Automatic transfer printing device

A pad printing device and automatic technology, applied in printing, printing machines, transfer printing, etc., can solve the problems of wasting manpower and material resources, and achieve the effects of improving production efficiency, ensuring continuity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

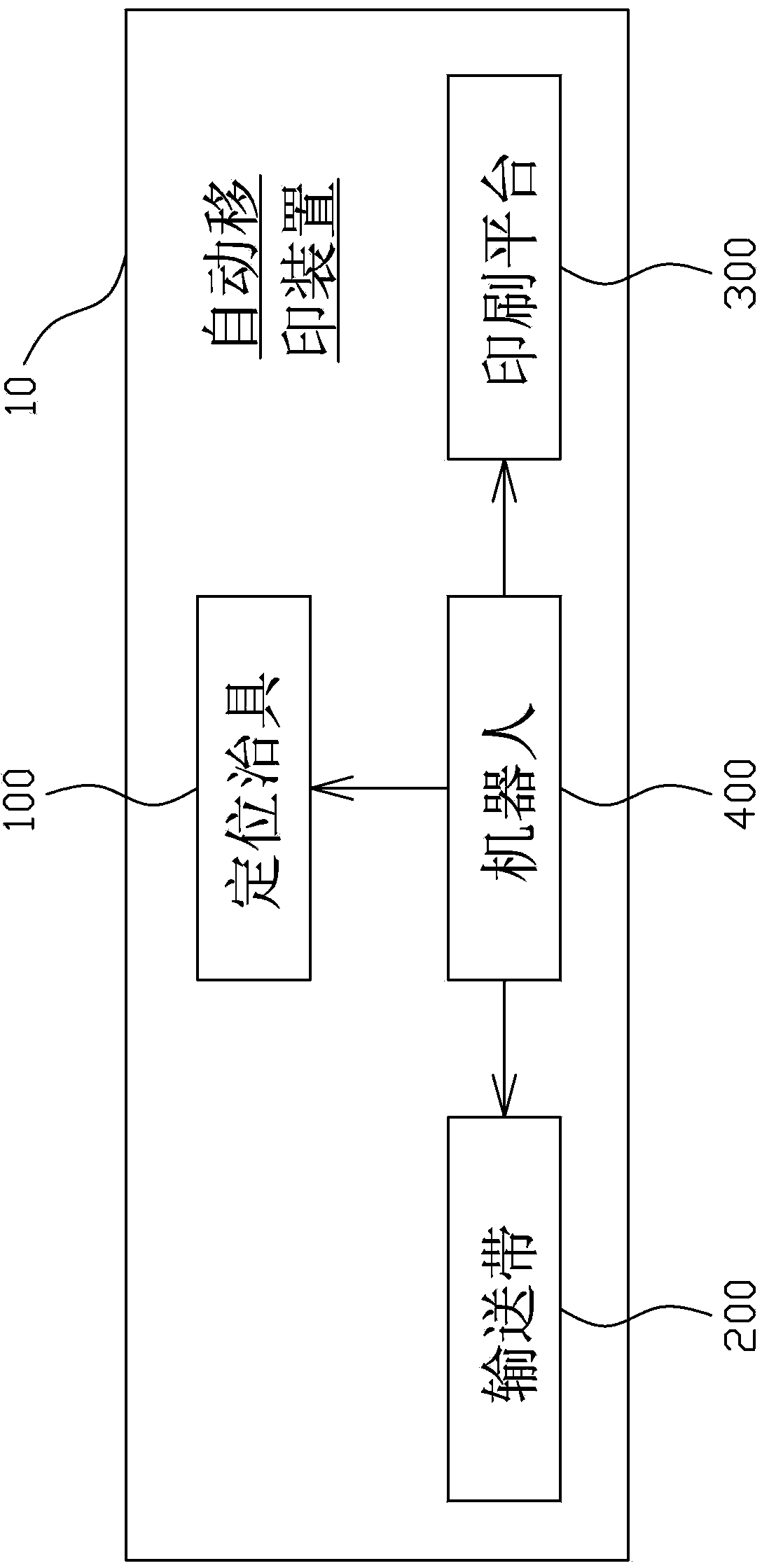

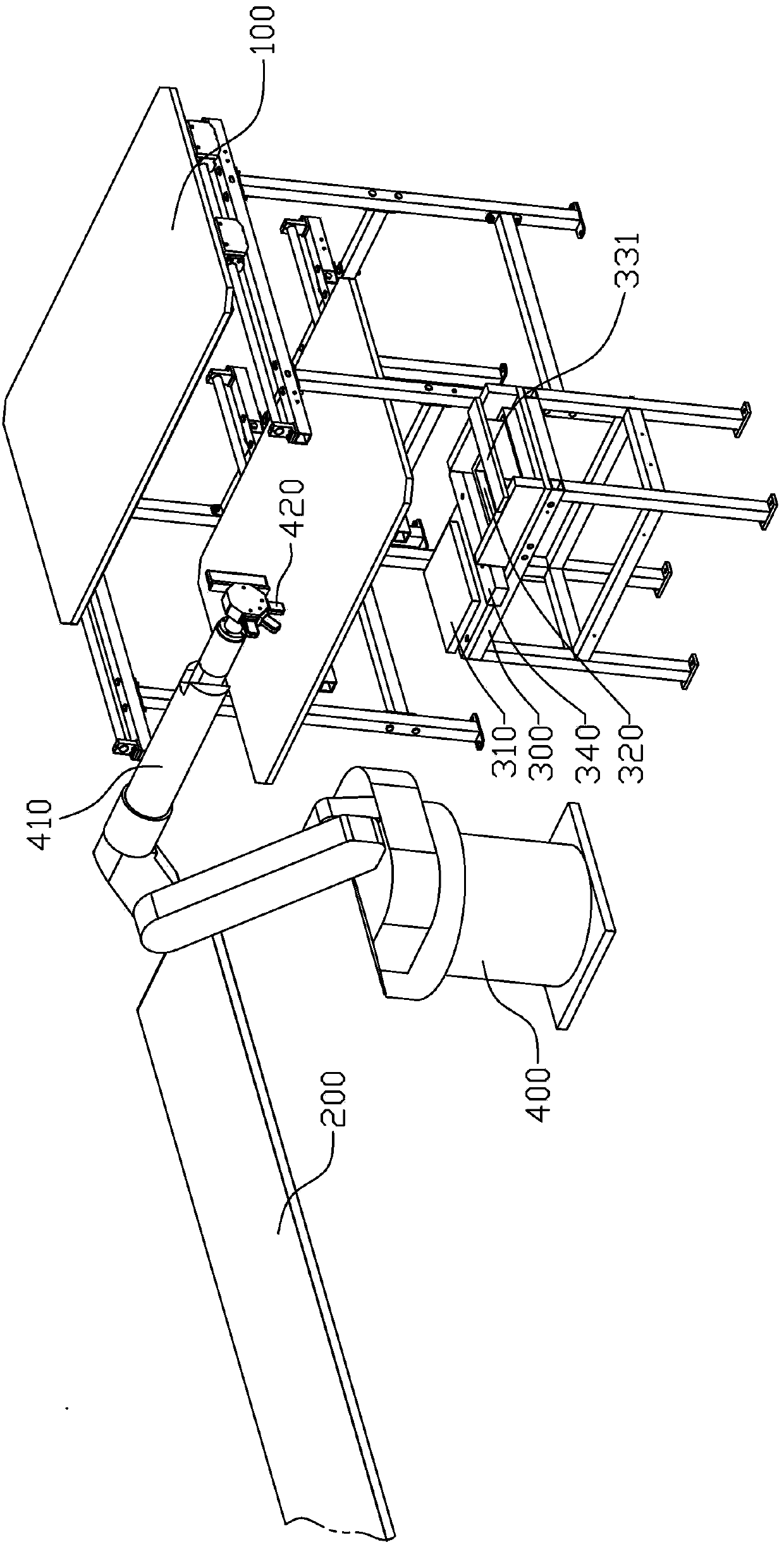

[0020] see figure 1 , figure 2 and image 3 As shown, the automatic pad printing device 10 of the present invention is used to print products. In this embodiment, the automatic pad printing device 10 includes:

[0021] A positioning jig 100, on which a product to be printed is placed;

[0022] Conveyor belt 200, the conveyor belt 200 is used to transport the printed product to the oven for baking;

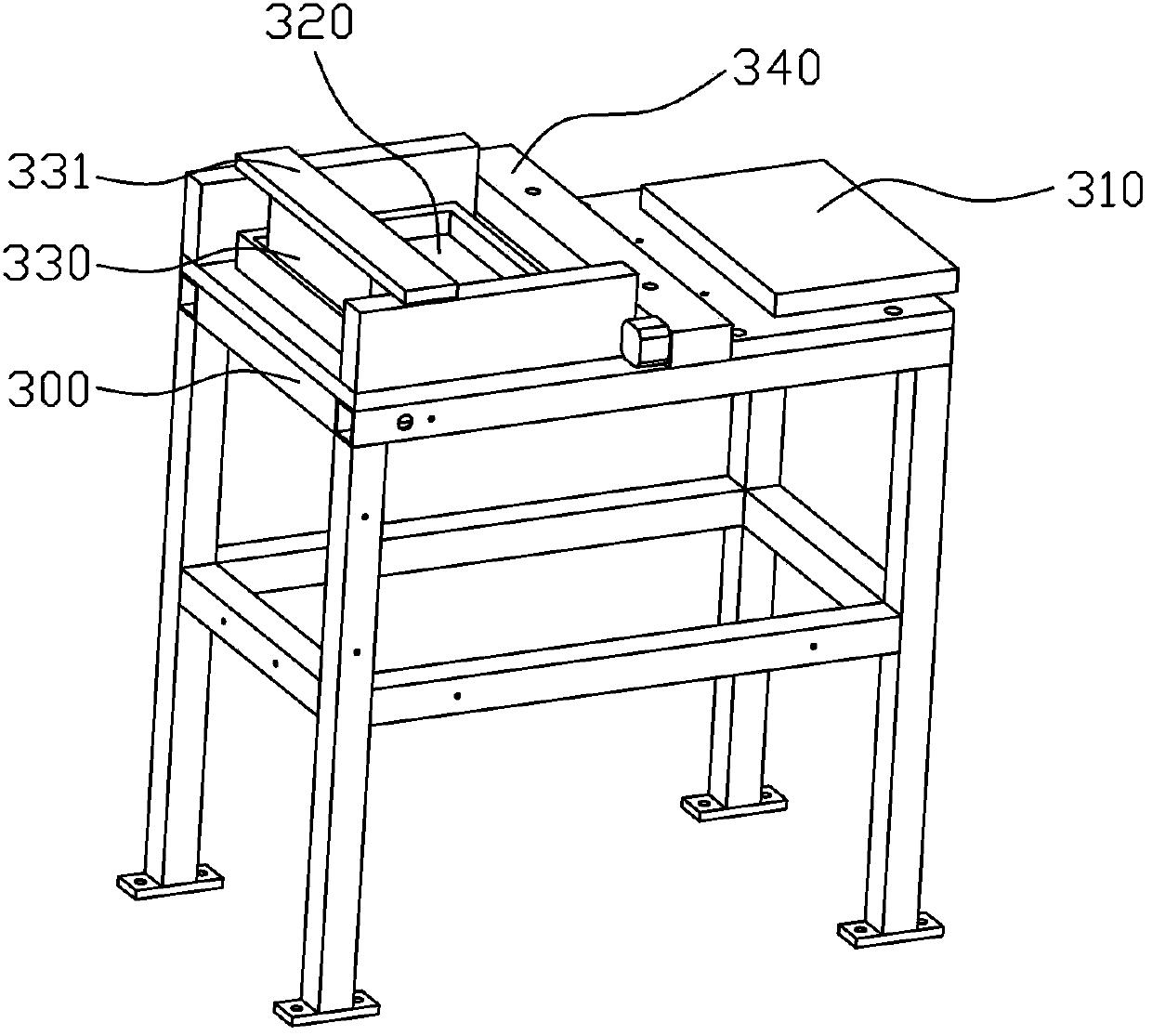

[0023] The printing platform 300 is provided with a printing fixture 310, an etching plate 320, a scraper 330, an adhesive tape, and a tape motor 340 that drives the movement of the adhesive tape; wherein the printing fixture 310 is used to position and place the product to be printed; Wherein, the etched plate 320 is engraved with words or patterns to be printed, and is movably arranged on the printing platform 300, and can be easily replaced when the etched plate 320 needs to be replaced; wherein, the scraper 330 is movably arranged on the printing platform 300 At the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com