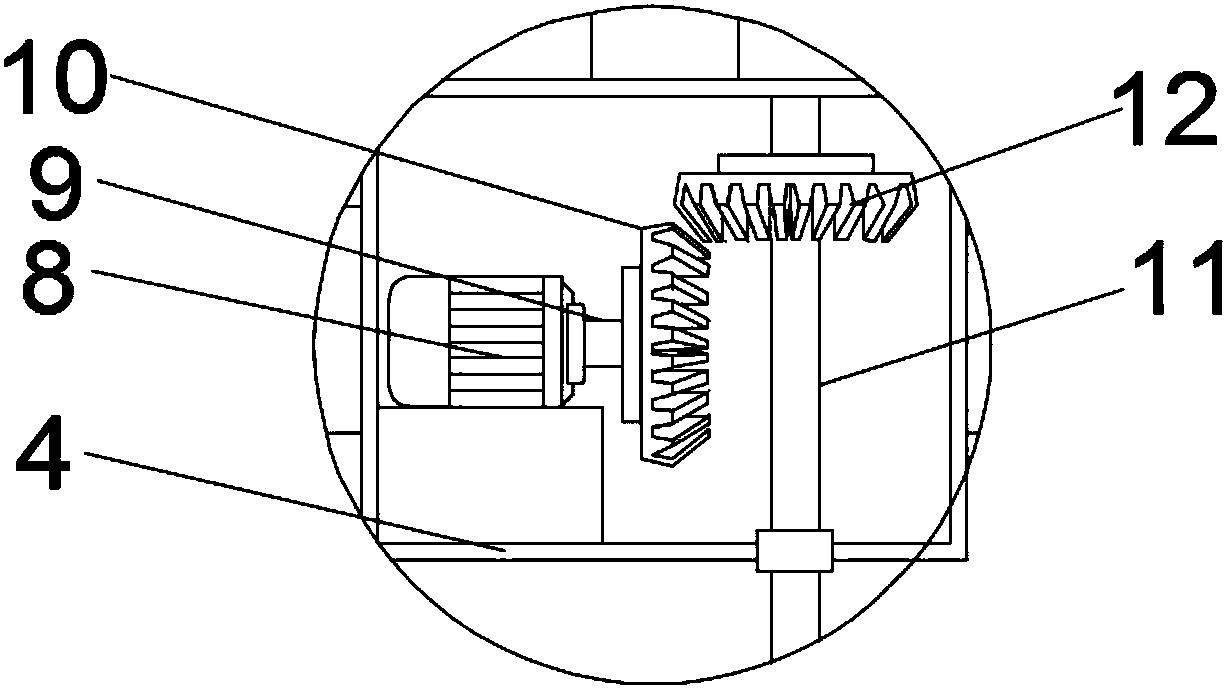

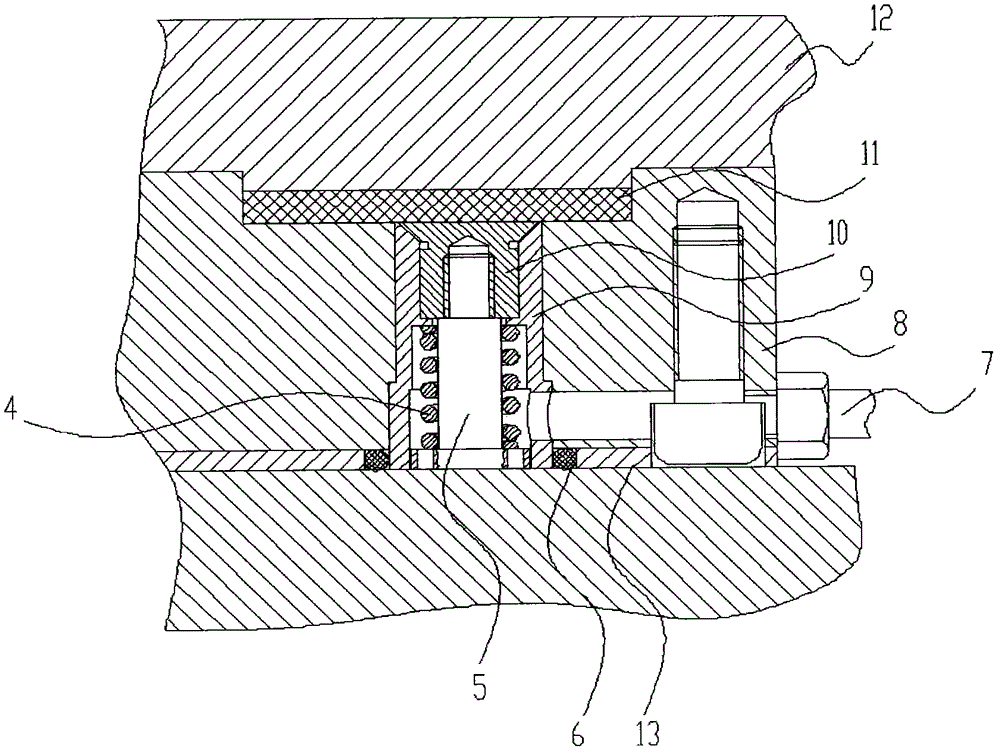

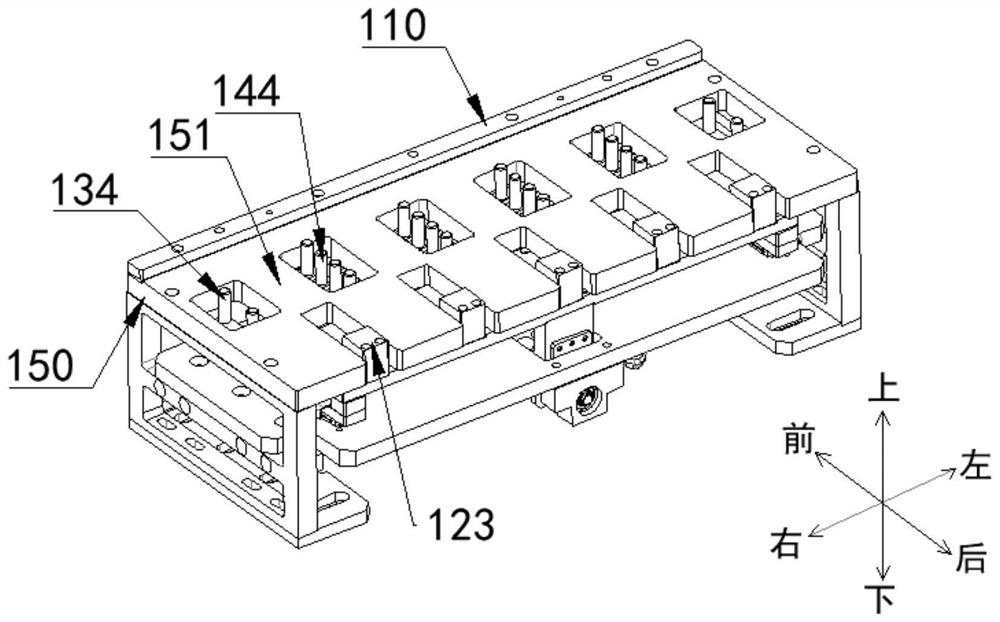

Machining tool for metal sealing gasket

ActiveCN114054591ASolve the waste of manpowerRealize the punching operationShaping toolsPerforating toolsMachine toolMachining

The invention discloses a machining tool for a metal sealing gasket. The machining tool comprises a stamping cavity, a die cavity, a bearing box and a workbench and further comprises a stamping mechanism, a feeding mechanism and a clamping mechanism, wherein the stamping cavity is formed in the workbench and composed of a top plate and four brackets located on the workbench, the stamping mechanism is located on the top plate, the bottom surface of the workbench is connected with the die cavity, control boxes are arranged on the left side and the right side of the die cavity, a die groove is formed in the die cavity, the upper portion of the die groove is not covered by the workbench, the feeding mechanism and the clamping mechanism are further arranged on the workbench and in the die cavity, the bearing box is arranged below the die cavity, the bearing box communicates with a waste box, a conveying belt is arranged in the waste box, a discharging port is formed in the joint of the conveying belt and the waste box, and universal wheels are connected to the bottom surface of the waste box. According to the invention, automatic feeding of metal plates, stamping machining of sealing gaskets and automatic ejection and taking can be achieved, waste materials are automatically discharged, manpower is saved, and the machining efficiency is improved.

Owner:烟台长鑫密封产品有限公司

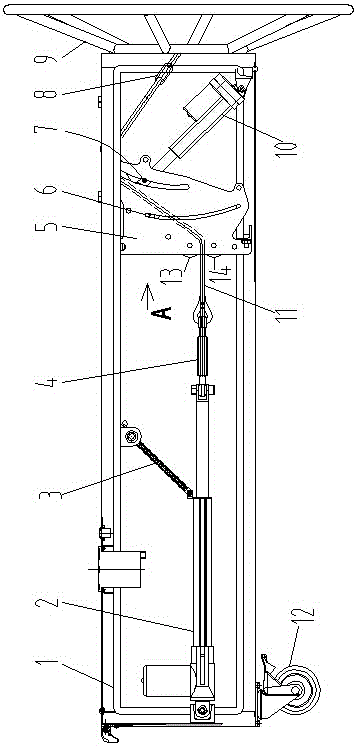

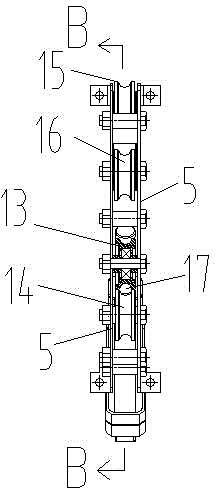

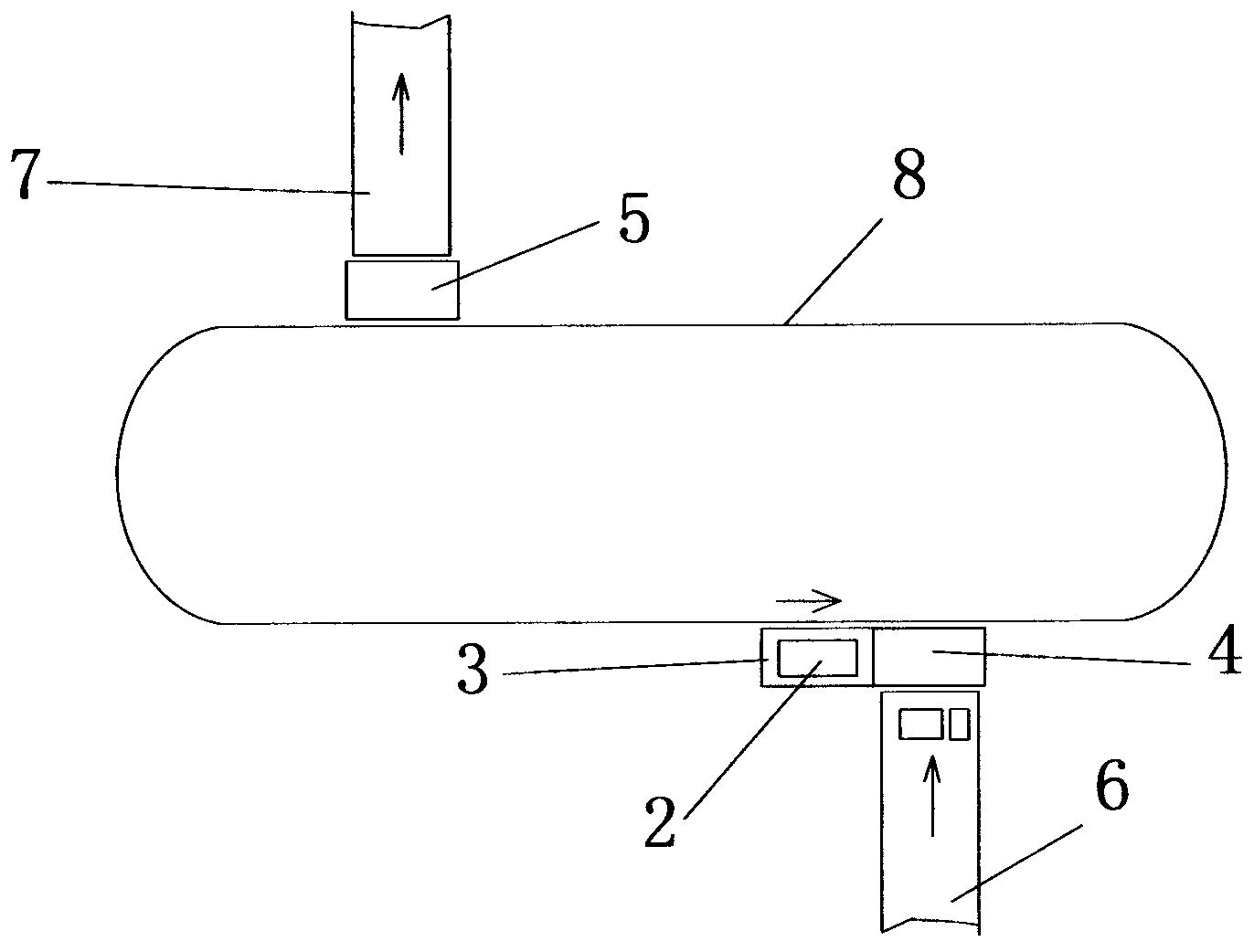

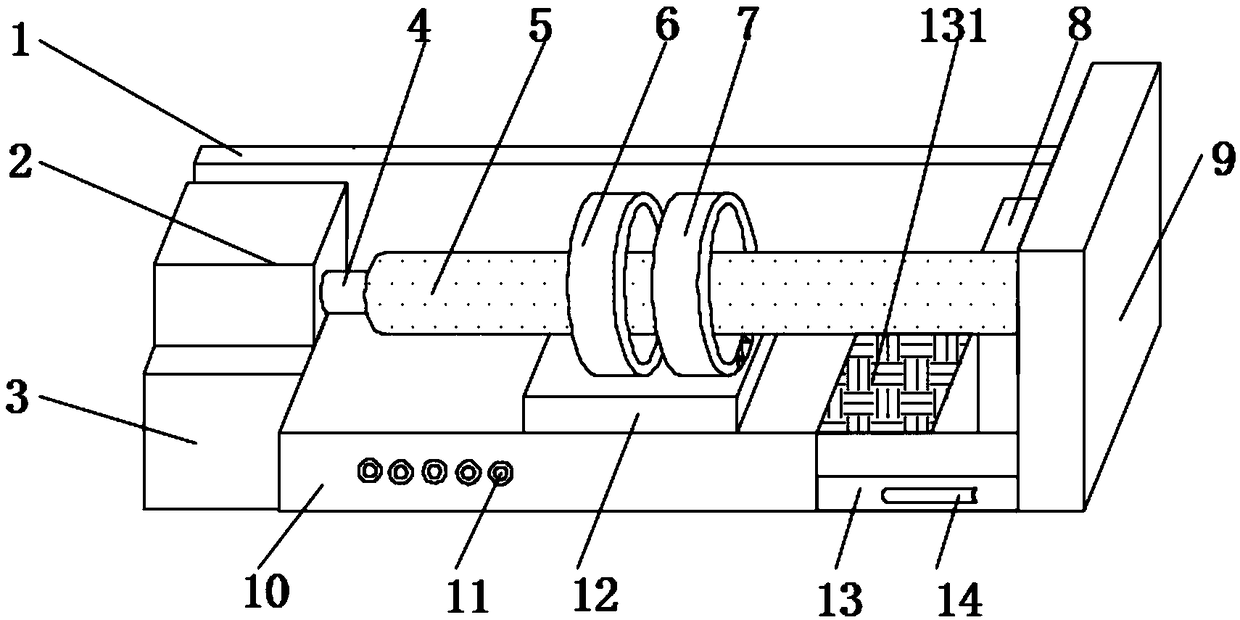

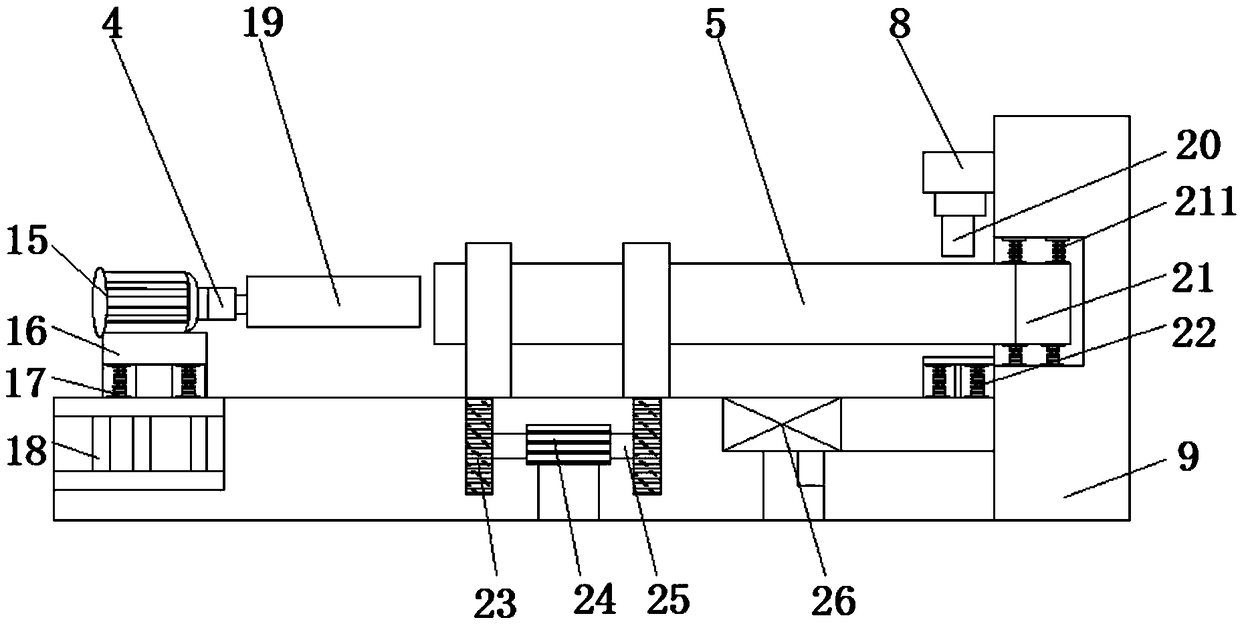

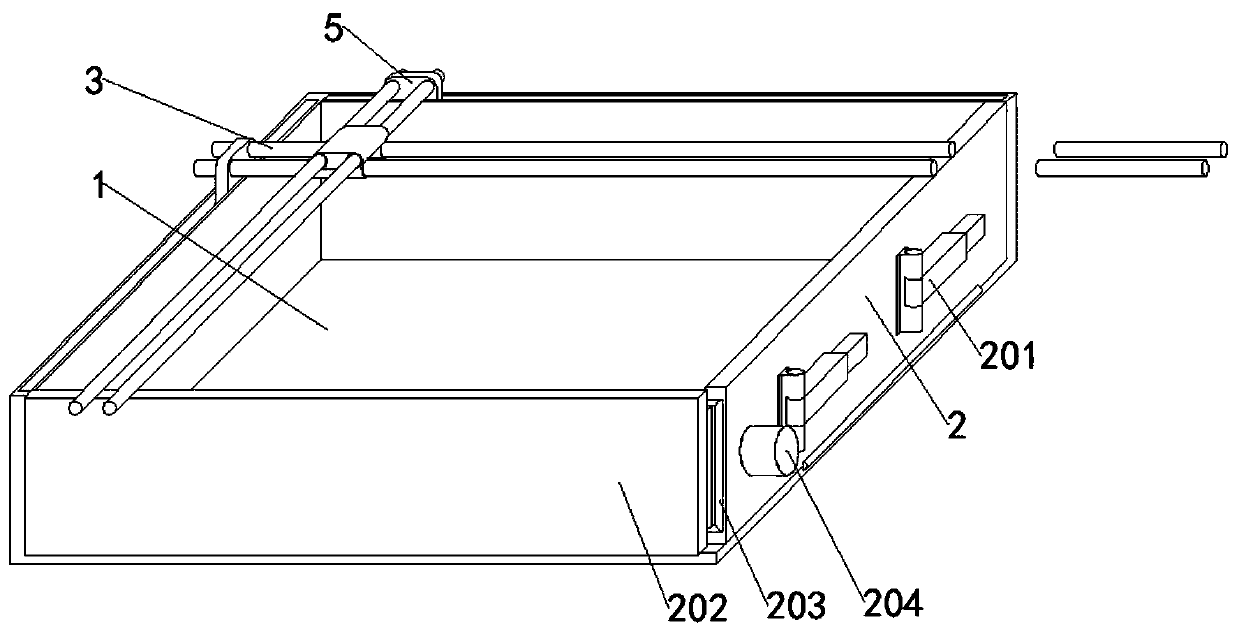

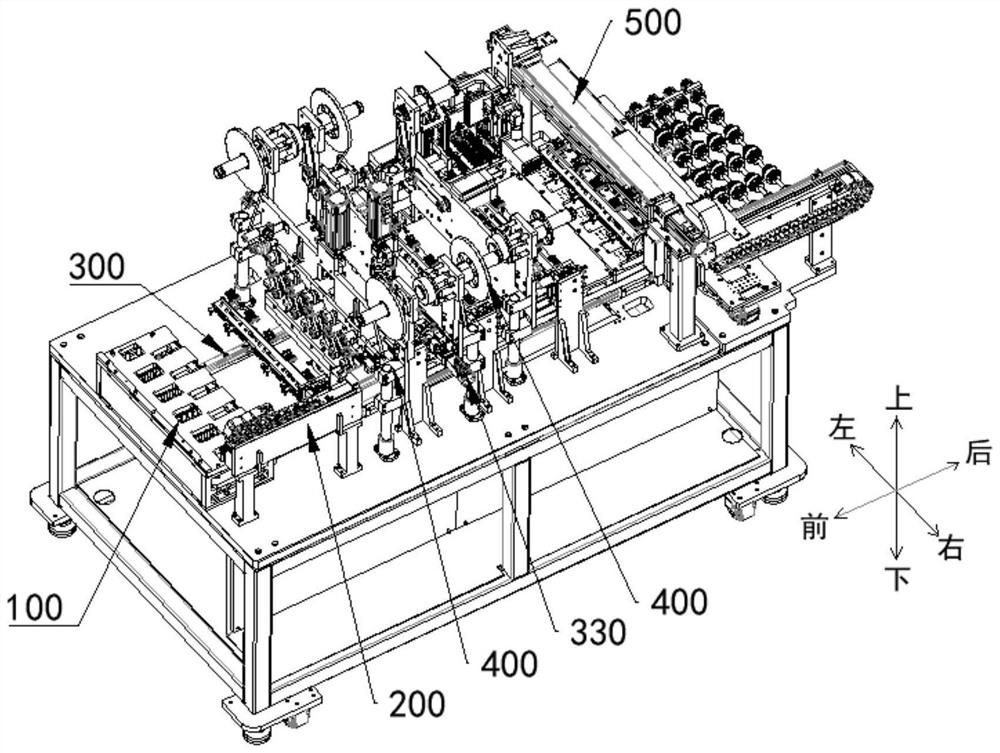

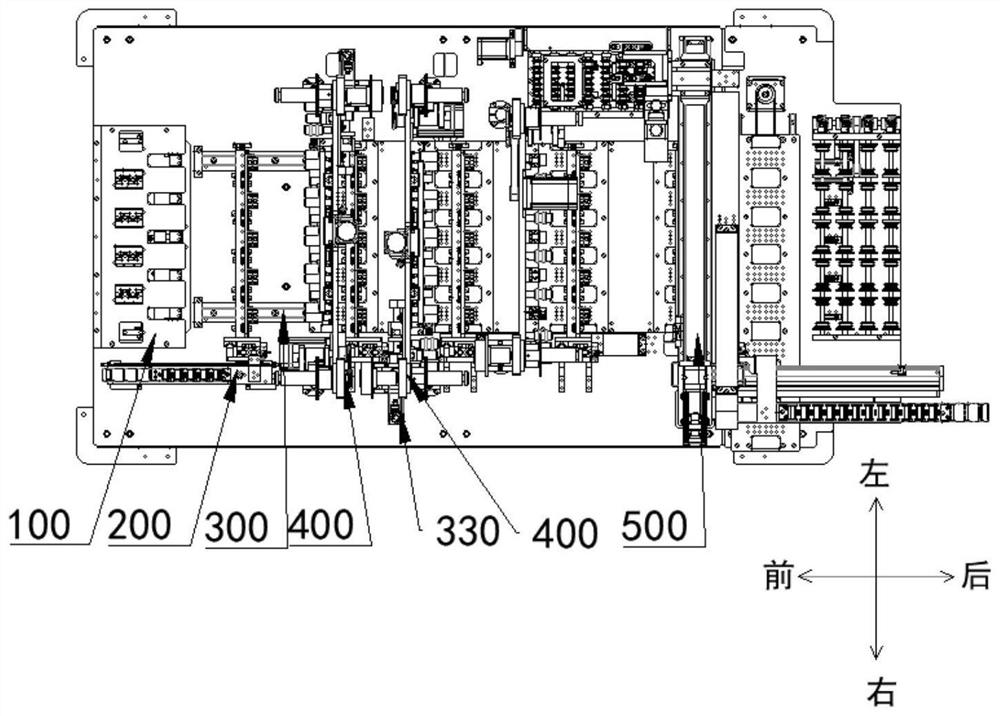

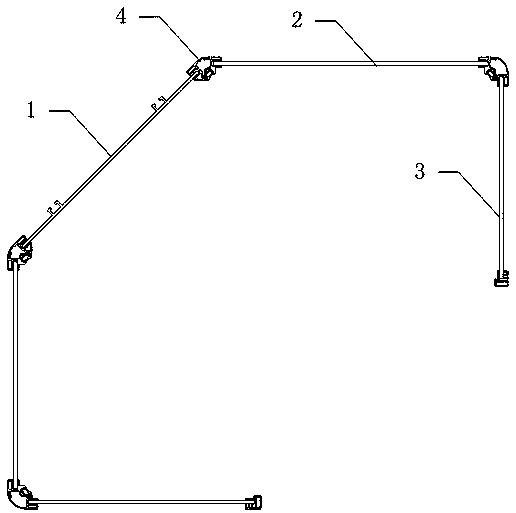

Heat-preserving pipe penetration device

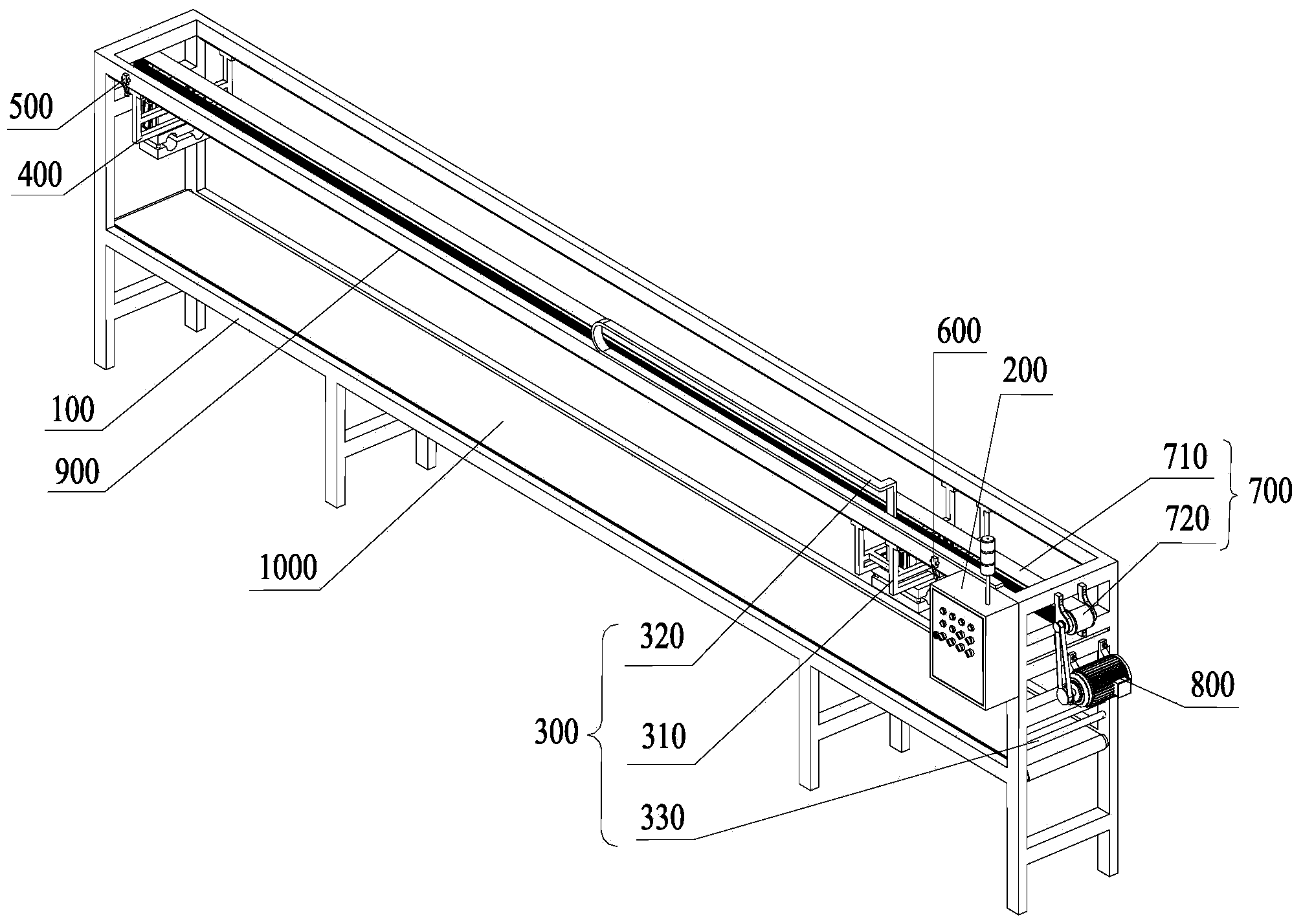

ActiveCN104353978ARealize automatic dressingSolve the waste of manpowerMetal working apparatusElectricityEngineering

The invention discloses a heat-preserving pipe penetration device applicable to penetration of a connecting pipe into a heat-preserving pipe. The heat-preserving pipe penetration device comprises a bracket, an electric control box, a conveying mechanism and a fixing mechanism, wherein the electric control box is arranged on the bracket; the conveying mechanism and the fixing mechanism are arranged on the bracket respectively; the electric control box is electrically connected with the conveying mechanism and the fixing mechanism respectively; the conveying mechanism is movably connected with the bracket and is suitable for moving back and forth along the bracket between two ends of the bracket; the fixing mechanism is fixedly connected with one end of the bracket, is suitable for grabbing the heat-preserving pipe and is used for positioning the heat-preserving pipe at a preset position. The motions of the conveying mechanism and the fixing mechanism are controlled by the electric control box respectively, so that when being sent at the preset position, the connecting pipe directly penetrates into the heat-preserving pipe, manual pipe penetration operation is replaced, automatic penetration of the heat-preserving pipe is realized, the production efficiency is effectively improved, and the waste of manpower is avoided. Finally, the problems,, of the conventional pipe penetration mode, that the manpower is wasted and the production efficiency is reduced are effectively solved.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

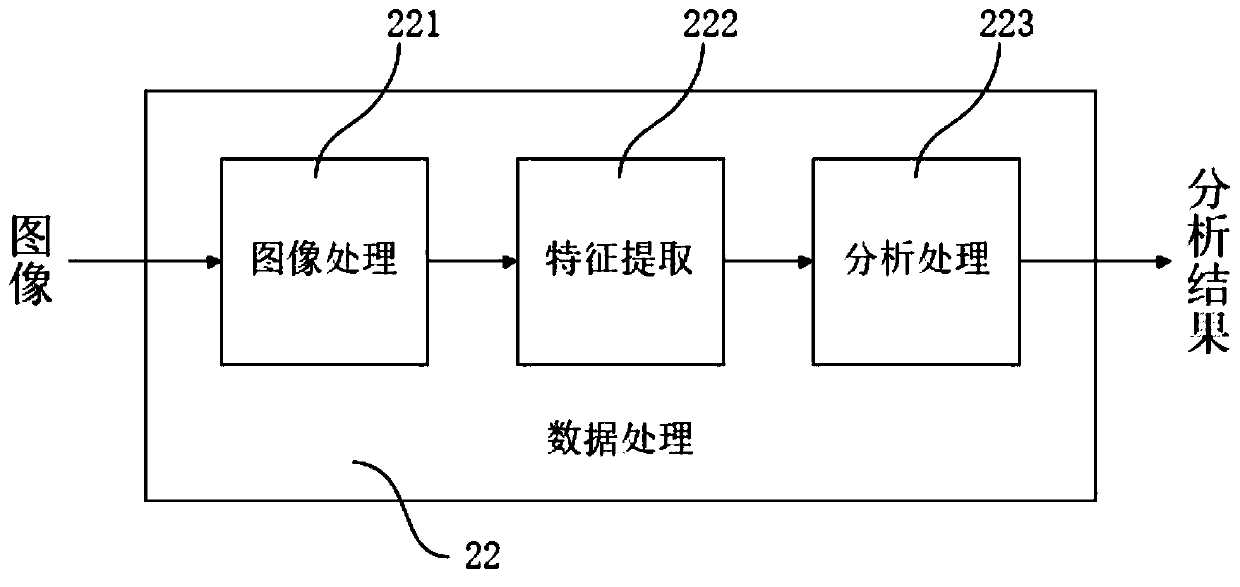

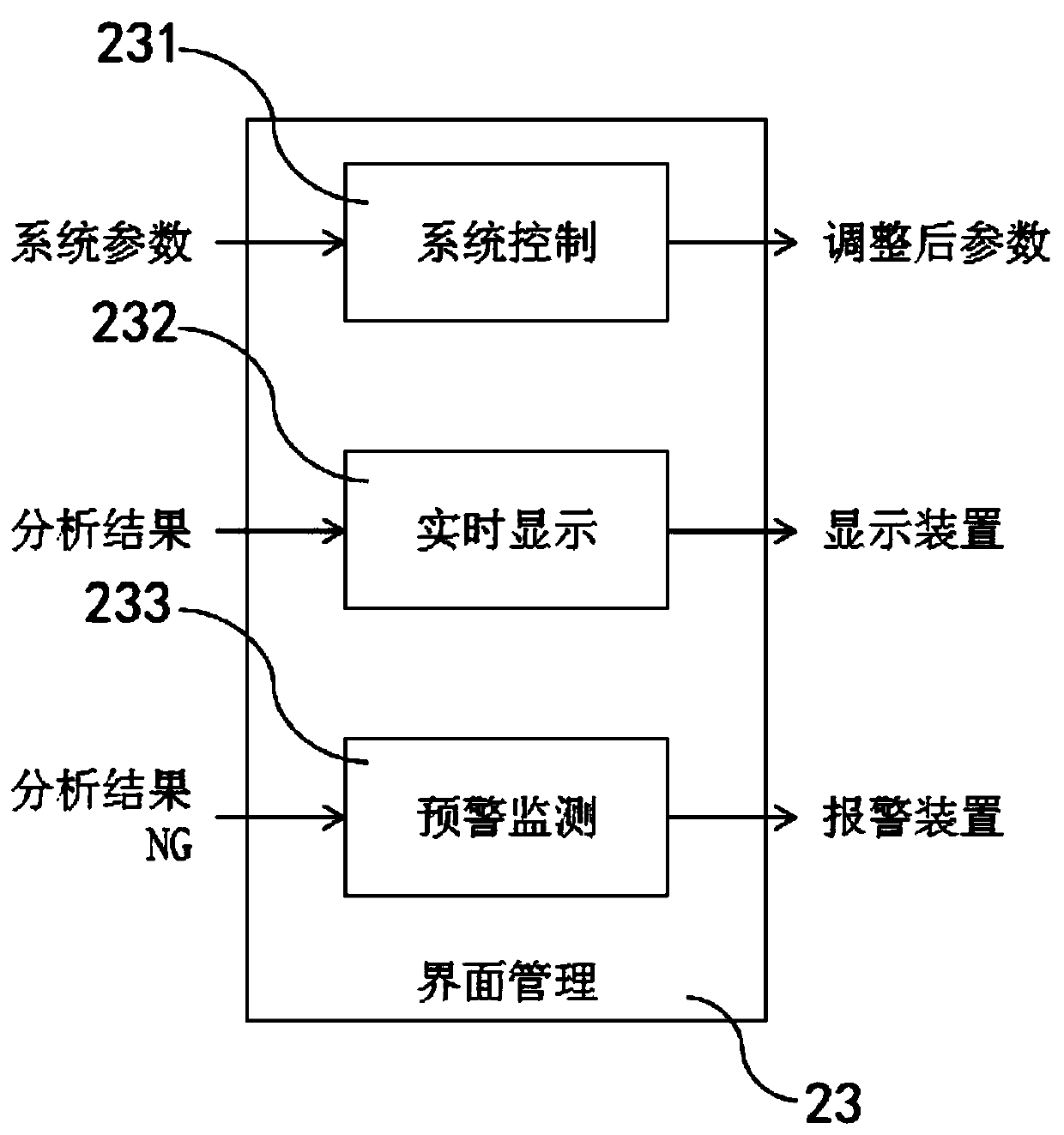

Real-time detection and monitoring system, real-time detection and monitoring method and chemical mechanical polishing equipment

ActiveCN111230723AReliable controlSolve the problem of longevityLapping machinesGrinding feed controlReal time analysisControl engineering

The invention provides a real-time detection and monitoring system. The real-time detection and monitoring system is used for detecting and monitoring the condition of a groove of a polishing pad in real time to manage and control the service life of the polishing pad. The real-time detection and monitoring system involves an image acquisition module, a data processing module and an interface management module. The invention further provides a real-time detection and monitoring method. The real-time detection and monitoring method comprises the steps that an image of the groove of the grindingpad is acquired in real time; and the image is analyzed in real time, whether the polishing pad reaches the service life or not is determined, and an analysis result is output in real time. The invention further provides chemical mechanical polishing equipment comprising the real-time detection and monitoring system. Image information is acquired through the image acquisition module, the image isanalyzed and processed through the data processing module, the result that whether the grinding pad reaches the service life or not is obtained in real time, and finally system control and state display are carried out through the interface management module, so that management and control of the service life of the grinding pad become timely and reliable, meanwhile, manpower is reduced, and theproblems that in the prior art, management and control over the service life of the grinding pad lacks instantaneity and reliability, and manpower is wasted are solved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Movable type fixed pull ring bearing dynamometer

ActiveCN104568587ASave manpower and material resourcesHigh degree of automationMaterial strength using tensile/compressive forcesDynamometerMaterial resources

The invention discloses a movable type fixed pull ring bearing dynamometer which comprises a rack, wherein a first electric push rod is arranged on the rack; the front end of the first electric push rod is hinged with the rack, and a metering dynamometer is arranged at the rear end of the first electric push rod; a steering assembly is arranged behind the metering dynamometer; the front end of a tensile rope is connected to the metering dynamometer and passes through the steering assembly; the rear end of the tensile rope can be connected with a fixed pull ring needing to be measured; and a frustum-shaped frame which is used for connecting an inflation product and expands backwards is arranged on the rear side of the rack. According to the movable type fixed pull ring bearing dynamometer disclosed by the invention, the manpower and material resources are saved, the degree of automation is high, and the working efficiency is high.

Owner:ZHENGZHOU WOLONG AMUSEMENT EQUIP

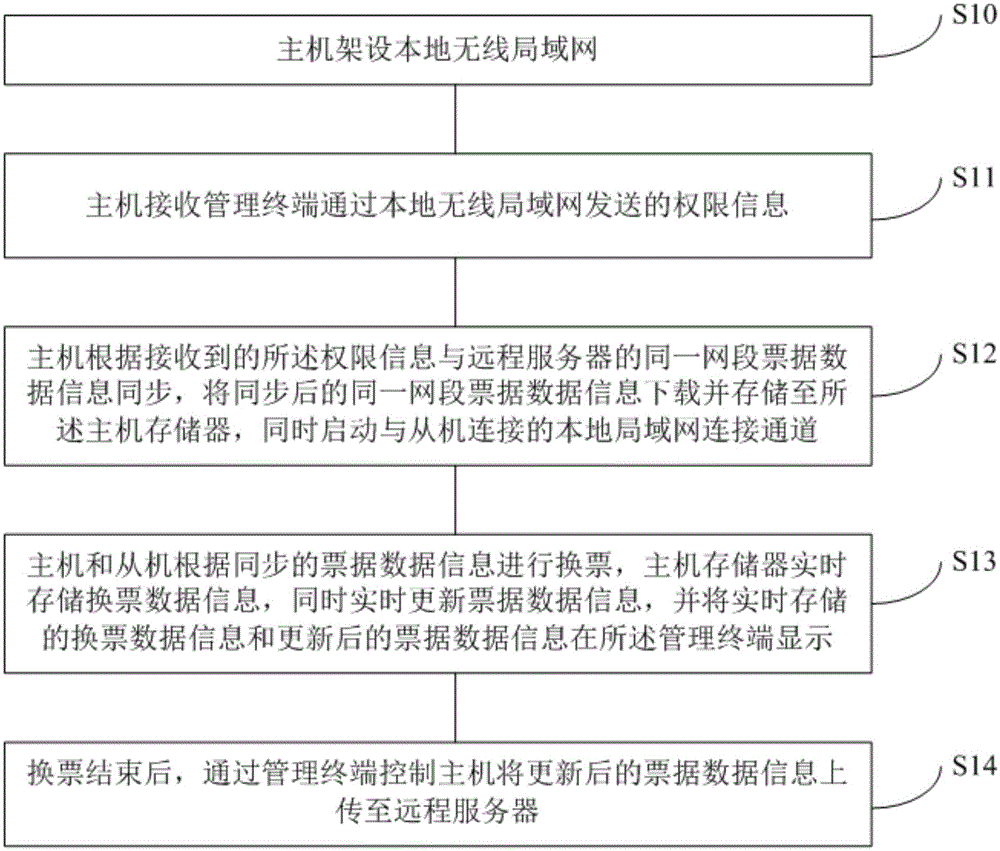

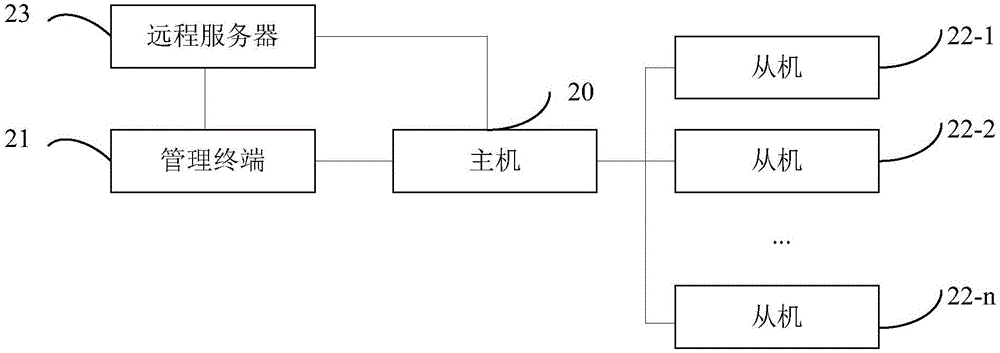

Local wireless ticket changing method and system

ActiveCN105160410ASolve the waste of manpowerRealize data sharingReservationsData switching by path configurationData informationNetwork connection

The invention discloses a local wireless ticket changing method. The method comprises the steps that: a host receives permission information sent by a management terminal through a local wireless local area network; and same-network-segment bill data information of a remote server is synchronized according to the received permission information, the synchronized same-network-segment bill data information is downloaded and stored to a host memory, the host and a slave perform ticket changing according to the synchronized bill data information, the host memory stores ticket changing data information in real time, meanwhile the bill data information is updated in real time, and the ticket changing data information stored in real time and the updated bill data information are displayed in the management terminal. At the same time, the invention furthermore discloses a local wireless ticket changing system. According to the local wireless ticket changing method and system, IDC data is downloaded to a host storage module when a network is available, and a wireless local area network connection with the slave without a data processing function is established after a network connection is cut off, so that the stability and reliability of business are enhanced and the data transmission speed is increased; and monitoring is performed by the host, so that the manpower is reduced.

Owner:BEIJING HONGMA MEDIA CULTURE DEV

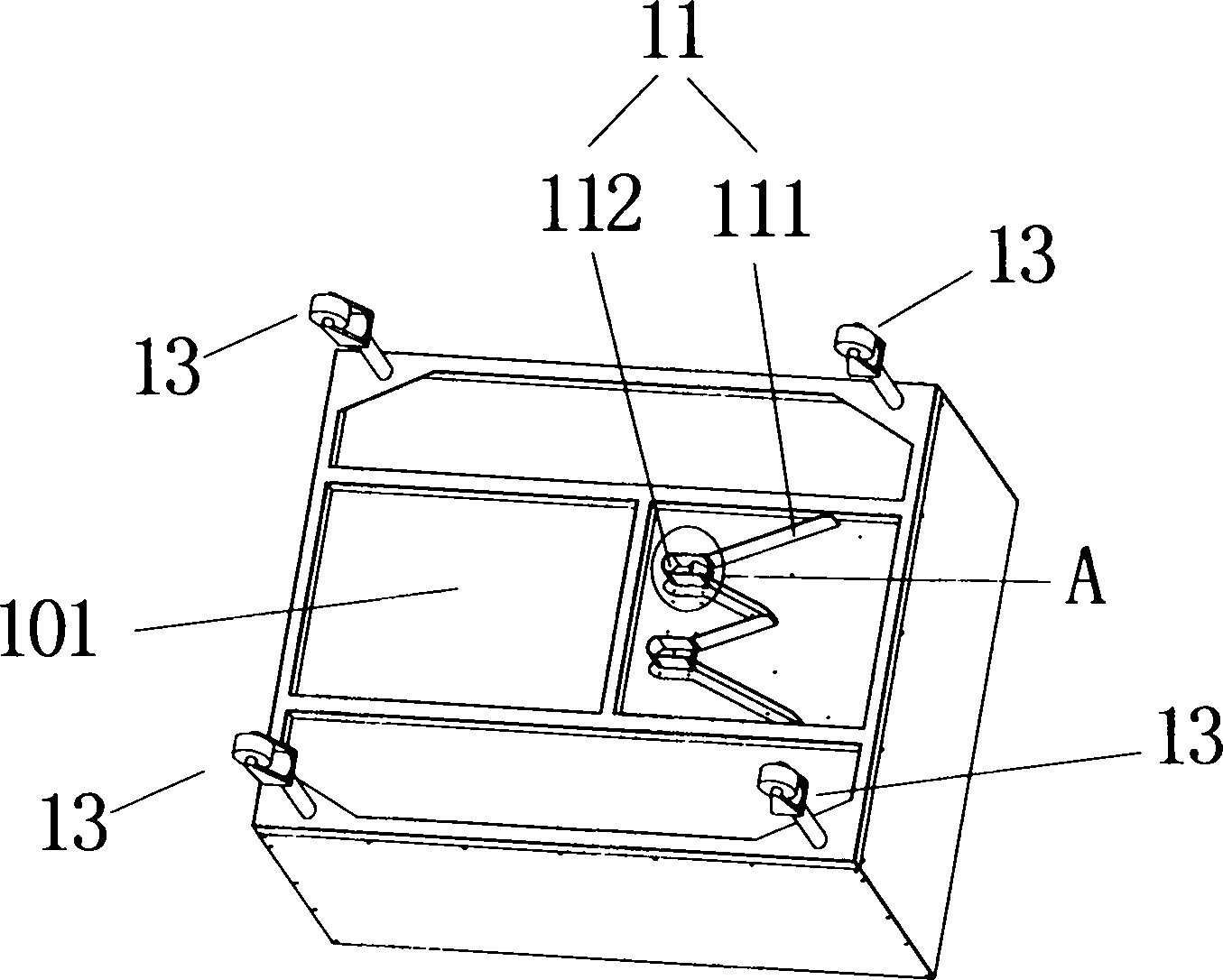

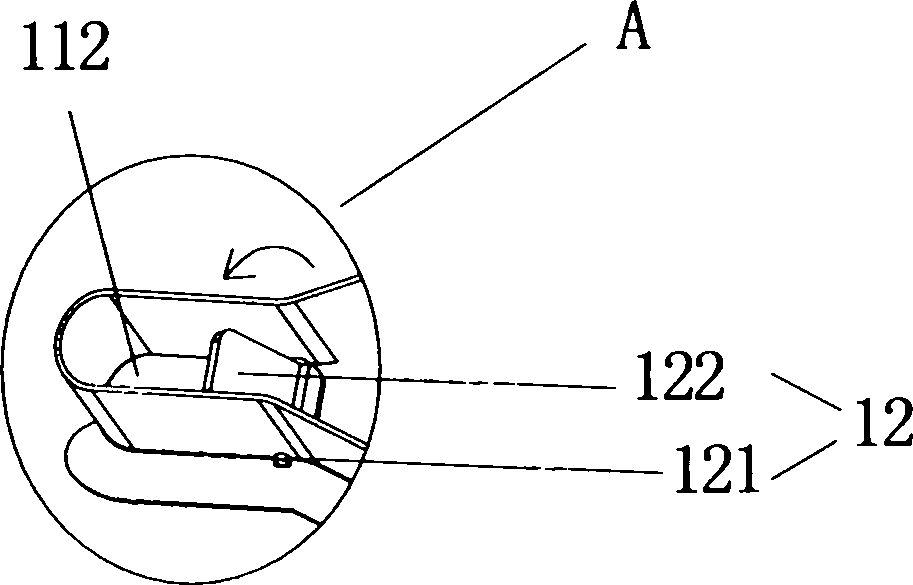

Automatic seamless connection method of main material and backup material boxes and automated guided vehicle system using same

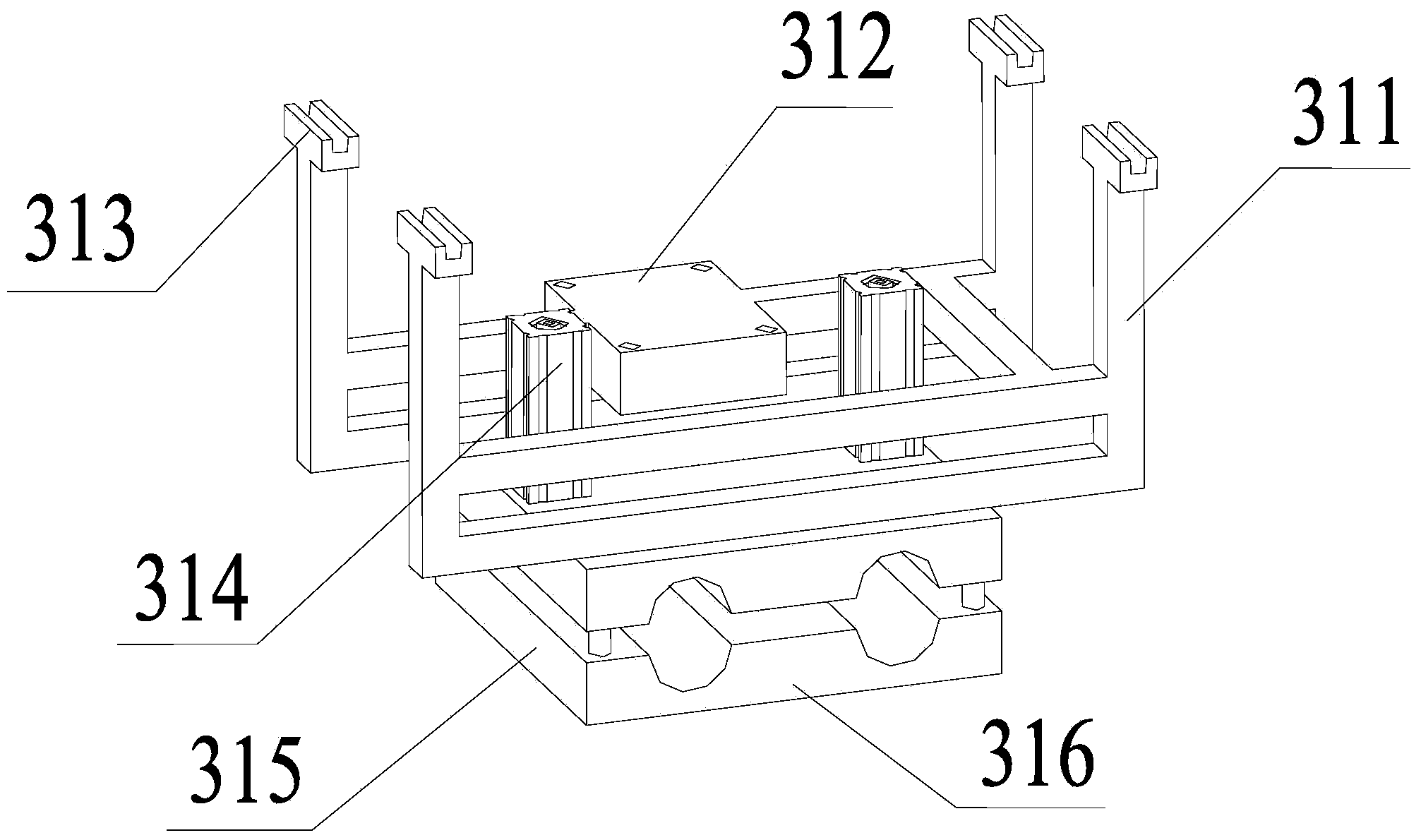

ActiveCN104229421ARealize automatic seamless connectionSolve the waste of manpowerControl devices for conveyorsAutomated guided vehicleEngineering

The invention relates to an automated guided vehicle system comprising an automated guided vehicle, a main material box, a line conveyor and an operating line. The automated guided vehicle carries the backup box to operate on the operating line. The main material box is used for receiving or conveying material on the line conveyor. The automated guided vehicle carries the backup material box and the main material box to allow seamless switching. A fixing support and a limiting mechanism are arranged at the bottom of each box and are used with carriers of the automated guided vehicles, automatic seamless connection of the main material box and the auxiliary material box under receiving or conveying on the line conveyor is achieved in an automatic loading and positioning and separating manner, and the problems of the prior art, such as labor waste and low work efficiency, are solved.

Owner:深圳市今天国际智能机器人有限公司

Polishing device for steel pipe machining

InactiveCN108747636AStable supportEasy to grindRevolution surface grinding machinesGrinding drivesVibration amplitudeArchitectural engineering

The invention discloses a polishing device for steel pipe machining. The polishing device for steel pipe machining comprises a base, a motor pedestal is fixedly arranged on the lateral surface of thebase, and a first motor box is fixedly installed on the upper surface of the motor pedestal. Due to the arrangement of a double-shaft motor, gears, a large gear, a first polishing wheel and a second polishing wheel, on the one hand, steel pipes are conveniently supported, and on the other hand, the outer walls of the steel pipes are conveniently polished and treated; due to the arrangement of a groove, a telescopic rod, second springs and third springs, the steel pipes with different pipe diameters are conveniently fixed, and the steel pipes with different sizes are conveniently polished and treated; due to the arrangement of first springs, a first supporting plate, supporting posts, an electric telescopic rod and a third polishing wheel, stable supporting of the motor is facilitated, andmeanwhile the vibration amplitude generated when the motor works is reduced; and due to the arrangement of a through hole, an exhaust fan and a waste scrap drawer, waste scraps generated in the steelpipe polishing process are conveniently collected and treated.

Owner:天津亚源泰钢管有限公司

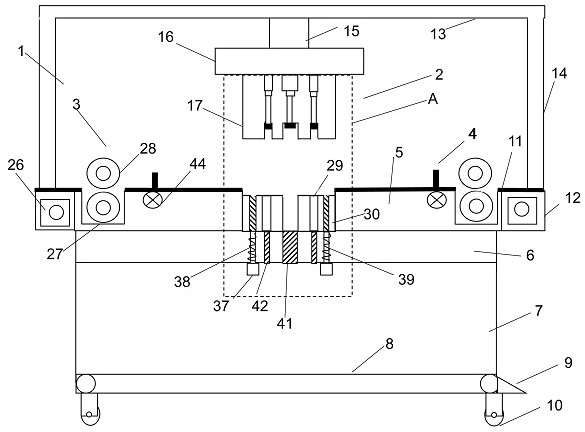

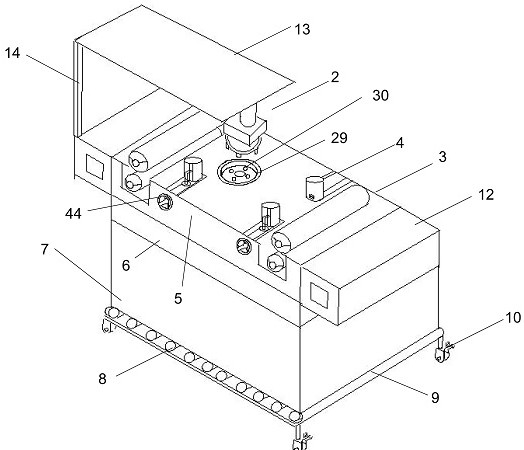

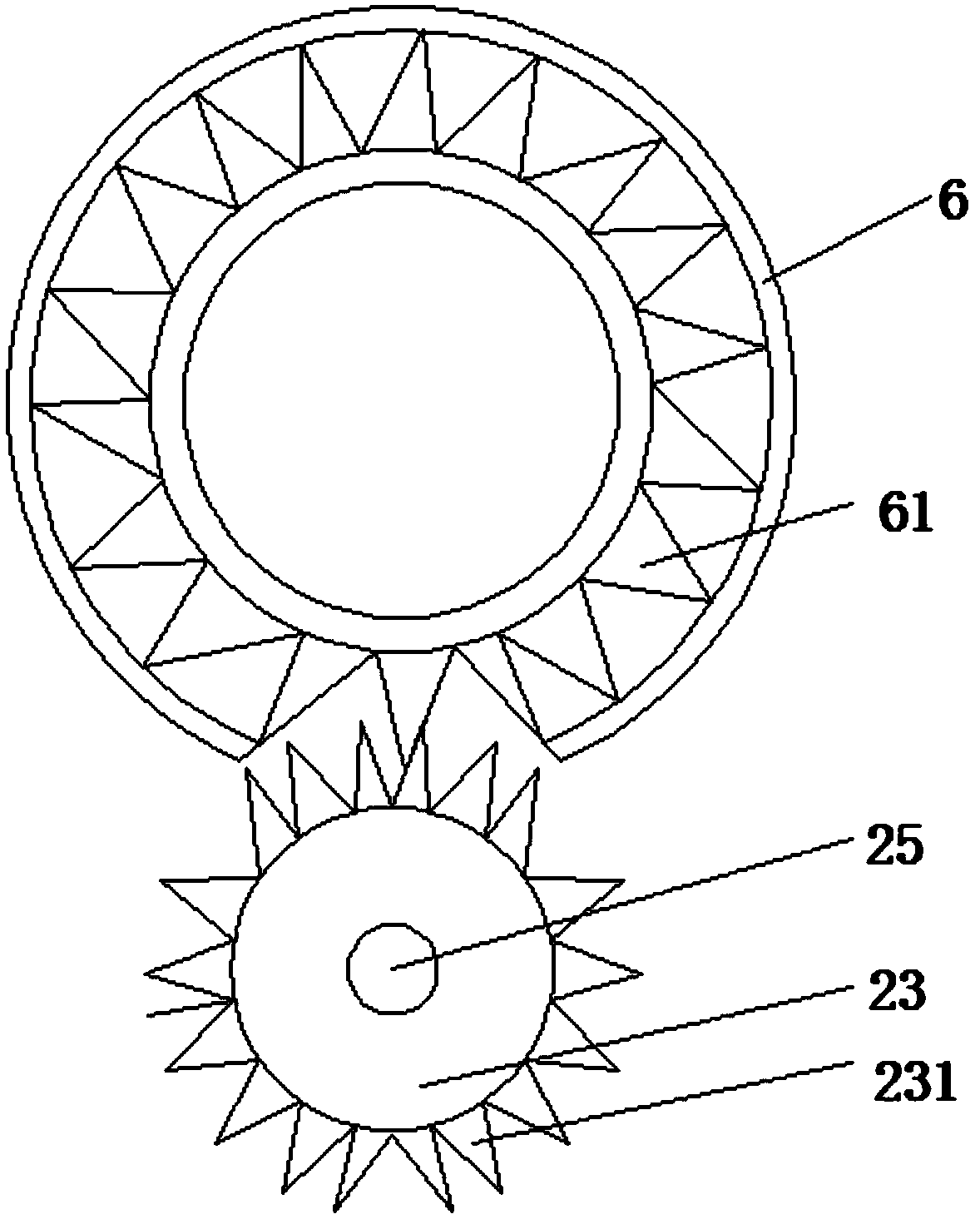

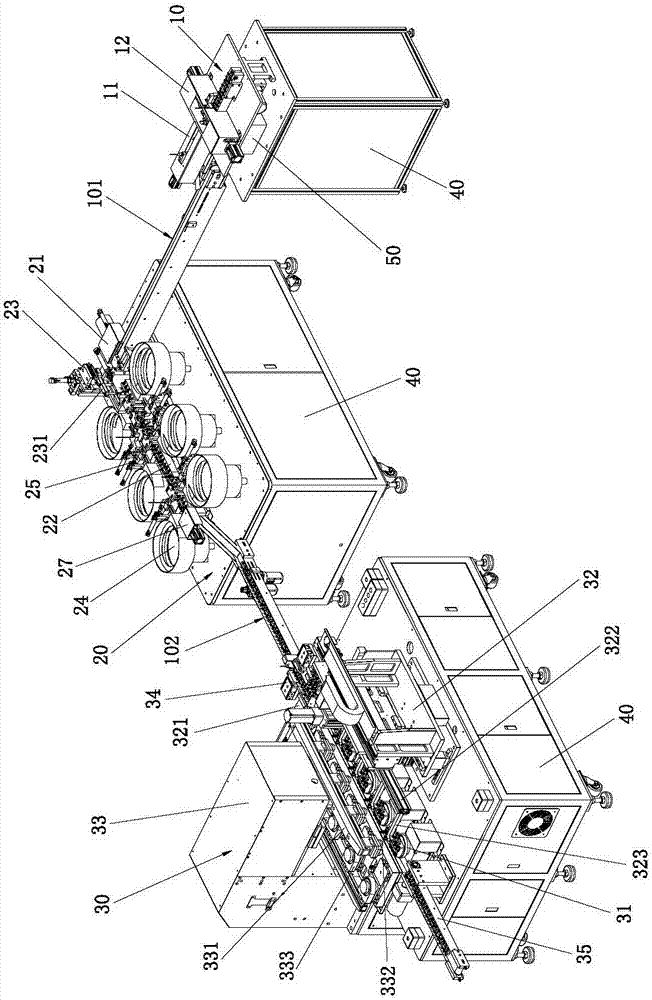

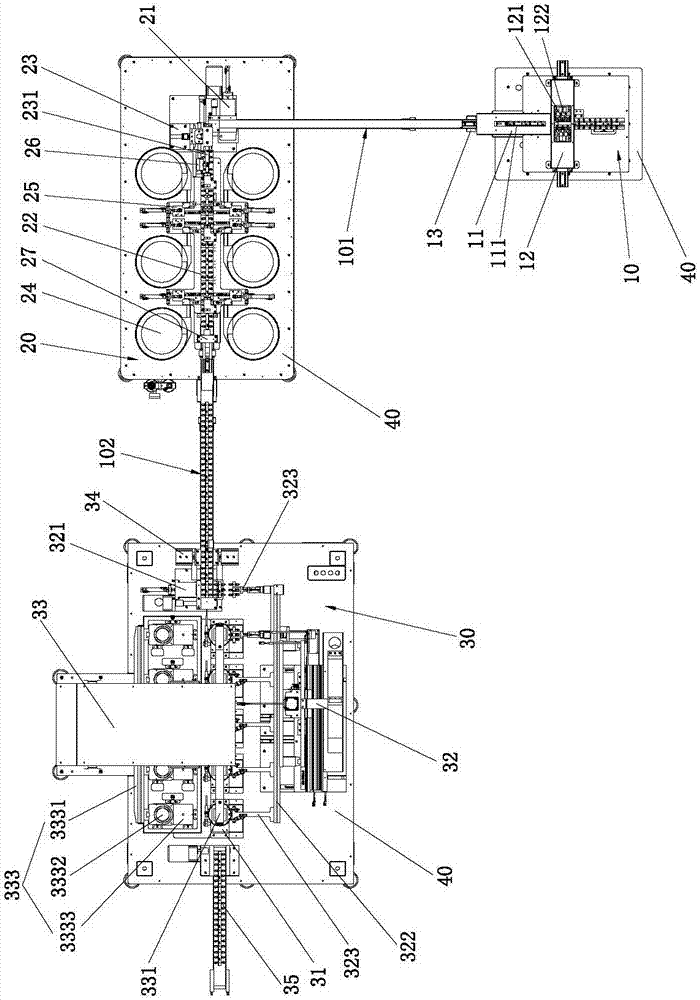

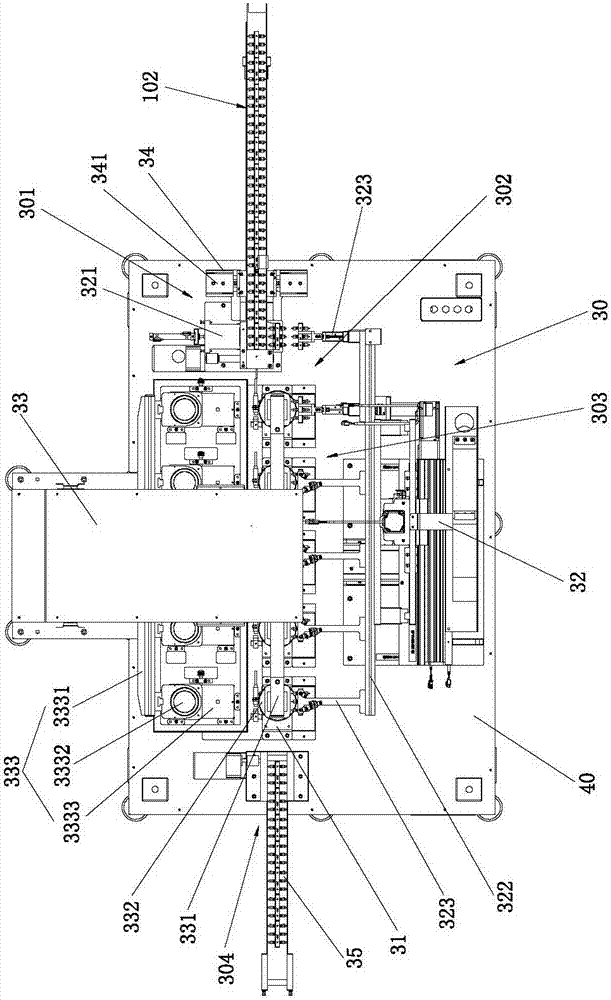

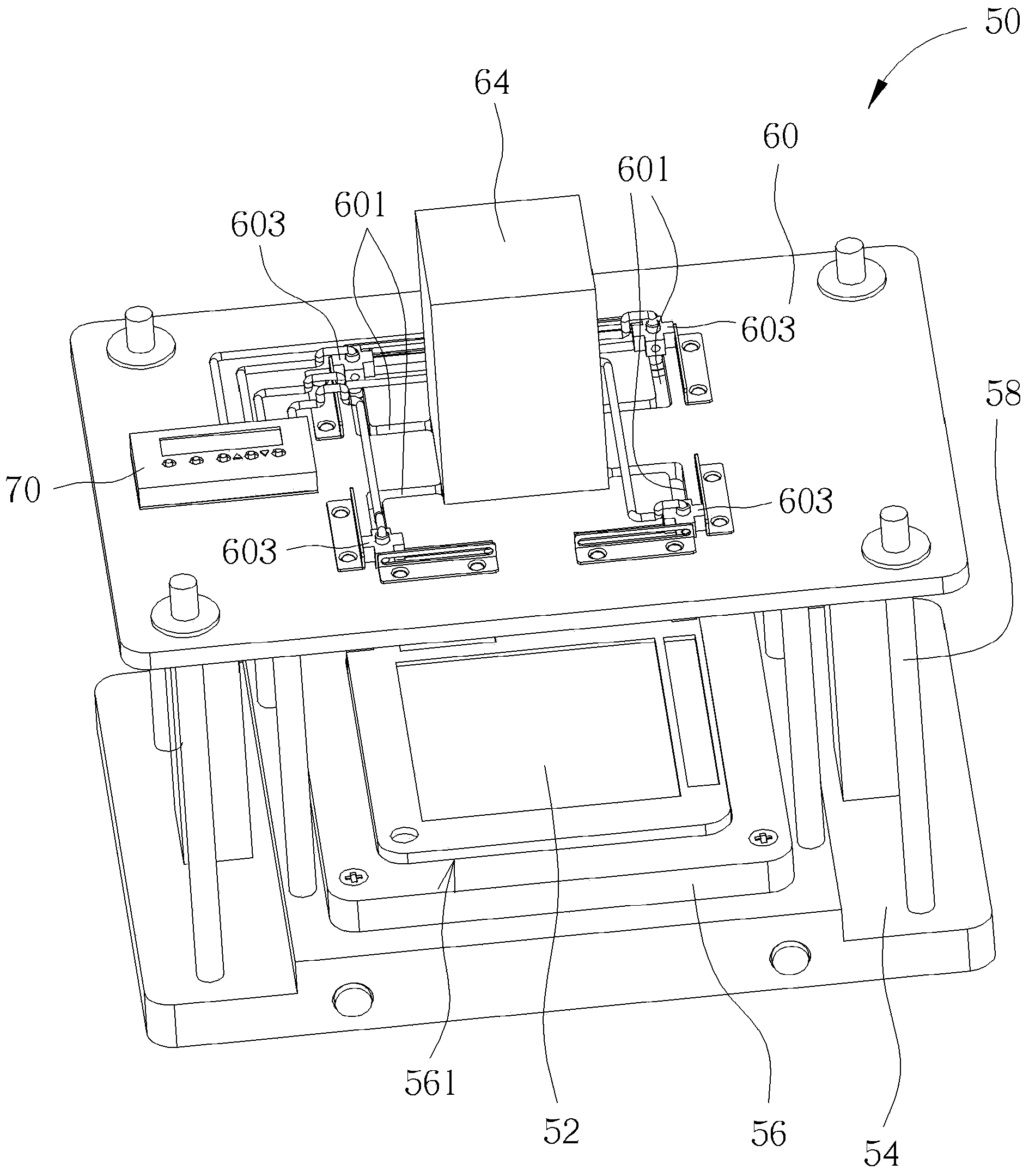

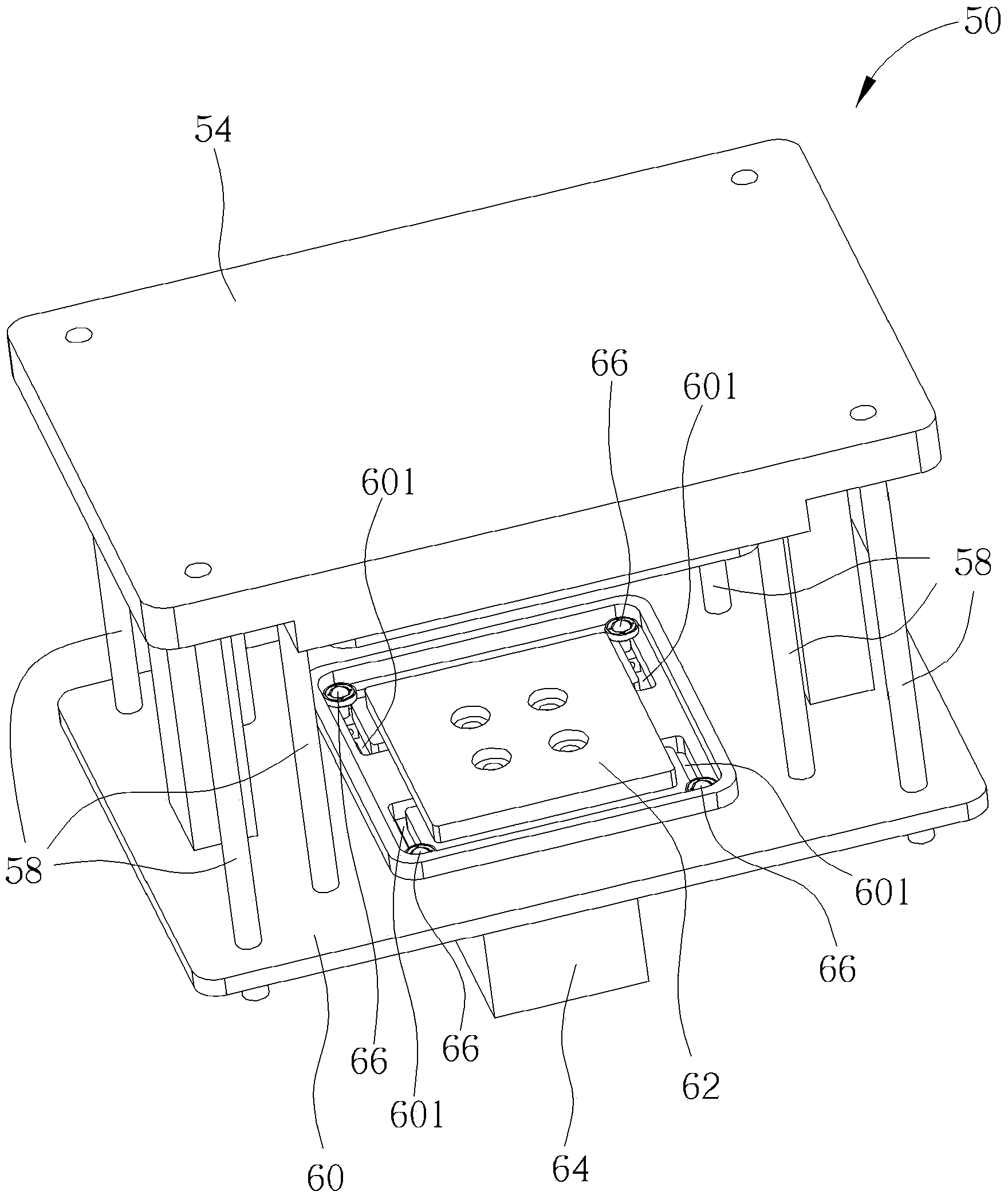

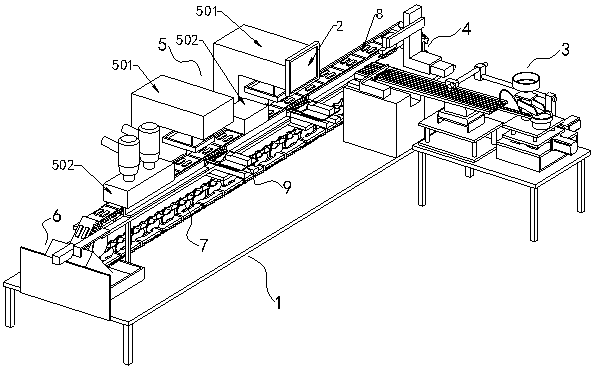

Automatic connected pad printing machine

PendingCN107310253AImprove work efficiencyImprove machining accuracyRotary pressesConveyor partsPad printingRobot hand

The invention discloses an automatic connected pad printing machine which comprises an automatic jig conveying unit, an automatic workpiece loading unit and an automatic pad printing unit which are sequentially connected according to the manufacture procedure sequence. The automatic pad printing unit comprises a feeding area, a pad printing area and a finished product output area. The pad printing area is provided with a plurality of jig storing rotary carrying tables, and jig transferring devices and pad printing devices are arranged on the two sides of the jig storing rotary carrying tables correspondingly. Each jig transferring device comprises a first pushing device body, a first displacement support, a first horizontal driving device body, a first lifting driving device body and a plurality of displacement manipulators. Each pad printing device is provided with a second displacement support, a plurality of pad printing heads, a plurality of ink disc assemblies, a second horizontal driving device body and a second lifting driving device body. Thus, through the automatic jig conveying unit, the automatic workpiece loading unit and the second lifting driving device bodies which are sequentially connected according to the manufacture procedure sequence, full-automatic manufacture procedures such as finished product automatic disassembly, jig automatic transferring, workpiece automatic loading and automatic pad printing are achieved, the working efficiency of the pad printing machine is improved, and the cost is reduced.

Owner:东莞市中民自动化有限公司

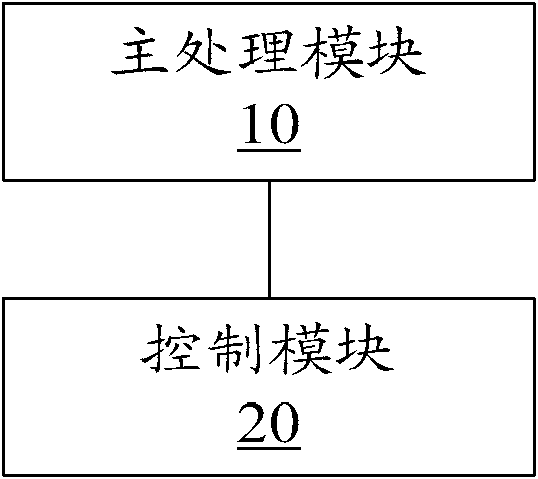

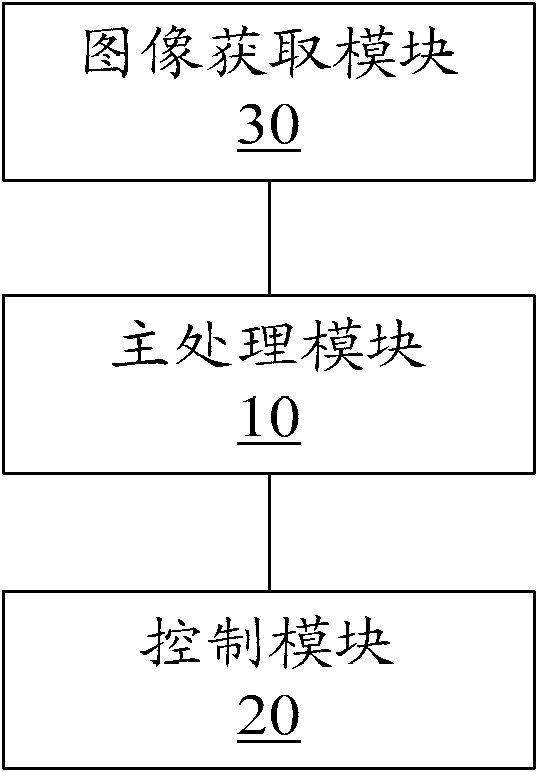

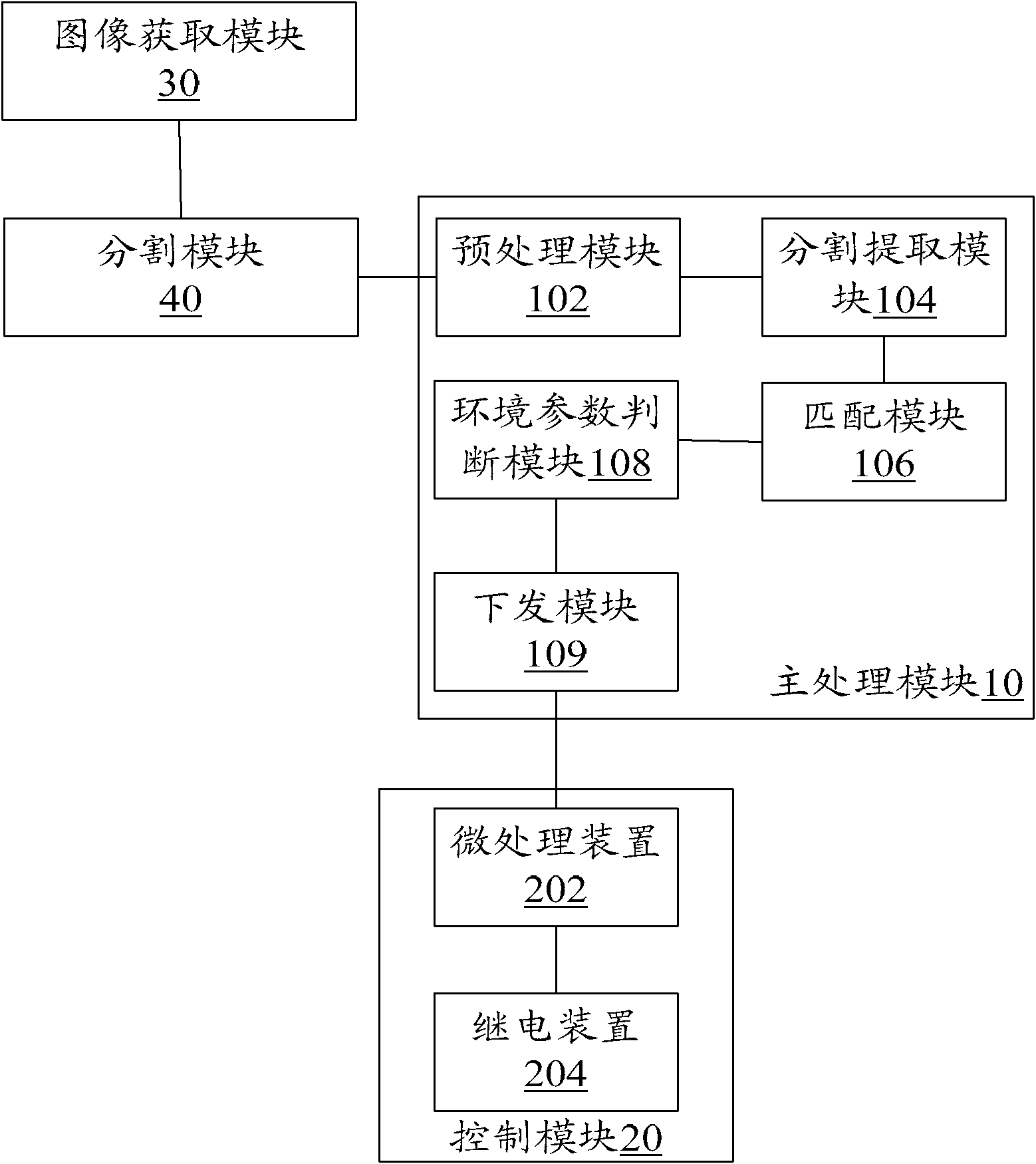

System power-on and power-off control device and method

ActiveCN102004537ARealize automatic controlRealize intelligenceVolume/mass flow measurementPower supply for data processingElectricityControl system

The invention discloses a system power-on and power-off control device and a system power-on and power-off control method. The system power-on and power-off control device comprises a main processing module for acquiring the environmental parameter values of the current environment of a system, and judging if the environmental parameter values go beyond preset ranges of environmental parameter values; and a control module for controlling the turning off of the power. The device and the method realize the intellectualization of the power-on and power-off control of the system and reduce labor intensity and workload for manual monitoring.

Owner:ZTE CORP

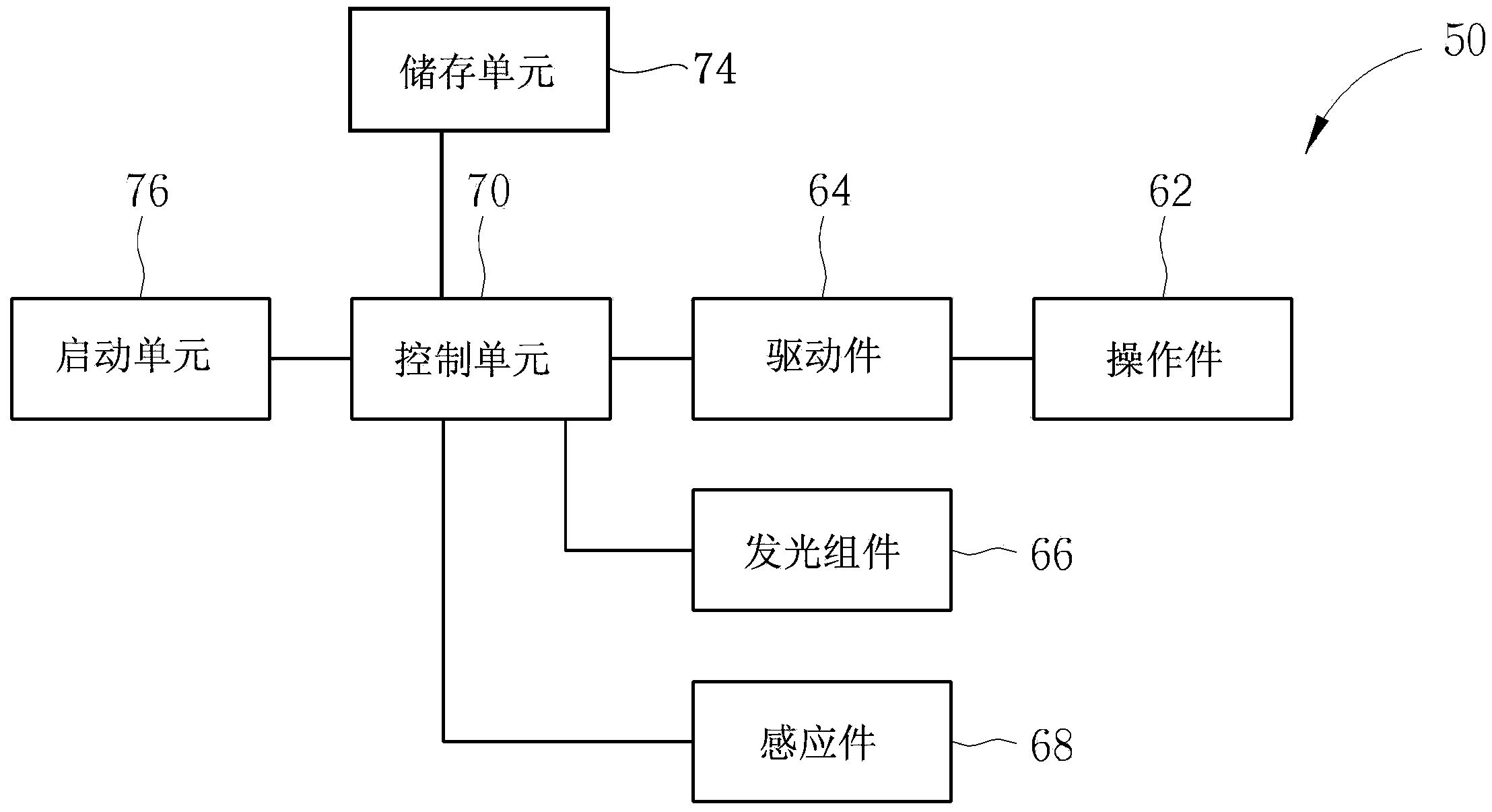

Test device and method for testing whether a workpiece is positioned correctly

InactiveCN104345314AAvoid damageSolve the waste of manpowerProgramme controlElectromagnetic wave reradiationEngineeringControl unit

A test device includes a base, a locating component installed on the base, a platform disposed on the base, an operating component, a driving component installed on the platform, at least one light emitting component, at least one sensing component and a control unit. The driving component is for driving the operating component. The at least one light emitting component is disposed on at least one track of the platform for emitting light. The at least one sensing component is for sensing the light emitted from the at least one light emitting component and reflected from the workpiece. The control unit determines whether to control the driving component to drive the operating component to move to the workpiece according a sensing result of the at least one sensing component sensing the light emitted from the at least one light emitting component and reflected from the workpiece.

Owner:WISTRON CORP

Infant nasal cavity cleaning device

PendingCN109985284ASolve the waste of manpowerImprove convenienceRestraining devicesMedical devicesMedical staffPediatrics

The invention discloses an infant nasal cavity cleaning device and belongs to the technical field of medical instruments. The device comprises an operating platform, a head fixing device, a limb fixing device and a negative pressure suction device, wherein the head fixing device, the limb fixing device and the negative pressure suction device are arranged on the operating platform; the operating platform is used as a carrier, the head fixing device is used for fixing the head of an infant, the limb fixing device is used for fixing the limbs of the infant, and the negative pressure suction device is used for sucking secretions in the nasal cavity of the infant, wherein a head pad and neck pad of the head fixing device provide higher pillow comfort for the infant, and the neck pad is higherthan the head pad, so that the head of the infant is tilted backwards, and the effect of cleaning the nasal cavity is improved; the distance between two fixing units is adjustable under driving of adjusting screw rods, and the two fixing units are suitable for fixing infants different in size. The fixing units are also provided with hand support plates for supporting the arms of medical staff, sothat the operation comfort of the medical staff is improved. The device can effectively solve the problems that since the cooperation of two people is required when the medical staff clean the nasal cavity of the infant, manpower is wasted.

Owner:柳州市柳铁中心医院

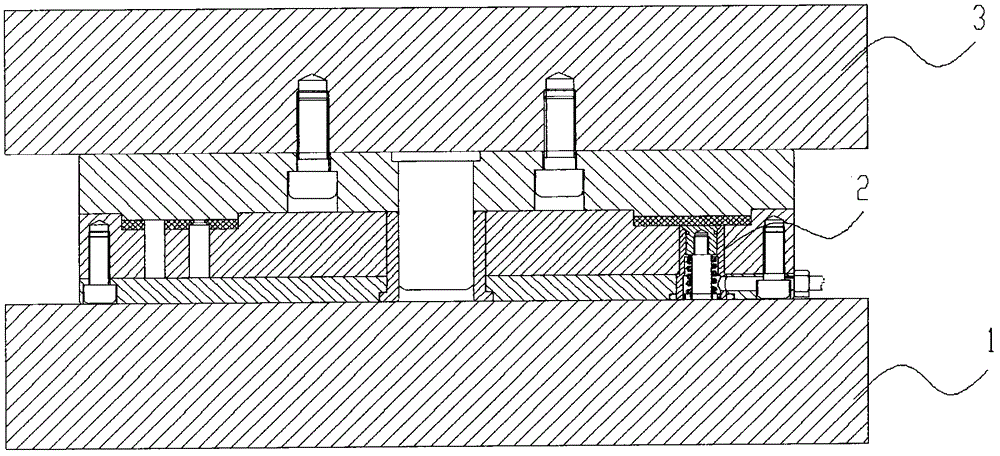

One-time forming mold for clutch facing

The invention discloses a one-time forming mold for a clutch facing, and relates to a mold. The one-time forming mold comprises a demolding ejection mechanism which is arranged between an upper heating plate and a lower heating plate of a four-column hydraulic press. The one-time forming mold is characterized in that the demolding ejection mechanism comprises an upper mold, a lower mold and a demolding device; the bottom of the lower mold is provided with a carriage; the demolding device is arranged between the upper mold and the carriage; and a workpiece to be machined is arranged between the demolding device and the upper mold. Three procedures are decreased compared with the traditional procedures, the quality and appearance of products are improved, the mold is easy and convenient to operate, and a series of problems of raw material waste, manpower waste, equipment loss and the like are solved.

Owner:来安县隆华摩擦材料有限公司

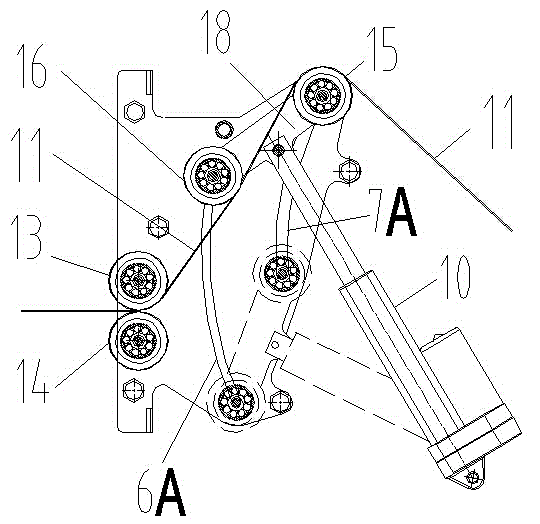

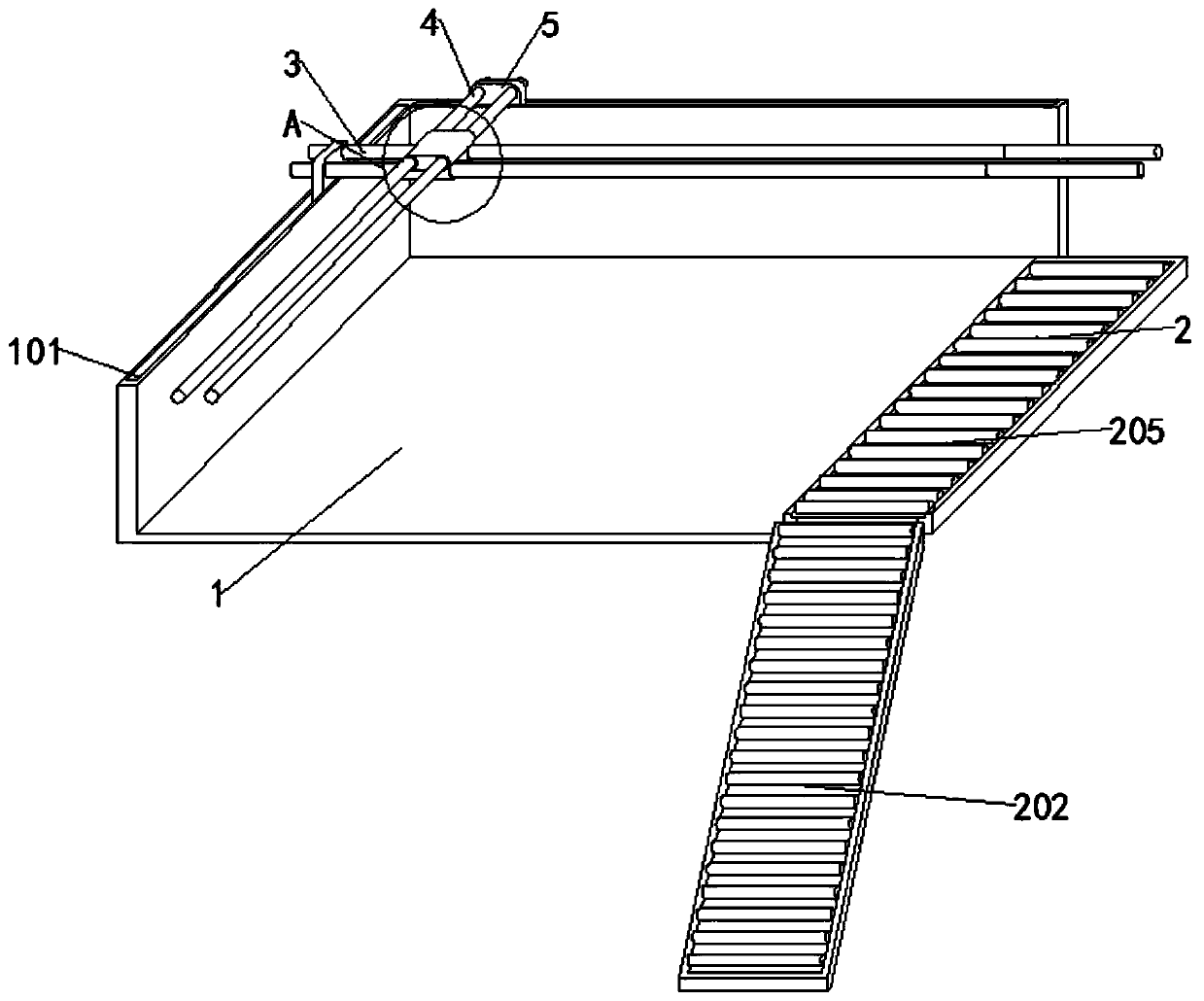

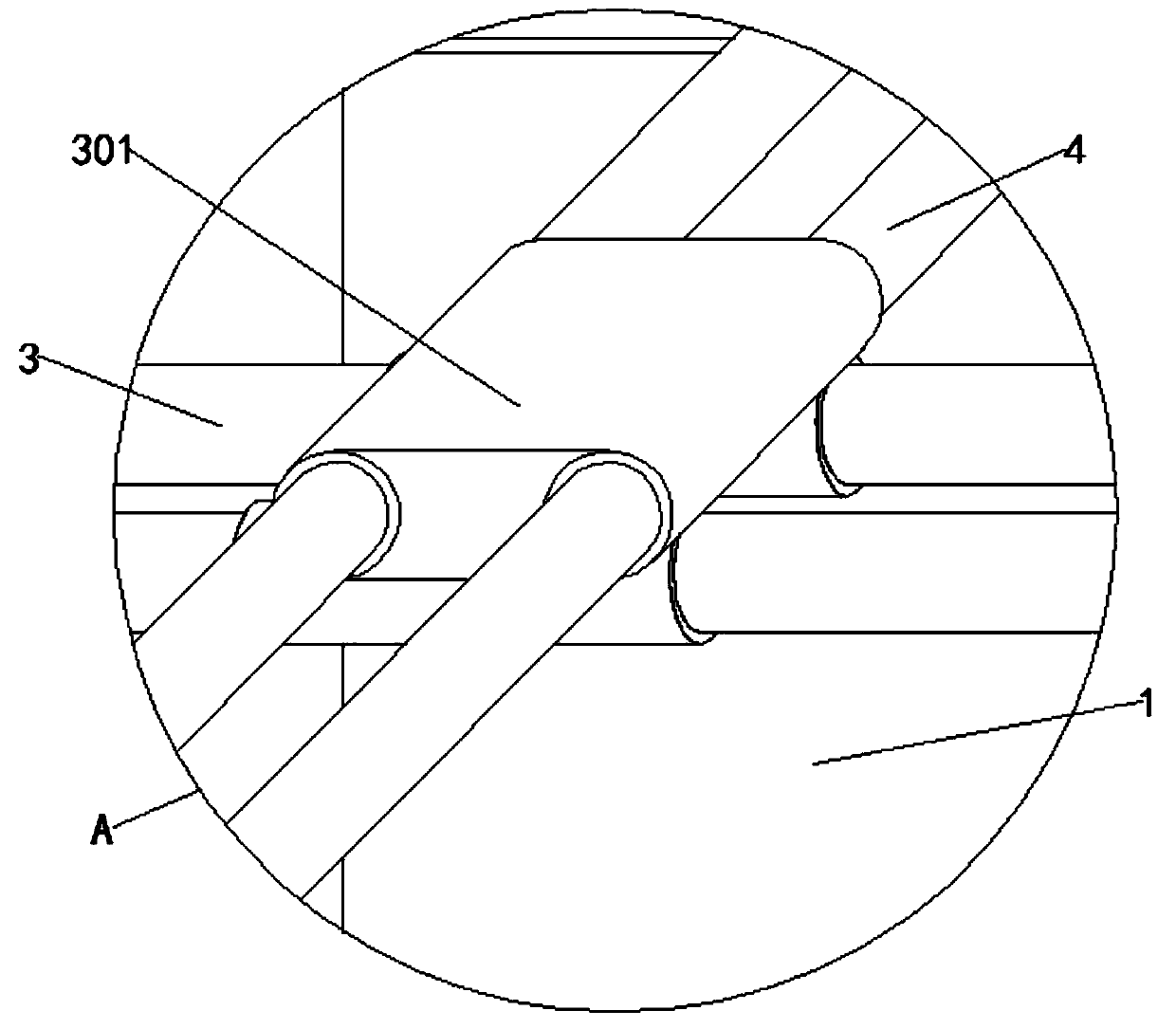

Biaxial multi-directional grounding carrying type semi-automatic road step laying device

ActiveCN110172895APlay the role of supporting the bottom of the slidewayReduce usageRoads maintainenceTransmission beltSemi automatic

The invention provides a biaxial multi-directional grounding carrying type semi-automatic road step laying device, and belongs to the technical field of road construction. The biaxial multi-directional grounding carrying type semi-automatic road step laying device includes a placing groove, sliding slots, sliding rods, a slide, manual telescopic support rods, an inclined slide, an offset gear, a first electromotor, a first small transmission gear, a large transmission gear, a second small transmission gear, a first roller, a cross rod, a snap ring, vertical rods, a sliding plate, a second electromotor, a transmission belt, a second roller, a hydraulic rod, a sleeving-connecting ring, a sleeving-connecting block, a sliding hole, a contact block, first springs, second springs, a fixed rod, brackets, rubber plates, a threaded fixed rod and a motor; and the sliding slots are formed in the tops of the left side and the rear side of the placing groove in a nested and sleeved mode, the sliding rods are fixedly connected to the left side and the right side in the sliding slots, the slide is movably connected to the surface of the right side surface of the placing groove through a hinge, the manual telescopic support rods are movably connected to the surface of one side of the slide, the inclined slide is movably connected to the surface of the front end of the slide, and the offset gear is movably connected to the tail end of the top of the inclined slide through a hinge.

Owner:石岩

Adhesive removing equipment

ActiveCN113042462AFree laborSolve the waste of manpowerSortingCleaning processes and apparatusAdhesive beltProcess engineering

The invention provides adhesive removing equipment, and relates to the technical field of surface adhesive removing. The adhesive removing equipment comprises a conveying clamp, an adhesive removing device and a sorting device. The conveying clamp is used for fixing screens to be subjected to adhesive removal and conveying the screens to an adhesive removal station and a sorting station in sequence in the conveying direction. The adhesive removing device comprises an adhesive pressing mechanism and an adhesive tearing mechanism. The adhesive pressing mechanism is used for pasting adhesive tape on the surface of the screens to be subjected to adhesive removal, and the adhesive tearing mechanism is used for tearing the adhesive tape from the screens to be subjected to adhesive removal, so that residual adhesives on the surfaces of the screens to be subjected to adhesive removal are removed. The sorting device is used for detecting whether the screens subjected to adhesive removal have residual adhesives or not and sorting the screens with the residual adhesives to a defective product area. According to the adhesive removing equipment, the operation of fixing, adhesive removing and sorting can be completed in sequence, the labor force of workers is greatly liberated, and the problems of manpower waste, redundant manual transfer and transportation, low production efficiency, uneven manual adhesive removing effects, defective products caused by misoperation and the like existing in an existing production mode are solved.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

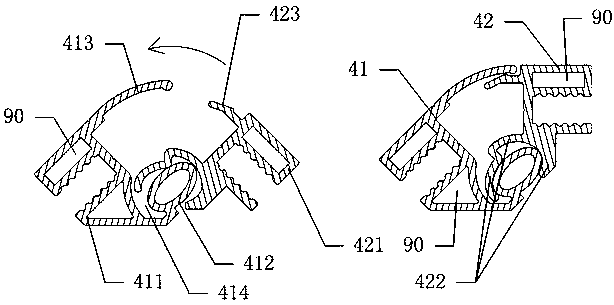

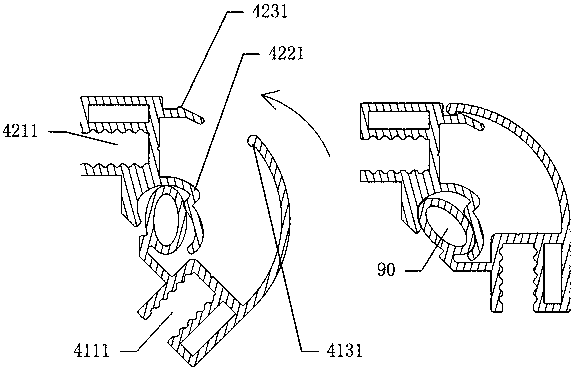

Wallboard connecting structure for shower room

PendingCN107752854AQuick connectionSolve the waste of manpowerBathsDouchesAgricultural engineeringGlass sheet

The invention provides a wallboard connecting structure for a shower room. The wallboard connecting structure comprises a center control panel, two rear glass panels symmetrically arranged on the twosides of the center control panel, and two front glass panels connected to the front ends of the two rear glass panels. The center control panel and the rear glass panels are connected through sectional bar assemblies, and the rear glass panels and the front glass panels are connected through sectional bar assemblies. Each sectional bar assembly comprises a sectional bar female part and a sectional bar male part which are buckled. The problems that manpower is wasted and the installation efficiency is low during wallboard installation are solved.

Owner:佛山市品柏智能科技有限公司

Chain type automatic transfer printing device

PendingCN108177428AEasy to collectMake sure to recycleConveyorsRotary pressesProgrammable logic controllerBiochemical engineering

The invention discloses a chain type automatic transfer printing device, which comprises a rack, a PLC (Programmable Logic Controller), a feeding unit, a loading unit, a transfer printing unit, a reciprocating type chain wheel conveying device and a discharging unit. The feeding unit and the loading unit are arranged on one side of the rack; the transfer printing unit is arranged in the middle ofthe rack; the discharging unit is arranged on the other side of the rack; the feeding unit is arranged on the right side of the loading unit, and comprises a blanking cylinder, a vibrating plate and amulti-track vibrating and feeding device; the vibrating plate is arranged under the blanking cylinder; and the multi-track vibrating and feeding device is arranged on a discharge hole of the vibrating plate. Compared with the prior art, the chain type automatic transfer printing device provided by the invention realizes full-automatic processes comprising automatically disassembling finished products, automatically feeding jigs, automatically assembling workpieces, automatically transfer printing, and the like, solves the problem that manpower and material resources are wasted, and is beneficial to reducing cost.

Owner:东莞市铧美电子有限公司

Assembling wall body

The invention provides an assembling wall body. The assembling wall body comprises a plurality of wall bases and a plurality of wall surfaces; the wall bases are connected by first fasteners; the wallsurfaces are detachably arranged on the wall bases; the wall bases adjacent to the wall surfaces are connected by second fasteners; and the adjacent wall surfaces are connected by third fasteners. The assembling wall body effectively solves the problem of economic and manpower waste caused by the need of dismantling an entire wall of a building external wall when electrical equipment of a transformer substation is repaired and maintained in the prior art.

Owner:STATE GRID BEIJING ELECTRIC POWER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com